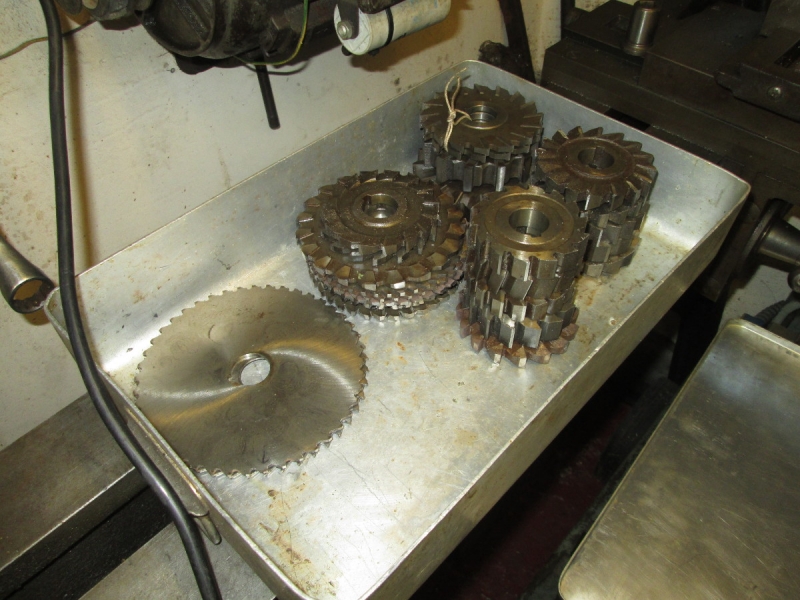

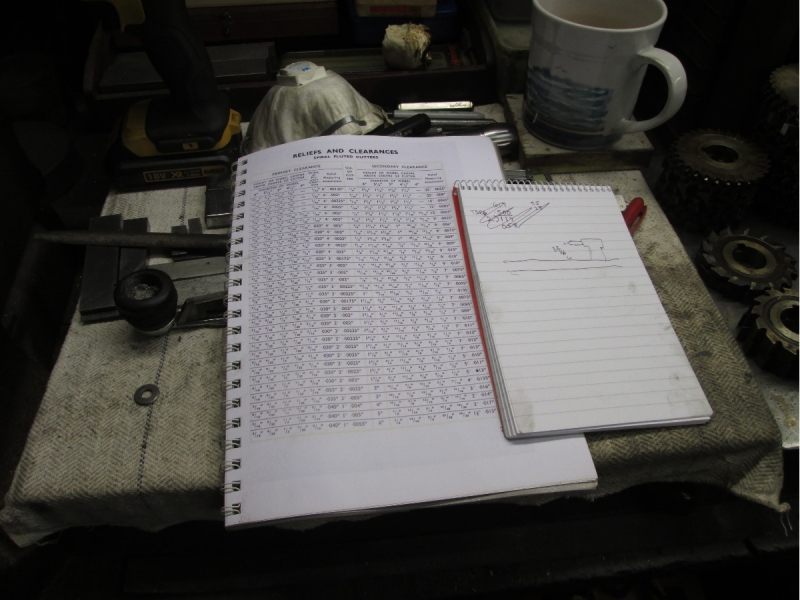

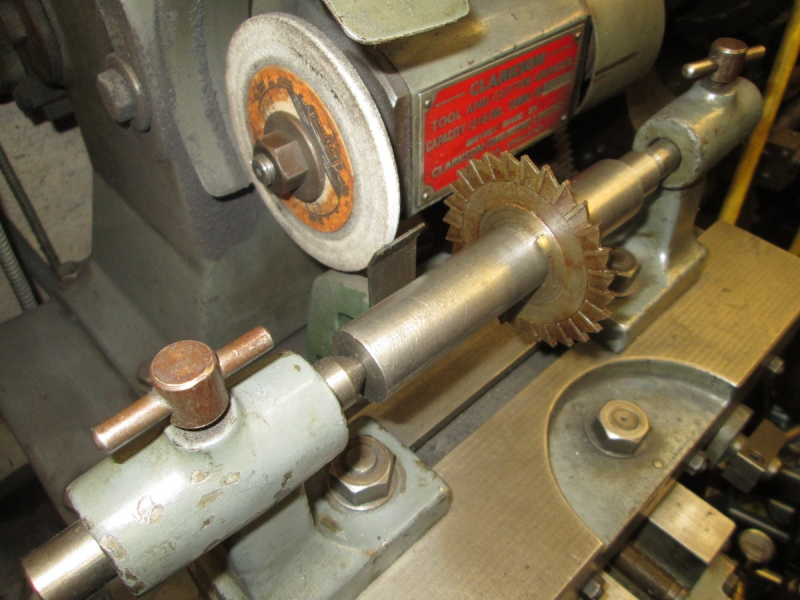

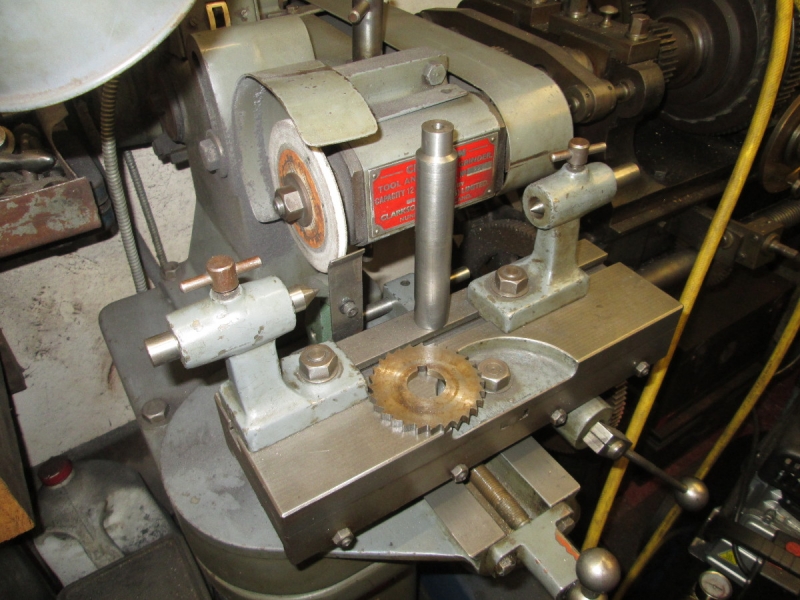

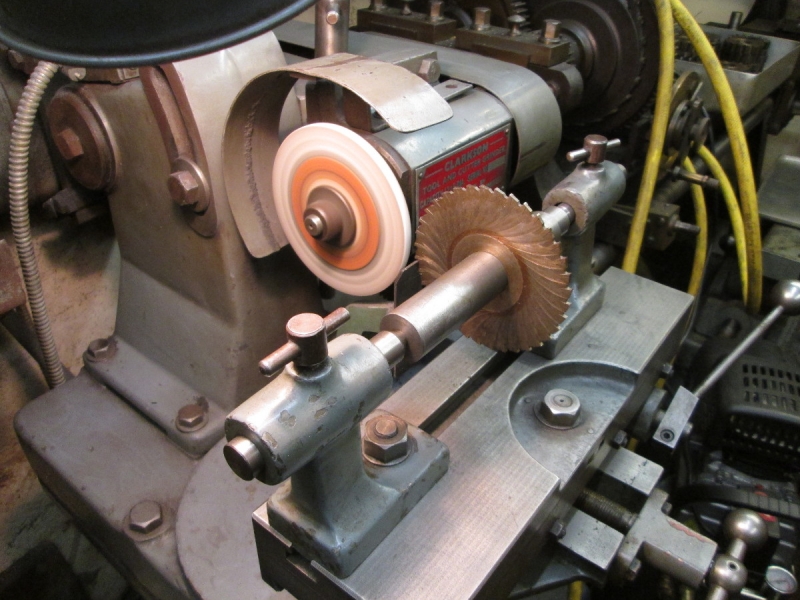

I got in the shed shortly after 07:00 and started sharpening a cutter hoping that the shriek I had yesterday out of the motor was simply overheating. No such luck! It did it again straight away. No getting past it, I had a problem. I didn't despair, I have a spare motor if it is needed but before I did anything I had to get the grinder out into the shed so I can get at the motor.

