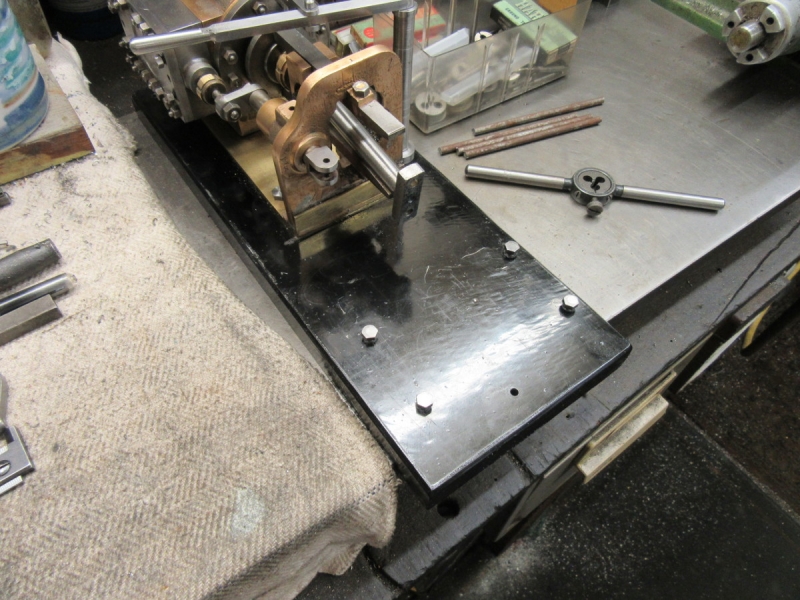

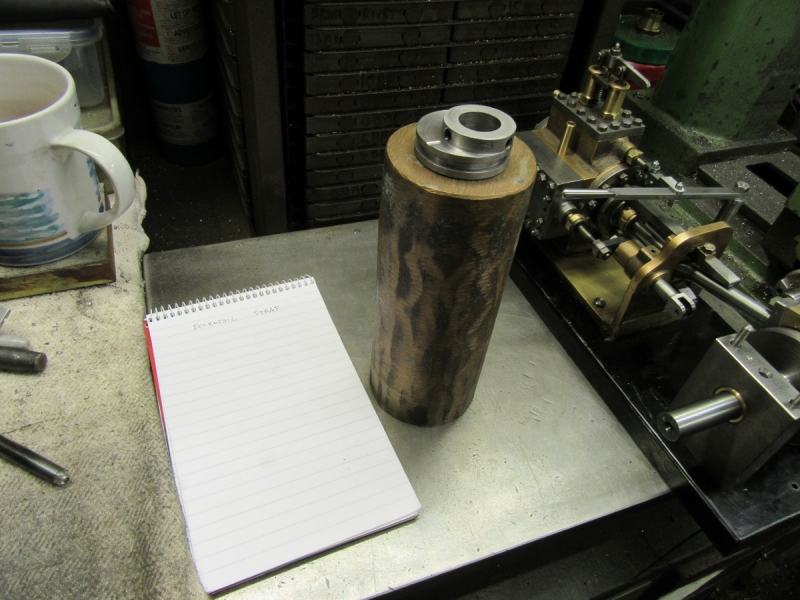

Last thing yesterday I set the worm up in the vice and filled the depression at the top with penetrating oil on the grounds it could do nothing but good. First thing I gripped it in the vice and tried the threaded insert with the square on the end with a big adjustable spanner. Obvious it wasn't going to even think about shifting.

