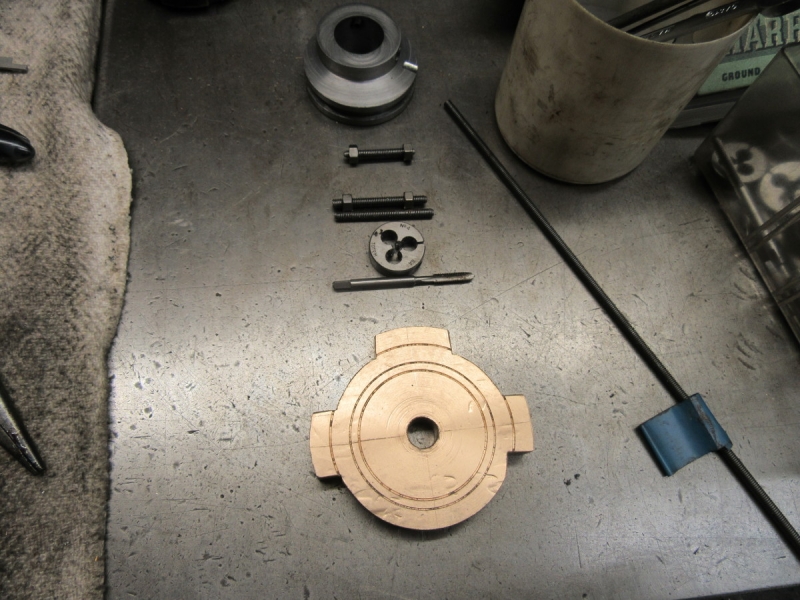

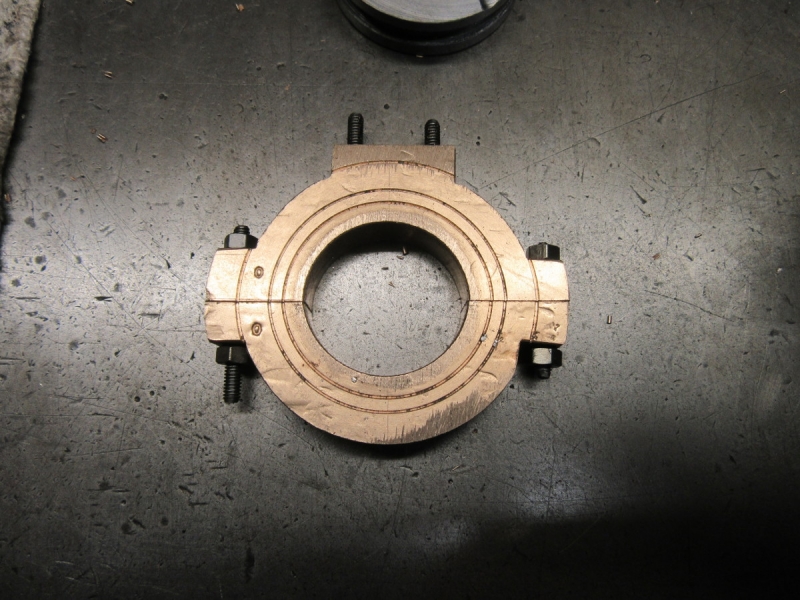

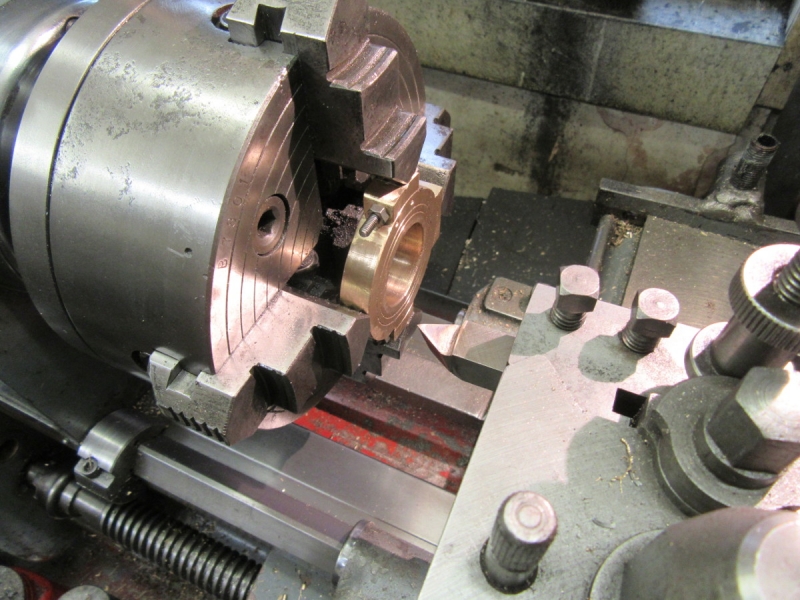

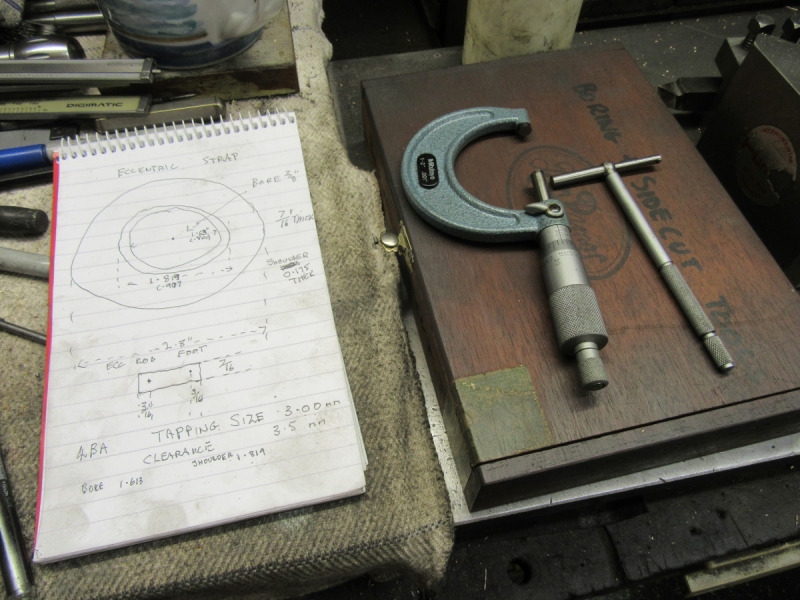

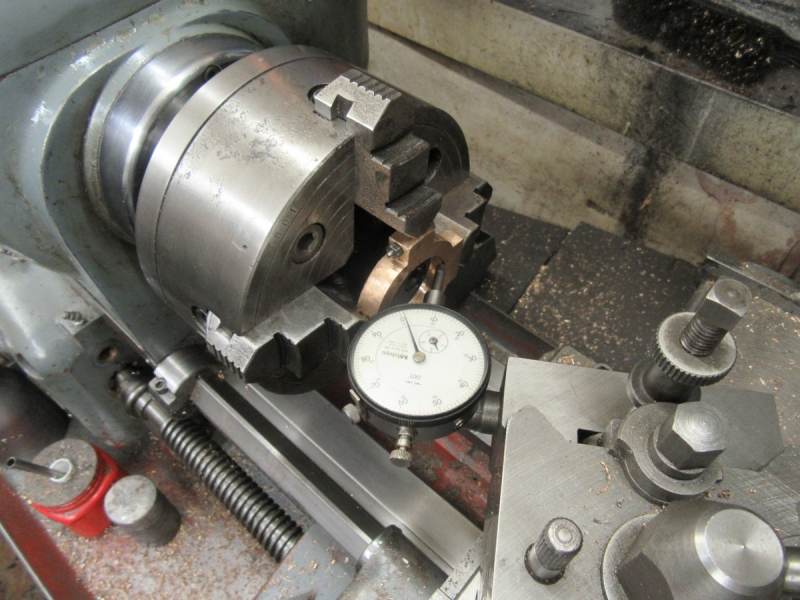

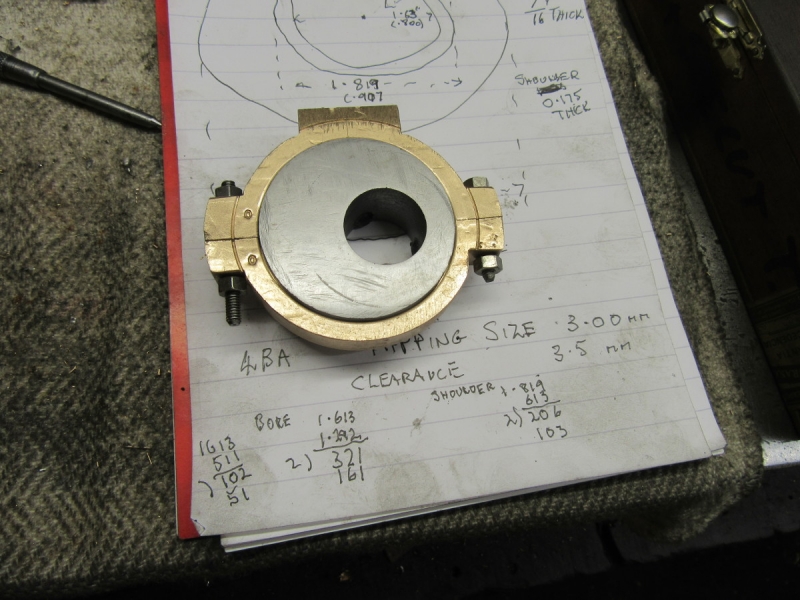

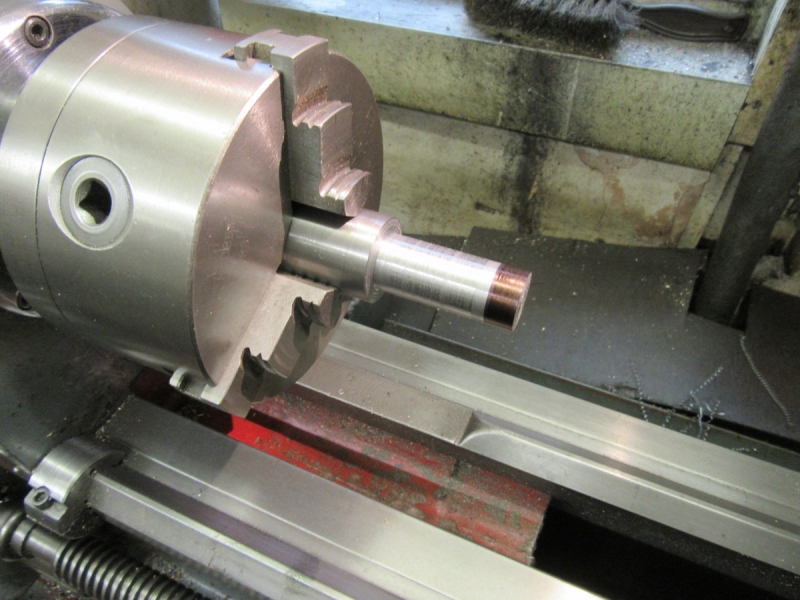

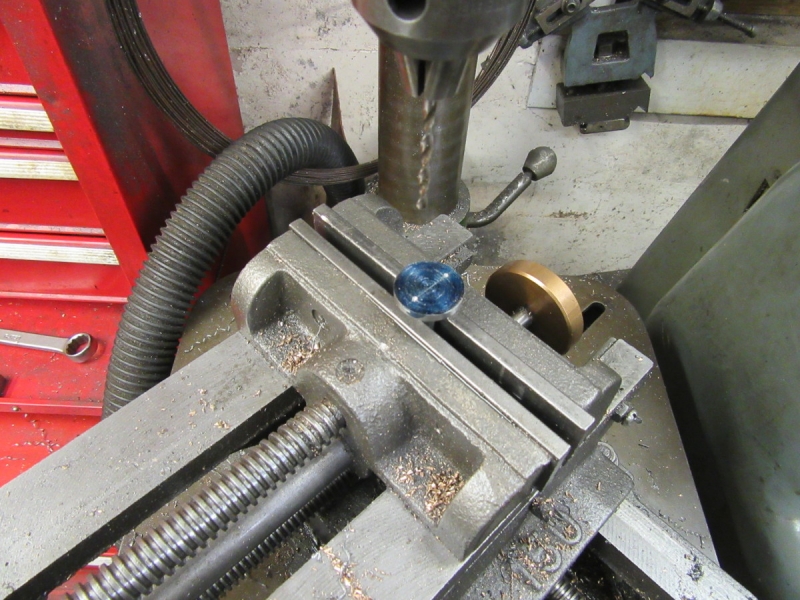

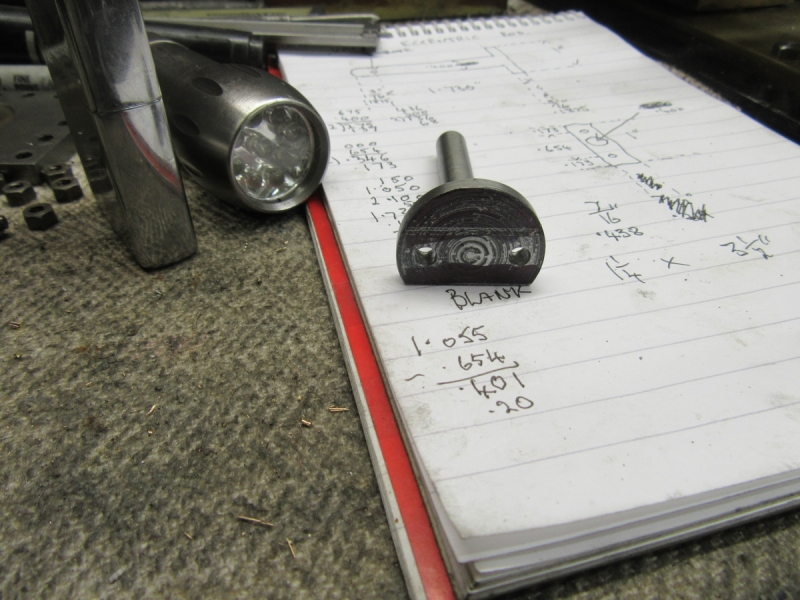

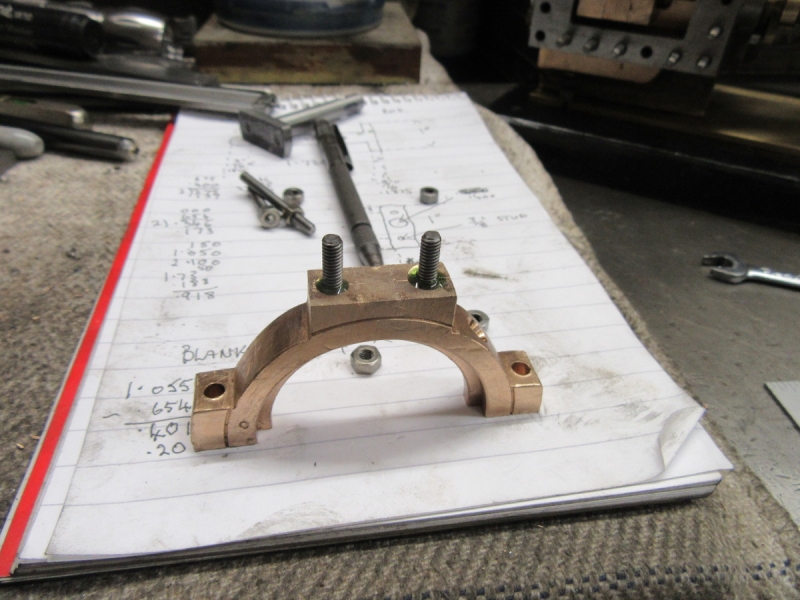

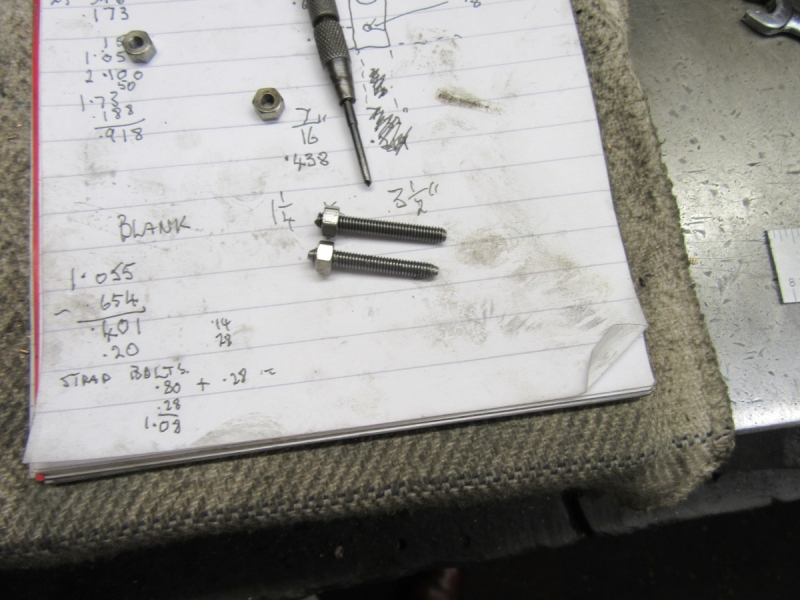

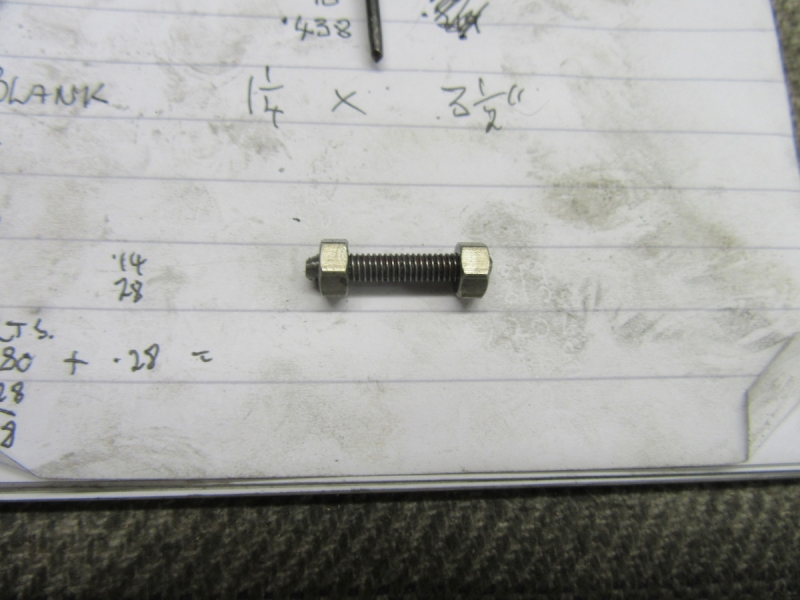

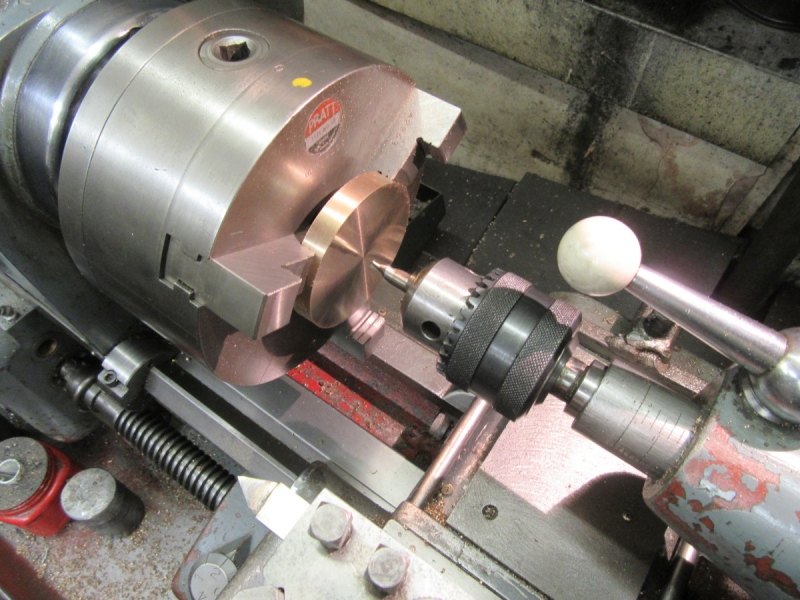