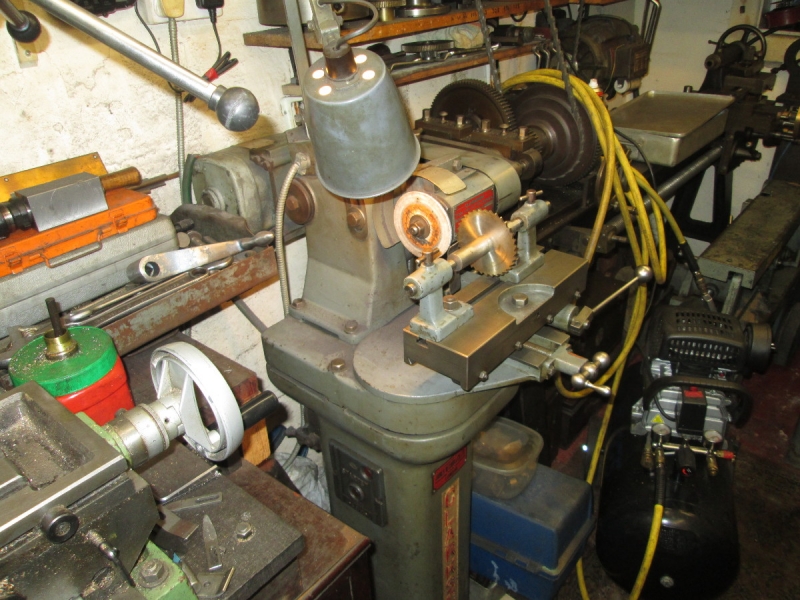

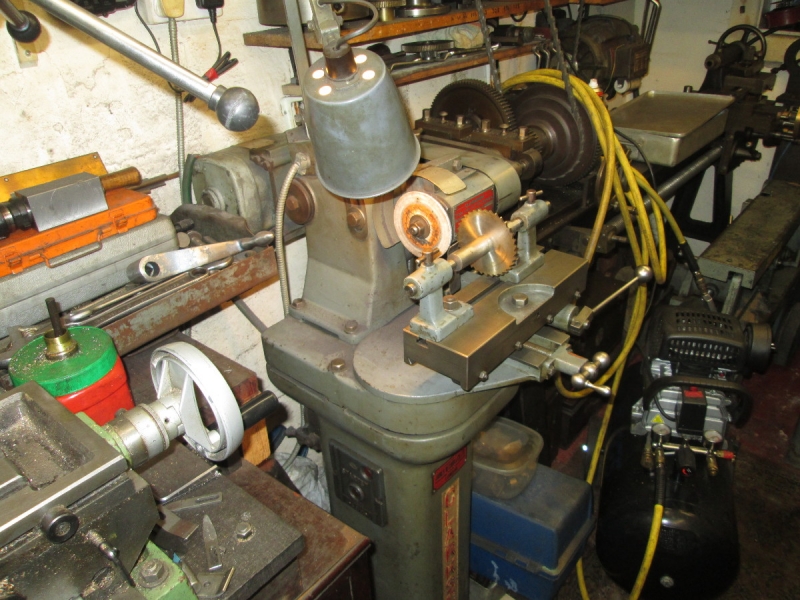

There are many advantages in having a small shed.... it cuts down on wasted effort but when you have to do something like this I freely admit it's a bugger! You wouldn't believe the amount of stuff I had to shift before I could even get started and of course wherever I put it it's going to be under the feet.