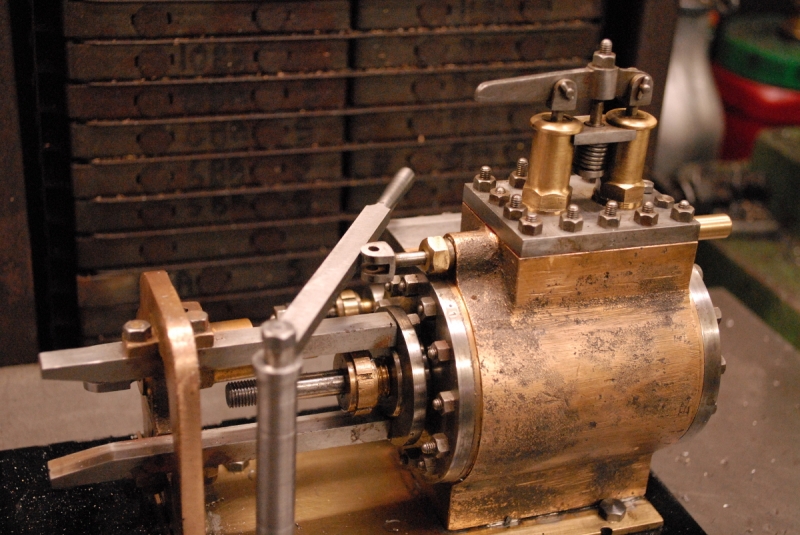

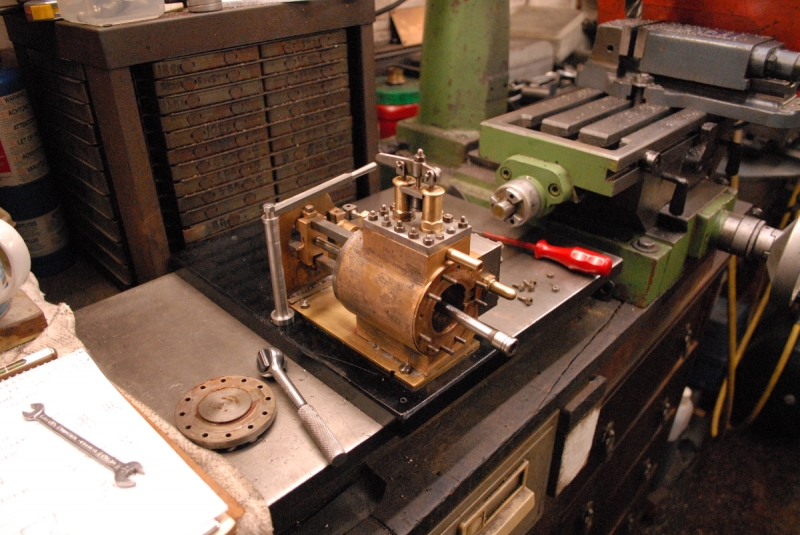

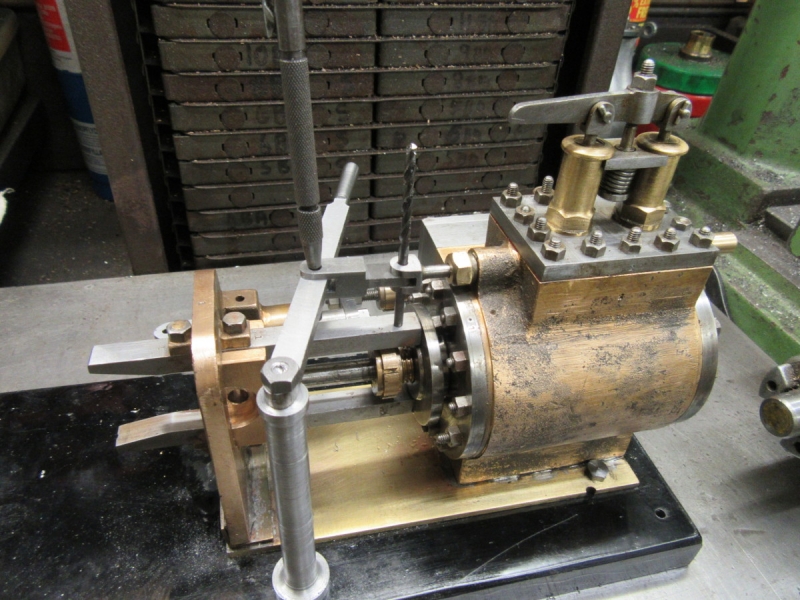

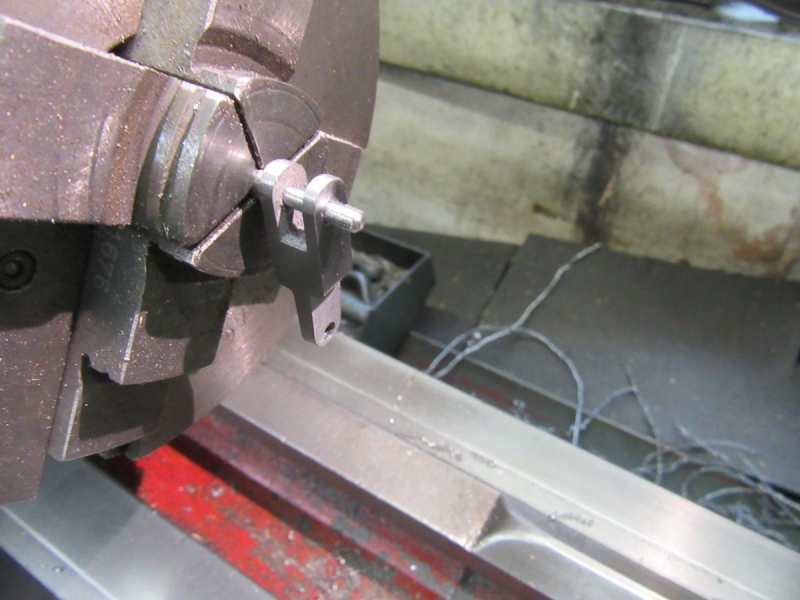

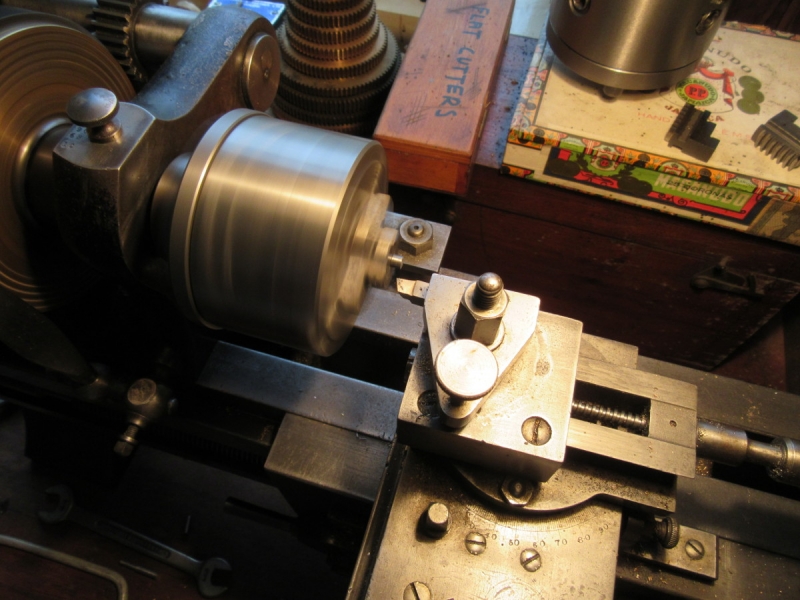

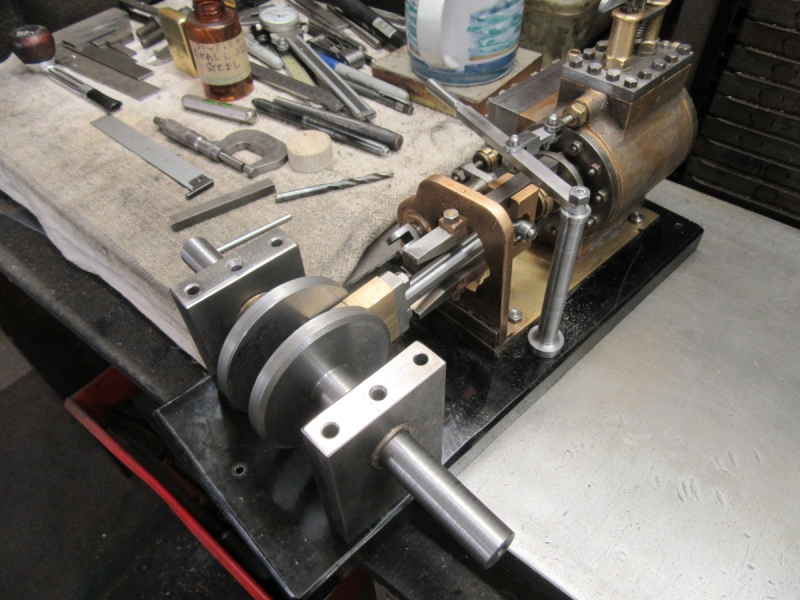

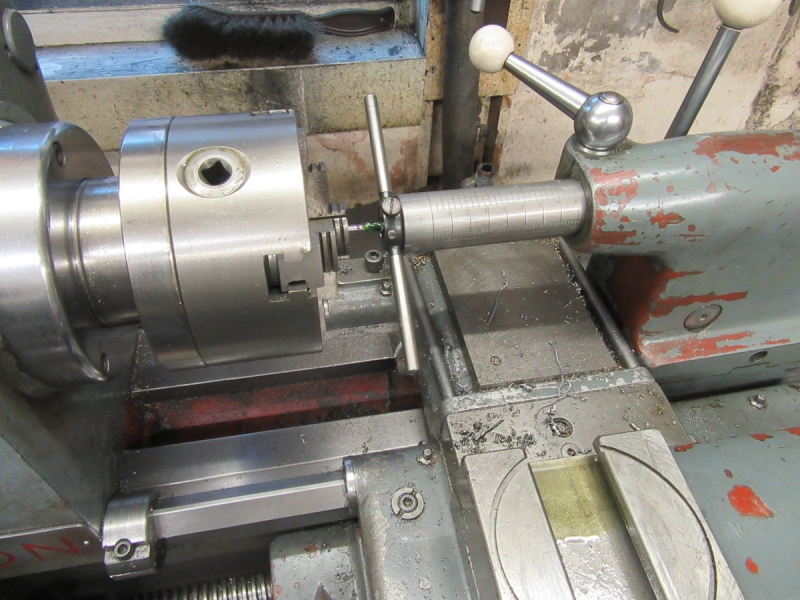

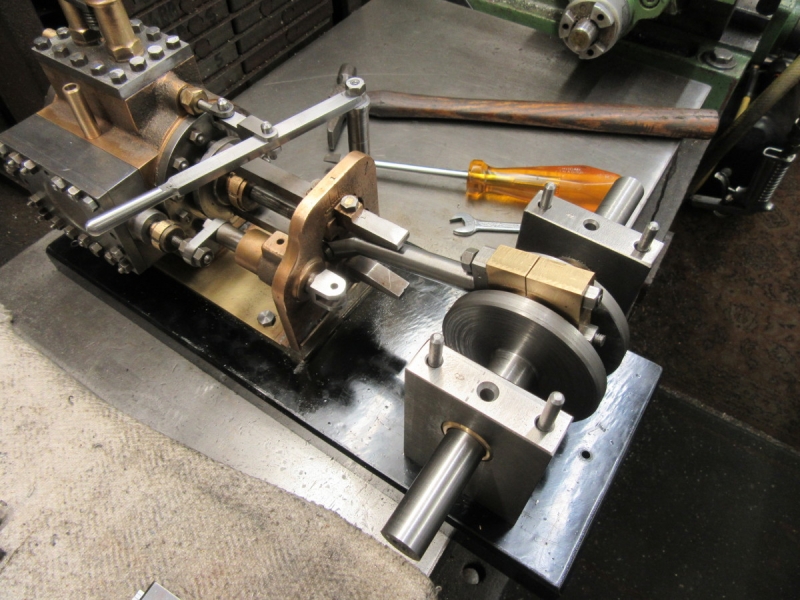

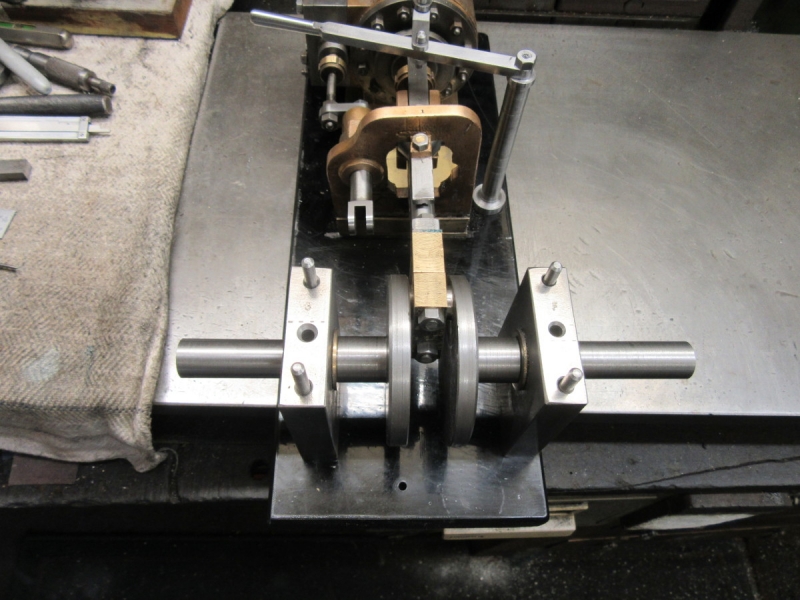

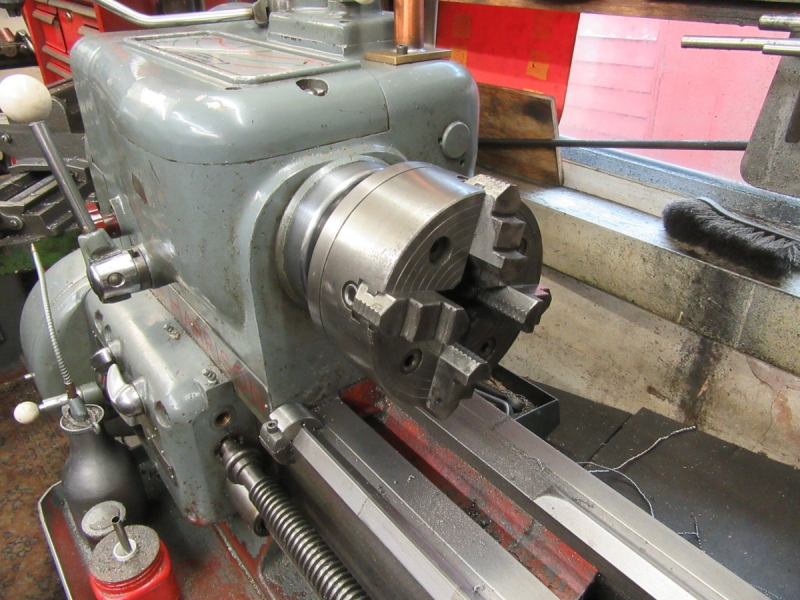

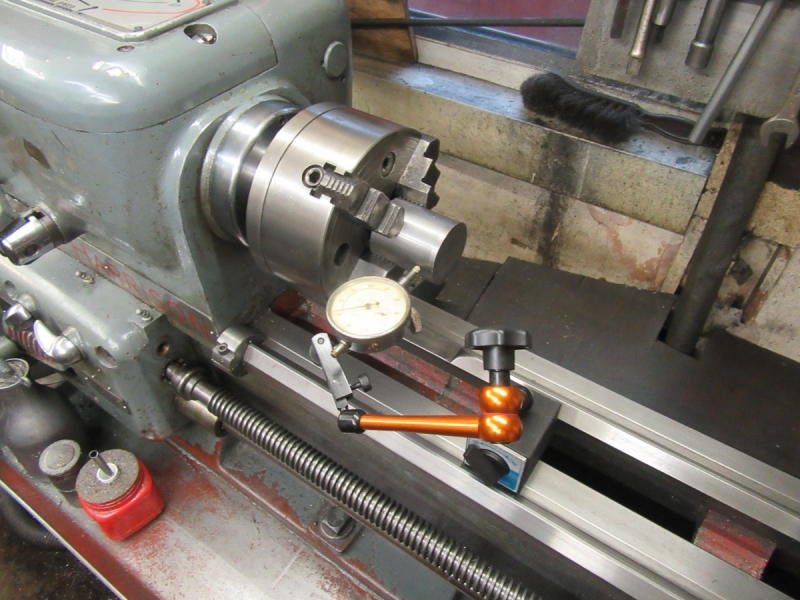

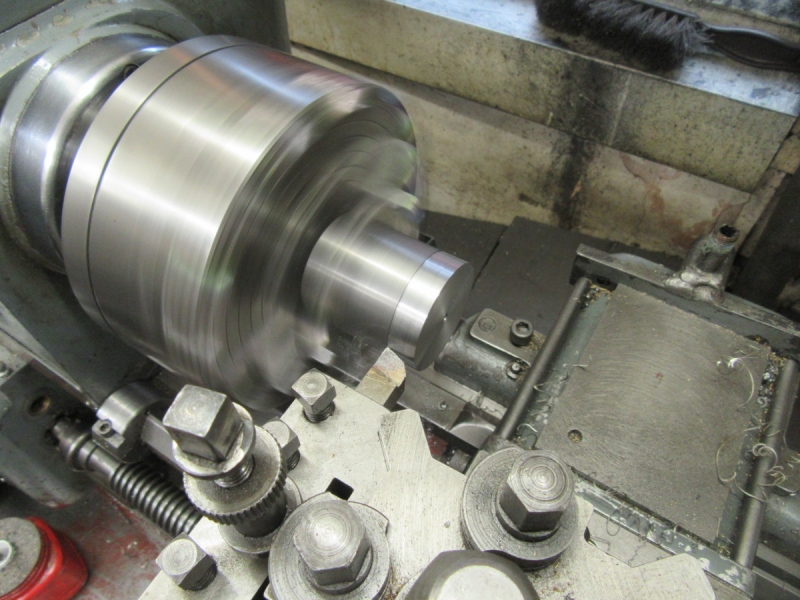