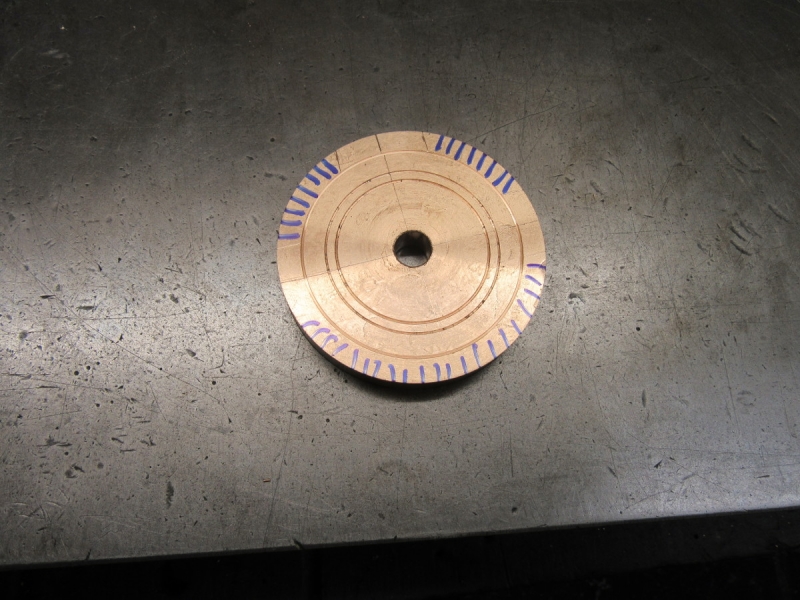

I've done my thinking overnight and realised that I need a 3/8" hole in the centre so I can mount the blank on the rotary table. I also need circles marking for the bore, the cut back and the limit of the outside cuts to get the shape. In case you're wondering I forgot the latter but went back to do it. Before I did this marking I had to do some careful measuring. If you're with me you'll realise that when I split the strap the bores will need doing again because they will have shrunk because of the cut but I will still have my marker.