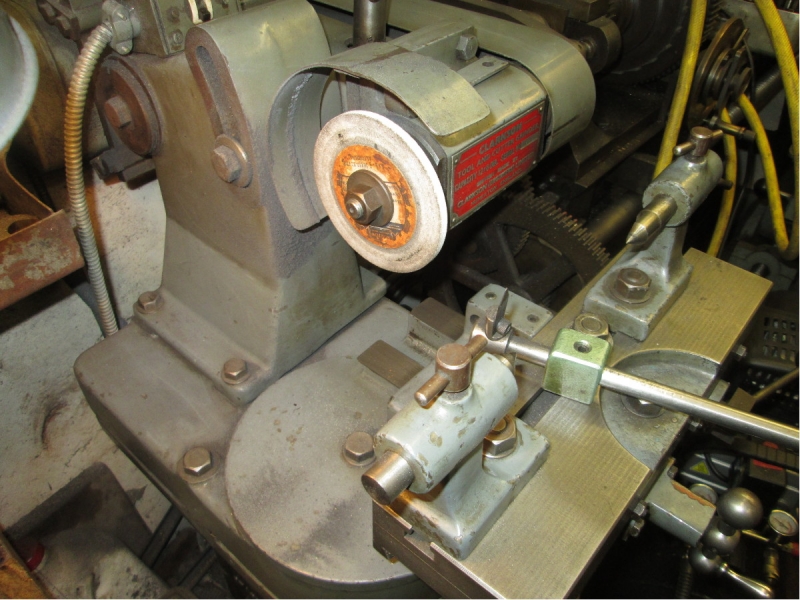

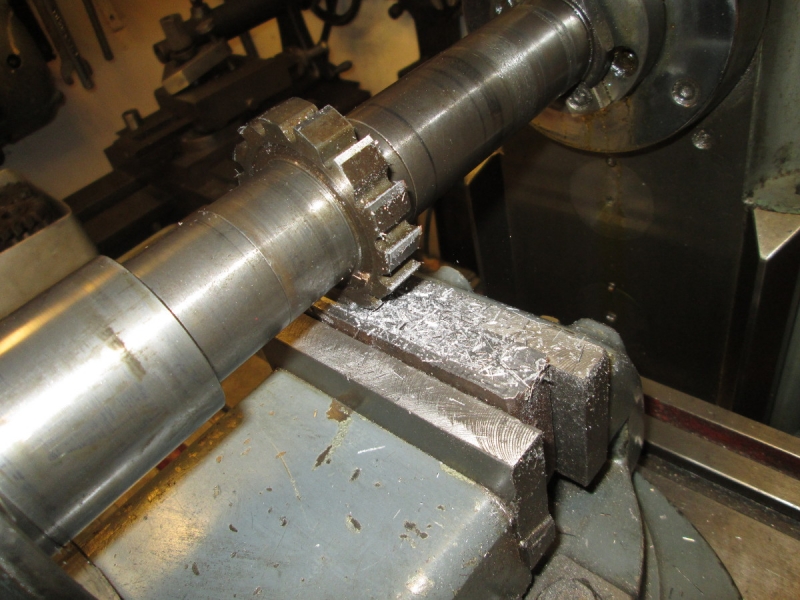

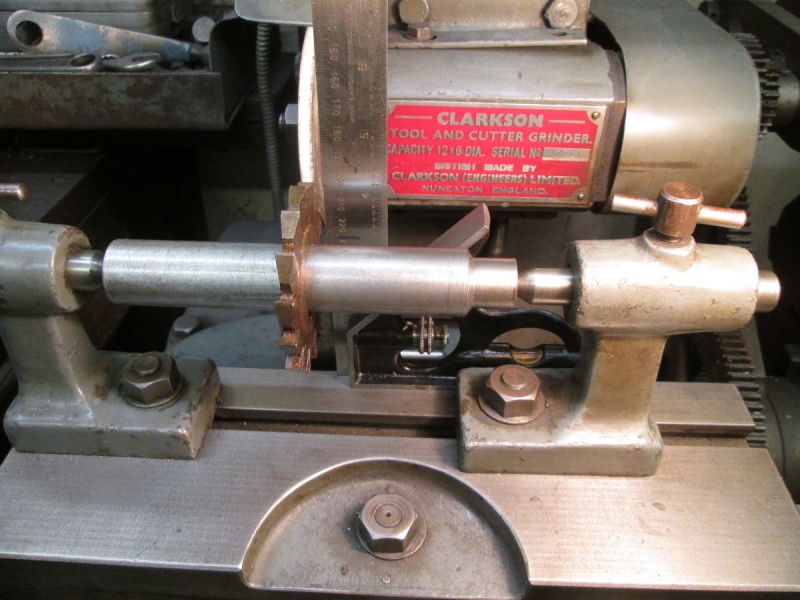

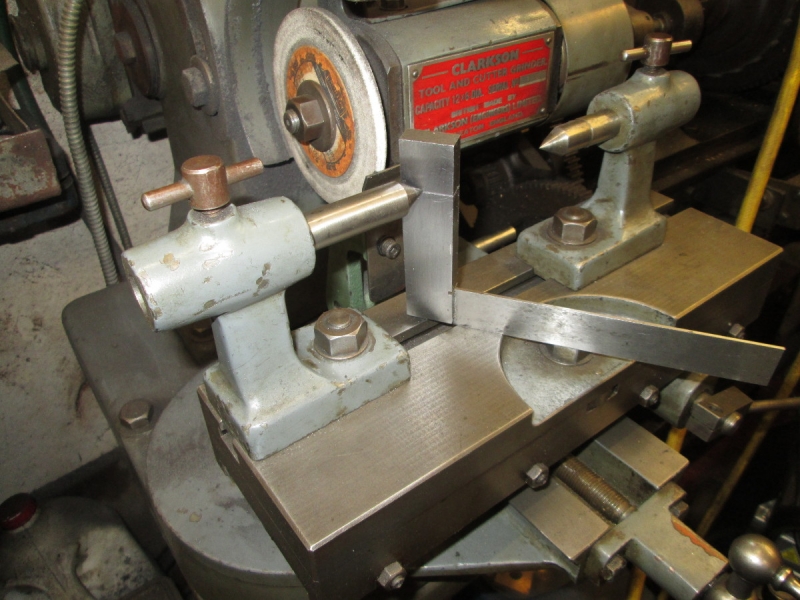

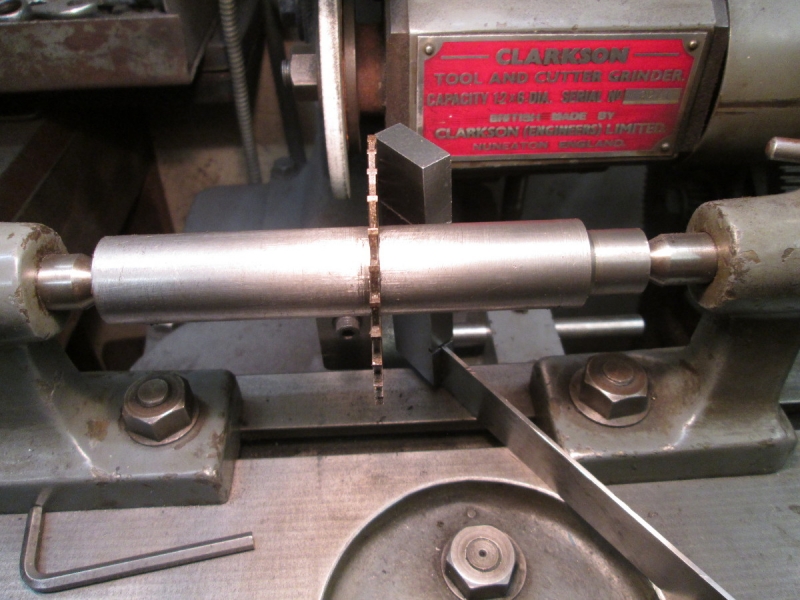

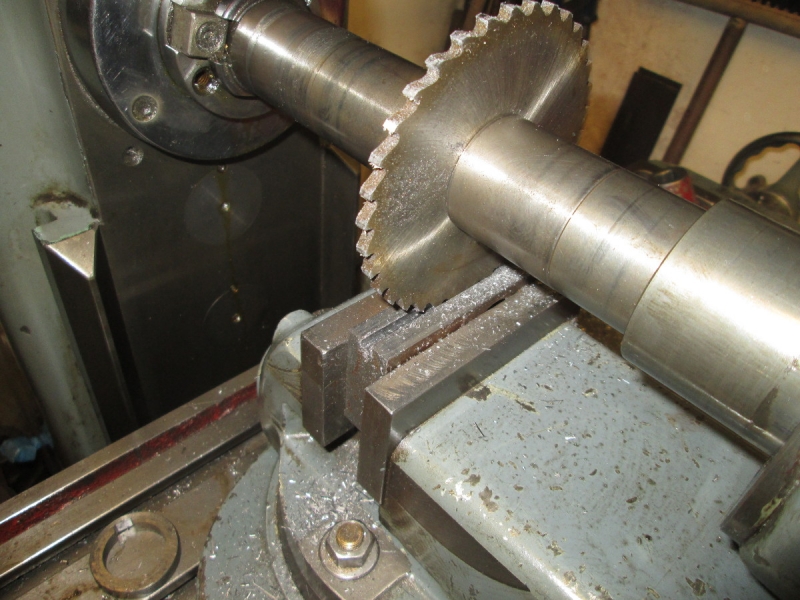

