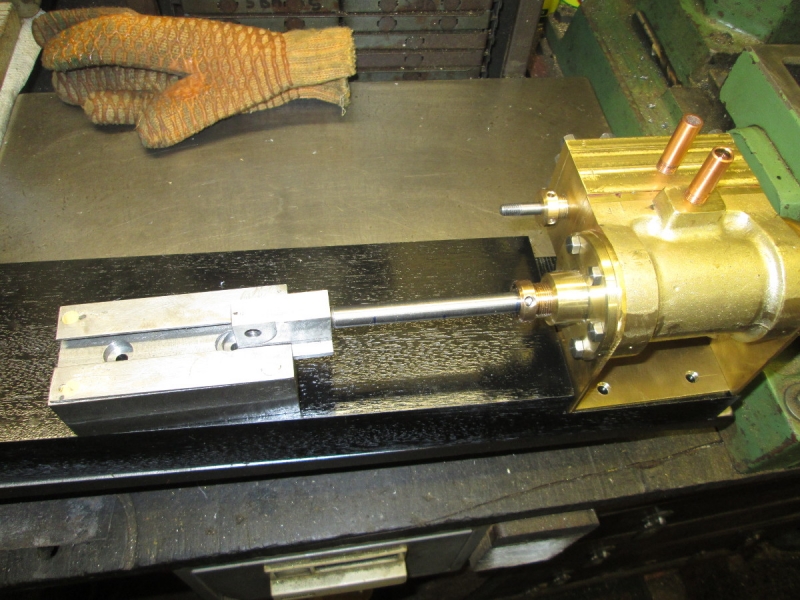

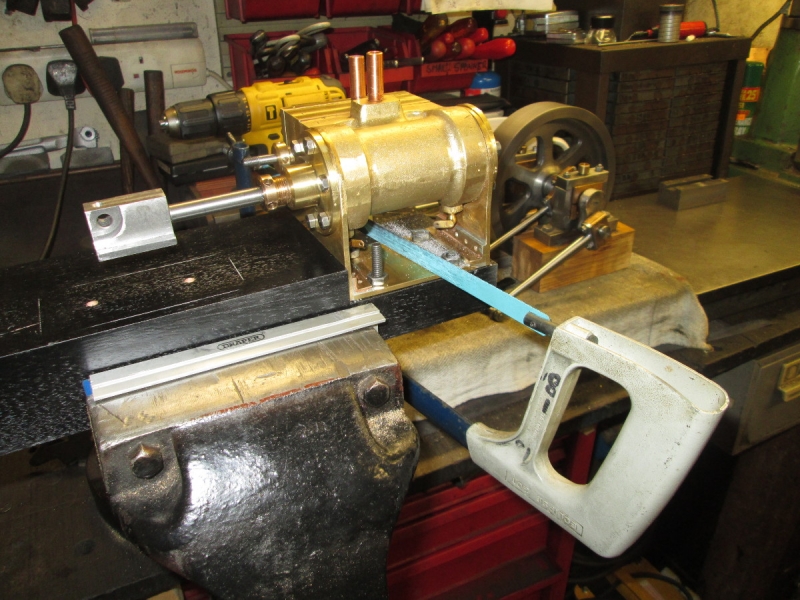

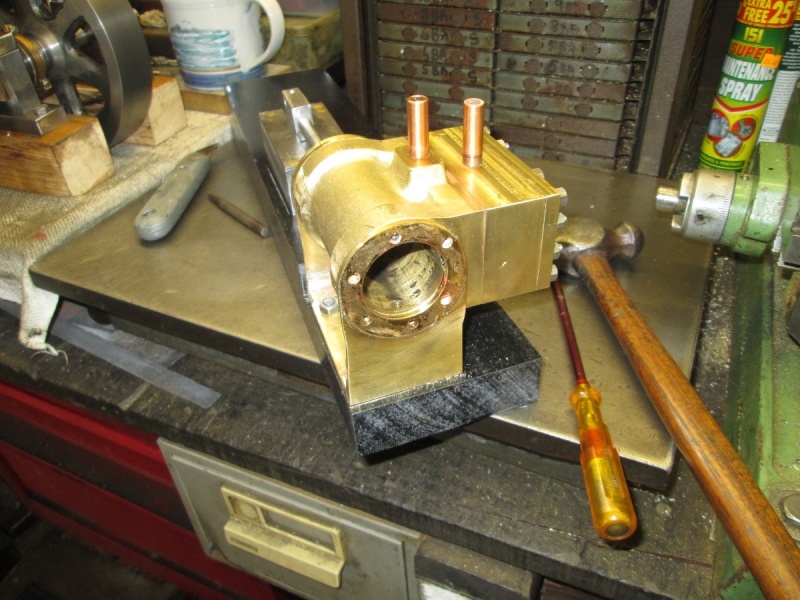

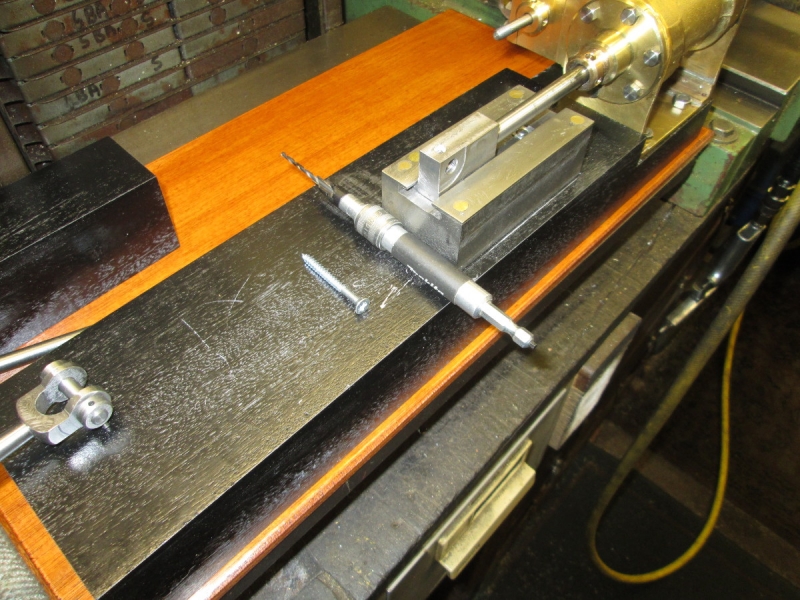

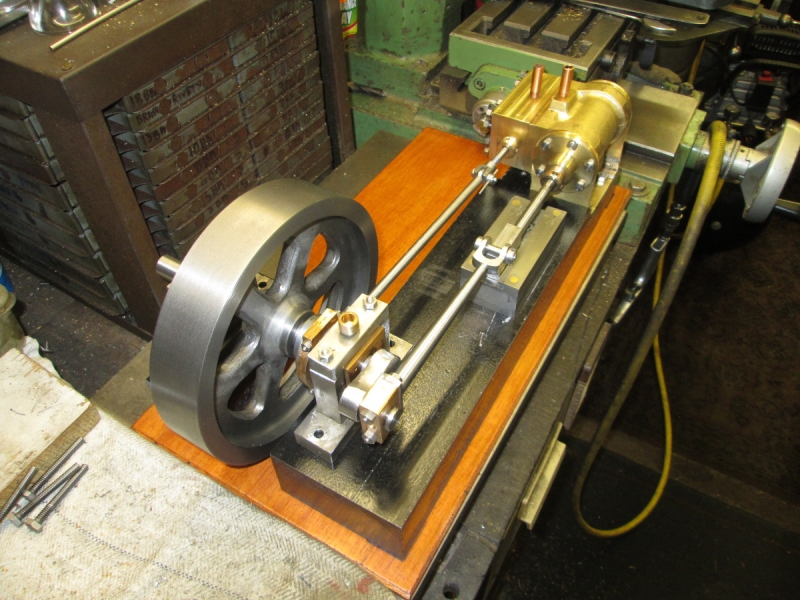

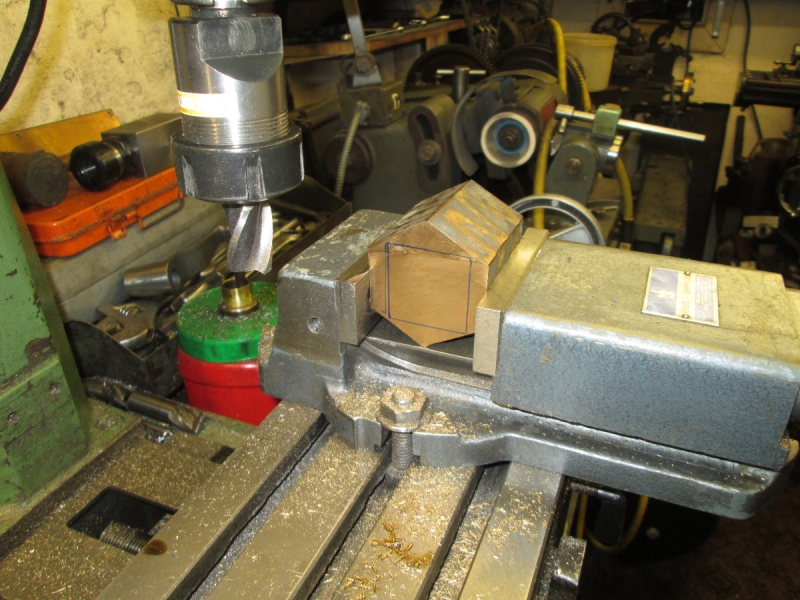

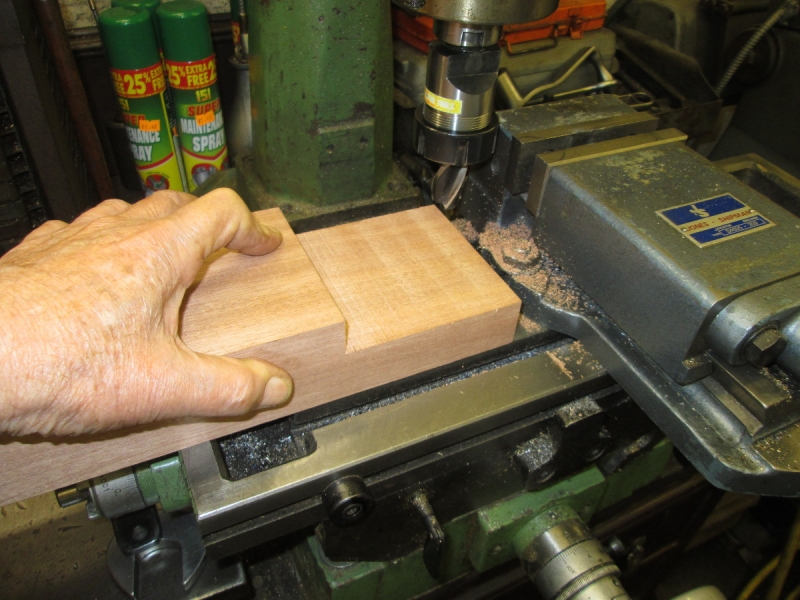

Have you ever noticed how good your eye can be at picking up discrepancies? When I first picked the wood for the bed up from B&D, to my eye, the rebate for the cylinder didn't look quite right. I measured it this morning and it slopes up to the end by .025". I mulled over how to correct it and then it struck me, I had the ideal tool! I set the cutter to the low shop and milled the rest of it off. Perfect solution but then I had to vacuum up the wood dust, I hate it on my machines, quick way to corrosion!