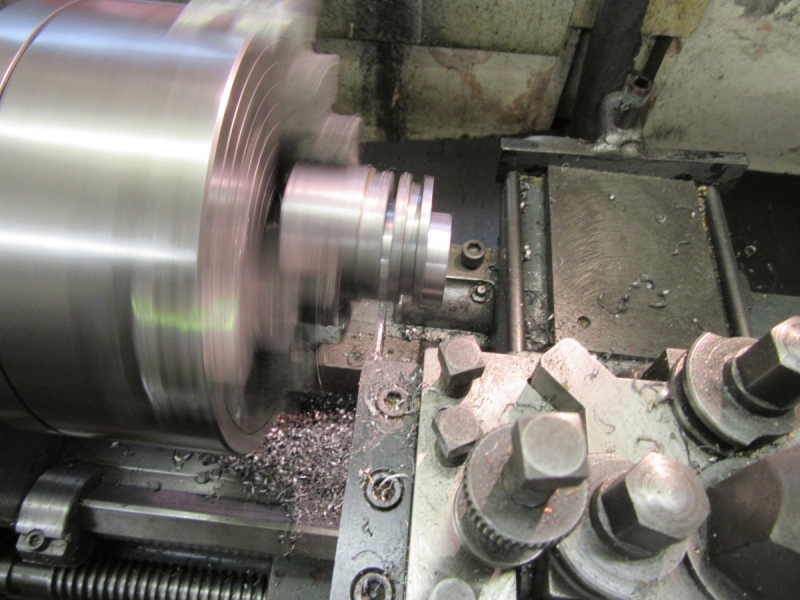

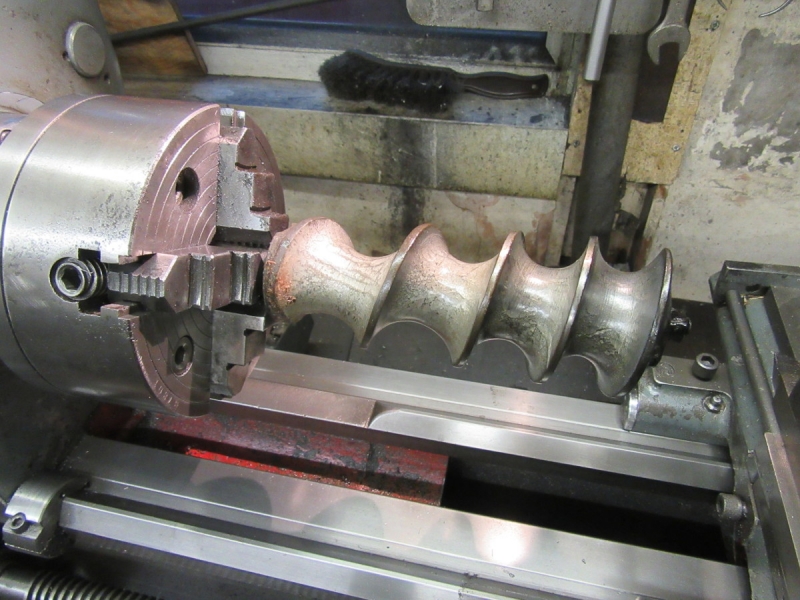

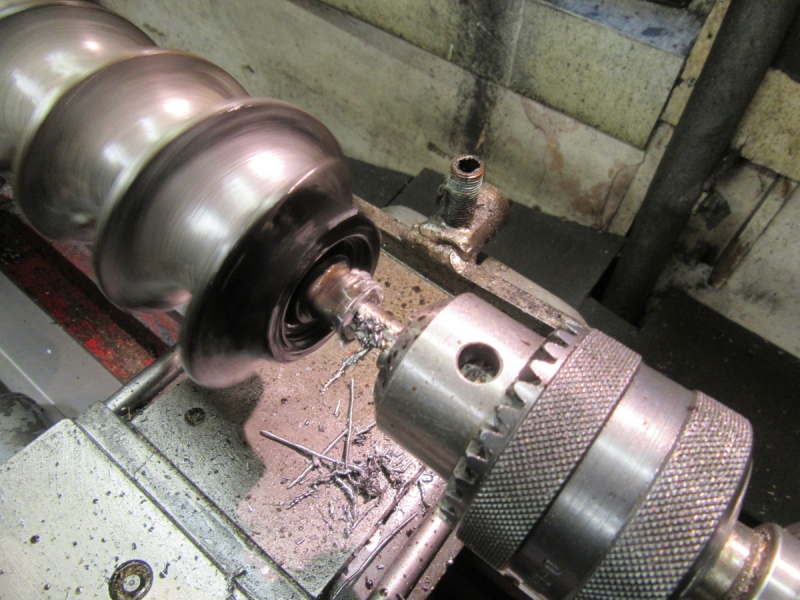

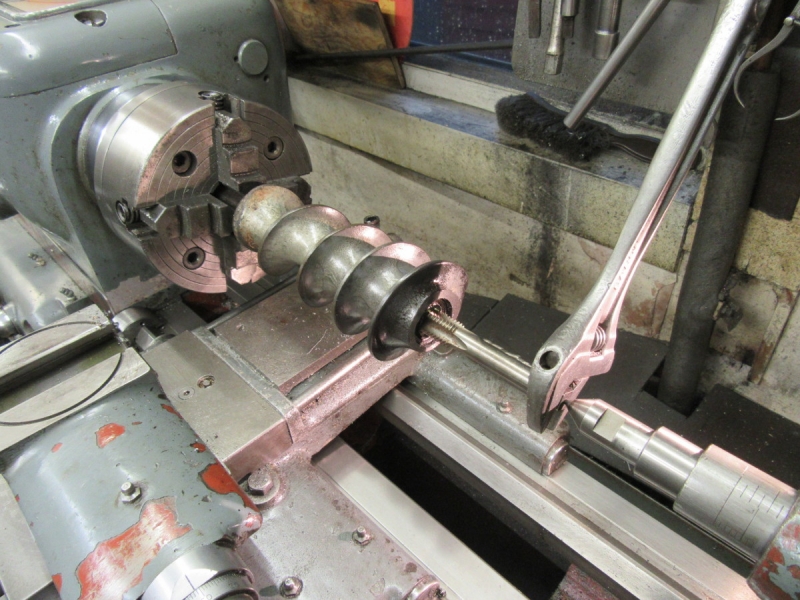

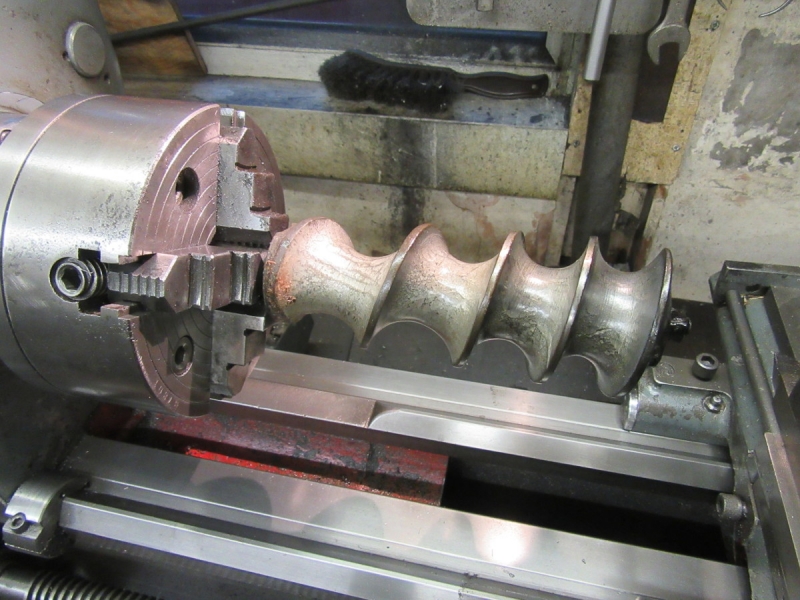

I set it up in the 4 jaw and got it as near running true at the end as I could. No chance of using an indicator on it, I had to do it by eye using the cutter. It's not bad. Then I faced the broken end of the pivot and found out that the square is hardened which makes things interesting!

