Both of my precision levels came out to play because the larger one is the less sensitive of the two and is good for getting a rough reading before I fine tune with the smaller one. It also means that I can have one for each axis.

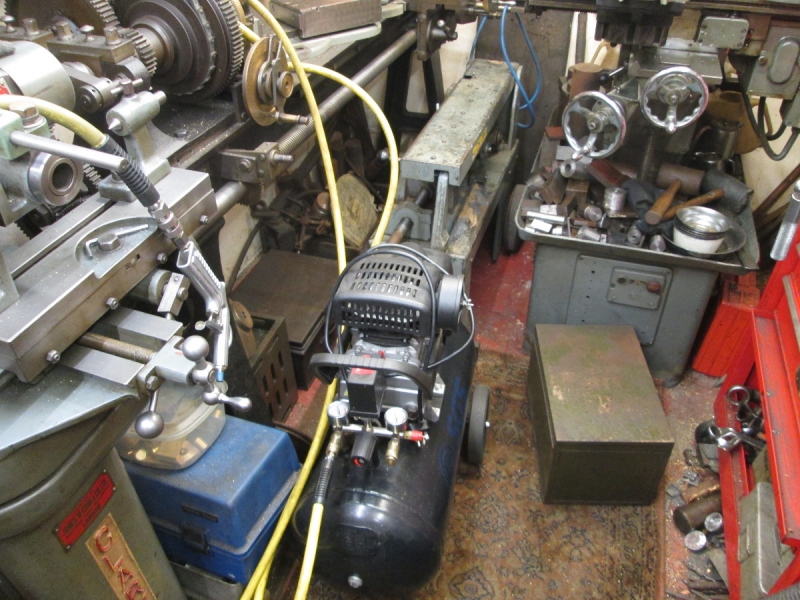

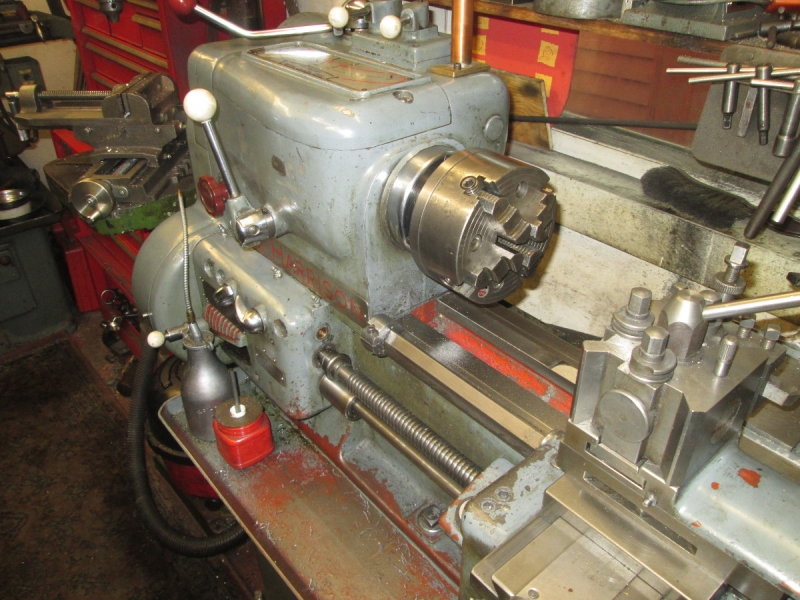

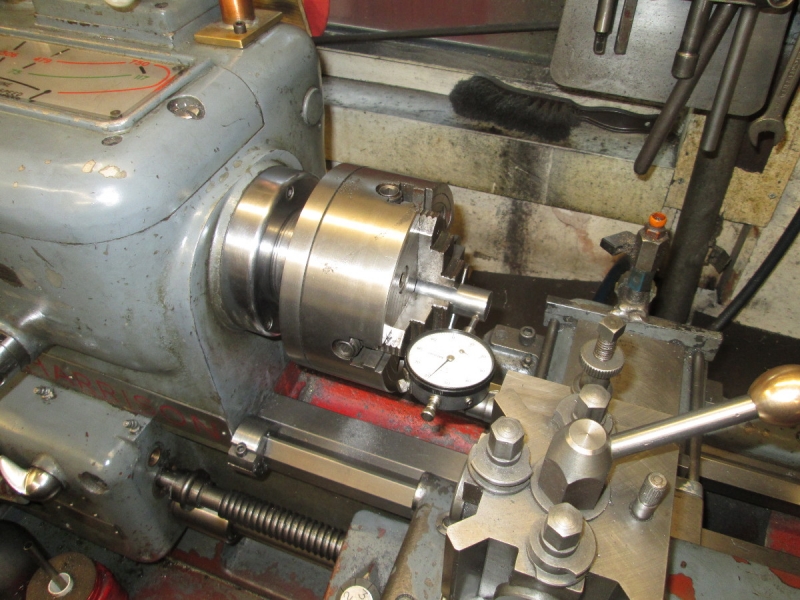

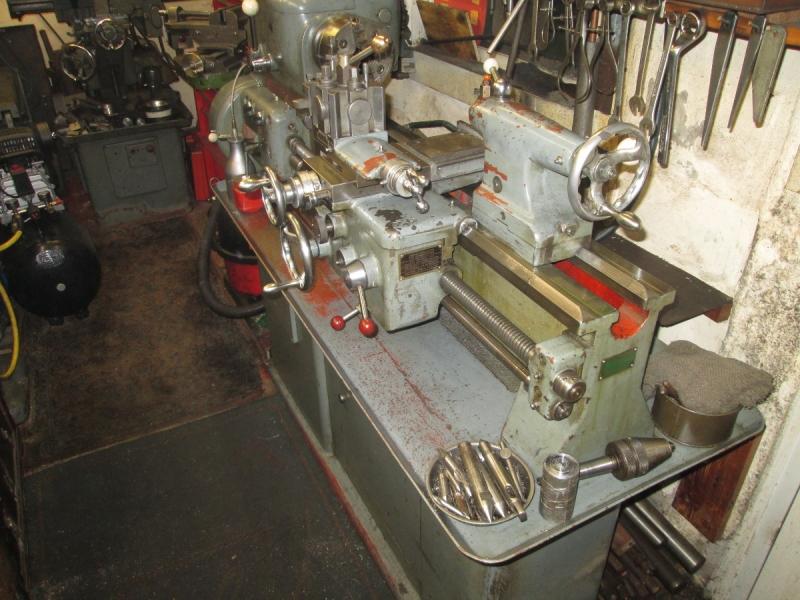

Here we are in action and there isn't anything to show you really. I started with the back adjusting screws because they are harder to reach. I started by making quite sure the back was high and then used the front ones to actually get the crossways level. At this point I am not bothered about the slope lengthways, it isn't as important. Once I was certain I had the cross reading spot on I addressed the slope which was quite easy to correct, the tailstock was miles too low because the floor slopes. Once I had that right I rechecked the crossways level and made very small adjustments to that. Then checked the slope and again went back to the crossways level and made tiny adjustments. This is as good as I can get it and it's about an inch off the floor now. Surprising how evident this is when you stand in front and use the controls!

One thing to remember, start from the principle that your levels aren't accurate. Here's one of my bleeding obvious tips... you can check any spirit level by reversing it and seeing if the readings agree. With the sensitive one particularly use the average of the two readings and you won't be far out.

Quite a lot of my time was taken up with another small matter. Caused by my own stupidity.... again! I have been using the Moore and Wright dial calliper that I thought was damaged when I dropped it but rescued. This morning there was a bit of grit in the rack so I did the obvious and totally wrong thing, I blew the rack out air with compressed air and blew the bezel and crystal off. I found the bevel but god knows where the crystal went, I searched high and low but no joy. I'm certain that it will turn up at some point but I shall call in at the jeweller's this morning and see if he has a 12mm crystal. So top tip is don't do what I did!