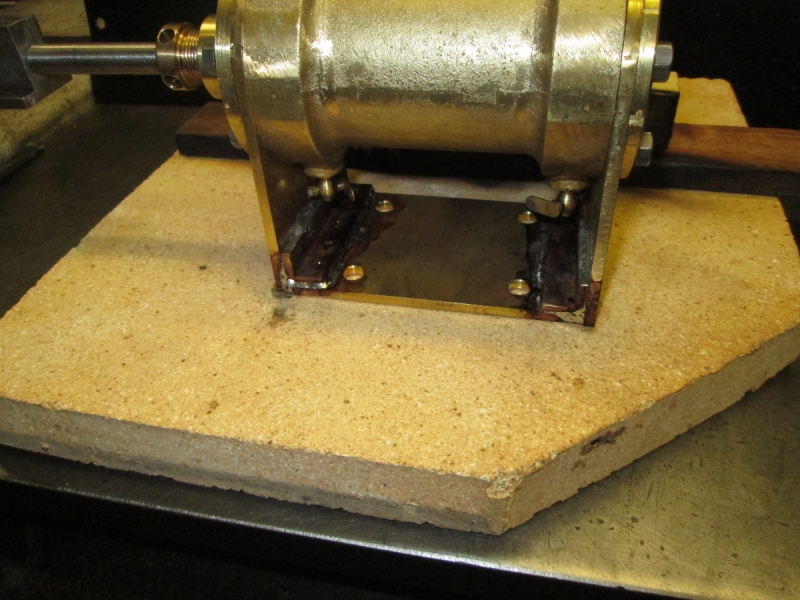

Then it struck me that the promised rain hadn't arrived so I grabbed the chance to get outside onto the welding bench and give both the beds a coat of primer. (I've decided they will be black and the base clear varnish over the natural grain.)

