Page 58 of 62

Re: STEEPLEJACK'S CORNER 2012

Posted: 02 Dec 2017, 07:13

by Stanley

One of the consequences of the demolition was that I came in for a lot of flak. I was seen as a vandal but I let it all flow over me because I was absolutely certain that we had done the right thing and perhaps in the process reinforced what I have always contended, that Scheduling is no good at all for protection if there aren't involved people on the ground active,y conserving!

Re: STEEPLEJACK'S CORNER 2012

Posted: 24 Mar 2018, 05:12

by Stanley

Re: STEEPLEJACK'S CORNER 2012

Posted: 24 Mar 2018, 08:51

by chinatyke

Looking at the second photo made me think how fast would the ropes would be travelling. If the flywheel was 20' diameter and ran at 30 rpm then the ropes would be travelling at about 20 miles per hour. Does that seem right?

Re: STEEPLEJACK'S CORNER 2012

Posted: 25 Mar 2018, 04:44

by Stanley

Slower than general practice China. Ellenroad ran at 88ft per second which was high end but I'd have to look up Kenyon's data to give yo the recommended design speed.

I relented and got his lecture on the transmission of power by ropes out.... Ellenroad ran at 5280ft/min. His table of horse power for different size ropes in ideal conditions runs from 1000ft/min up to 8000ft/min. These are two extremes and most engine designers would be aiming for mid range, about 4,500ft/min.

Re: STEEPLEJACK'S CORNER 2012

Posted: 25 Mar 2018, 11:57

by chinatyke

5280'/min or 88'/sec is 60 mph. I didn't realise that they moved so fast. They're fair zipping along. Must have been dangerous things to be near. Thanks for the information.

Re: STEEPLEJACK'S CORNER 2012

Posted: 26 Mar 2018, 03:56

by Stanley

They didn't seem to move that quickly if the engine motion was smooth and they ran in a smooth catenary curve. The time when they were dangerous was on some engines that weren't 'quartered'. This is setting the the cranks on engines with cranks on both ends of the flyshaft like cross compounds or double tandems, so that one (on cross compounds always the low pressure) was set forward 90 degrees so that there were four power strokes per revolution on the shaft. This helps alleviate any lack of smoothness in the power strokes. On any single crank engine or one that wasn't quartered it was possible for ropes to be thrown off the wheel if the imbalance coincides with the harmonics of the drive and this was very dangerous! It usually happened on start up when the harmonics were changing as the engine gathered speed and at some point reached the trigger condition. See Newton Pickles in the LTP for examples of this.

Re: STEEPLEJACK'S CORNER 2012

Posted: 17 May 2018, 05:43

by Stanley

I got mail from John Burlison this morning;

Former Maple Mill site, Hathershaw, Oldham

Hello Stanley.

Attached is all that remains of the Maple Mill's No.'s 1-2, both mills were destroyed by fires, the No. 2 mill in 2009, and the No. 1 Mill in 2016. the site today in the middle of a Council estate resembles something from the blitz, residents told me people were arriving scavenging for the Accrington bricks, but teenagers have been reported in the press as starting fires at an opening at the bottom of the chimney as smoke appeared from the top of the stack on evening, and GMFRS arrived on scene to discover a propane bottle on another call out close to the stack, one method for Swifty there

In the background is the Belgrave Mill.Regards, John Burlison

Re: STEEPLEJACK'S CORNER 2012

Posted: 13 Jun 2018, 19:07

by Spinningweb

Five photographs show Preparations for demolishing the Hopwood Mill chimney at Lees Rd, Oldham, in 1897. The wooden props were almost 20 courses high.

Re: STEEPLEJACK'S CORNER 2012

Posted: 14 Jun 2018, 03:05

by Stanley

Welcome to the site! Thanks for those. Was the Smith mentioned to Lancashire Steeplejack from Milnrow?

Re: STEEPLEJACK'S CORNER 2012

Posted: 14 Jun 2018, 07:17

by Spinningweb

Mr Smith is only mentioned as the foreman, the pictures were taken by John Swailes owner of The Oldham Cop Tube Company. The stack was 75 yards high, and 76 props were used

Regards

John Burlison

Re: STEEPLEJACK'S CORNER 2012

Posted: 14 Jun 2018, 08:21

by Stanley

John sent me this.....

Hello Stanley, I couldn't attach this picture to my reply on Steeplejacks Corner, but shows 76 props were used. I think steeplejacks in those times surpassed even Fred Dibnah's same copied method possibly using many more props, and cutting much more out of the stack. Regards

John Burlison

Re: STEEPLEJACK'S CORNER 2012

Posted: 24 Oct 2018, 14:43

by Invernahaille

Stanley

Read the topic on harmonics. Strange, when marine engines are running, they produce a hum. The harmonics, a beautiful sound.