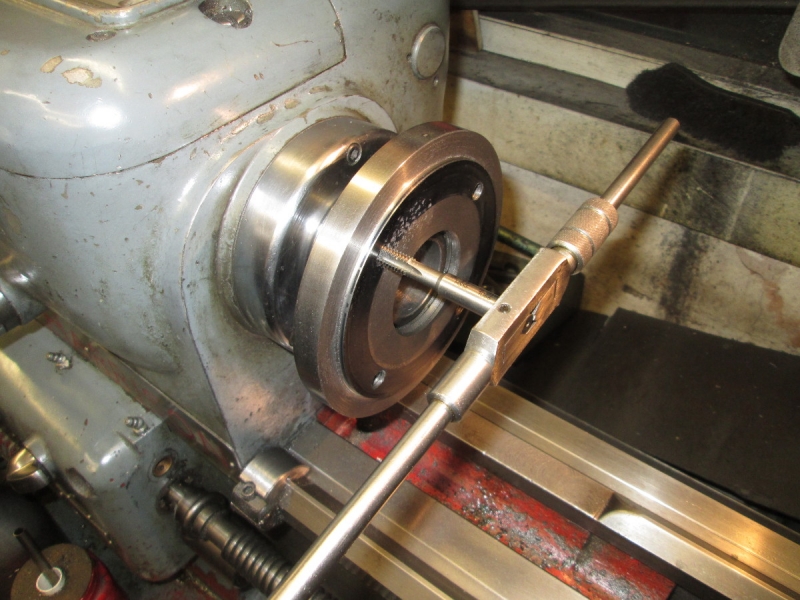

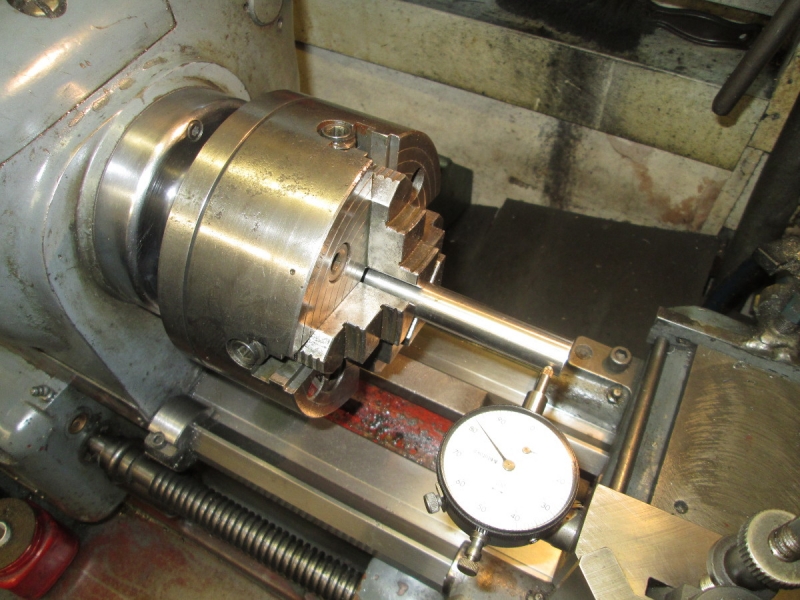

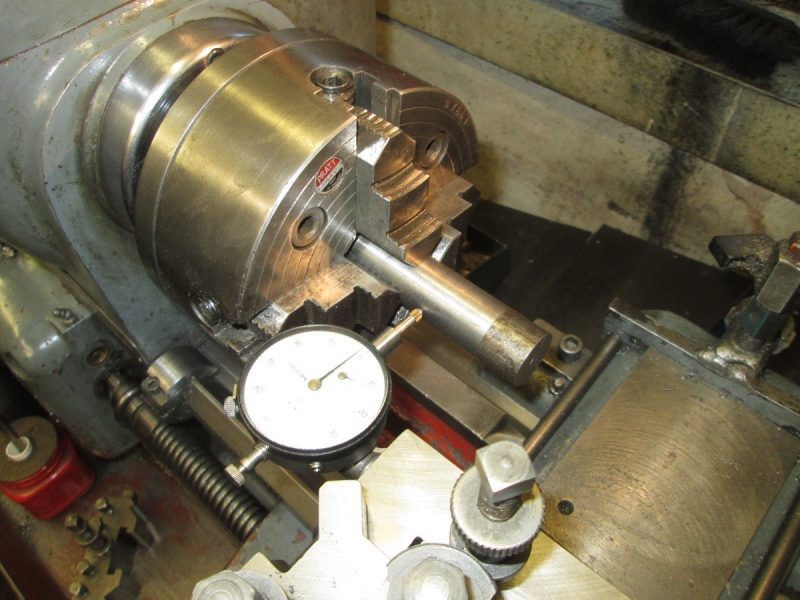

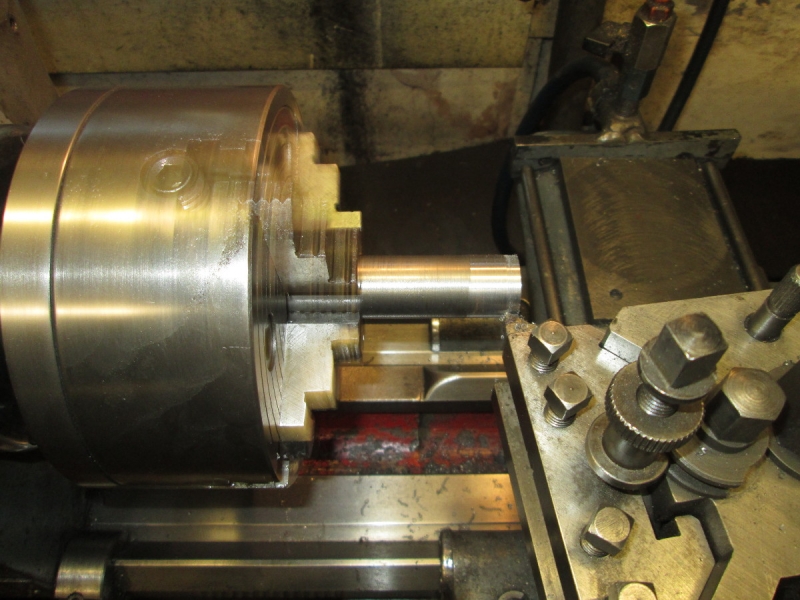