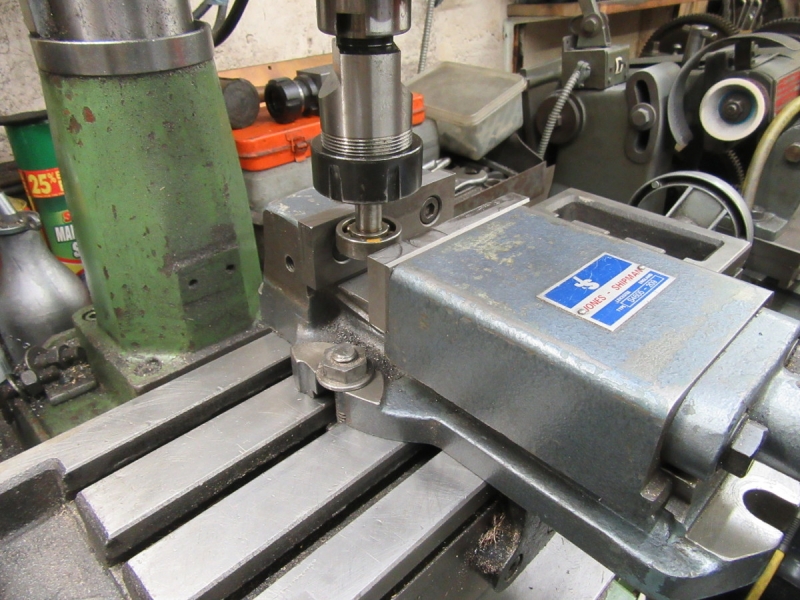

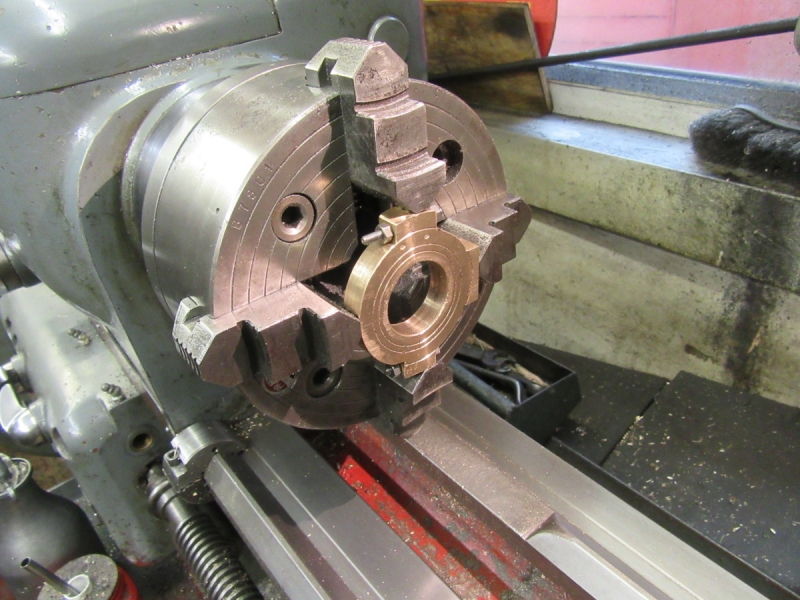

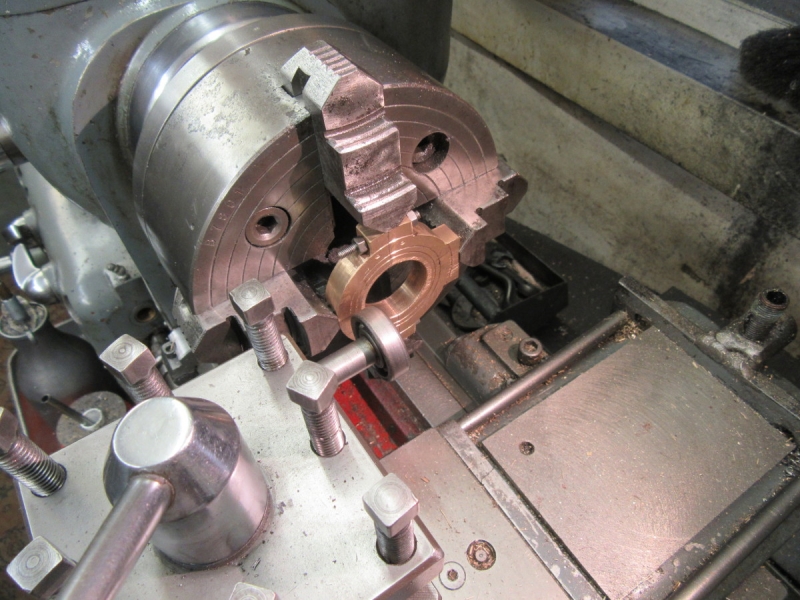

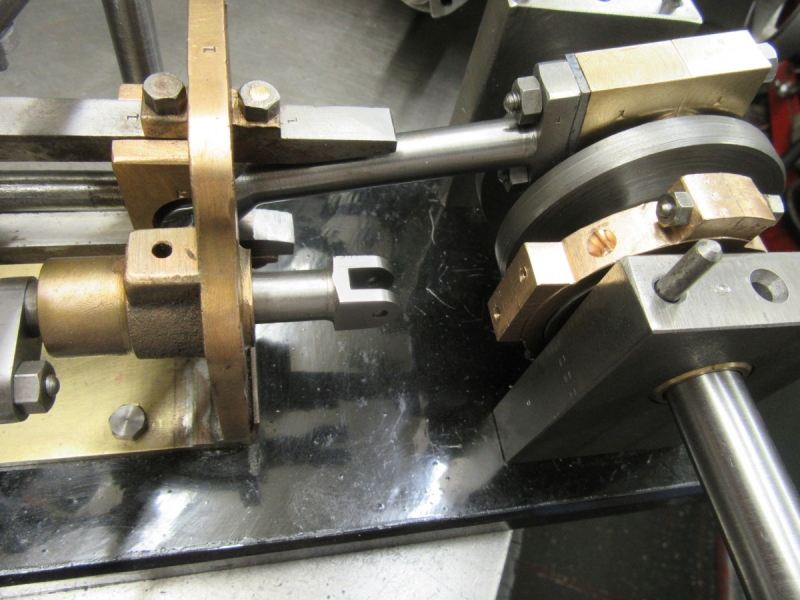

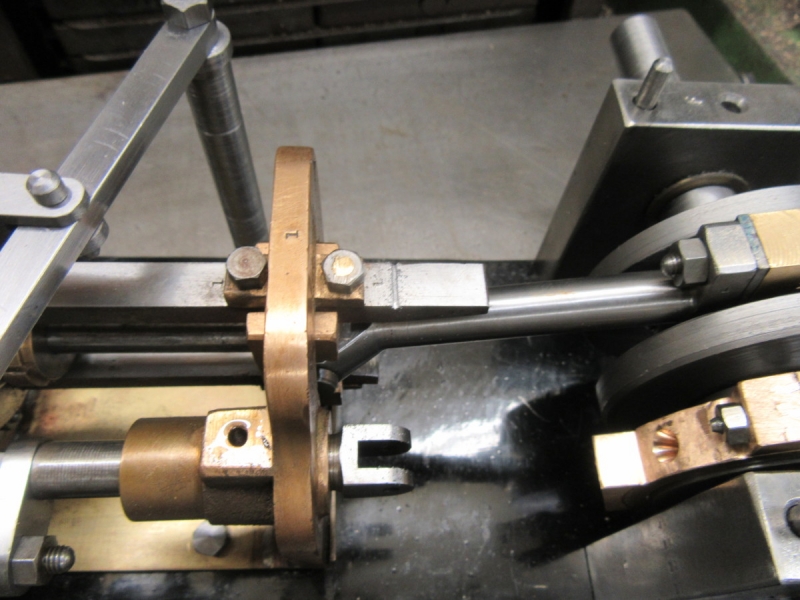

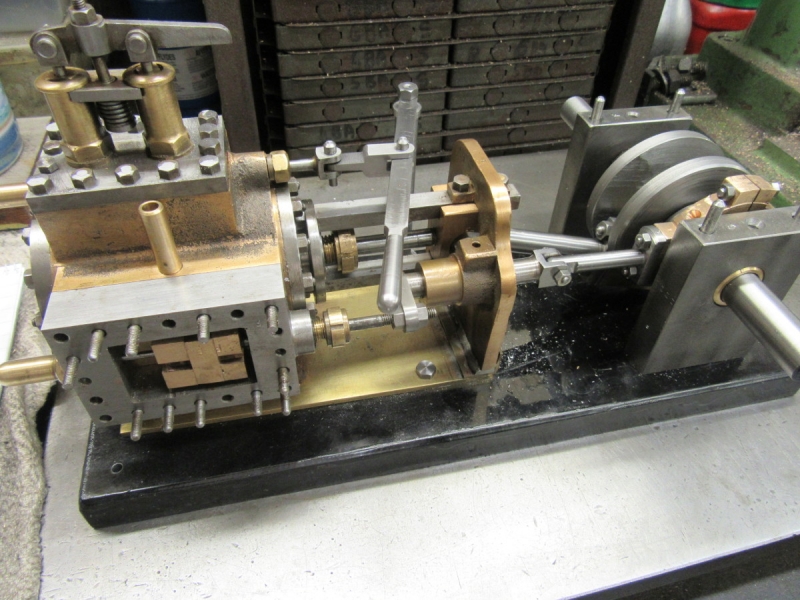

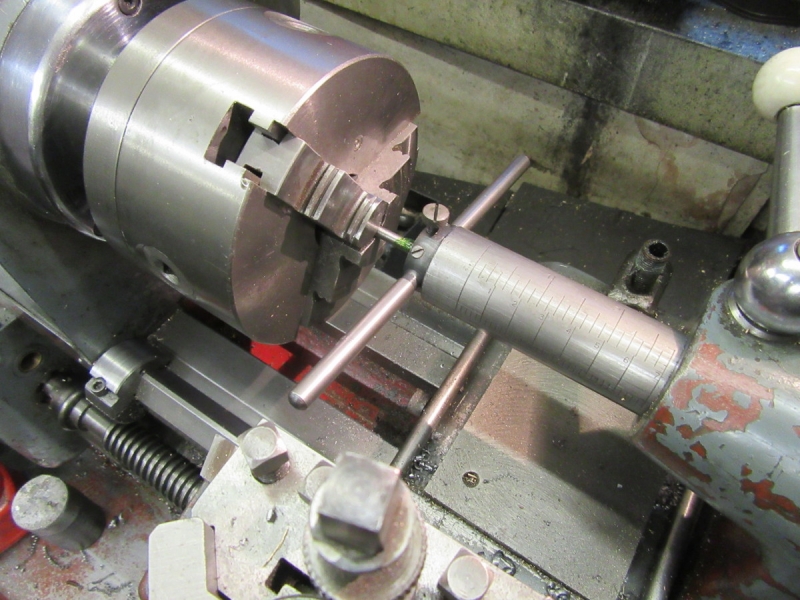

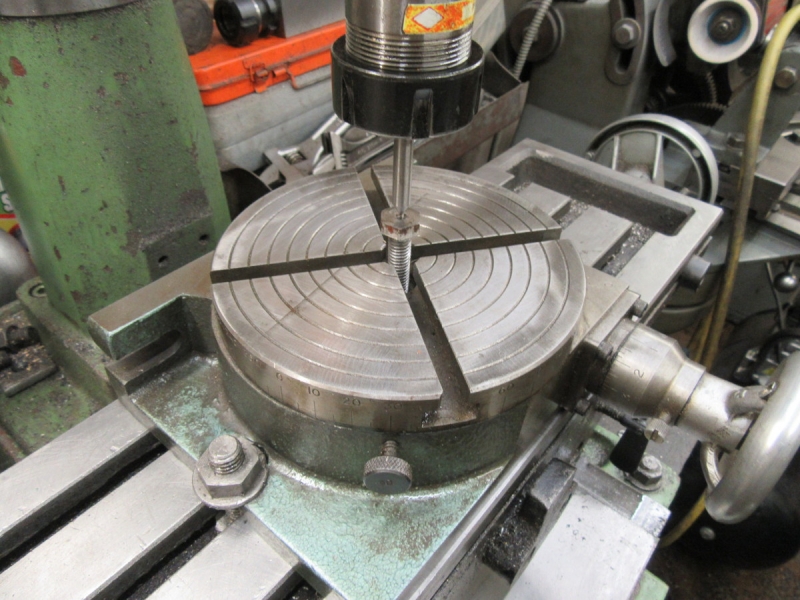

Next I put the rotary table up and found the centre and locked the sideways movement. (I can never remember whether it's X or Y!)