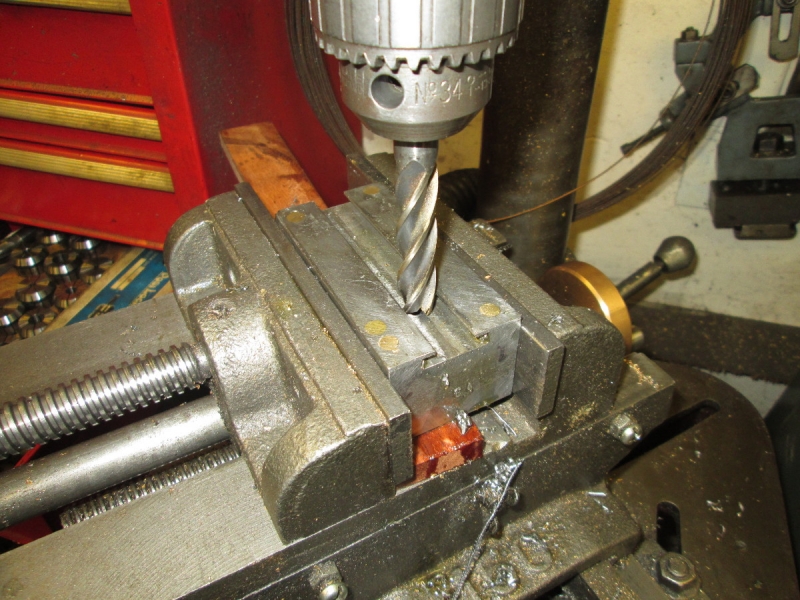

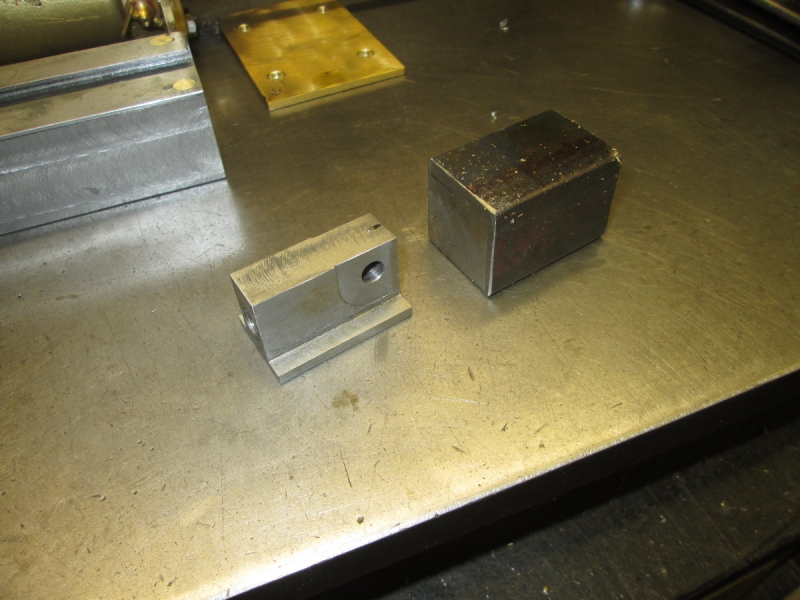

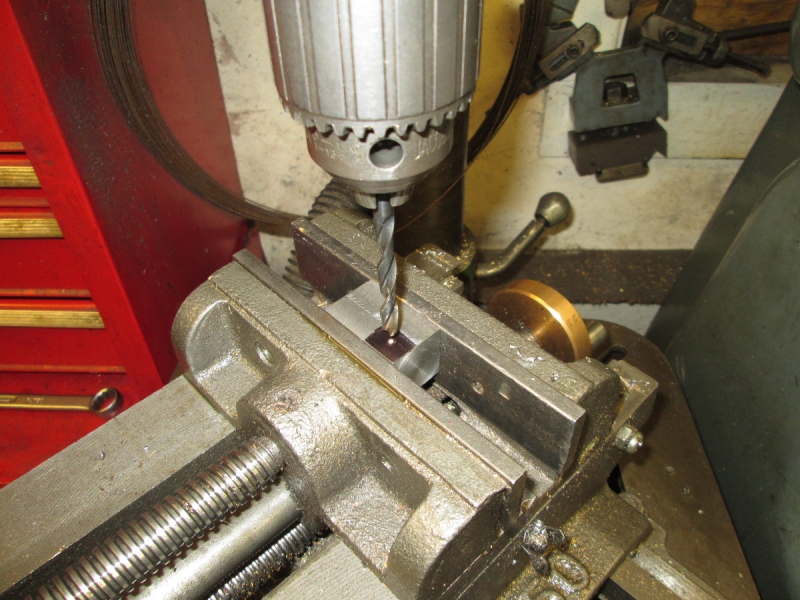

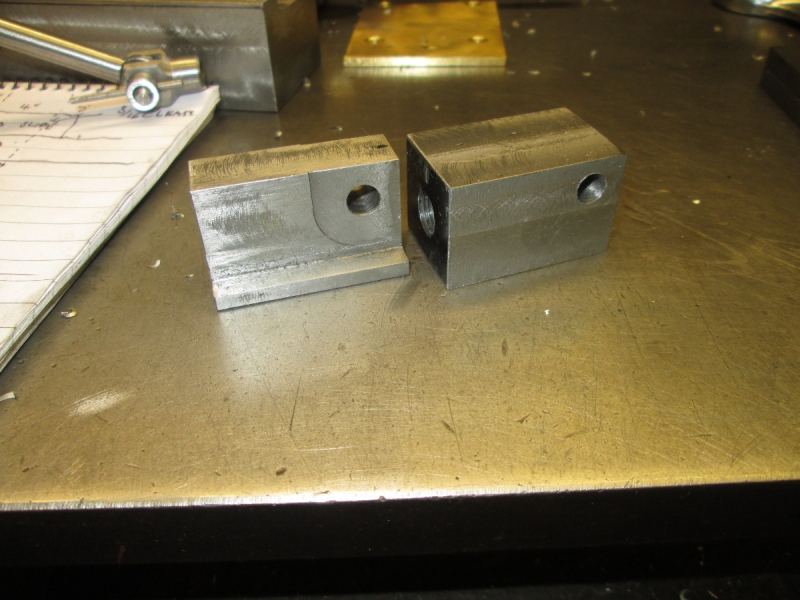

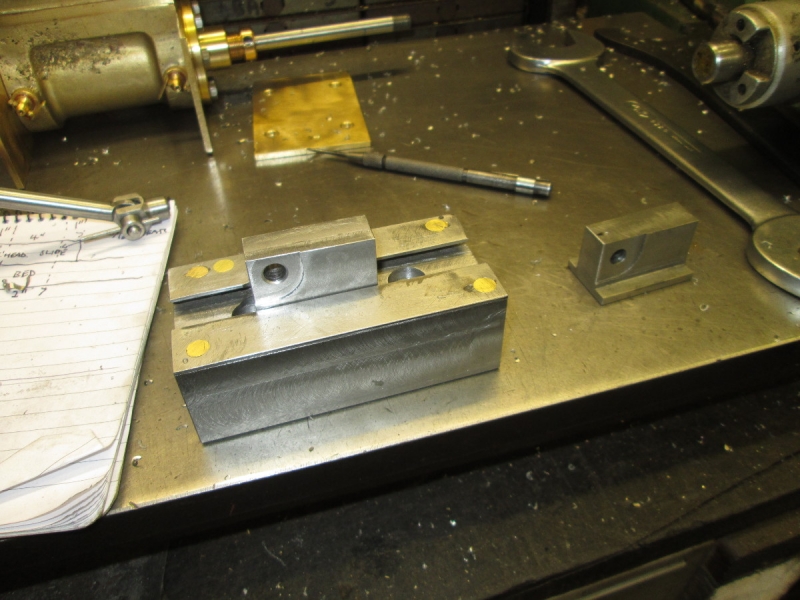

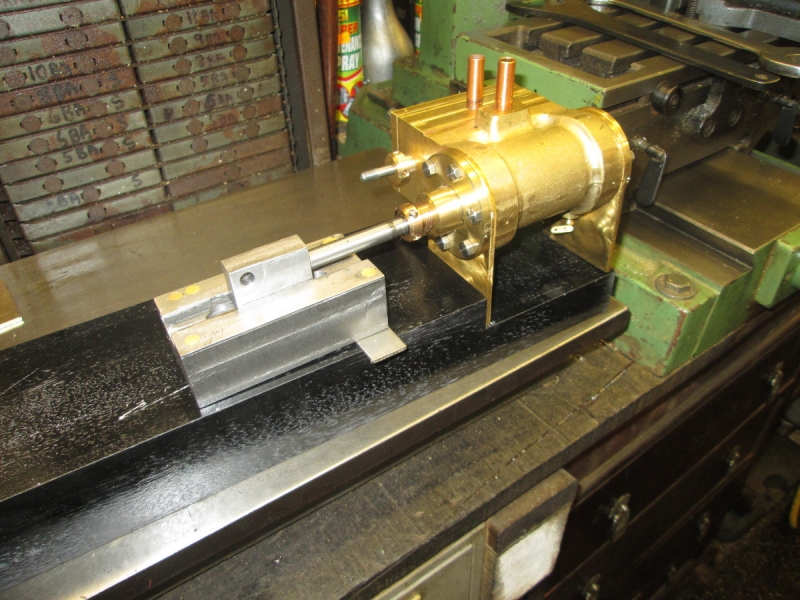