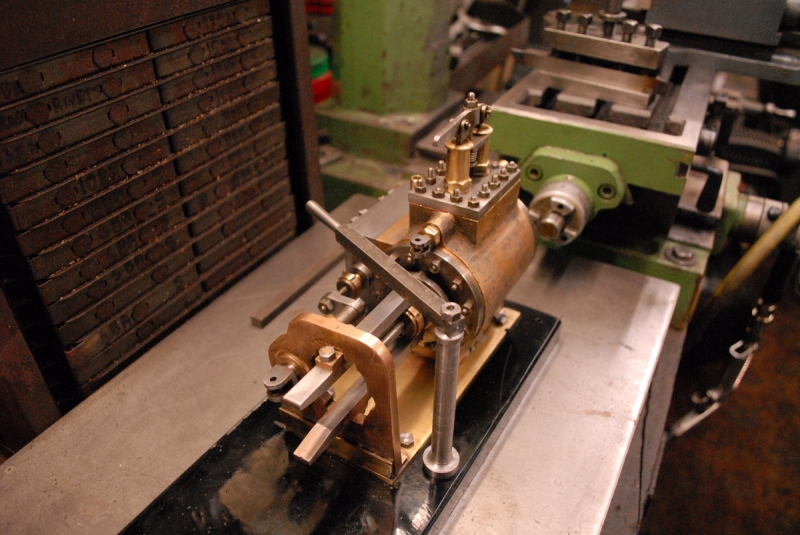

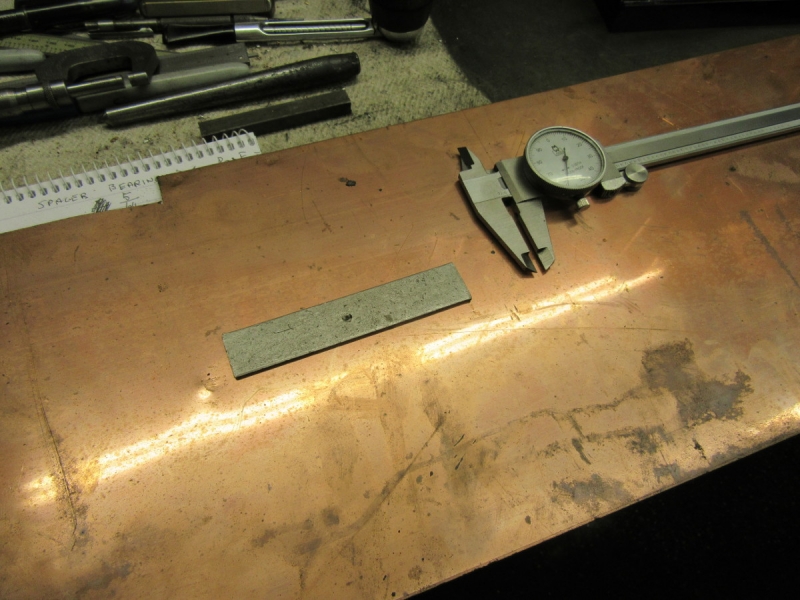

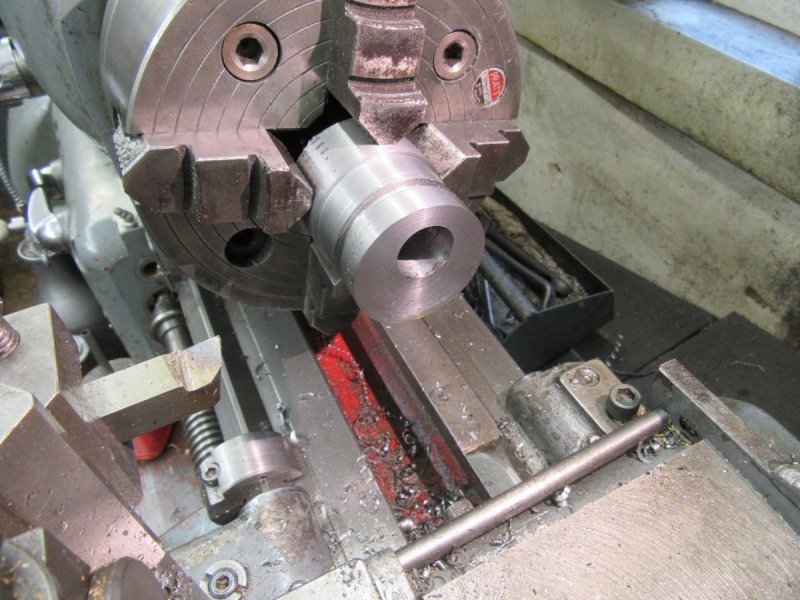

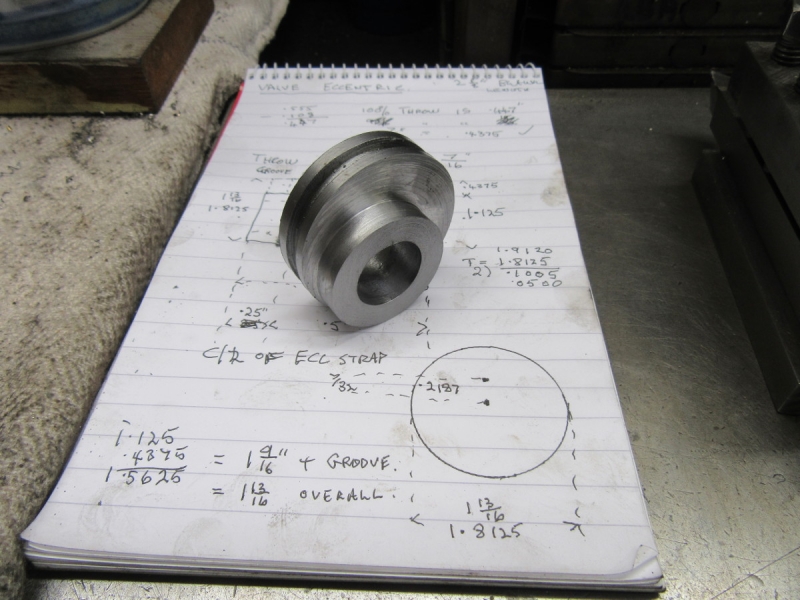

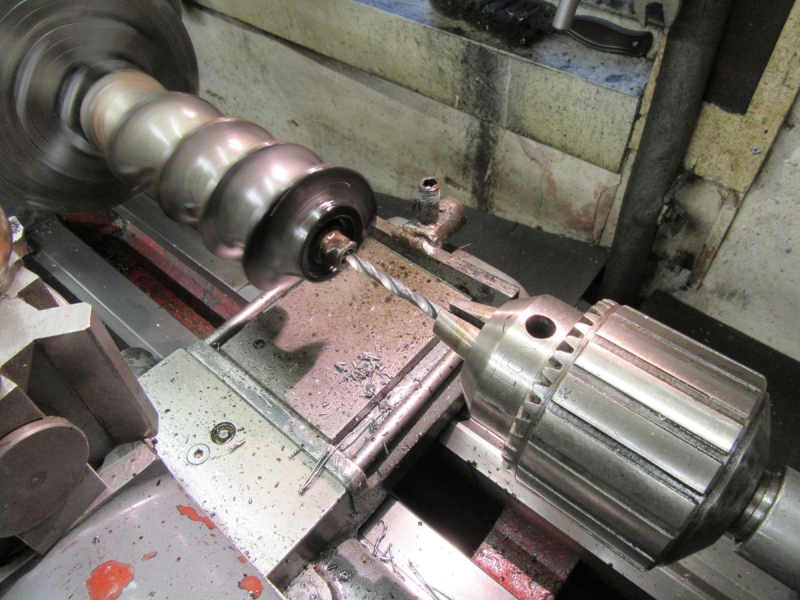

Next job was to put a good centre hole in the end. It looks surprisingly central!

