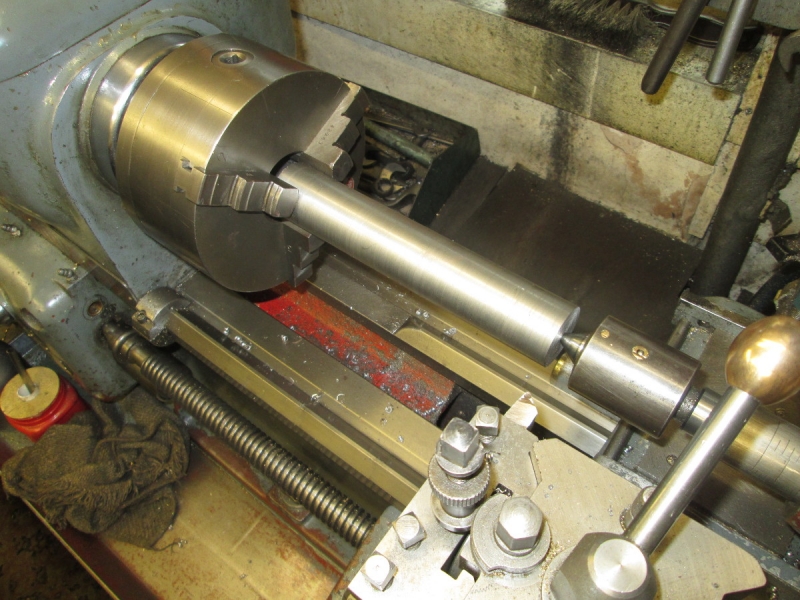

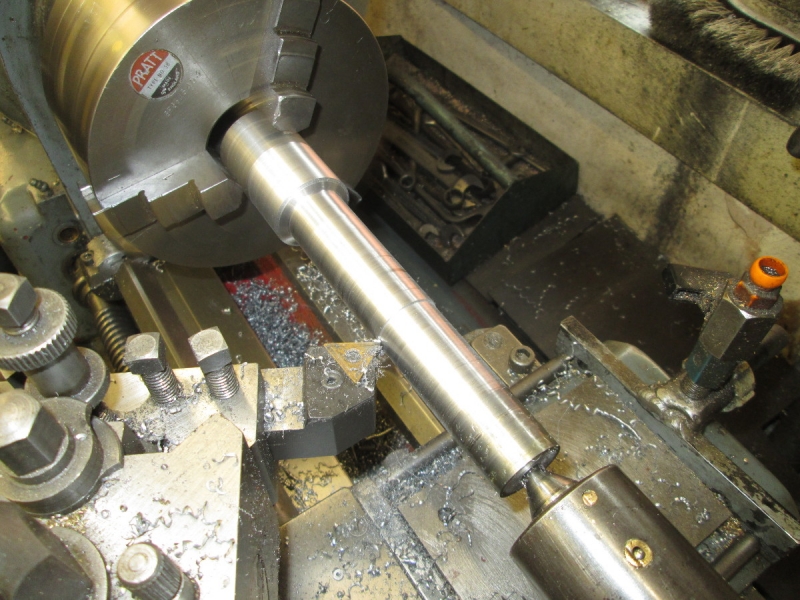

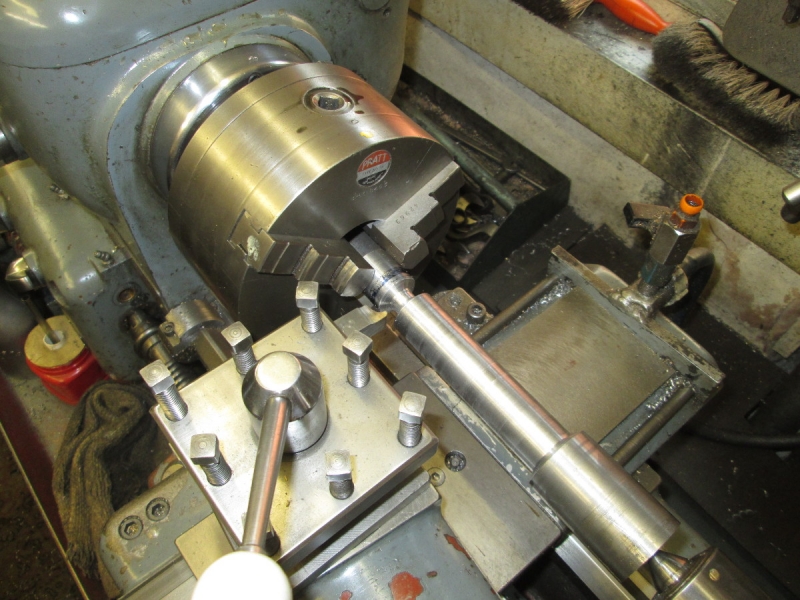

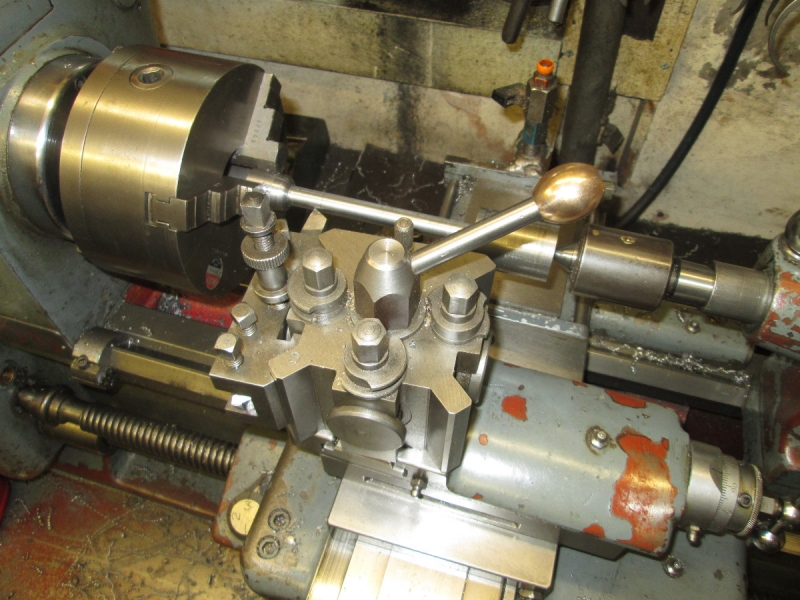