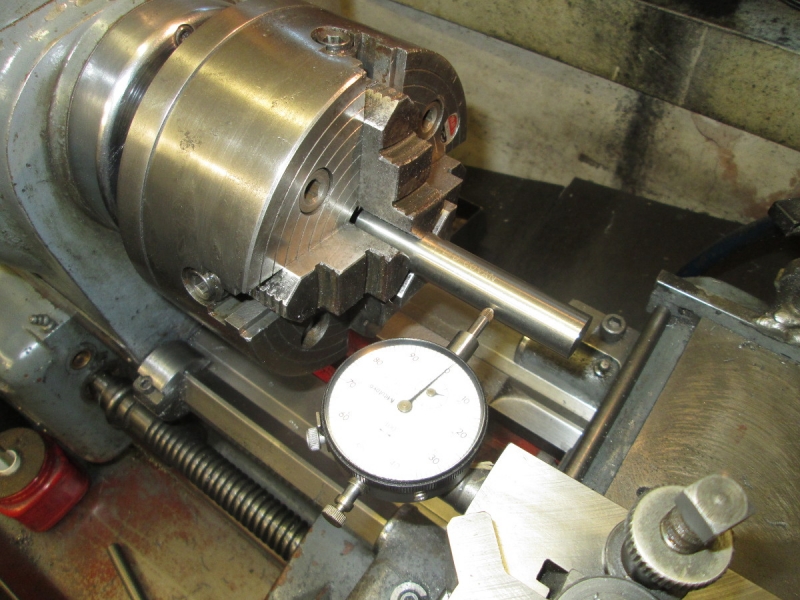

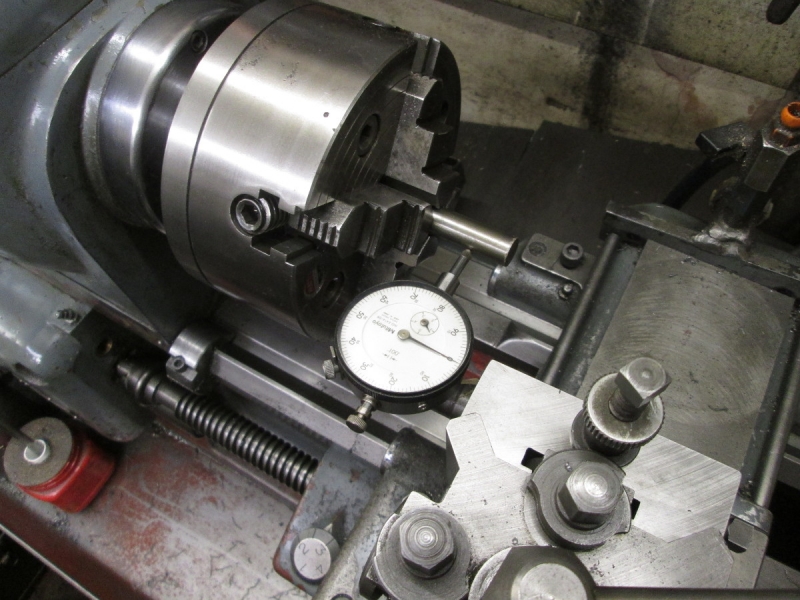

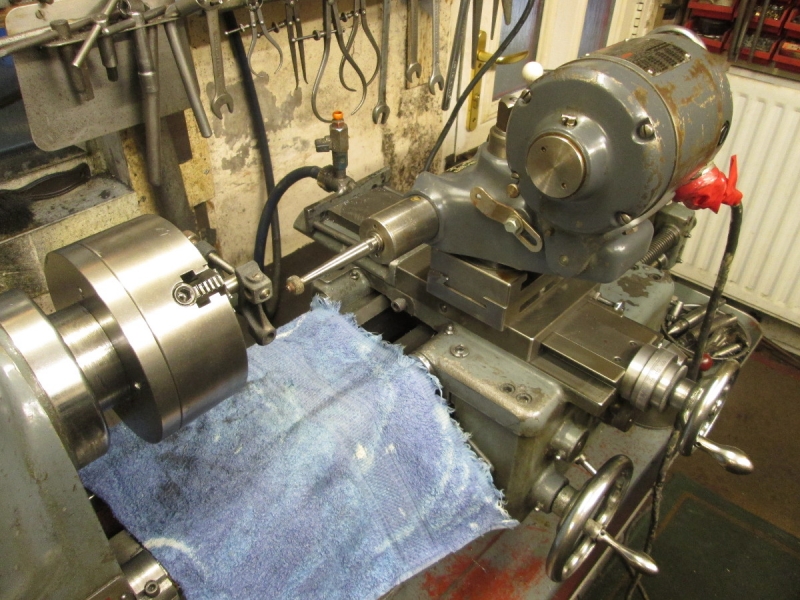