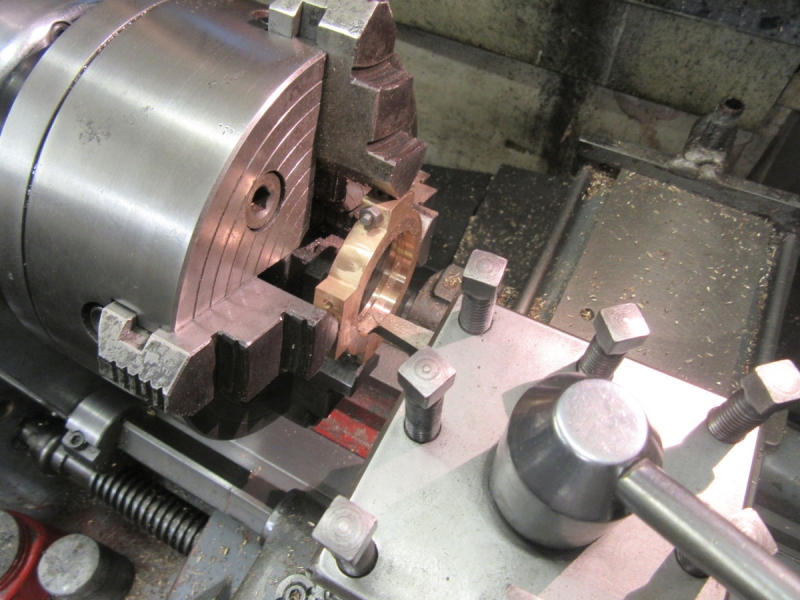

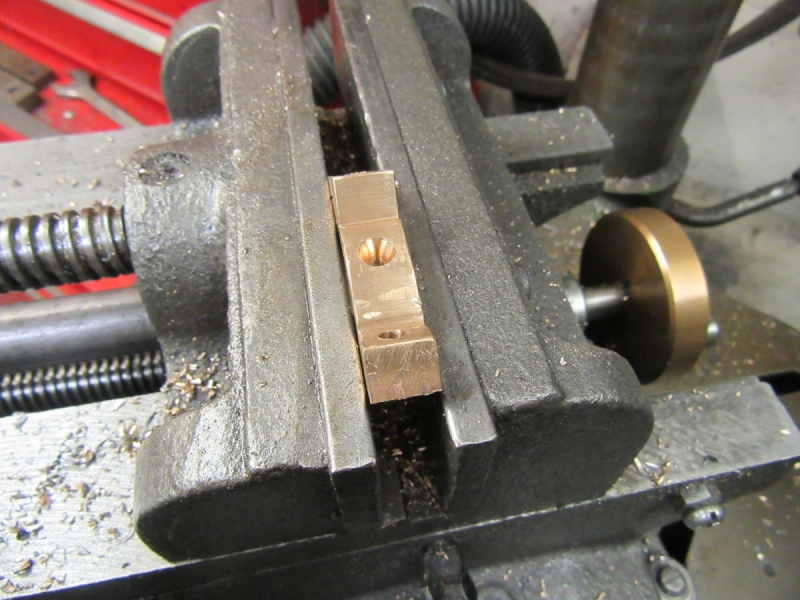

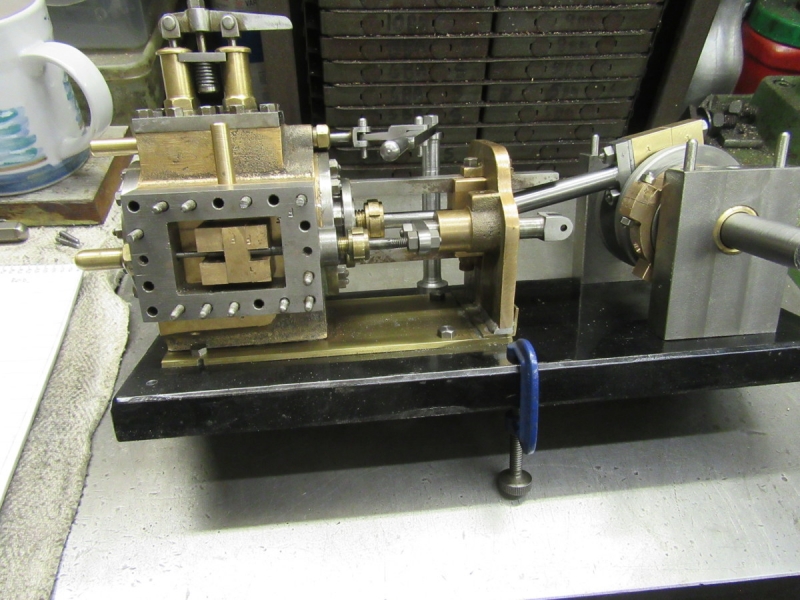

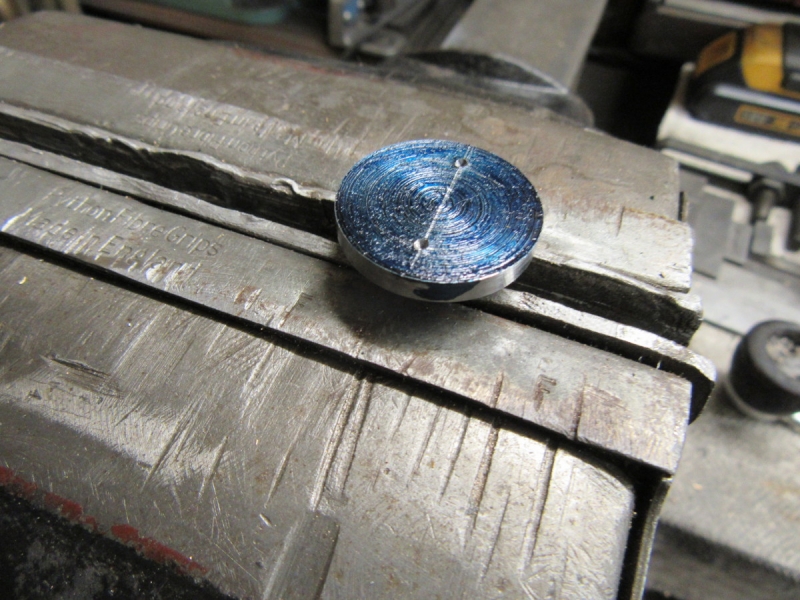

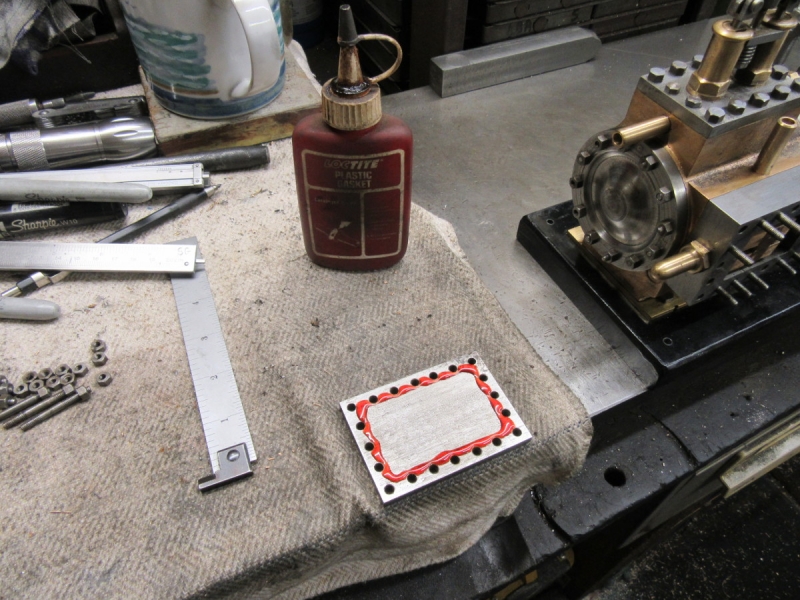

Some careful measuring and marking and I hatched the metal that needs to come out.