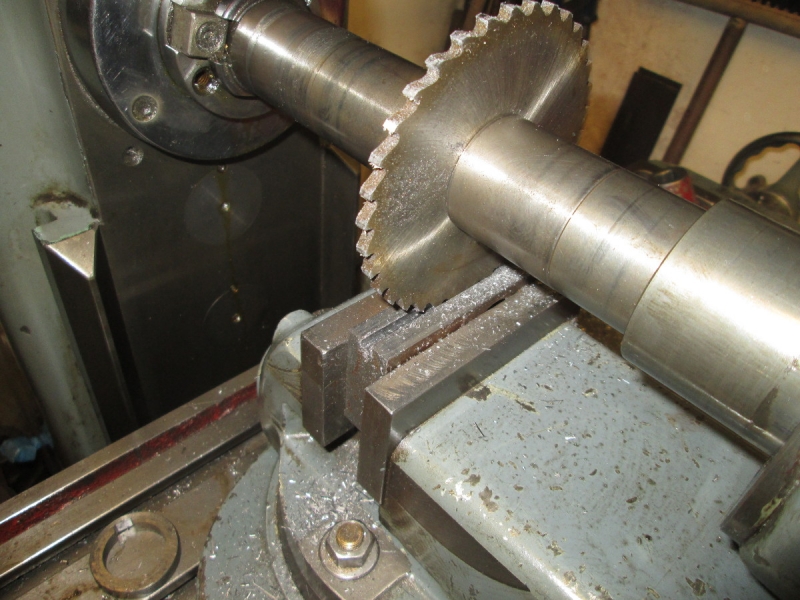

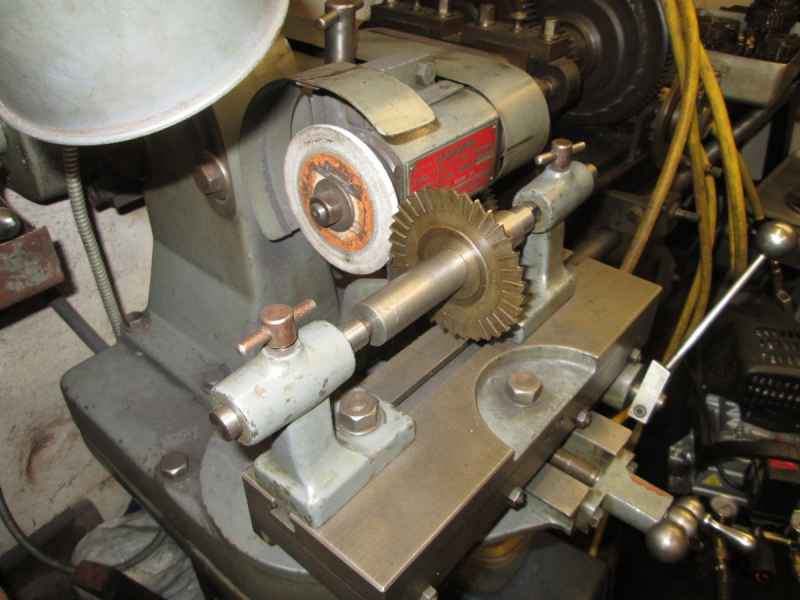

It took over an hour to get to this stage. All the clutter shifted, a good clean up, you'd be amazed how milling chips build up! Then I had to get the grinder raised up enough to get a couple of rollers under it. Once I got to this stage it was relatively easy to get it moved out. Than off with the guard and the driving belt and have a look at the rabbit!