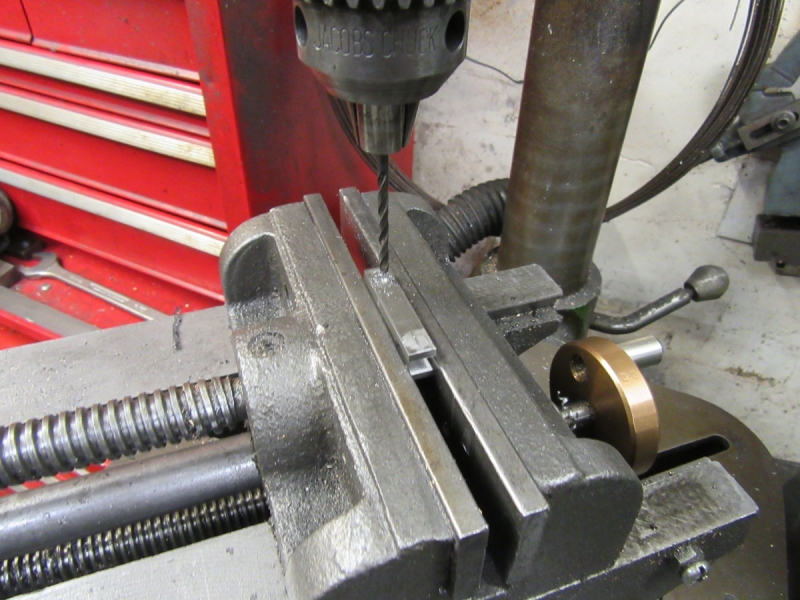

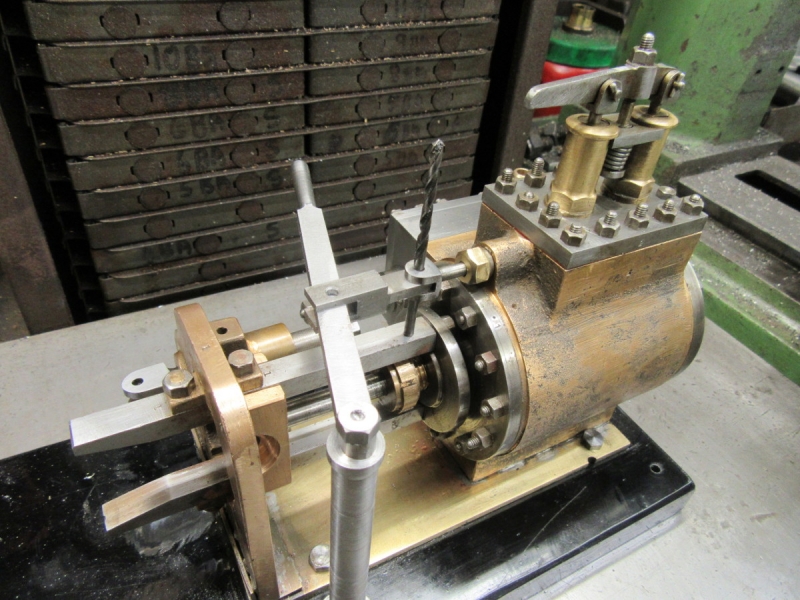

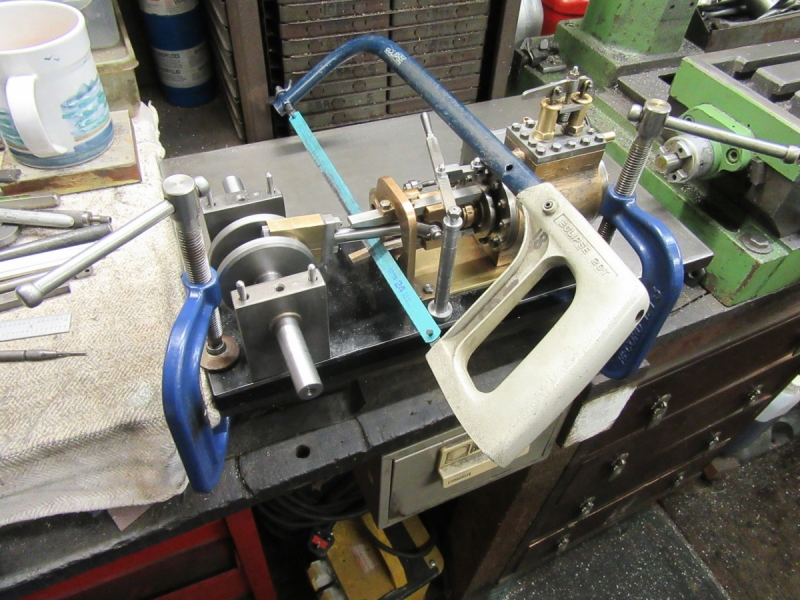

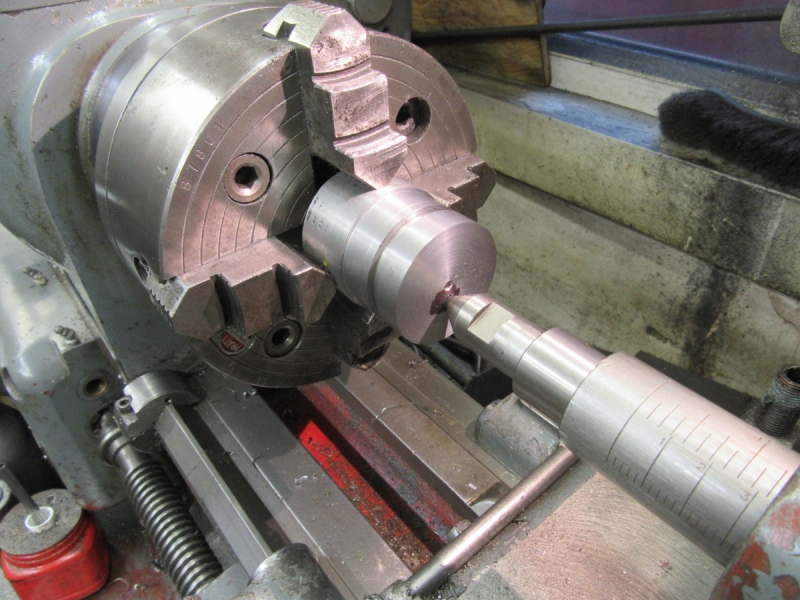

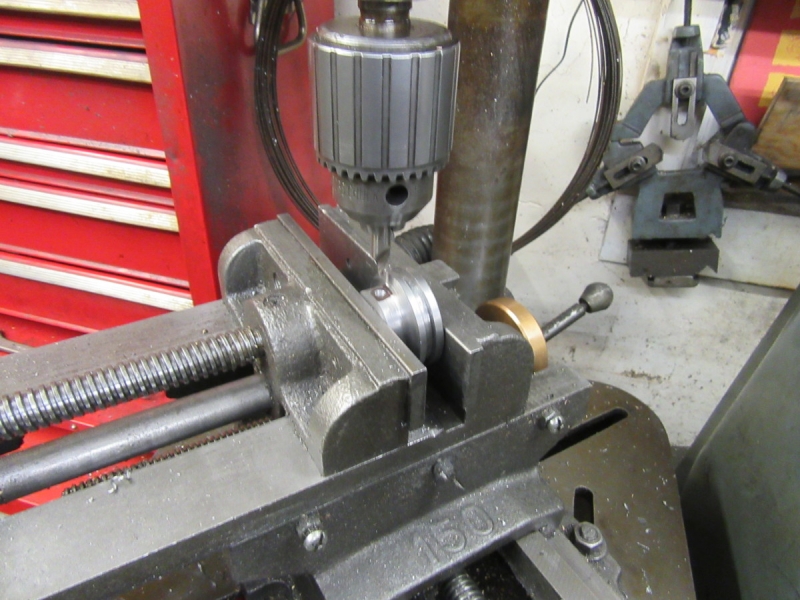

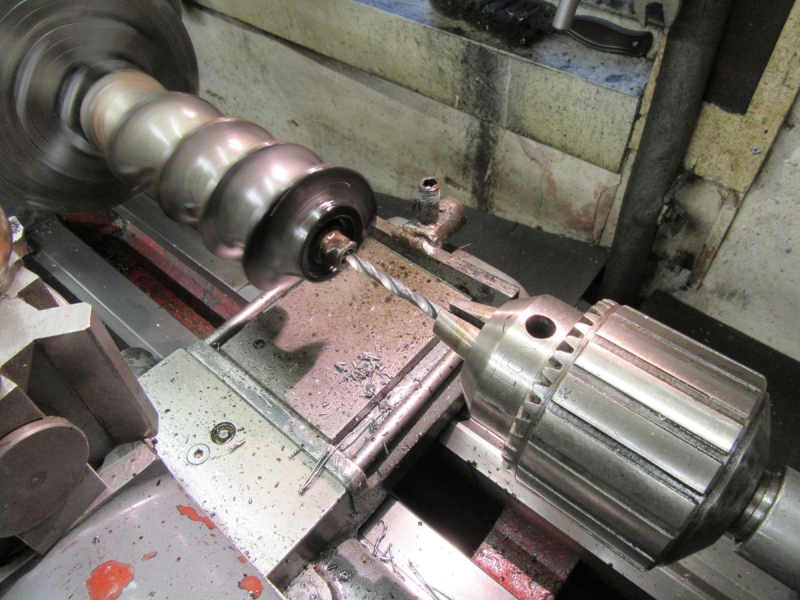

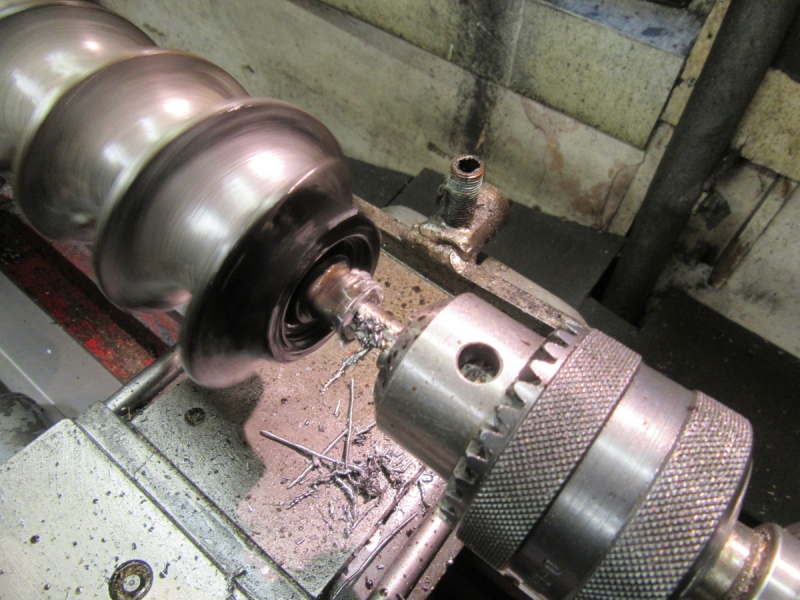

I used the 3/4" capacity Superchuck because it's the most rigid and accurate one I have. I started with the 1/4" drill and went in until I broke through the body of the stud and entered the cavity underneath.

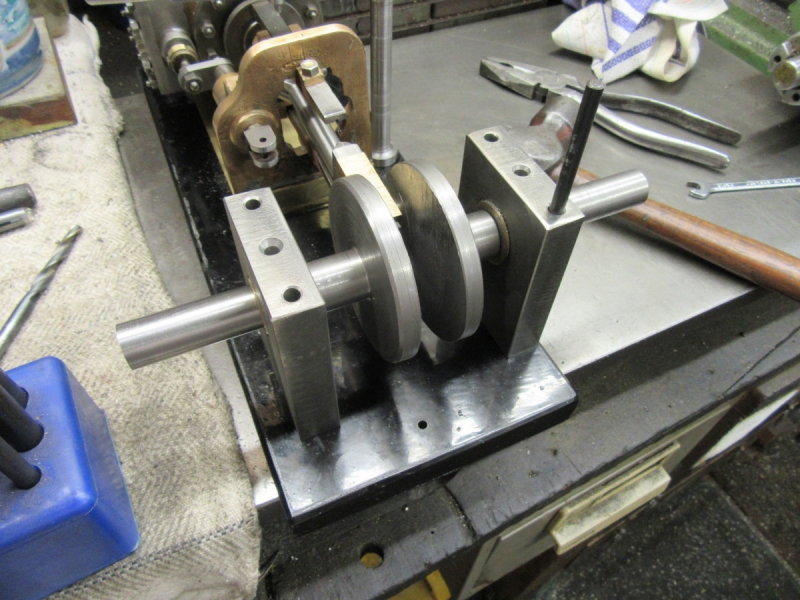

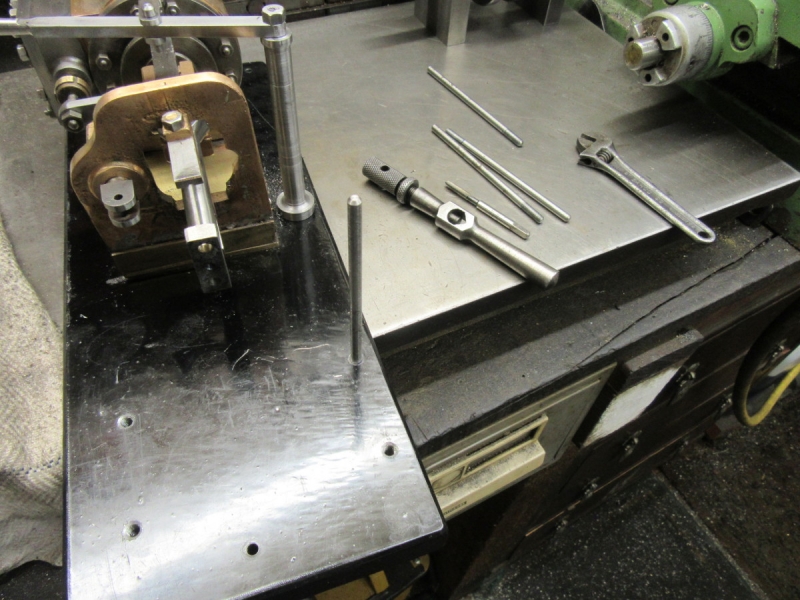

I bit the bullet and decided I could do without the square, the way out of this is going to bore the old stud out. Or at least that was what I assumed......