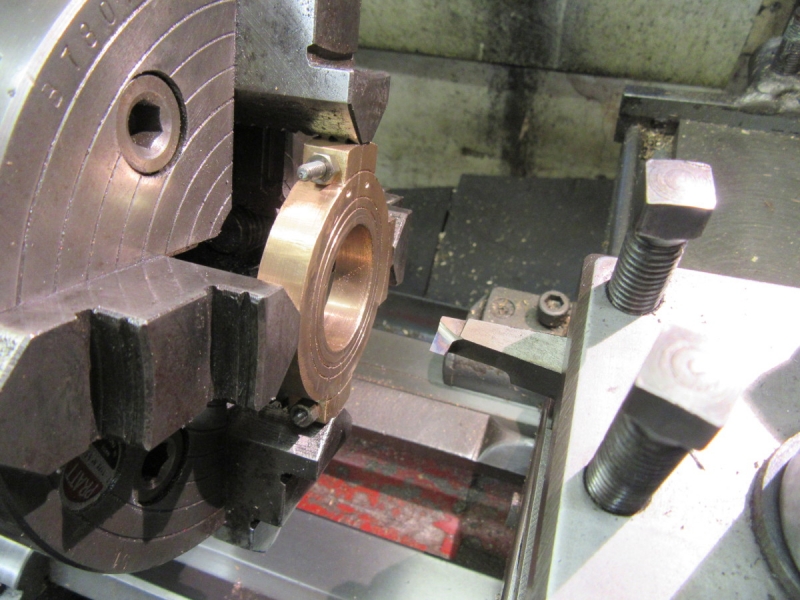

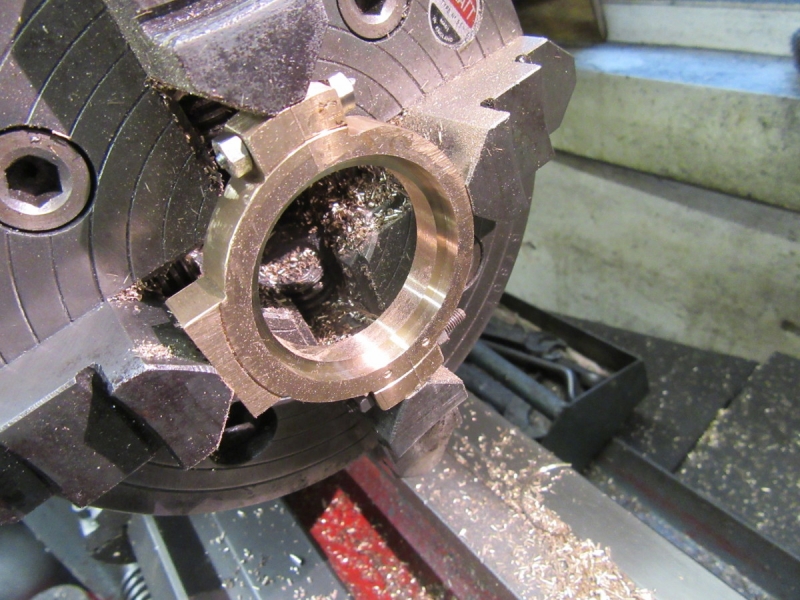

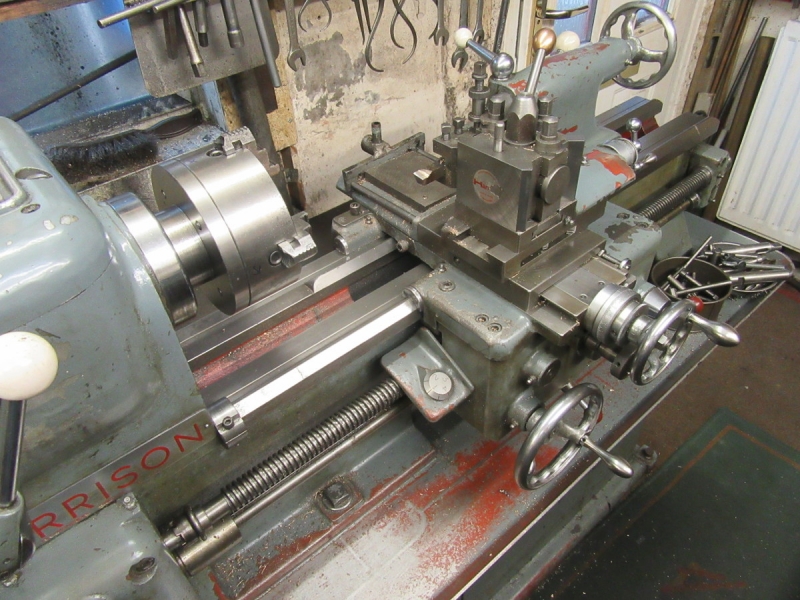

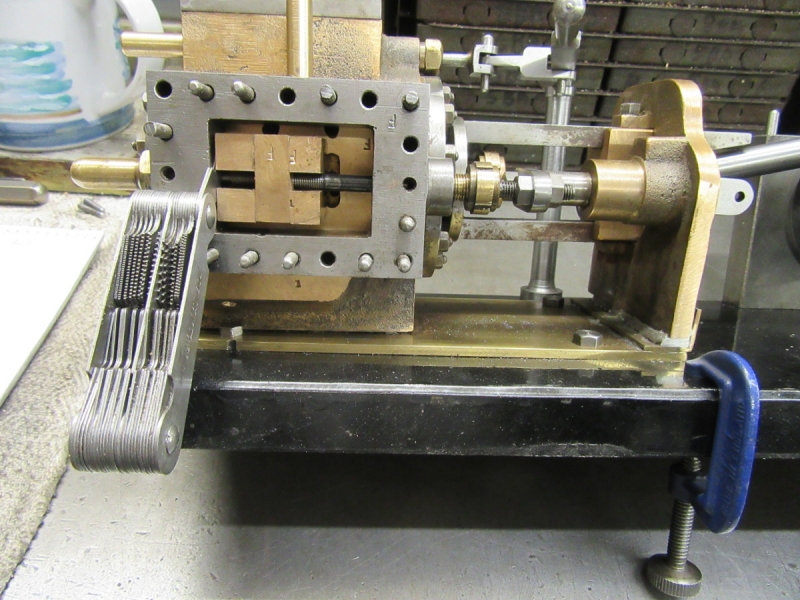

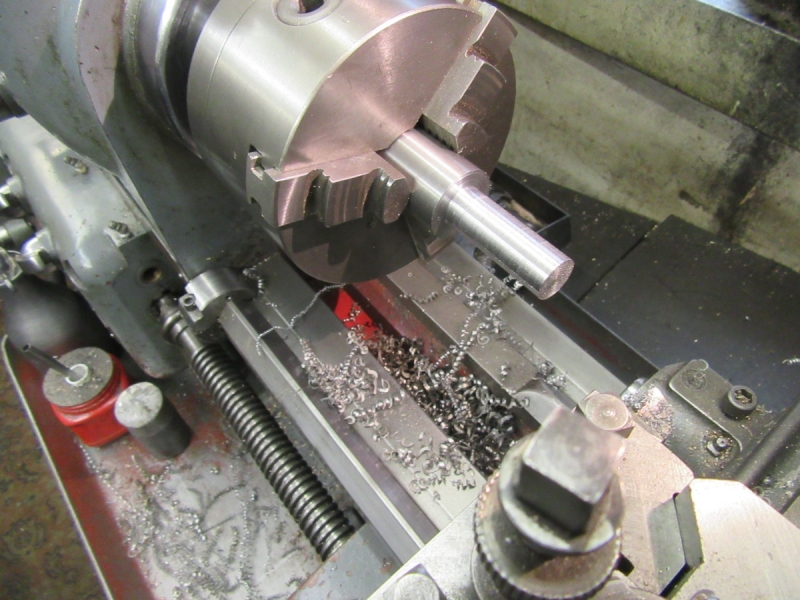

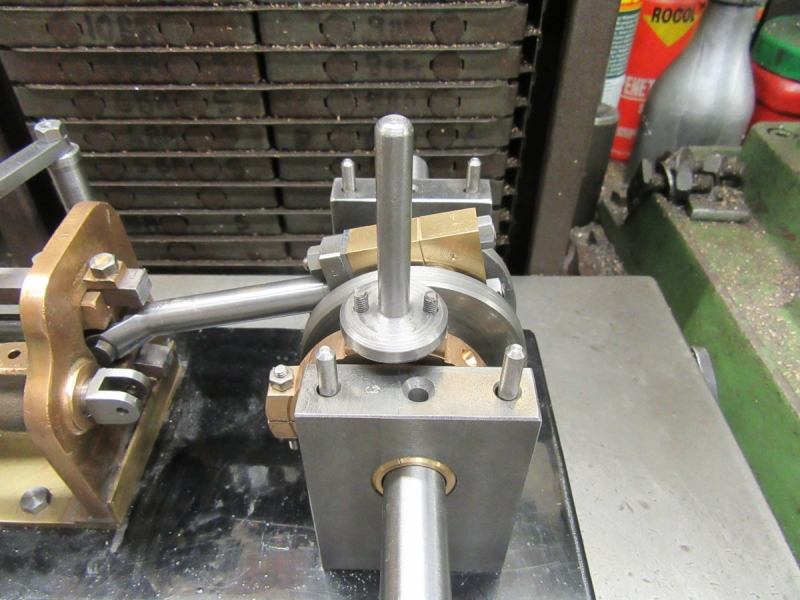

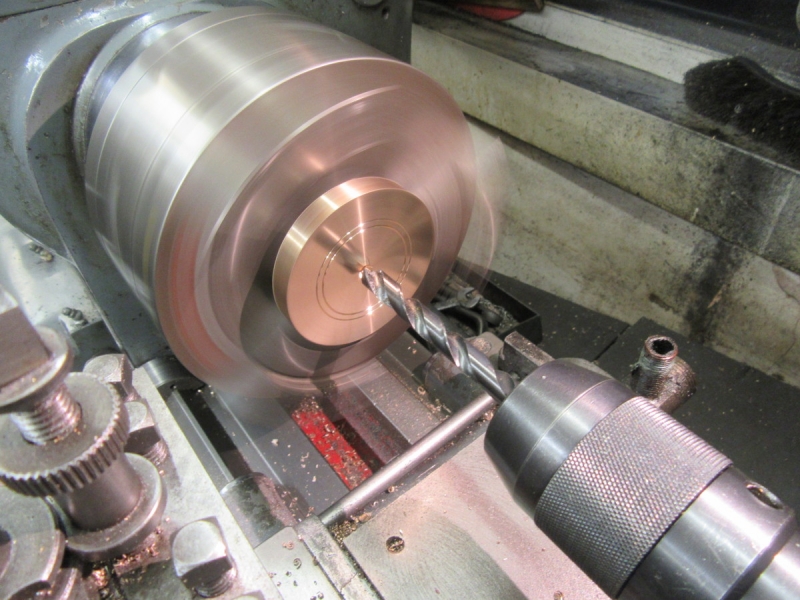

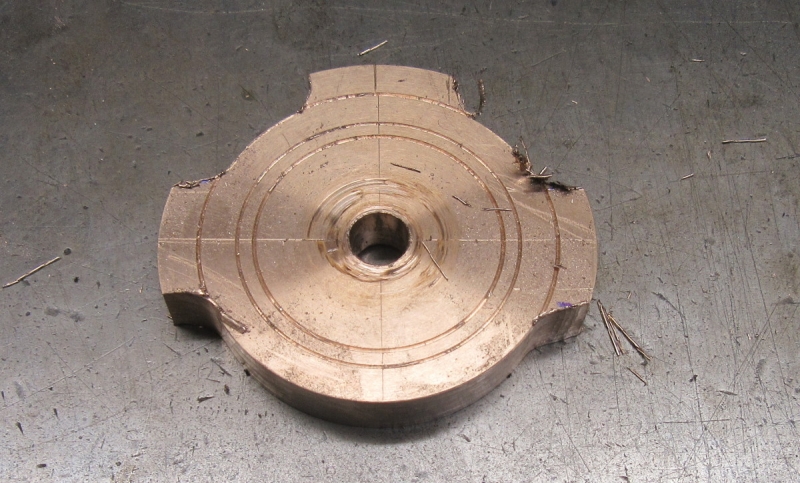

I found a sharp cutter for the side milling, put the speed of the spindle up to 1400rpm and started some careful cutting. What we are doing is taking the meat out and leaving a tidy concentric edge. I shall have to finish the ends of the cuts out by hand, the only way I can get them square.