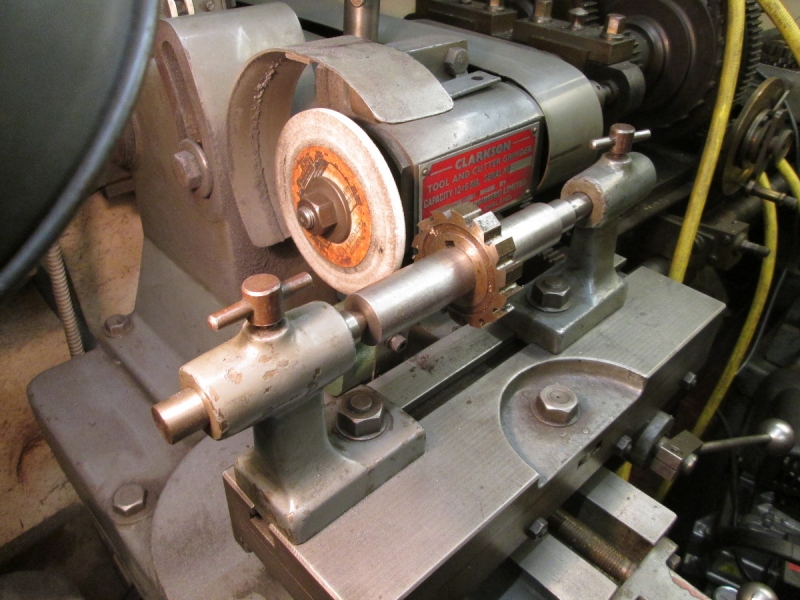

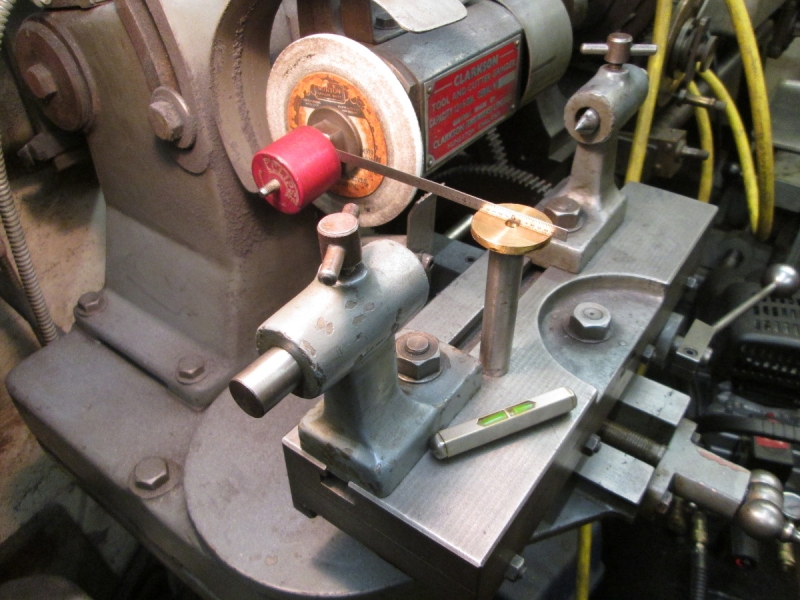

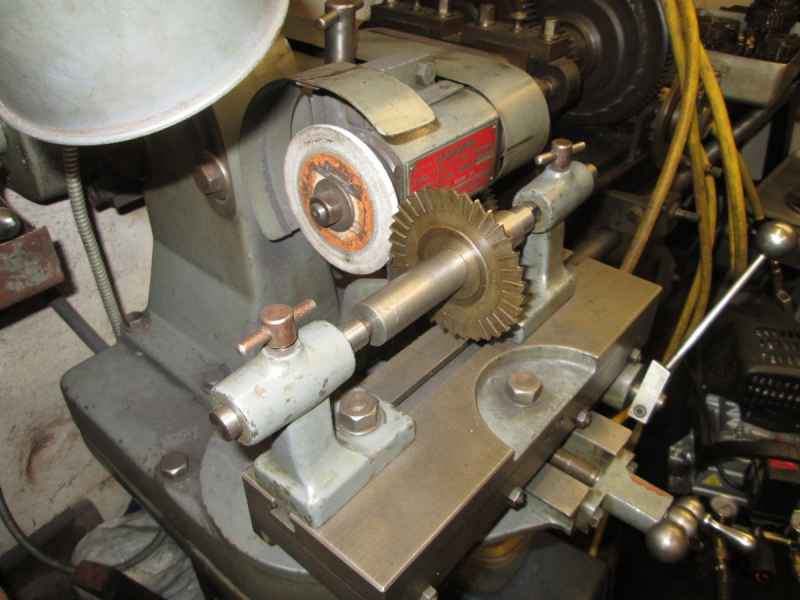

All right, the clever buggers amongst you have got the picture. When I got the grinder out far enough to get a shufti at the back, lo and behold there was a nipple on either end. Then the question arose, was it (as I suspected) just lack of oil? Only one way to find out. I oiled both bearings, not too much but what I thought was enough, and then switched on. It ran a lot better so I put the belt back on and tried it again. Same result so I decided to put the guard back on and give it another run. All seemed well and I think it's quieter so I decided to chance it and put everything back in place. Not as easy as it sounds but quietly away.....