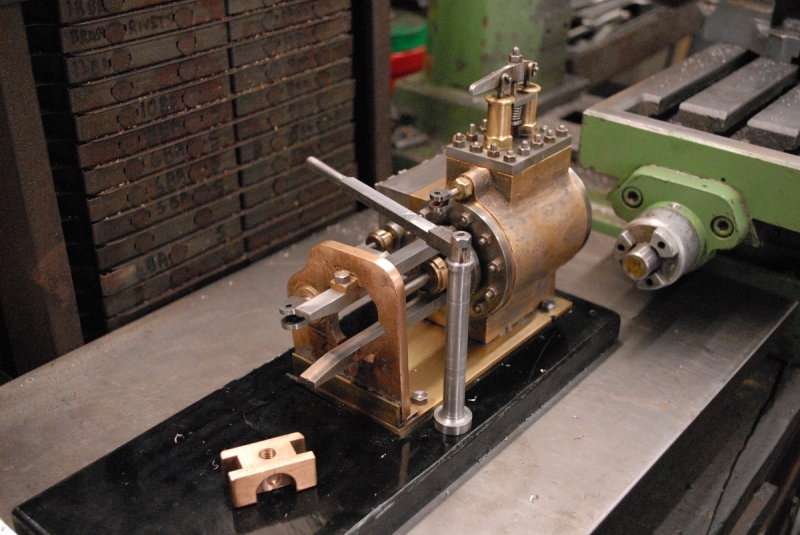

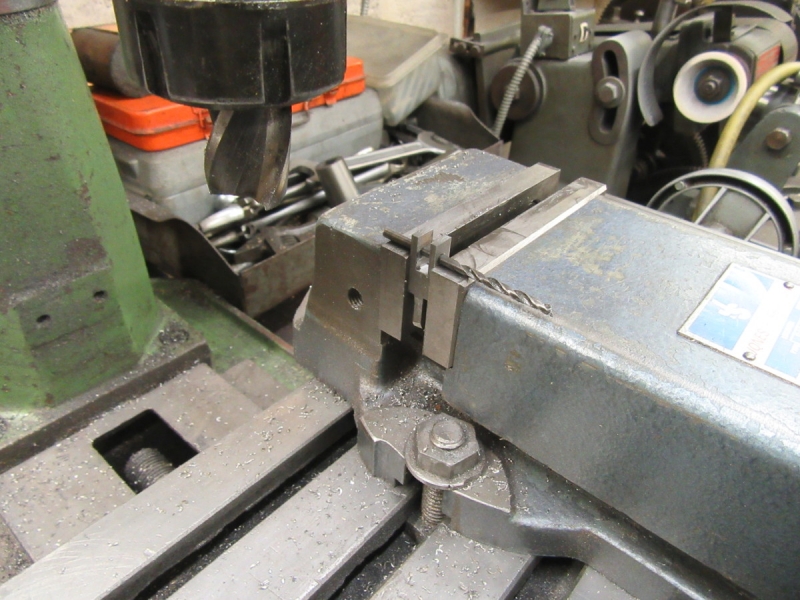

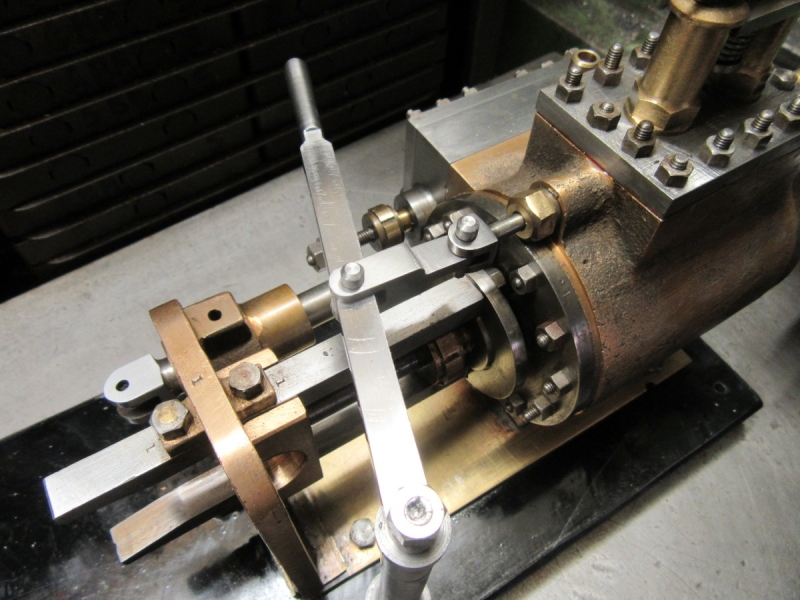

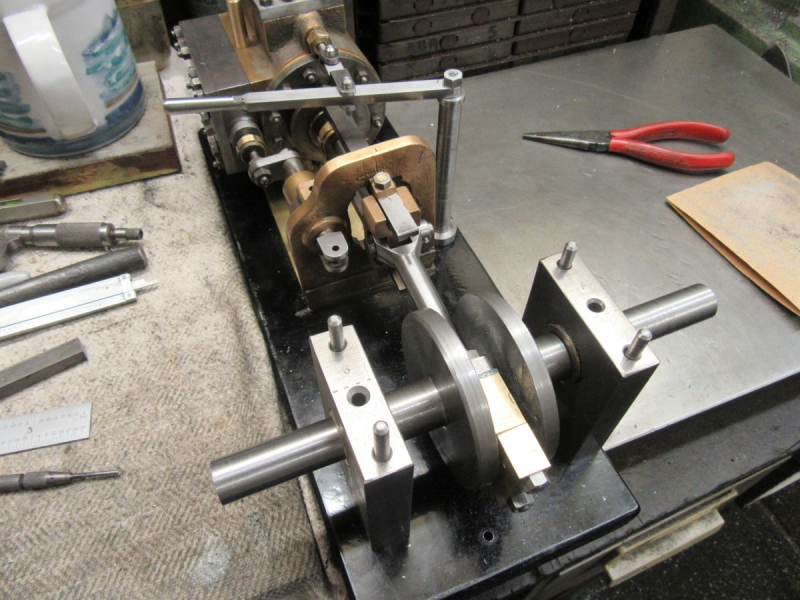

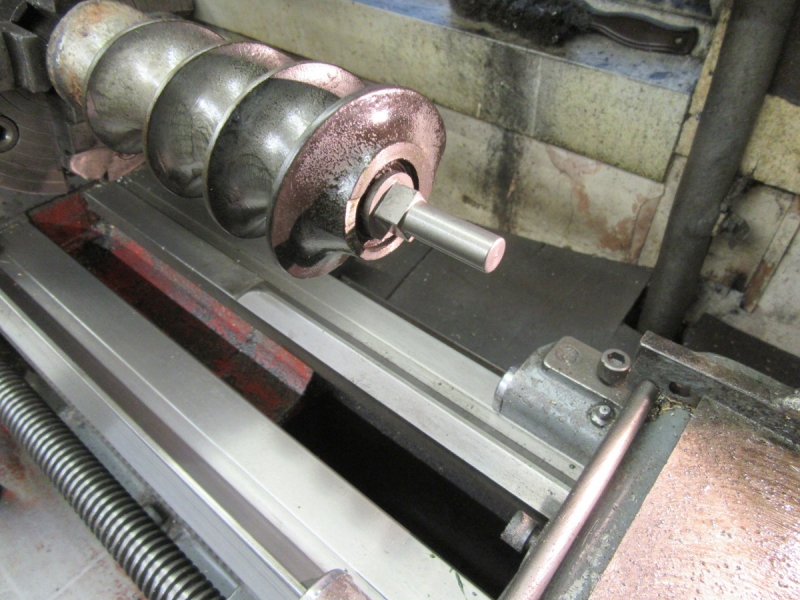

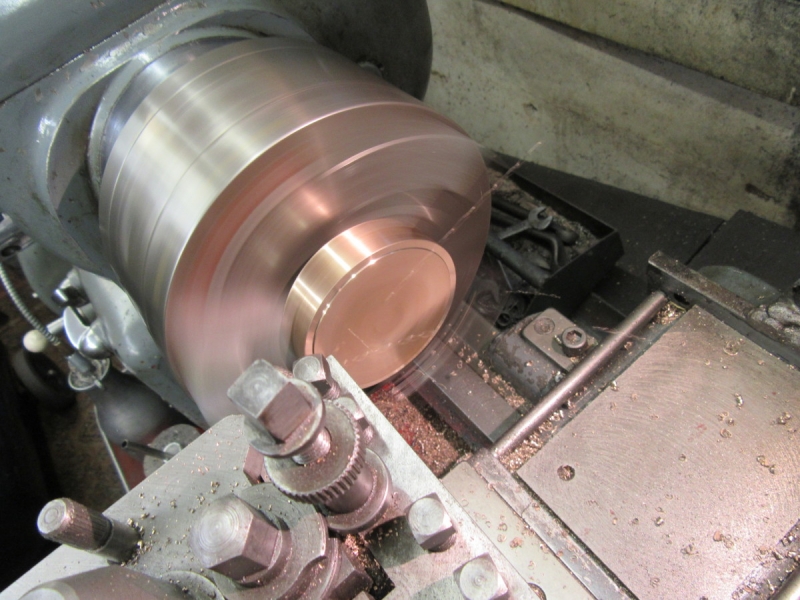

Off with it! It didn't do the hacksaw blade a lot of good..... Then I faced the end of the worm and the saw cut so I had a square cut.