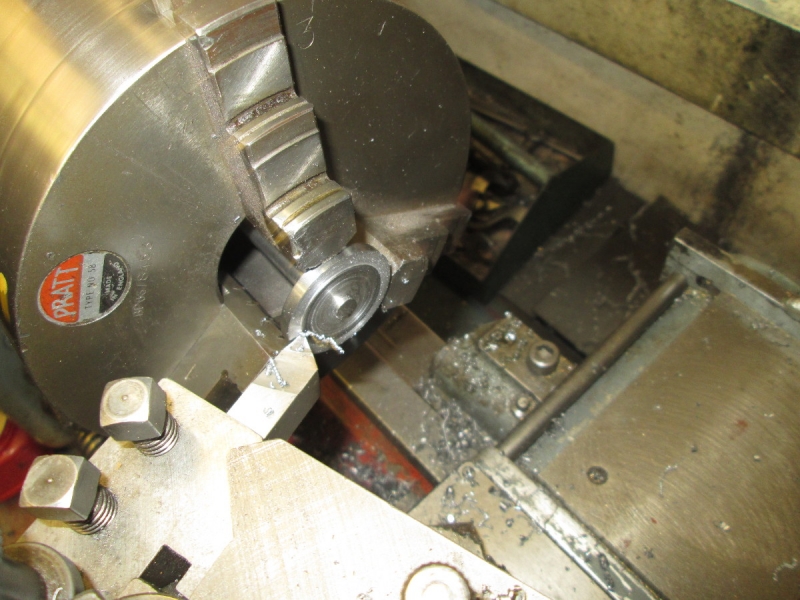

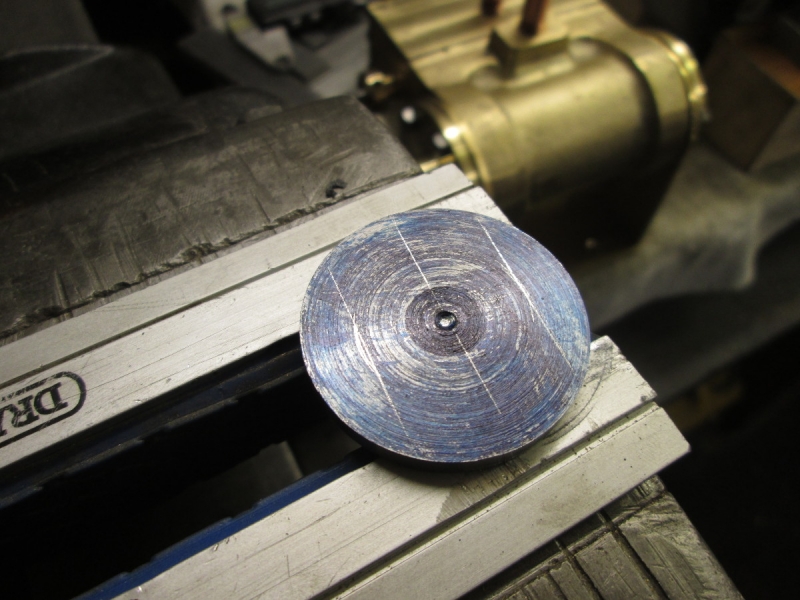

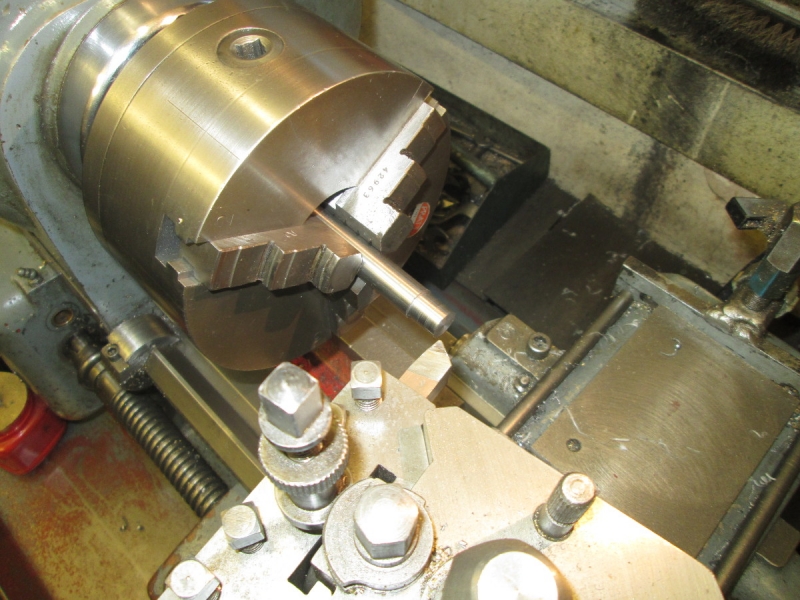

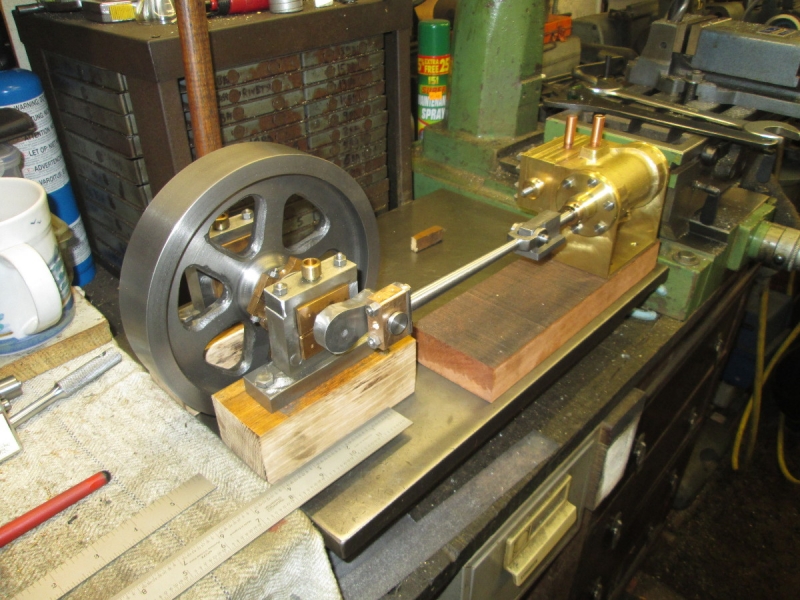

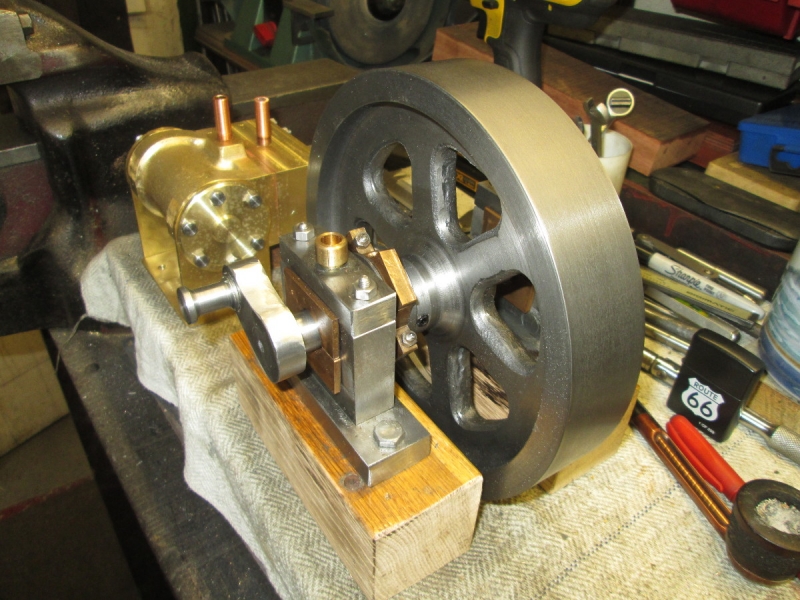

I managed just over an hour in the shed and started by putting about 30 minutes into improving the finish of the crank. Eventually I realised I had gone far enough!