Whenever that sound is interrupted you know something is wrong.

Even the sound of a pump or compressor starting changes these harmonics.

Its the engines talking to you.

I miss that so much.

Re: STEEPLEJACK'S CORNER 2012

Posted: 25 Oct 2018, 01:44

by Stanley

I can still hear it in my mind's ear Robert. It gets to be part of the soundscape of your life.

Re: STEEPLEJACK'S CORNER 2012

Posted: 30 Dec 2018, 18:06

by Tripps

I must have missed this - and it's only up the road.

Blown up or blown down - take your pick.

Looks like a good use of a drone.

Blowdown

Blown up

Re: STEEPLEJACK'S CORNER 2012

Posted: 31 Dec 2018, 03:30

by Stanley

That qualifies David. They come down faster than they go up!

Re: STEEPLEJACK'S CORNER 2012

Posted: 01 Jan 2019, 09:48

by plaques

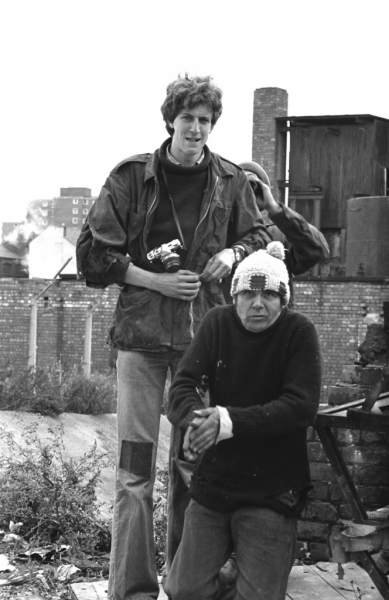

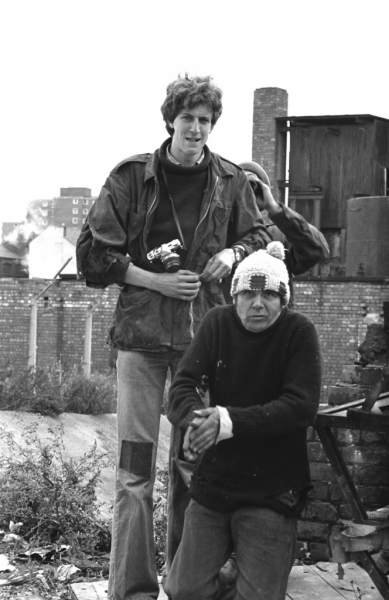

Another of Daniel Meadows talking films.

Peter Tatham

Re: STEEPLEJACK'S CORNER 2012

Posted: 02 Jan 2019, 04:34

by Stanley

Salford 1976. This was the chimney at Salford and here's possibly the only pic in the world of four men on a ladder at the same time. I introduced Daniel to Peter and the Salford chimney was the first time Daniel had been up to that height.

Here he is just before he went up that day. Peter made him go up last on the ladder so that if he fell off he wouldn't hit anyone else on the way down.....

Nice to hear Peter's voice again, he was a good man. It was the Capstan Full Strength that got him in the end not the chimneys.

Re: STEEPLEJACK'S CORNER 2012

Posted: 02 Mar 2019, 12:12

by Spinningweb

When looking through Roger Holden's book titled Stott and Sons I noticed either an inaccuracy by himself or from one of my Frank Wightman drawings of the Baytree - Laurel Mills at Middleton, the book mentions the Broadstone Mills at Stockport having eight boilers similar to the Baytree - Laurel Mills, the only difference was the Baytree - Laurel Mills shared their chimney, as the Broadstone Mills had separate stacks, but Frank Wightman's drawing shows only three boilers per mill.

I read the factory inspector visited the Baytree - Laurel Mills on account of black smoke being emitted longer than permitted, but they couldn't prosecute either company with sharing the same stack.

Re: STEEPLEJACK'S CORNER 2012

Posted: 03 Mar 2019, 03:25

by Stanley

I used to pass Broadstone at Reddish regularly as a lad and was always impressed by how modern it was with its glass fronted engine house. It was a double mill but I had forgotten it had two stacks....