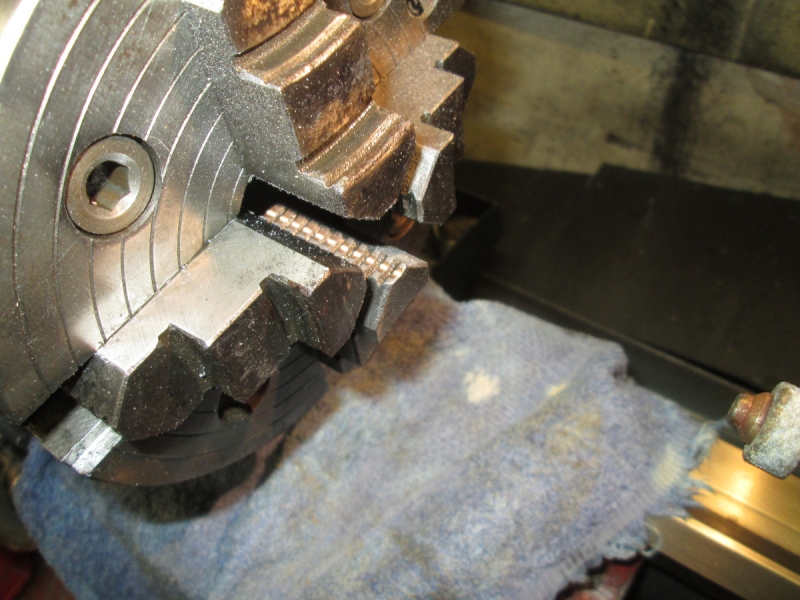

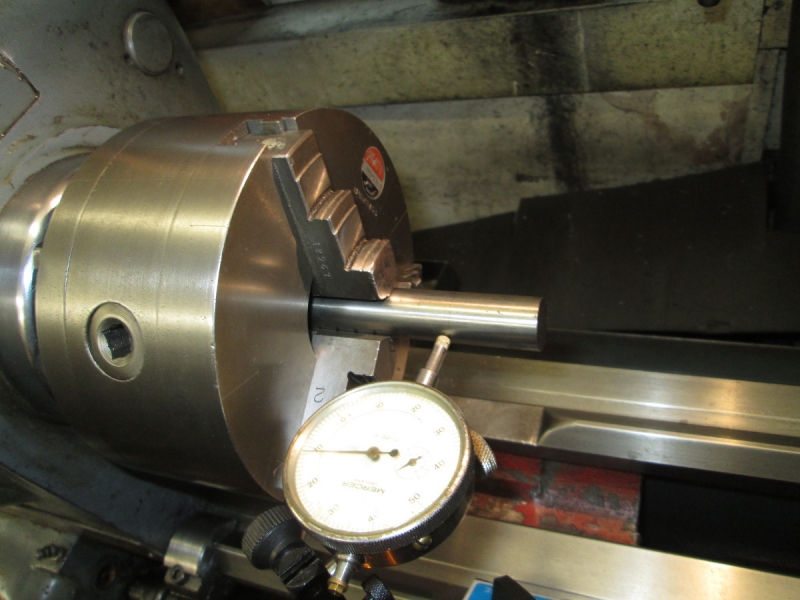

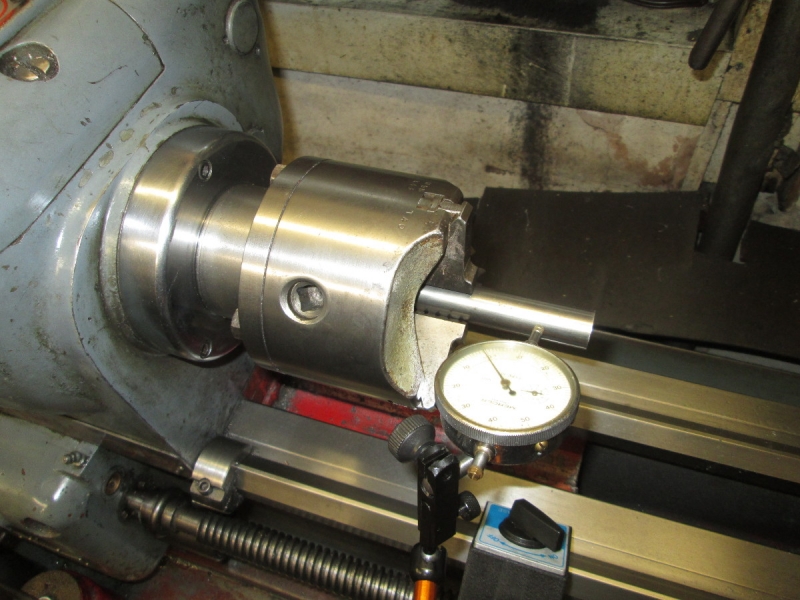

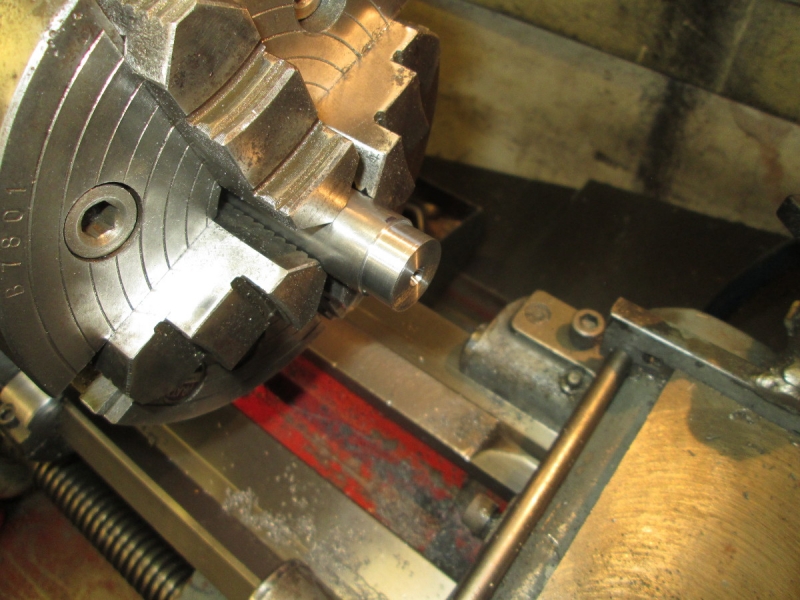