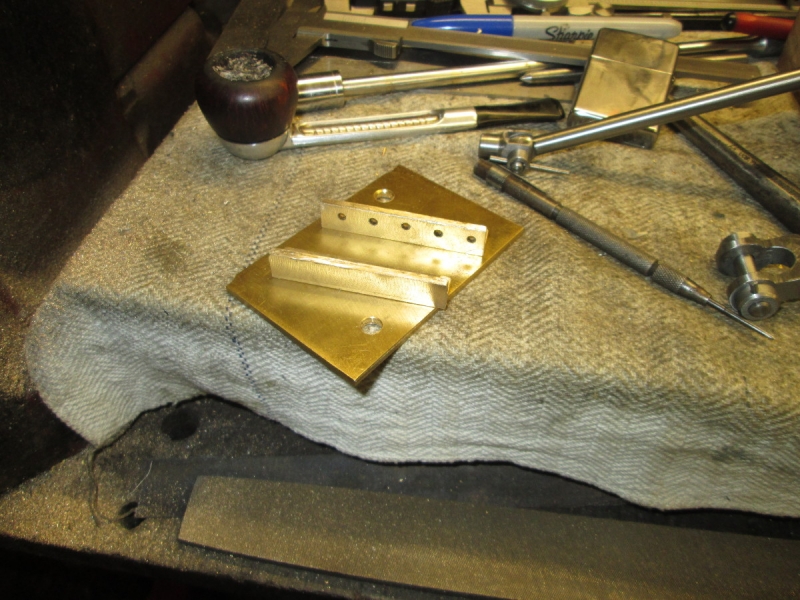

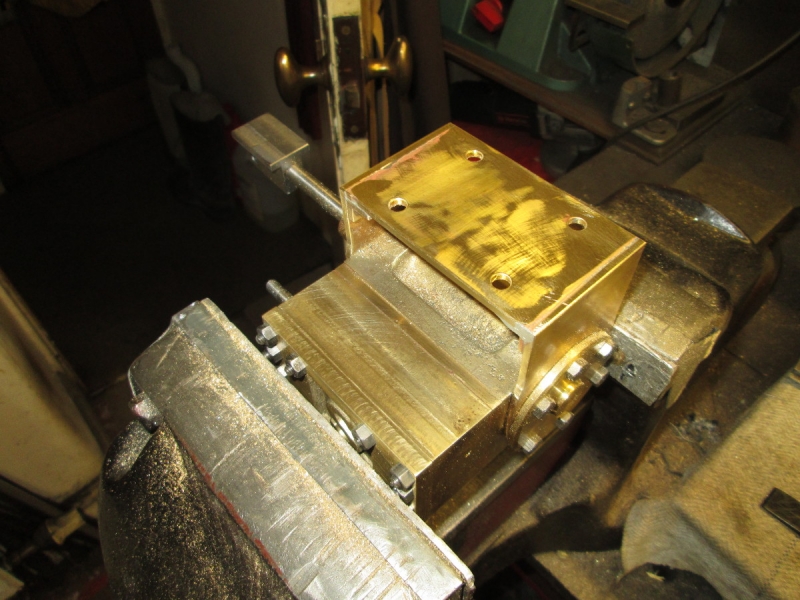

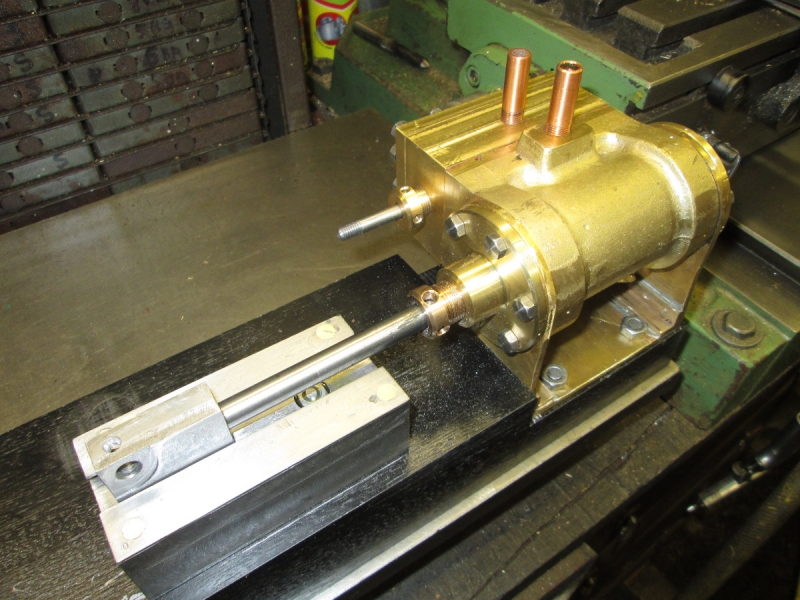

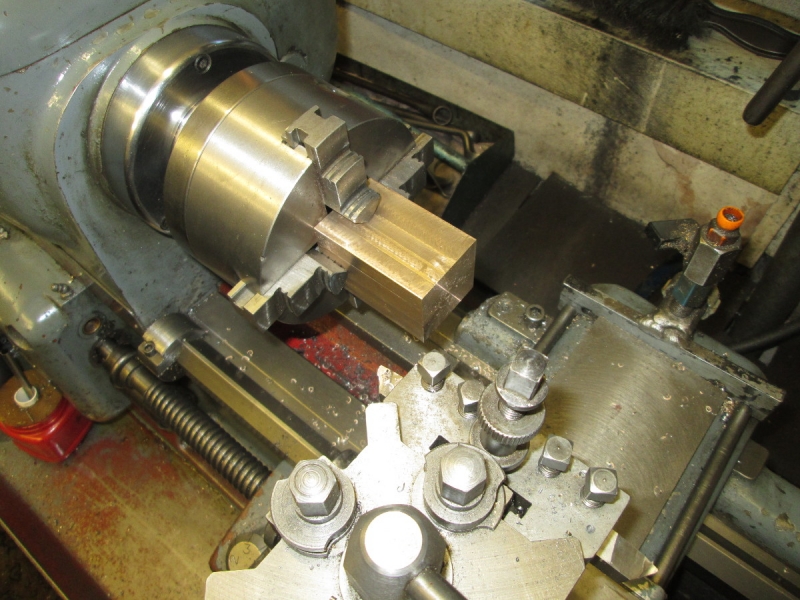

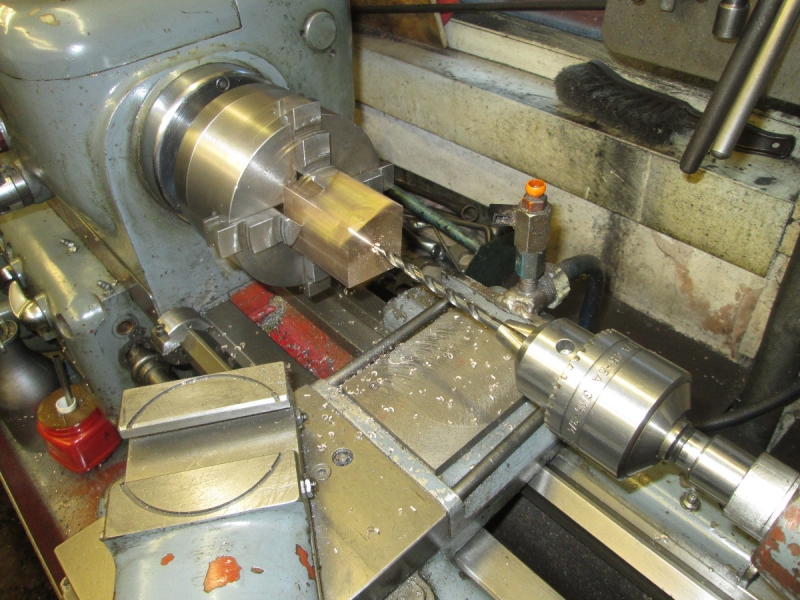