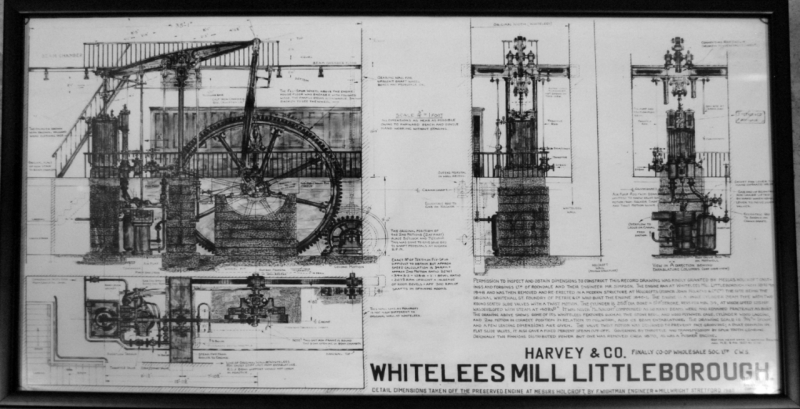

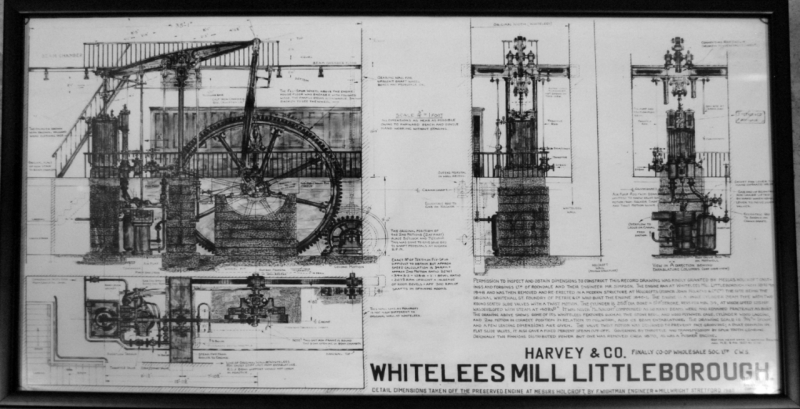

Frank wasn't infallible as I found out to my cost when I was rebuilding the Whitelees engine. Due to a cock-up at the Council they had lost the measured survey of the engine they did and I had to fall back on Frank's drawing. Unfortunately he had missed out the rising blocks for the trunnion bearings on the beam.....

Re: STEEPLEJACK'S CORNER 2012

Posted: 03 May 2019, 23:39

by Whyperion

chinatyke wrote: ↑25 Mar 2018, 11:57

5280'/min or 88'/sec is 60 mph. I didn't realise that they moved so fast. They're fair zipping along. Must have been dangerous things to be near. Thanks for the information.

Thats an interesting note, as I get the feeling that Steam Engines (Locomotives), ( are we in the wrong thread here?) work best when moving at 60mph. Although capable of going up to twice that velocity I think the efficency declines, and the mechanical forces get streched beyond sustainable capabilities, likewise slower allows for more slap and wear to occur.

Re: STEEPLEJACK'S CORNER 2012

Posted: 28 Oct 2019, 16:05

by Spinningweb

Today 28-10-2019. in the news Stanley was a man trapped at the top of the Shadden Mill chimney, Carlisle, built in 1836, and once the eighth tallest chimney in the world.

Re: STEEPLEJACK'S CORNER 2012

Posted: 28 Oct 2019, 16:31

by Tizer

More here...

`Carlisle Dixons chimney: Man stuck at top of 290ft structure'

LINK

Re: STEEPLEJACK'S CORNER 2012

Posted: 28 Oct 2019, 16:34

by Tripps

Even more

here

Not looking good.

Re: STEEPLEJACK'S CORNER 2012

Posted: 28 Oct 2019, 21:07

by Whyperion

I had noticed the unfortunate outcome, but did not intend to post here, questions appear unanswered as to how, or why, he had chosen to ascend the structure.

Re: STEEPLEJACK'S CORNER 2012

Posted: 29 Oct 2019, 03:39

by Stanley

"questions appear unanswered as to how, or why, he had chosen to ascend the structure."

Because it's there. Any jack will tell you that as soon as you ladder a chimney you have to take precautions to stop access to the ladder. Most common was to remove the bottom ladder each night or lash a scaffolding board to it blanking the rungs off. Otherwise some silly bugger will attempt the climb and cause problems. In the event of that happening the firm who laddered it had to have a defence to show they had taken steps to negate illegal access.

In the case of the Dixon's stack, I assume it was done using rock climbing techniques. Whatever the outcome the responsibility rests on the climber. Climbing stacks is specialised work.

.

I took the trouble to learn from the experts.

.

.