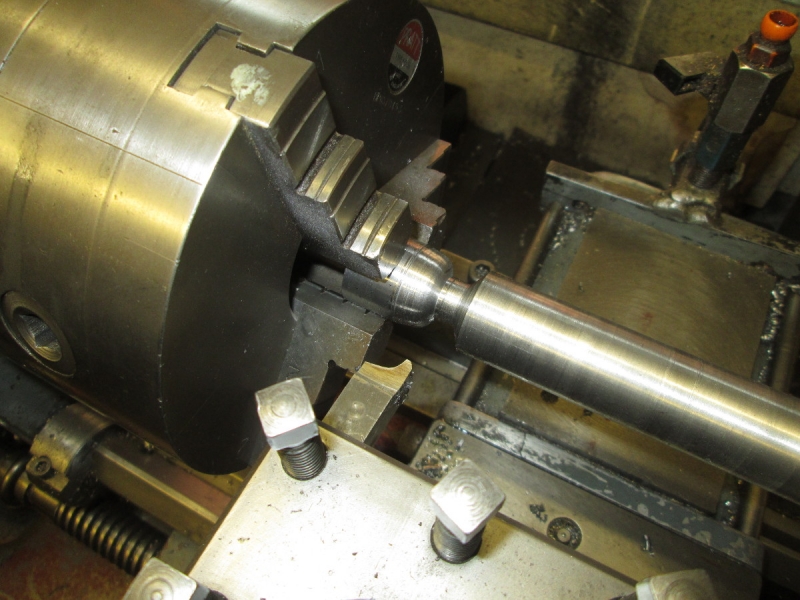

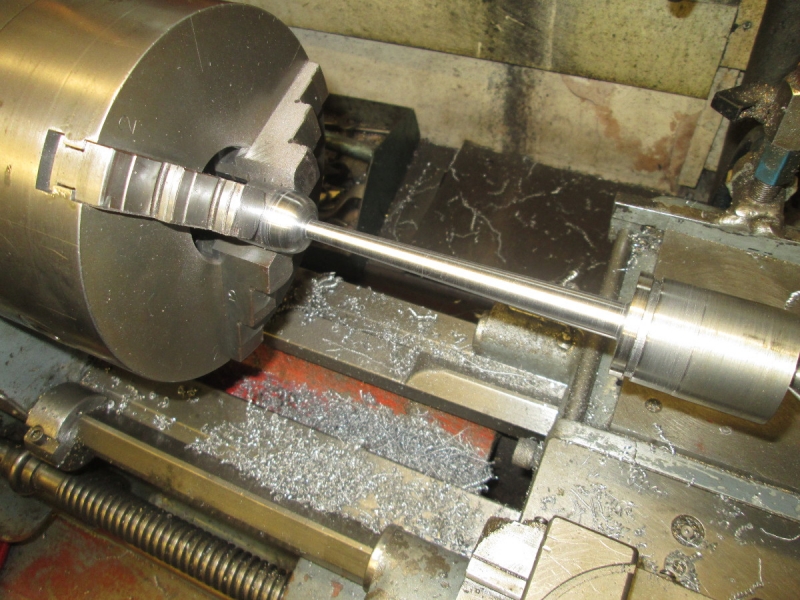

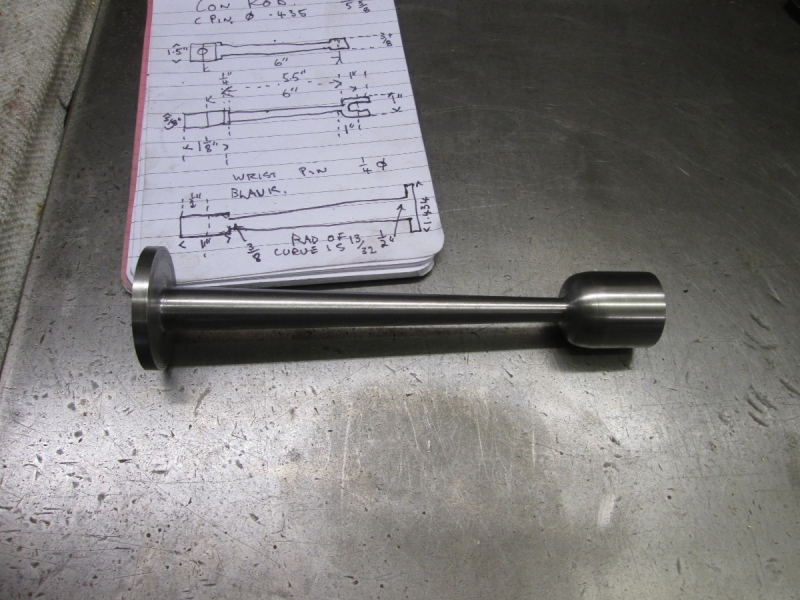

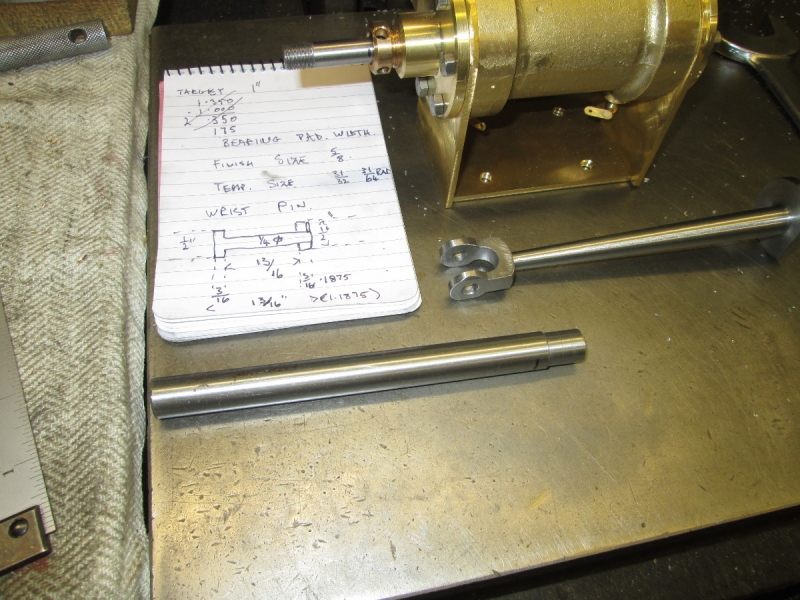

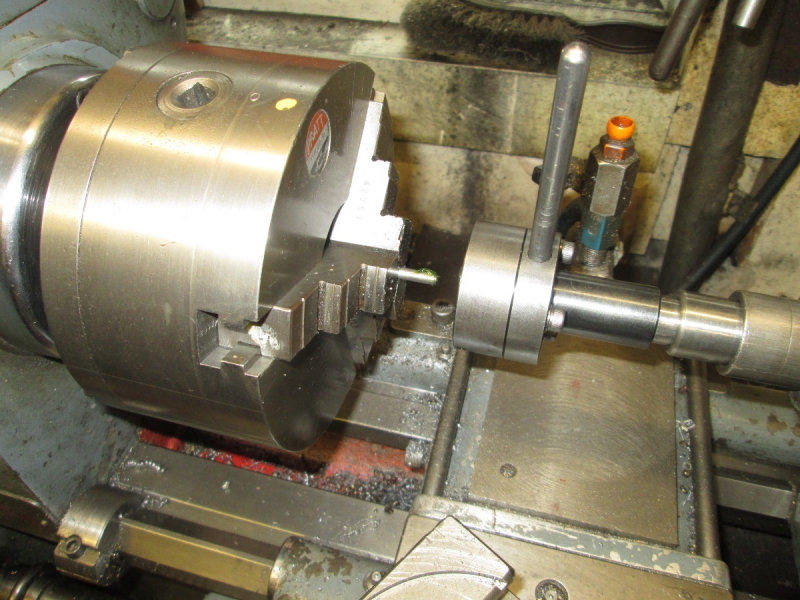

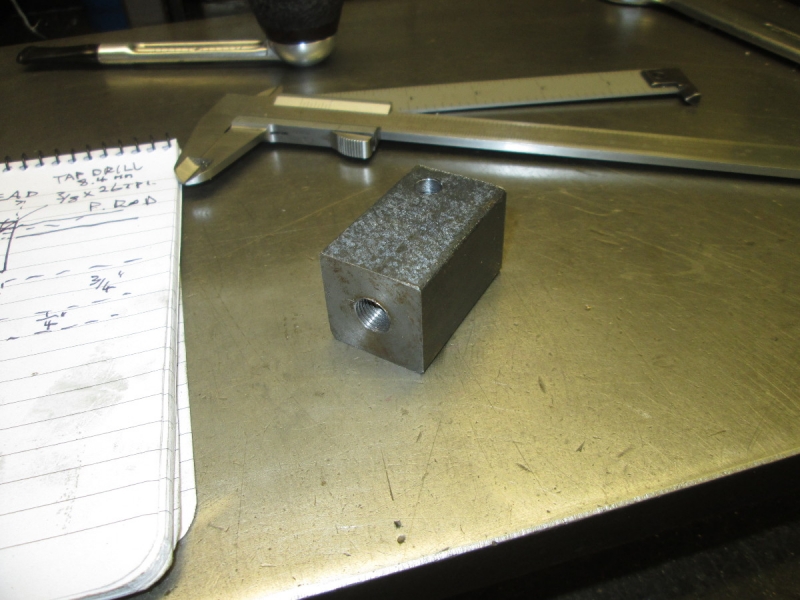