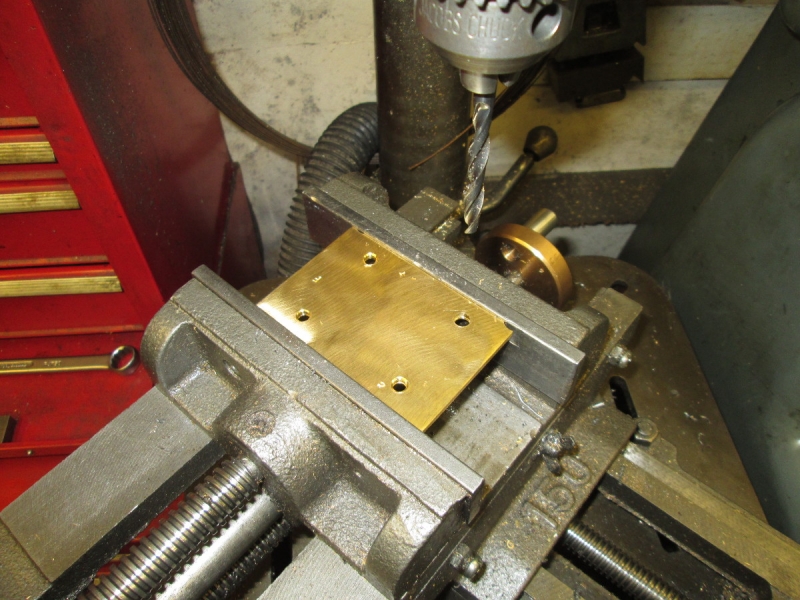

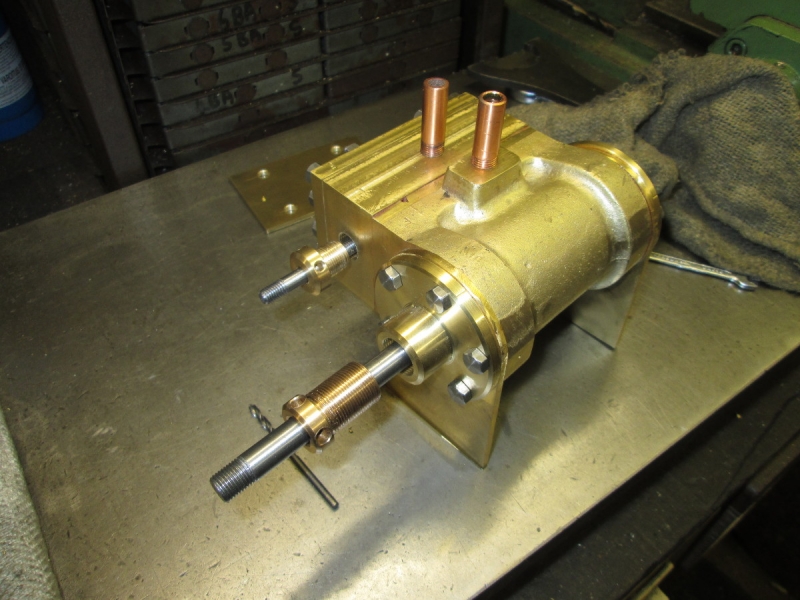

Next little adjustment was to open the holes out in the cylinder bedplate to 1/4", I've decided that the holding down bolts are going to be 1/4"Whit.