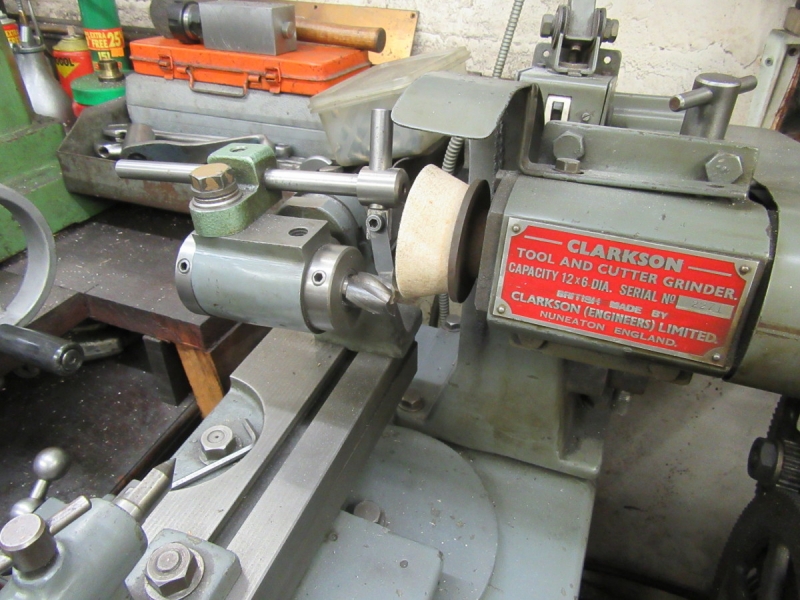

Then some careful patient cutting, needle sharp chips spraying all over the place!