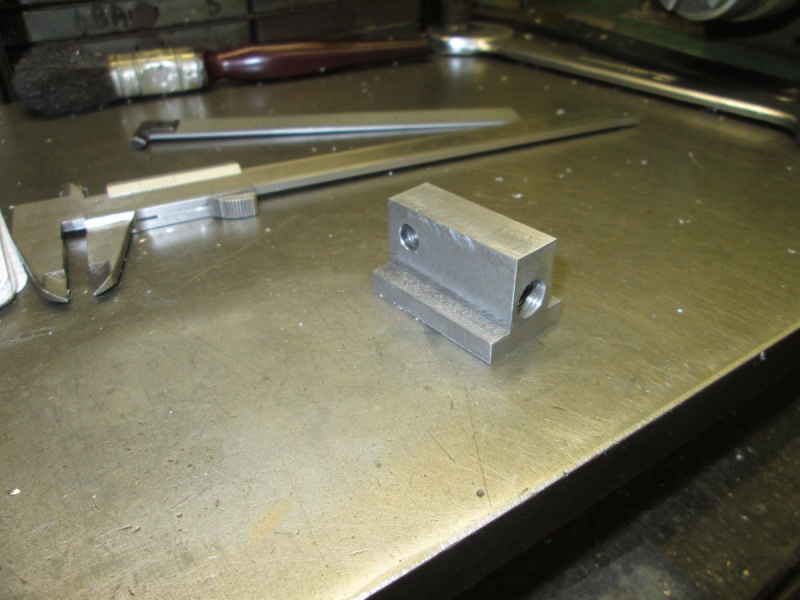

In my head the next job was to make a new crank pin but I realised that in the process of finishing the crank I had reduced the thickness and it was possible to rework the crank pin and make it fit properly.