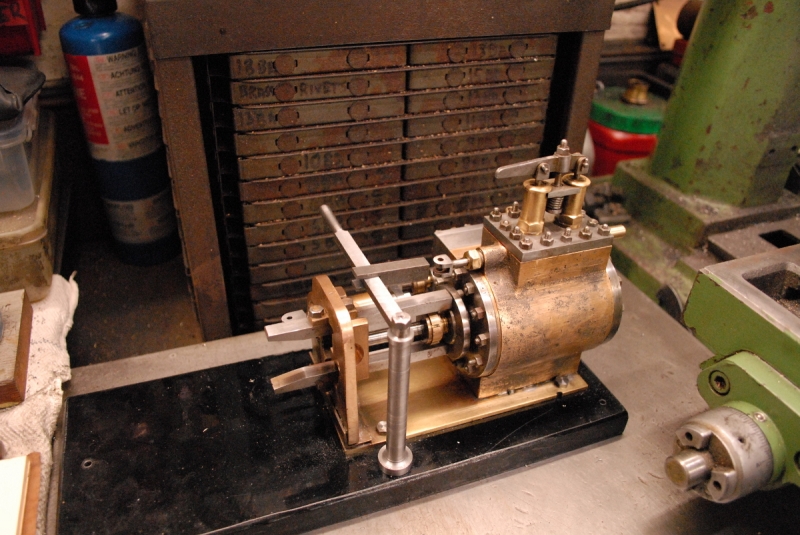

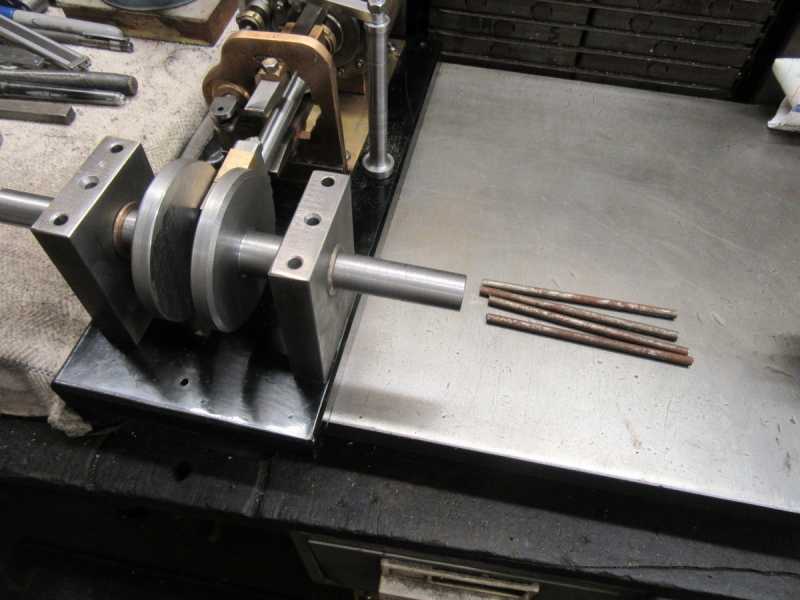

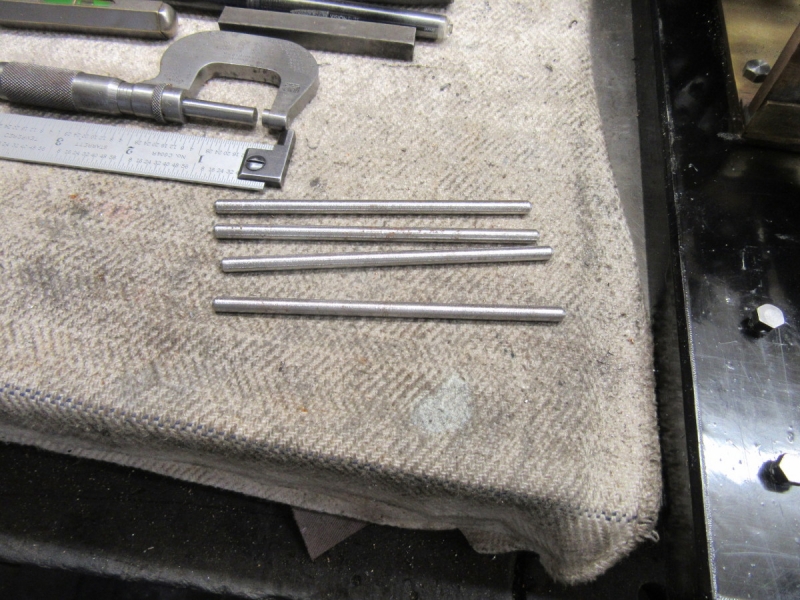

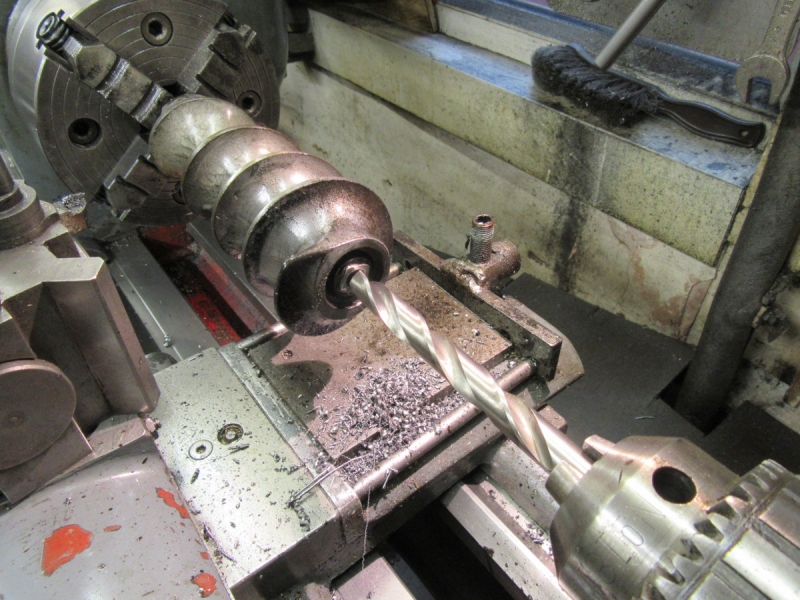

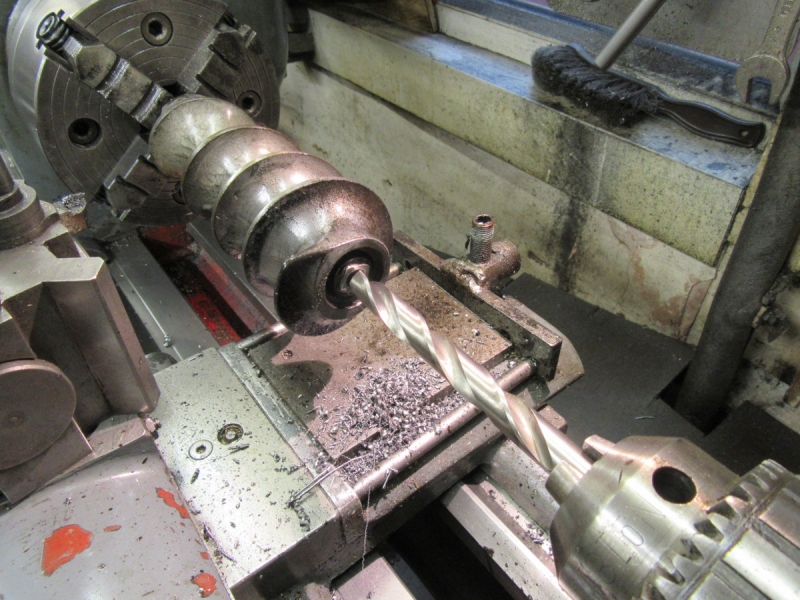

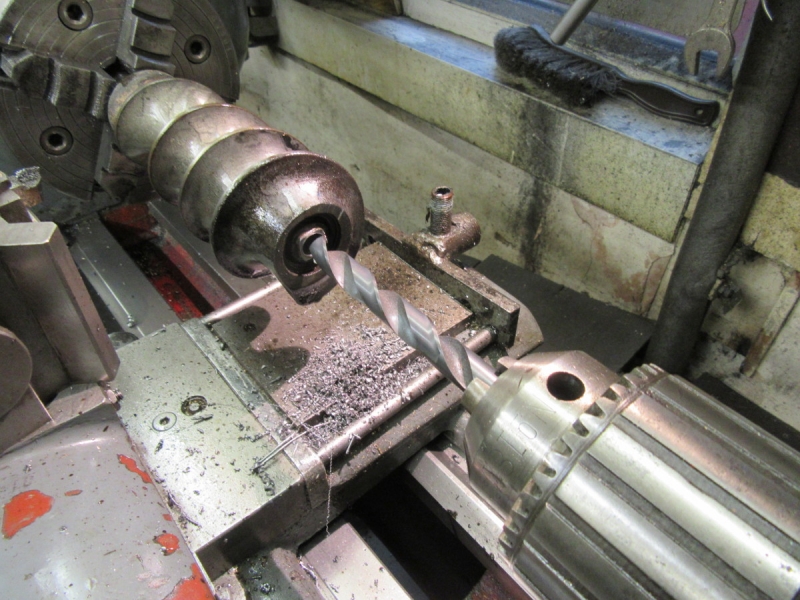

Careful increases in the size of the drill.

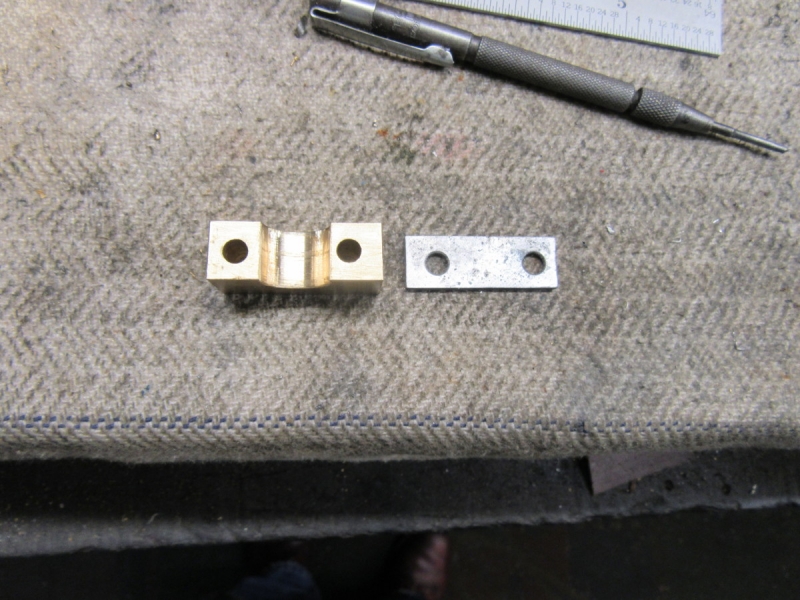

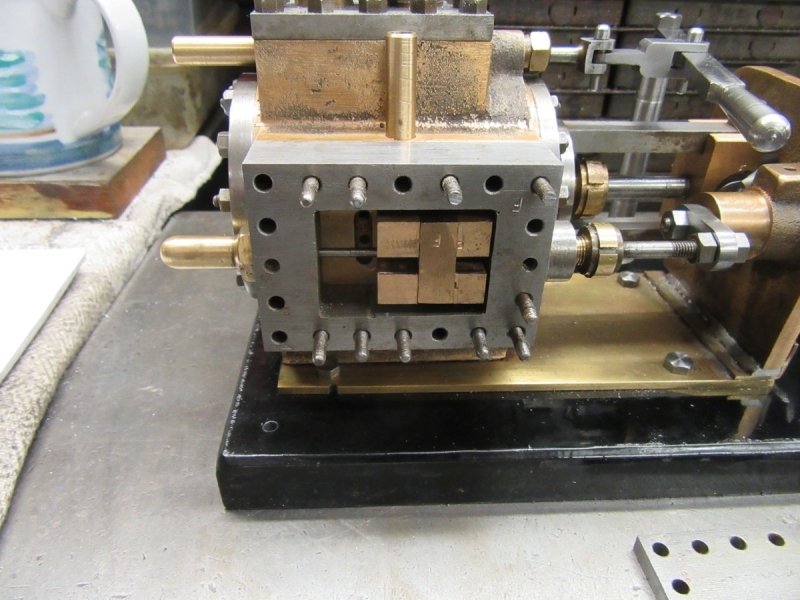

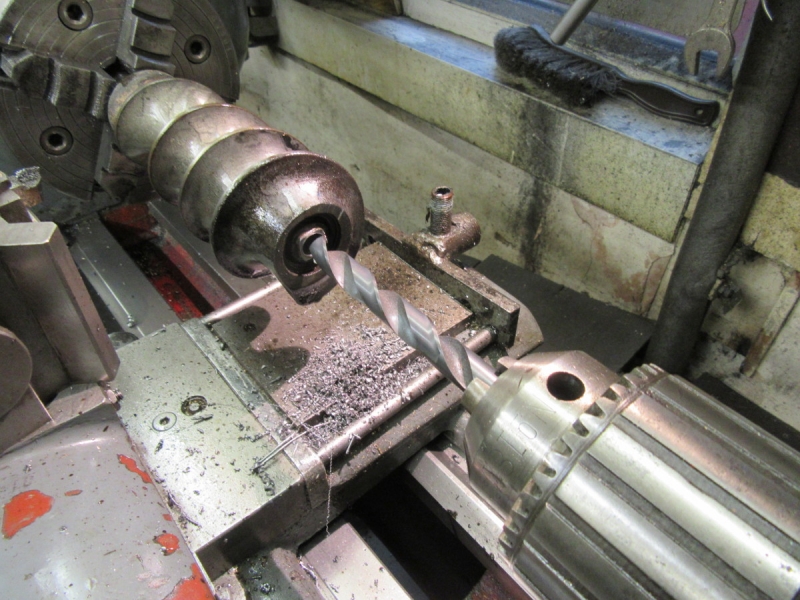

Then I countersunk the end hoping to undercut the flange. but it didn't work. I tried to cut the flange with a small sharp chisel but it's too thick still. Something very strange going on here.