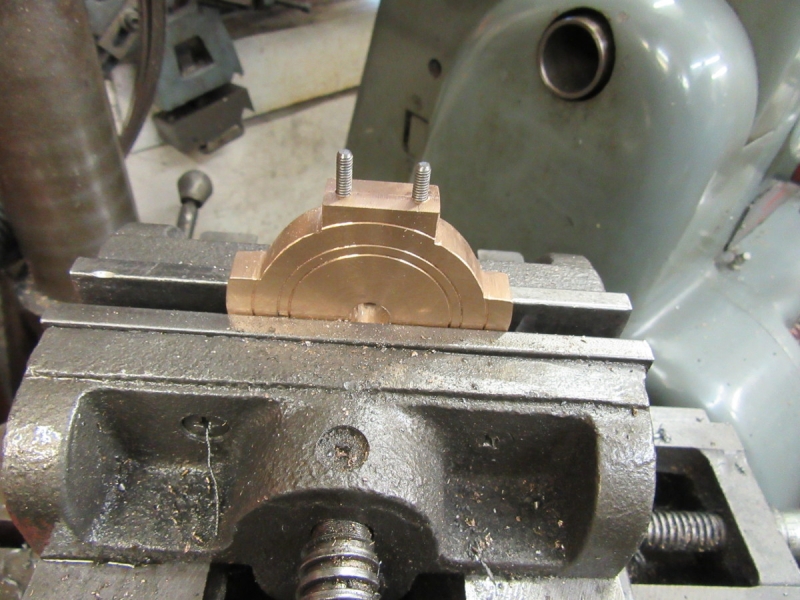

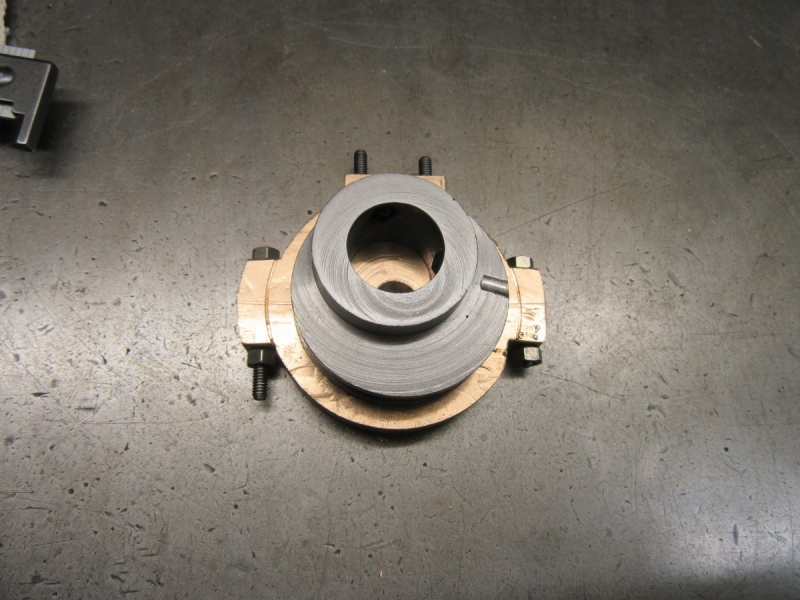

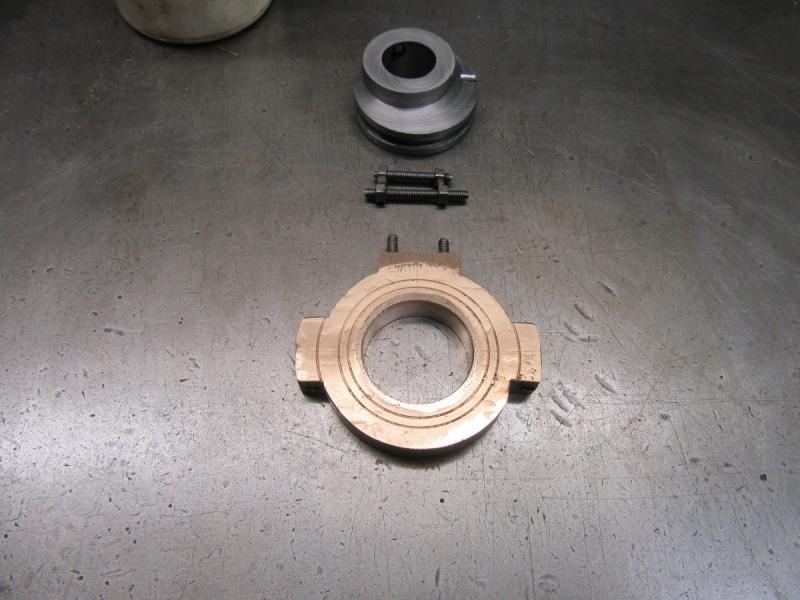

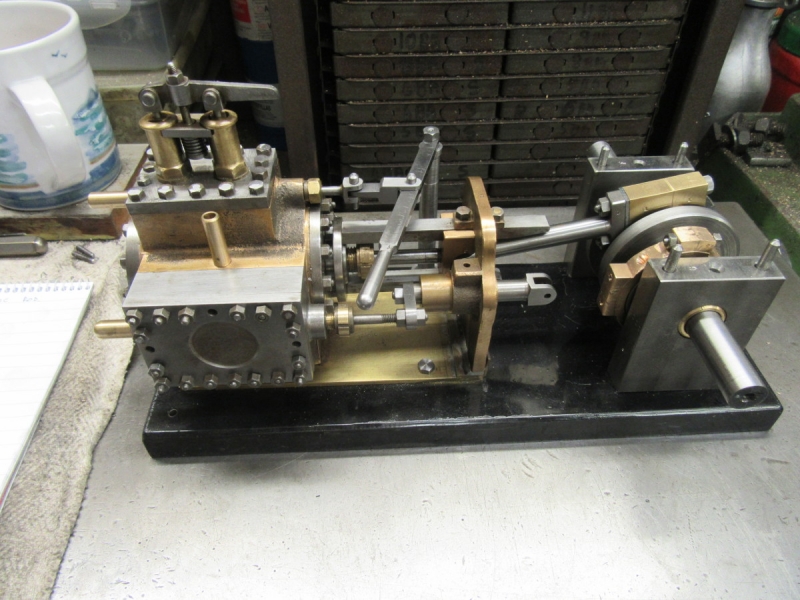

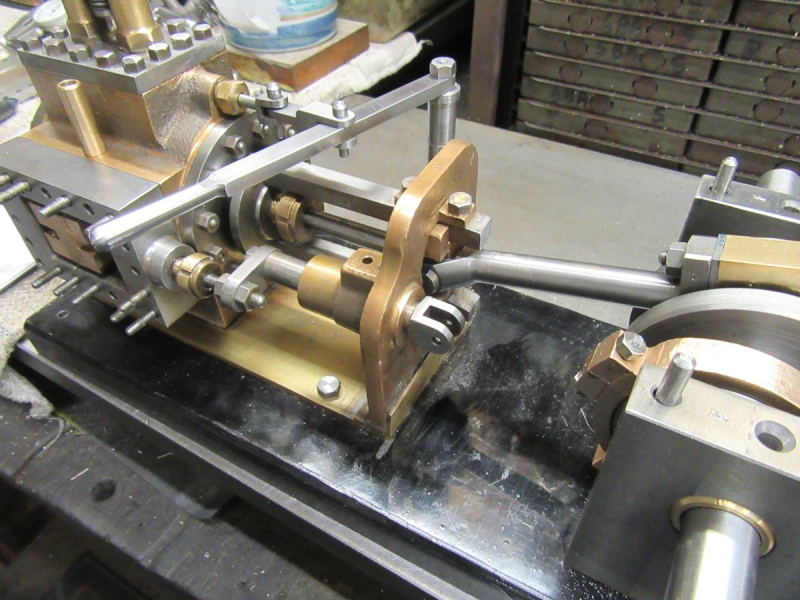

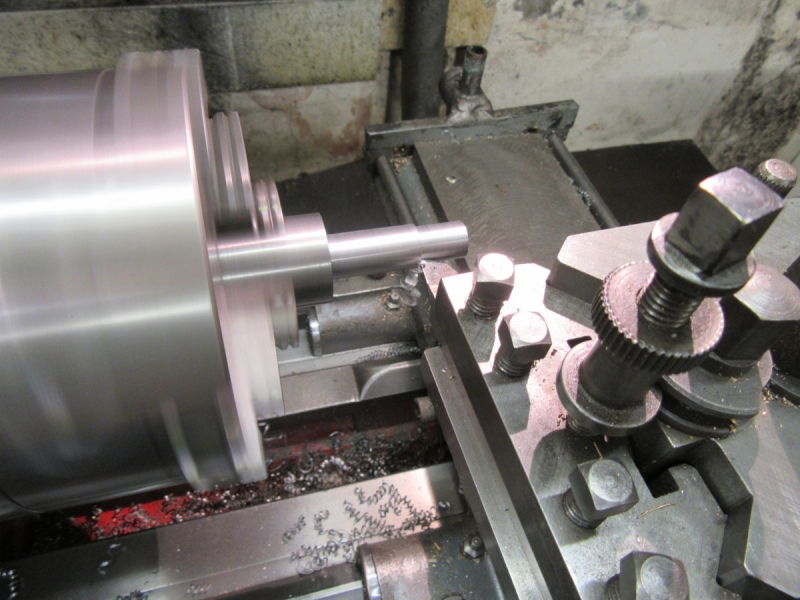

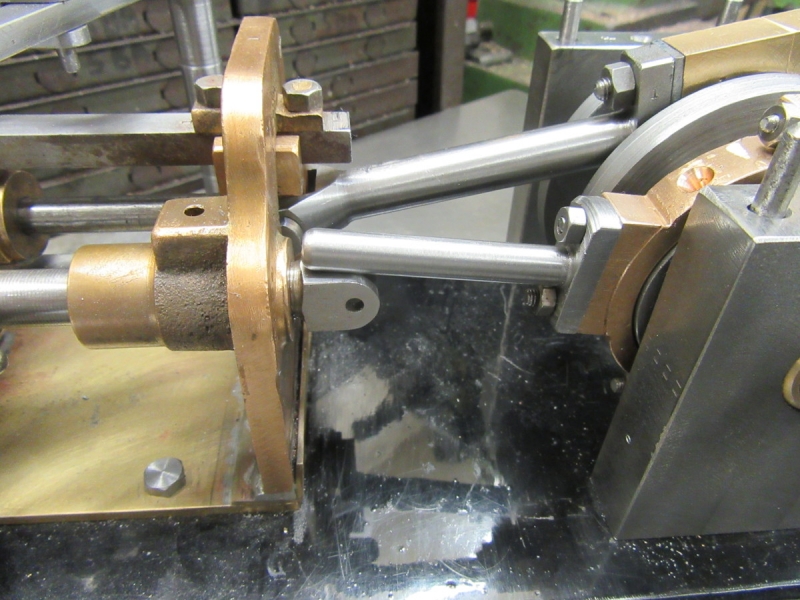

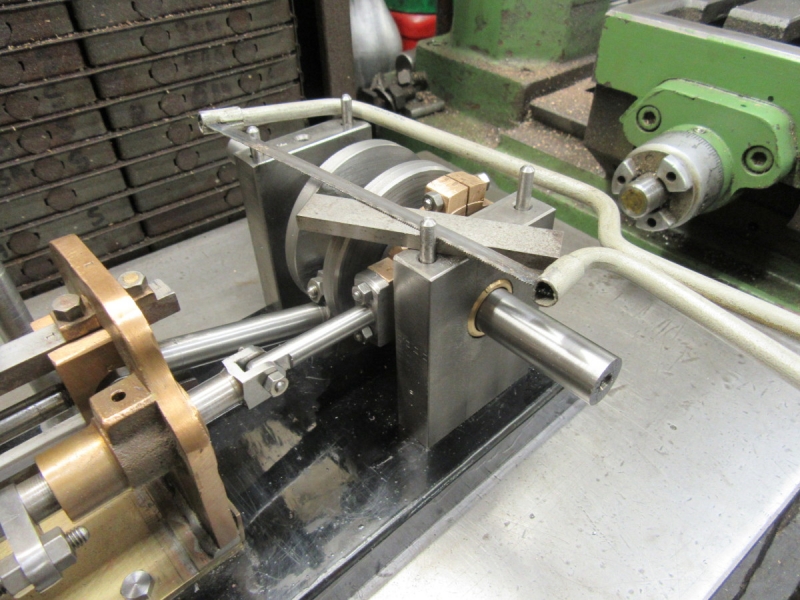

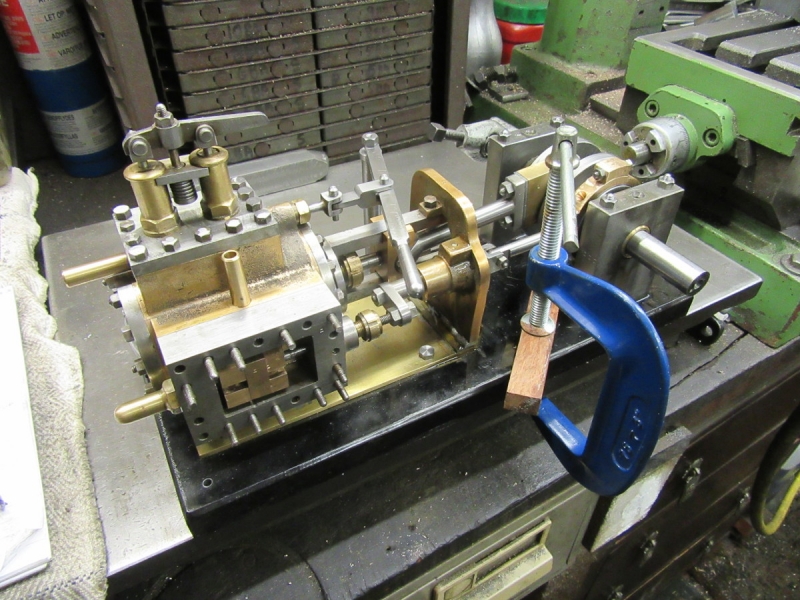

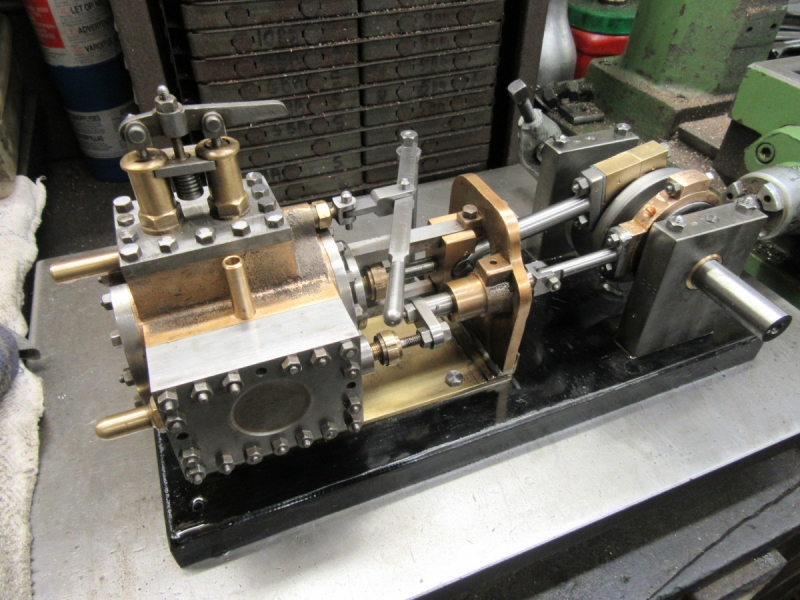

Some time later here's where we are. No slip ups, we are ready for boring the centre out, splitting the stock, squaring my edges and then of course installing the clamp bolts and re-finishing the bores. That's for tomorrow.

I put some stuff away, had a chip chase and then vacuumed the floor, it was covered with brass chips. Tomorrow I'll finish getting sorted and go forwards with the strap.