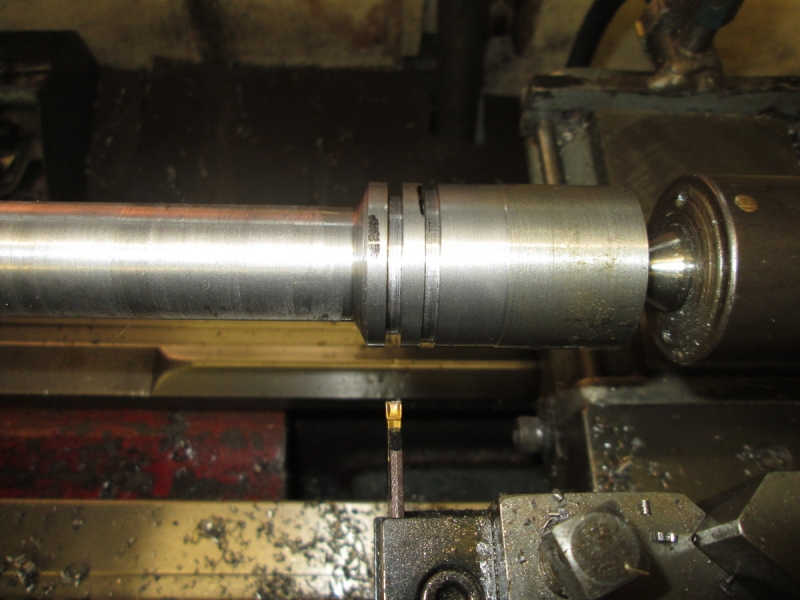

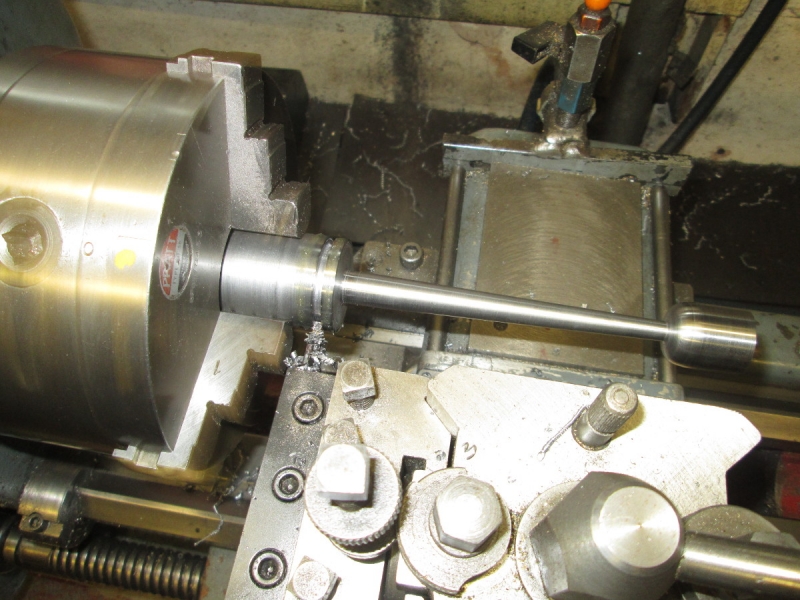

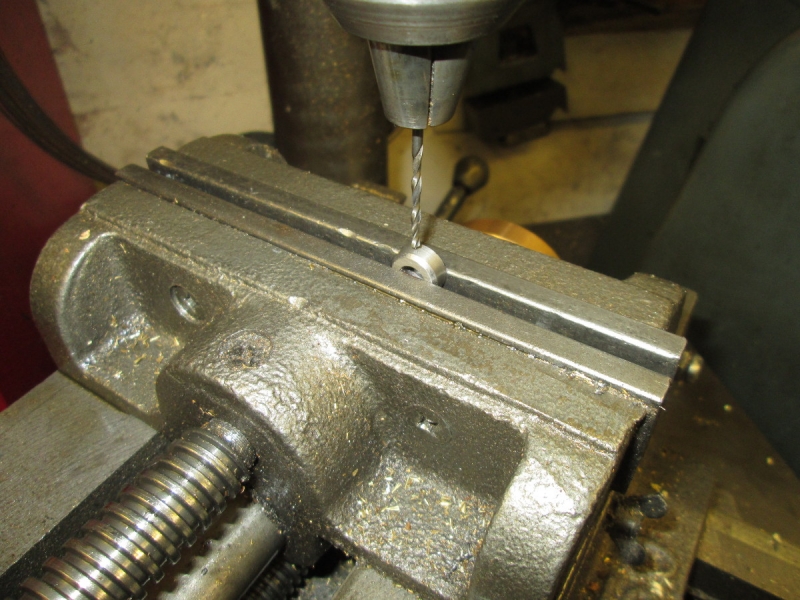

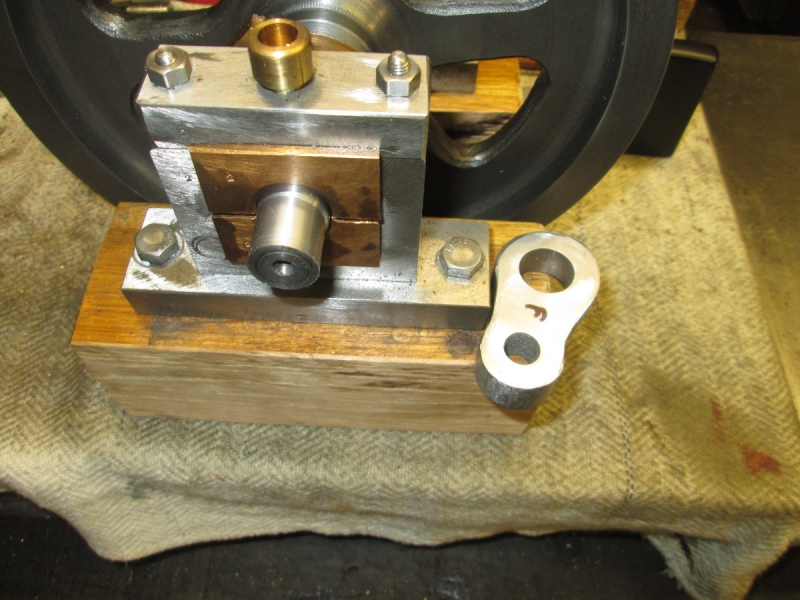

It worked and I was satisfied so I pressed it in and it was a good fit.

