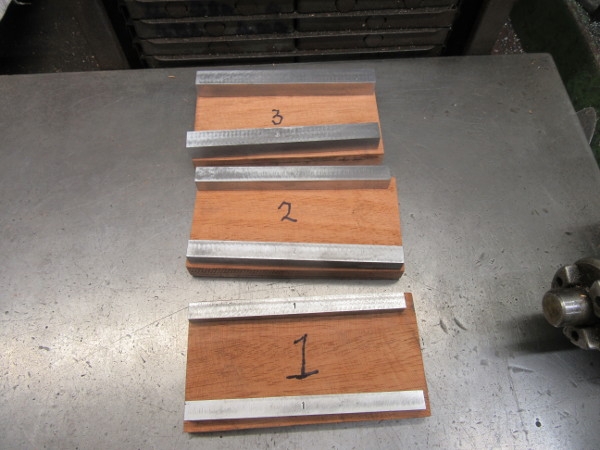

You might have noticed that I am not very enthusiastic about the wood I found for the carriages. I went on a further extended search this morning and found this piece of Mahogany which will cut into four pieces and I only need three. That will wait for daylight when I can get the chop saw out.

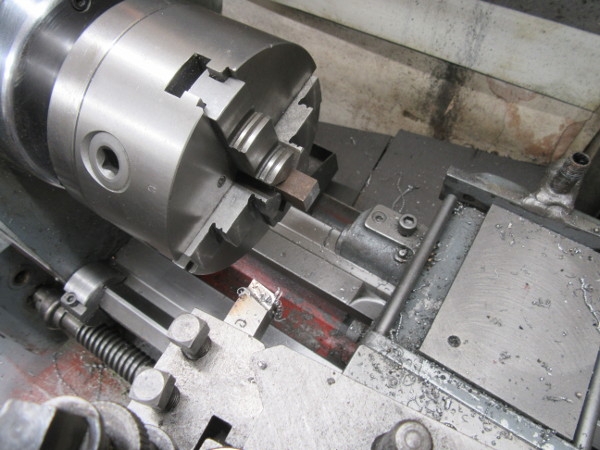

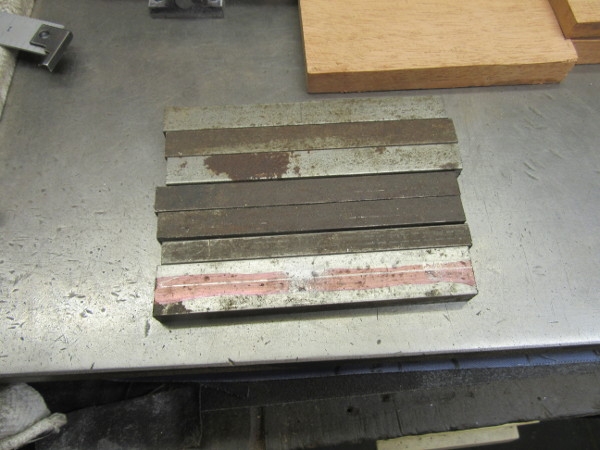

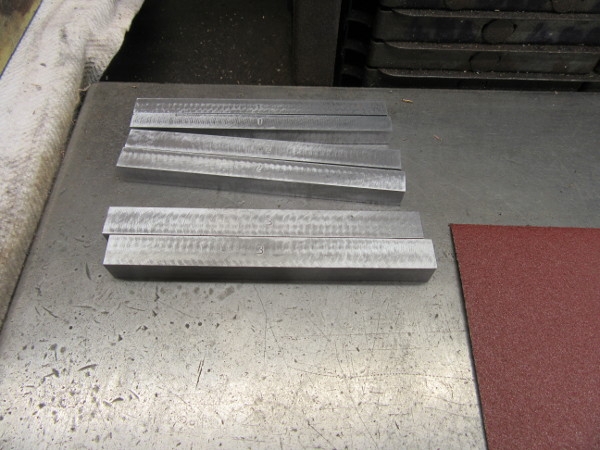

I also have a problem in that I hadn't found enough material to make the undercarriage of the gun carriages, let alone the right size. Again, a detailed search in every nook and cranny, a lot of it bent down or on my knees which is hard! I have enough but it will all need machining to size.

Came the dawn and I got the chop saw out on the bench in the back yard and made the cuts that I could. I couldn't do the splitting cut the throat of the saw is too small so that had to be done by hand. And yes, I know it should have been the rip saw but the cross cut saw wasted less material.

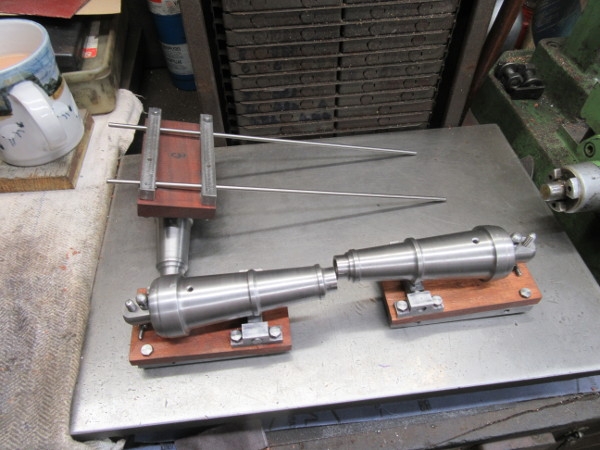

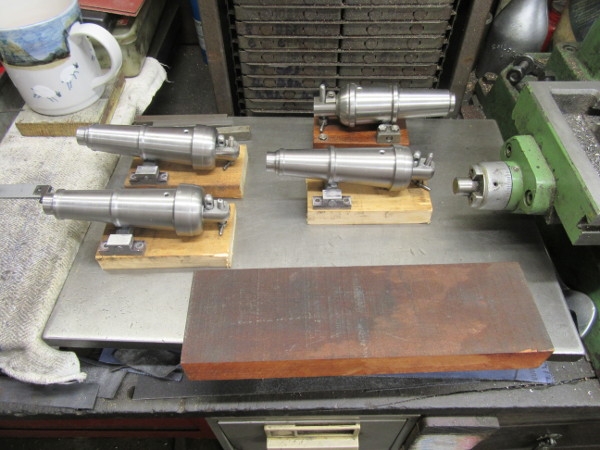

Knocking off time. (my knees are protesting against all the kneeling and being out in the yard in the frost!) I have four mahogany blanks which will make nice bases for the gun carriage when I have cleaned them up a bit. By the way, this mahogany was bought by Johnny Pickles to make the bench I use today in about 1930. Lovely timber....