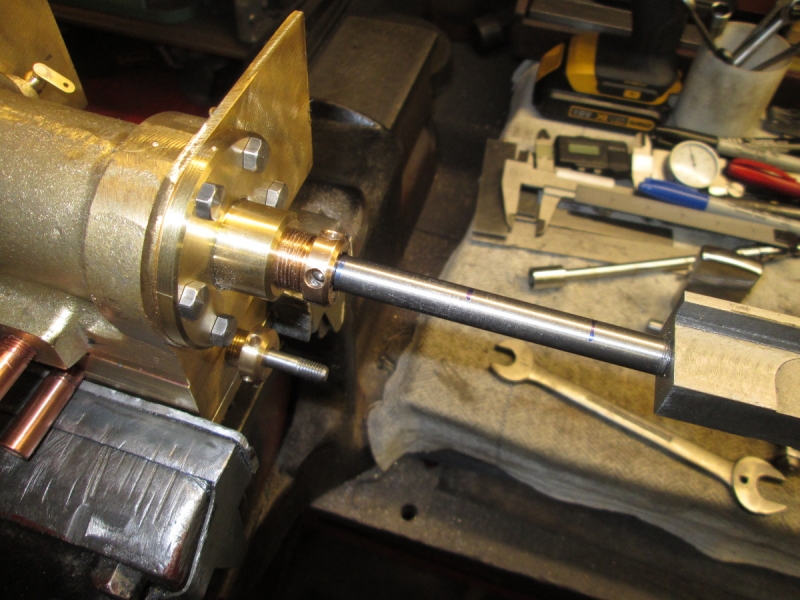

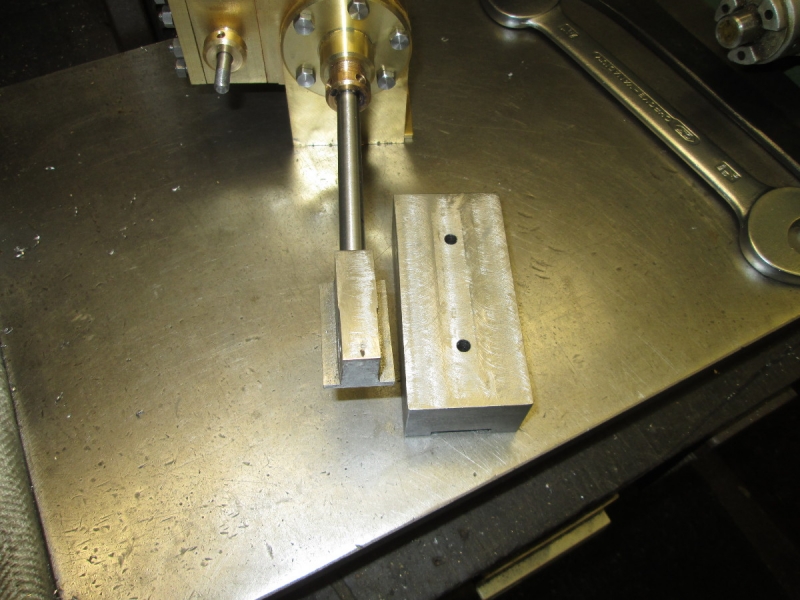

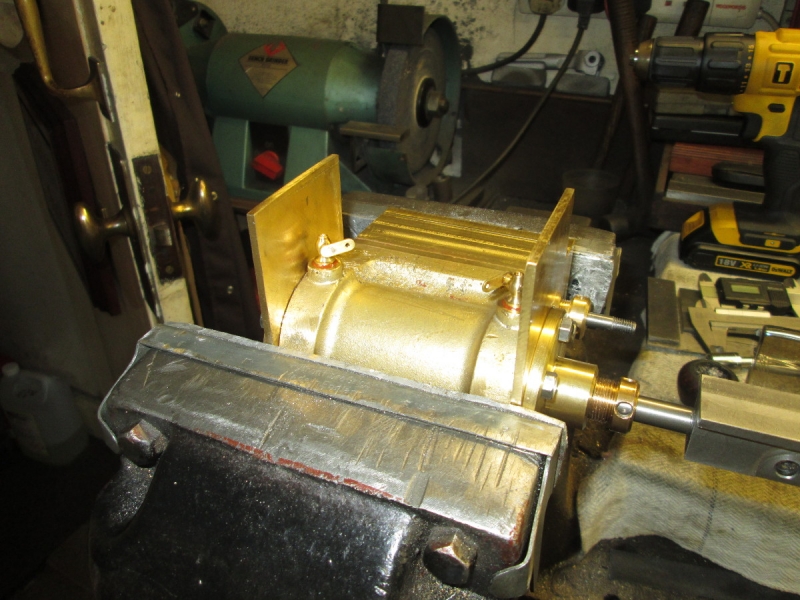

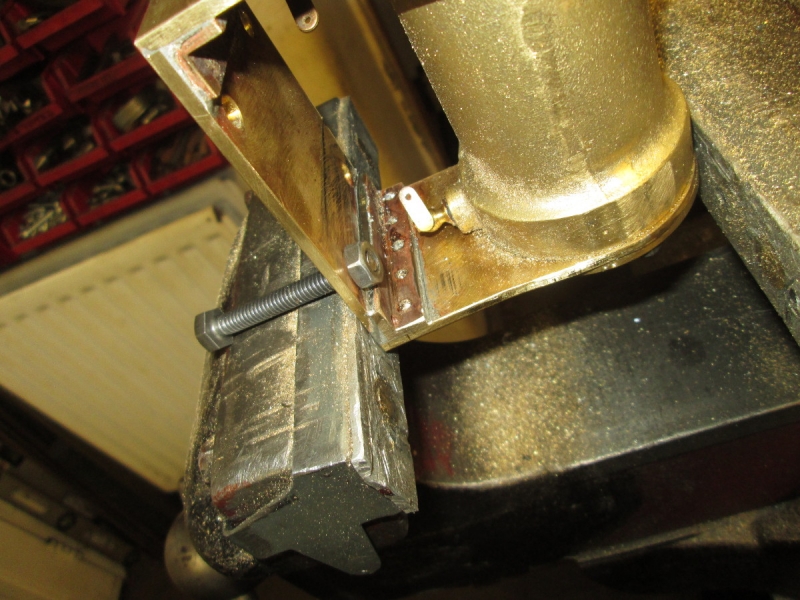

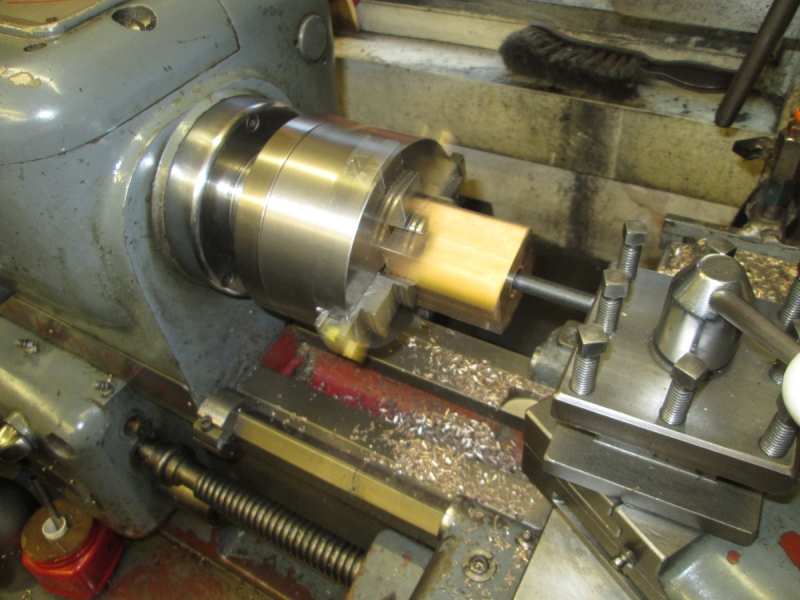

The next little job was to pack the piston with graphited asbestos yarn, my favourite seal for brass cylinders and pistons. Quite amazing how durable it is. Wrap the packing round the groove until is is slightly proud and then compress it with a Jubilee clip. Put plenty of oil in the bore. Leave enough of the piston protruding to engage with the bore, slacken the clip a bit and drive the piston in with a lump of wood. Don't be afraid of clouting it, it's going to be too tight anyway but will soon ease up when you start to move it.