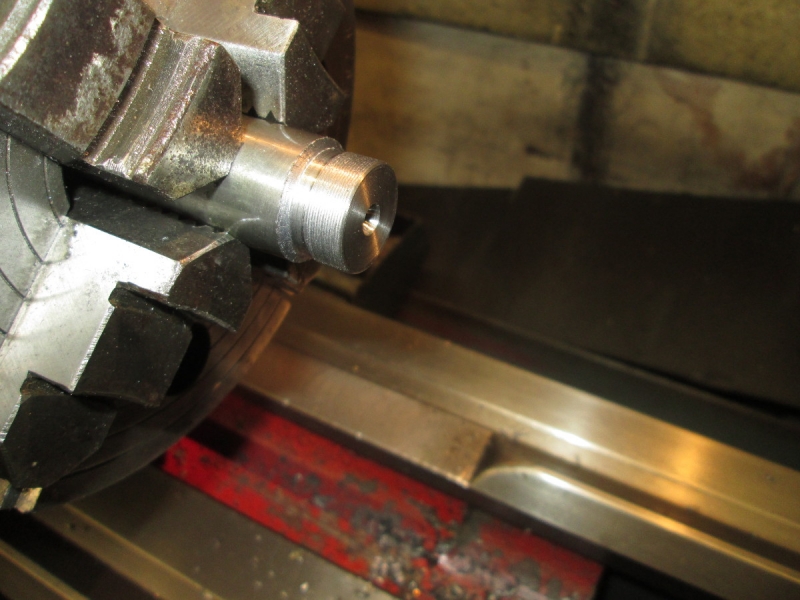

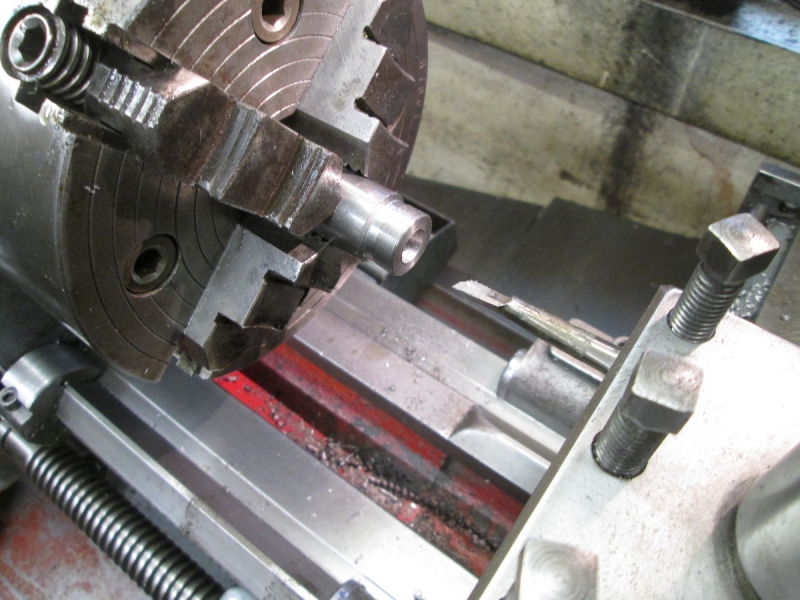

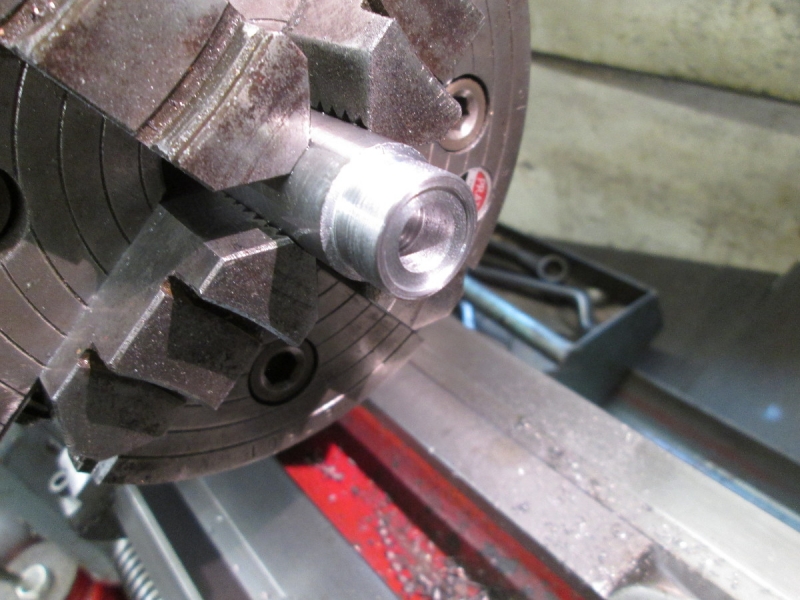

Here's where I finished up.... A clean, well oiled and level lathe with a good 6" 4 jaw independent chuck ready for action. Now I have to think about what I can do next!