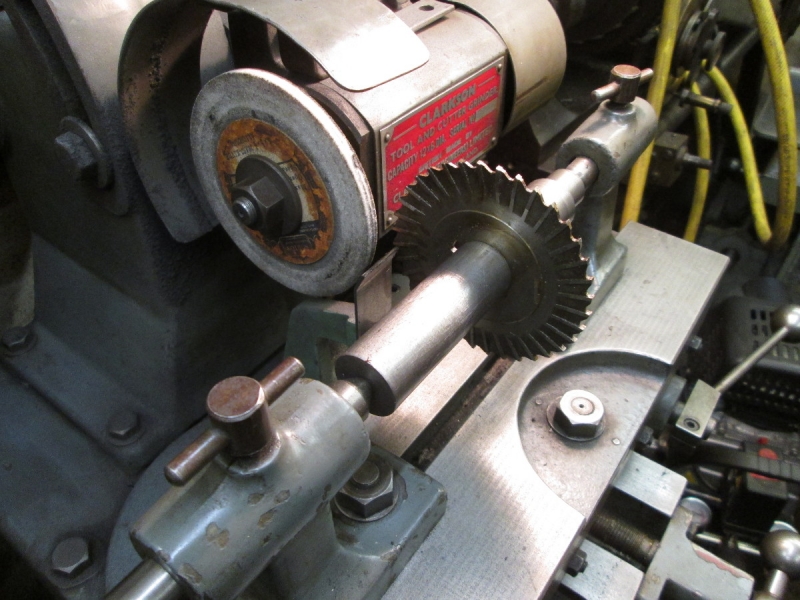

Then the acid test, I set the next cutter up and sharpened it. The motor shrieked once at me and my heart sank into my boots but I stopped it, restarted and that was the last I heard from it. I think the motor had to get warm so the oil could circulate. I decided that instead of going at the job like a silly bugger I would go back to testing each cutter after sharpening. Easier on me and it gives the motor time to cool down when I get into the swing. As it is it has only got slightly warm after four cutters.

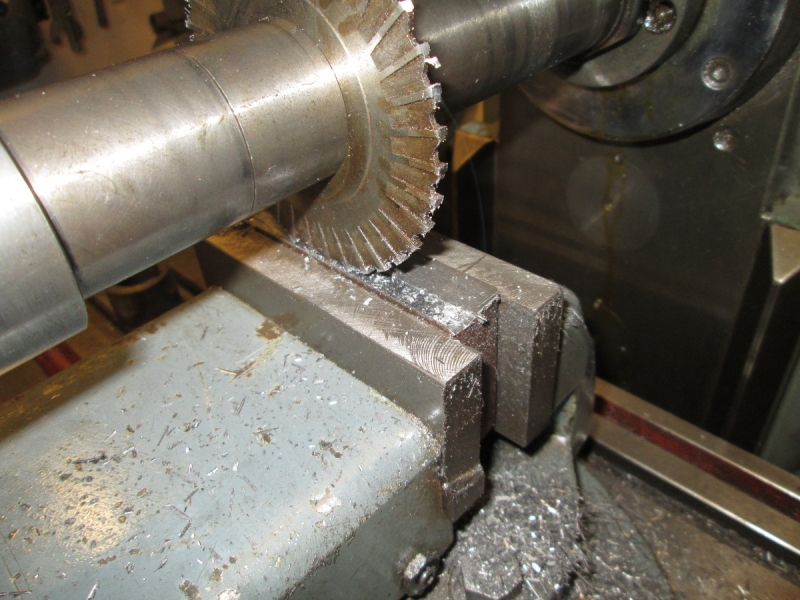

One thing at least went well, the cutter works beautifully and makes good cool chips.

I did four cutters and set the next one up. It took me two hours to get the grinder out, lubricated and back in place so I only had about 45 minutes actual grinding. But I think I've done a good job. Everything is cleaner and touch wood, I have solved my little problem! A tiring morning but good work I think..... I look forward to tomorrow. (It's nice to sit down! Things get harder as you get older!)