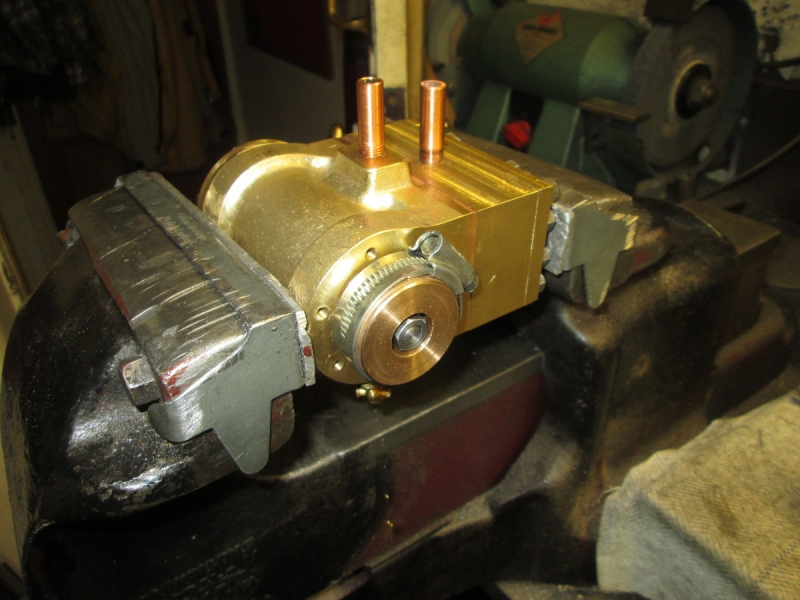

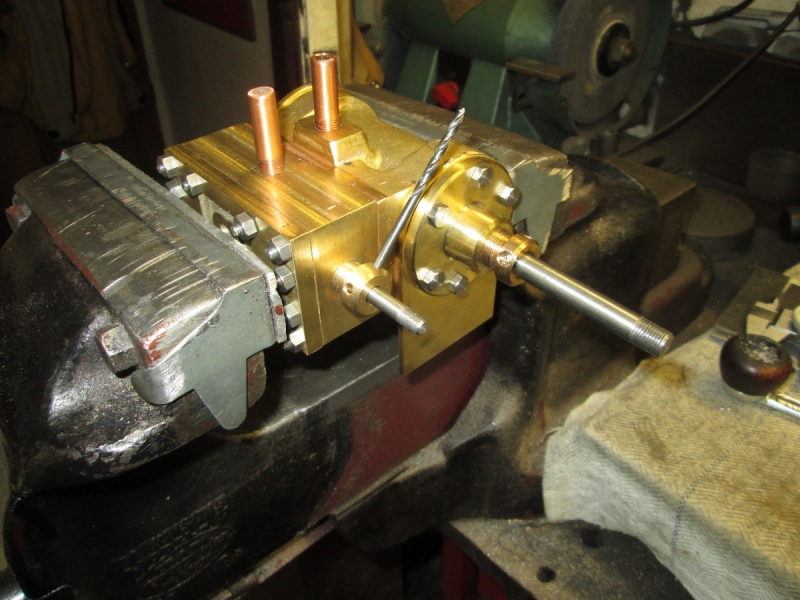

More packing, this time the glands.

While I was doing that it struck me it was still dry and the primer had been drying for over an hour.... So out into the yard and a coat of black paint. Strike while the iron is hot.

I had to dig another treasure chest out from under Johnny's lathe. I needed more packing yarn.

Then another packing session on the glands.

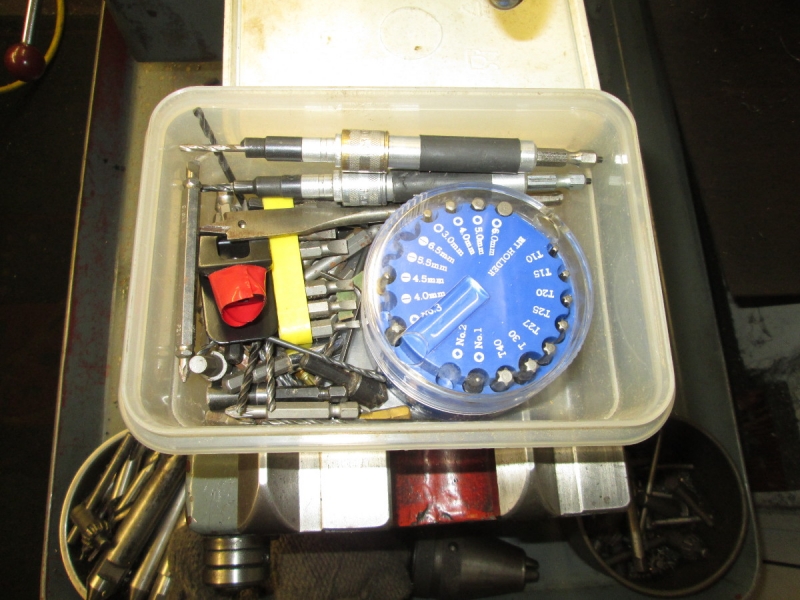

While I was getting a drill to use as a tommy bar for the valve rod gland I dropped a drill into this mess which sits behind the headstock. So I had to retrieve it and decided that after god knows how long sitting on the bed and collecting chips, my remaining time in the shed this morning would be well spent cleaning the spanners up and ditching the chips. These are all spanners which occasionally come in handy and it's good to have them to hand. I did that and for an encore swept Mrs Harrison as well and called it knocking off time. Two and a half hours on my feet is enough!