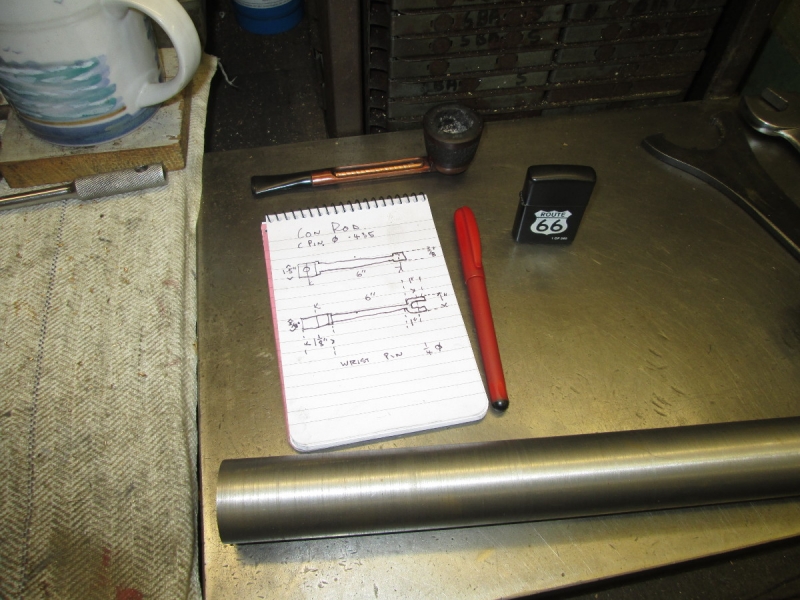

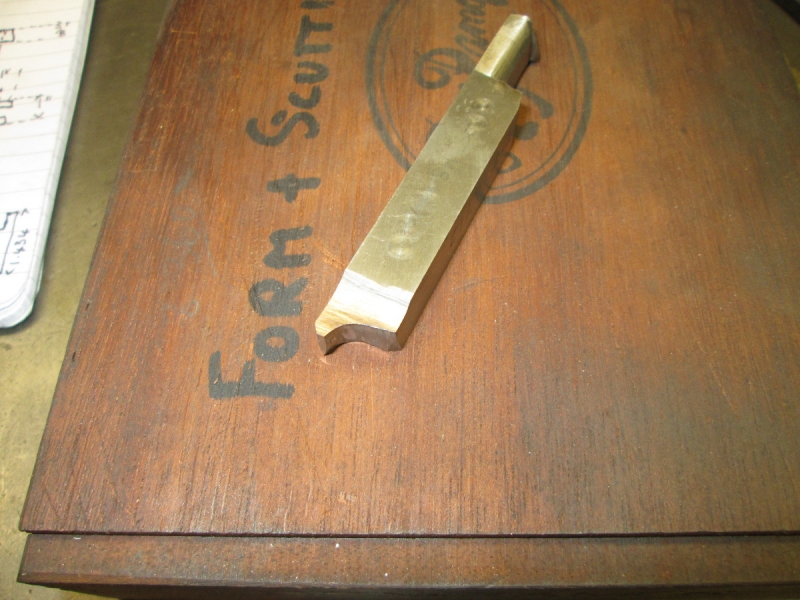

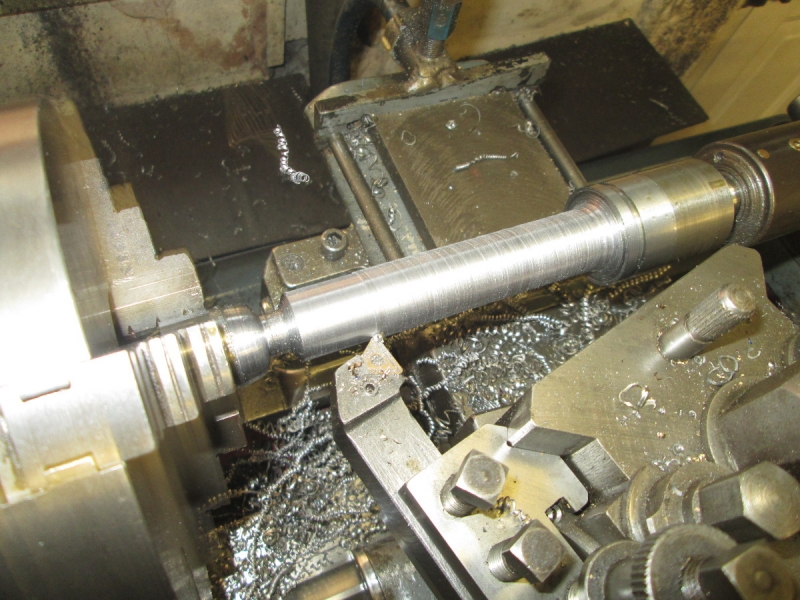

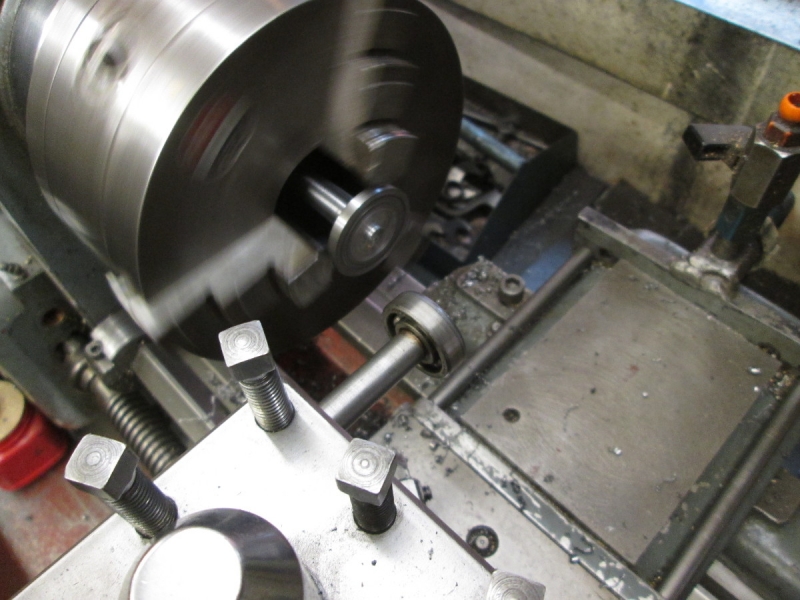

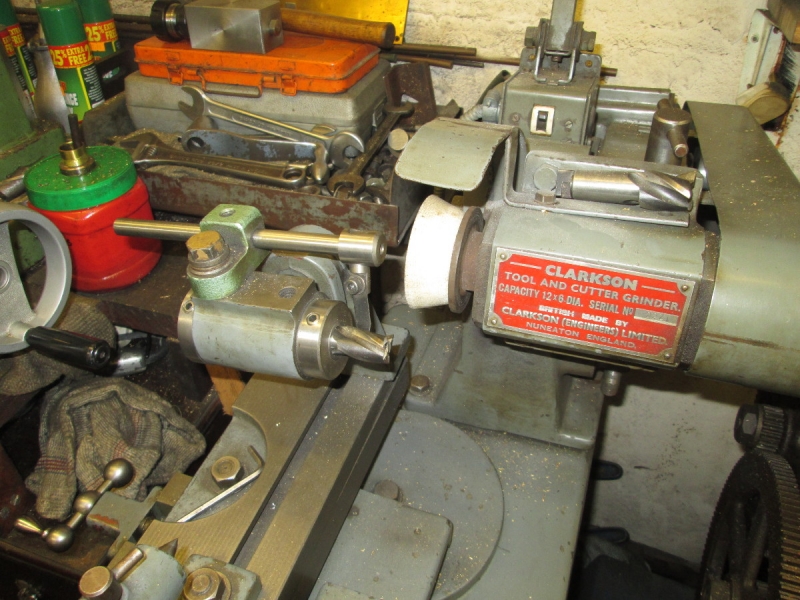

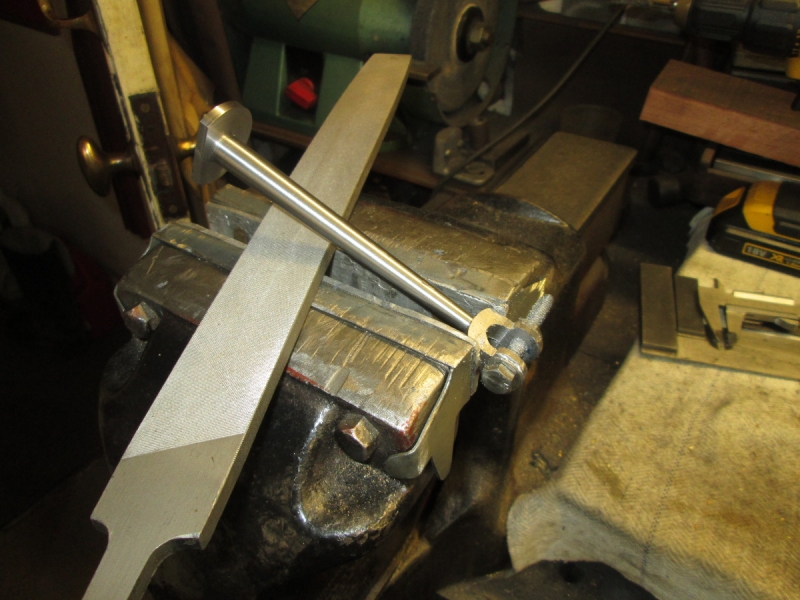

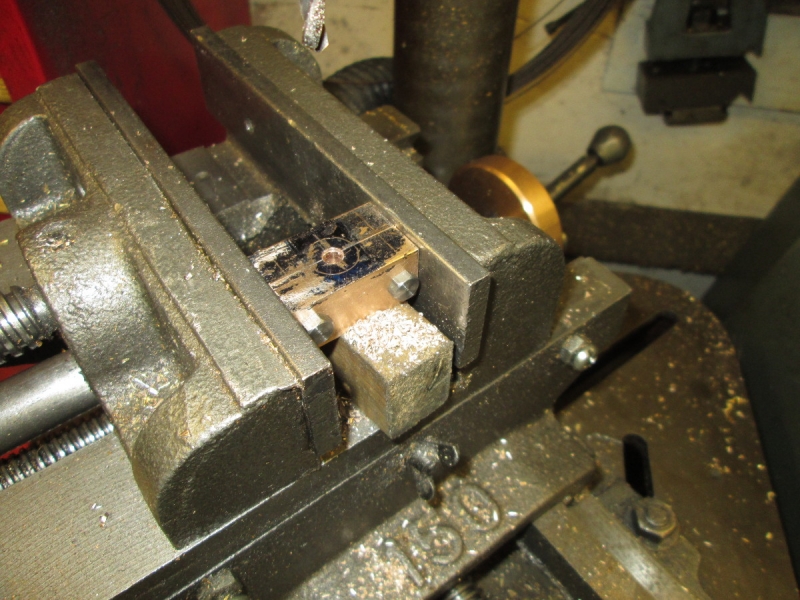

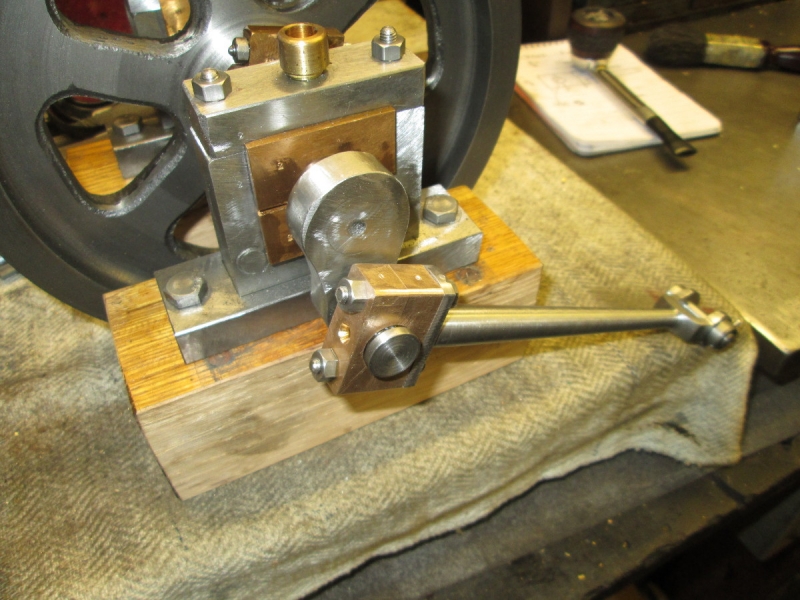

Pressing the crank on to the shaft was a brutal affair! The shaft is too long to fit in the vice and it was a heavier interference than I had anticipated. It finished up with a block of scrap brass for a dolly and a 4lb hammer. Not your classic careful controlled fitting but every now and then you have to break the rules! At closing time the shaft was installed and the end of the shaft dressed to make the fit look pretty. I can guarantee it will never move! Tomorrow I can go back to looking at the con rod and the bed.....