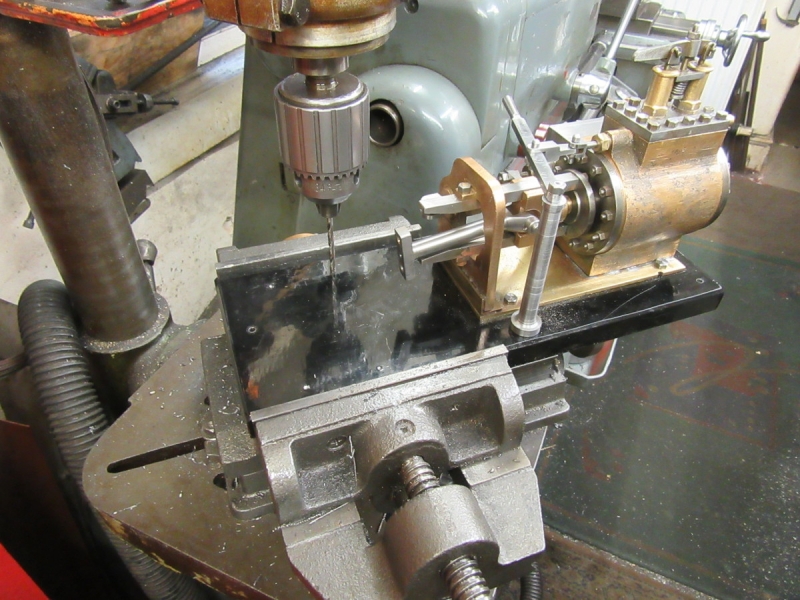

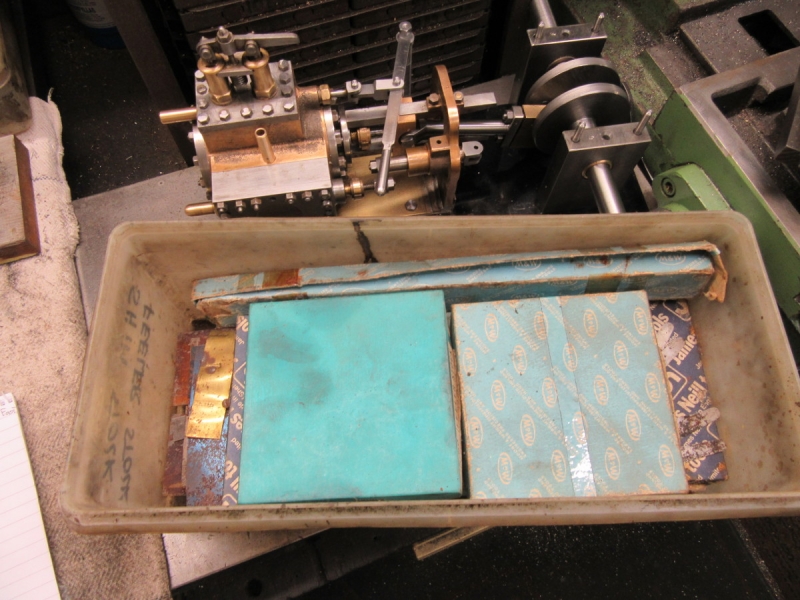

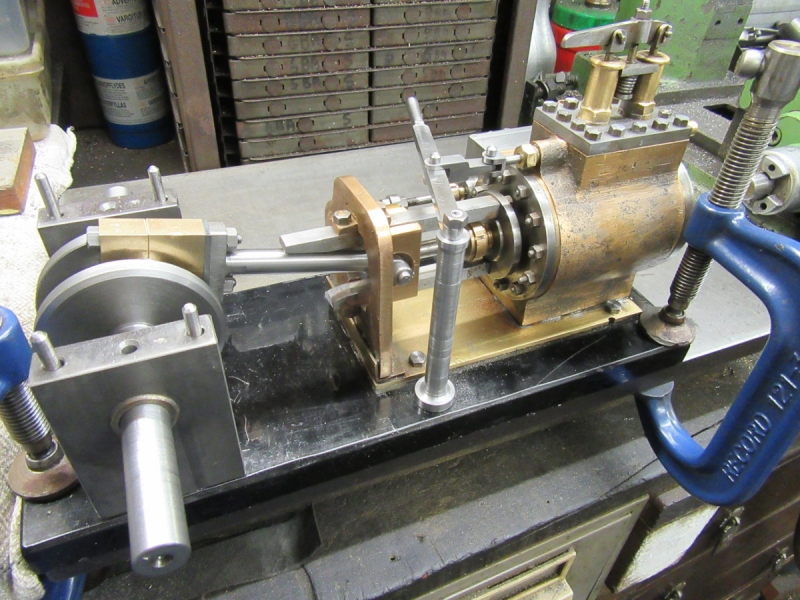

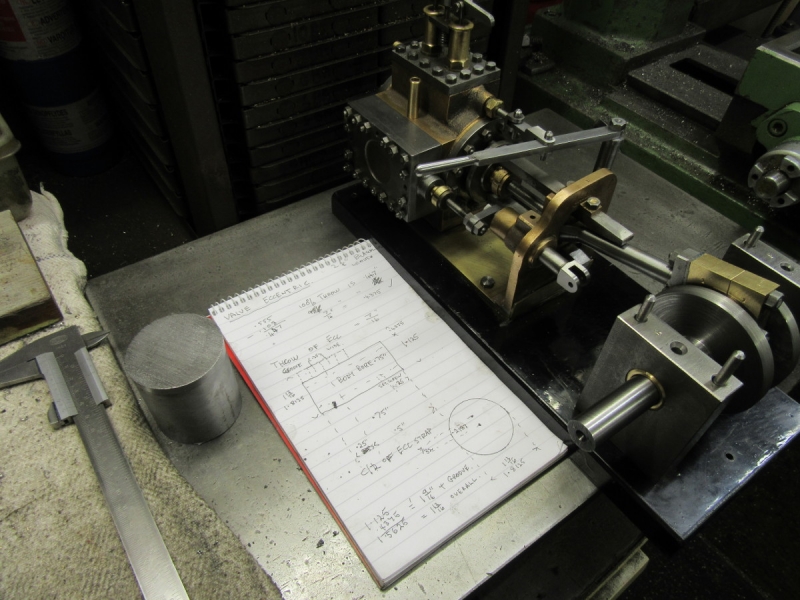

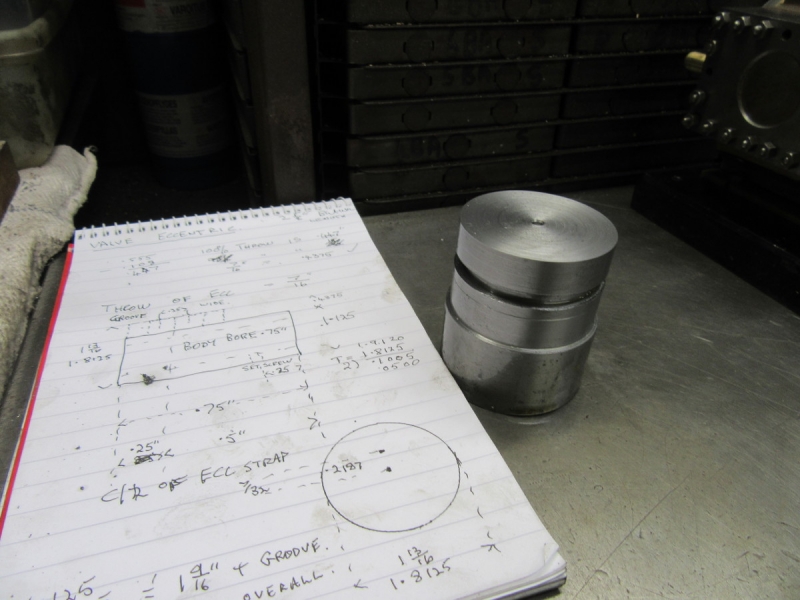

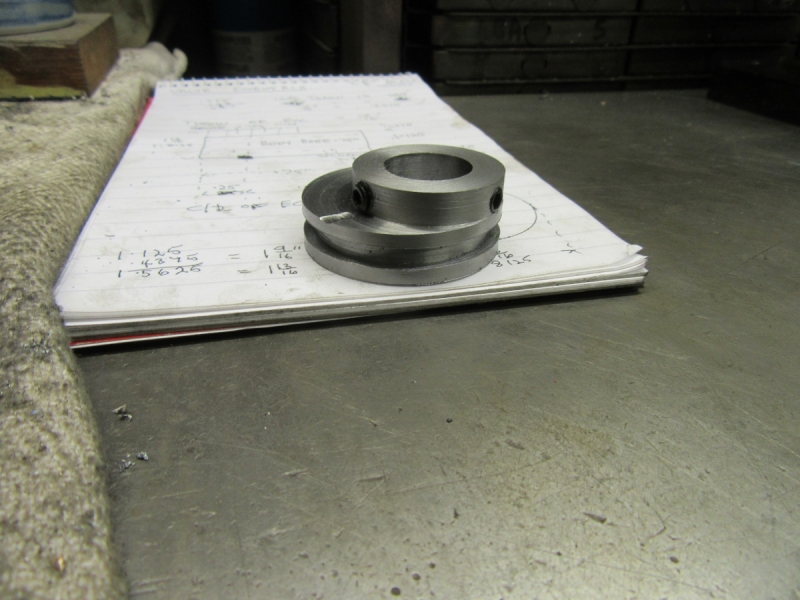

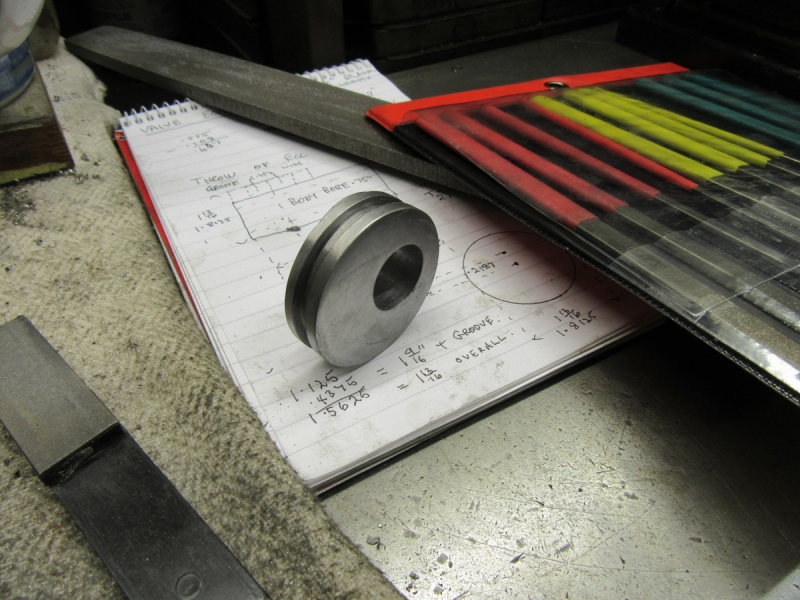

I made one last attempt but still no joy. Here I stopped. I have come to the conclusion that the new replacement insert which is 5/8" UNC is the wrong one. I ought to be finding the edge by now. I suspect it's a larger Whitworth thread. I can't make a new one as I have no reliable way of hardening the square drive. So I have decided to face the end of it in the bore, drill the old stud to tapping size for the new one, thread it 5/8" UNC and fit it with Loctite. That's the only way out I see. No point trying to get hold of an original that's the right size, I suspect the machine is older than I am and getting a new stud will be impossible.

Interesting if frustrating morning. Quietly forward tomorrow!