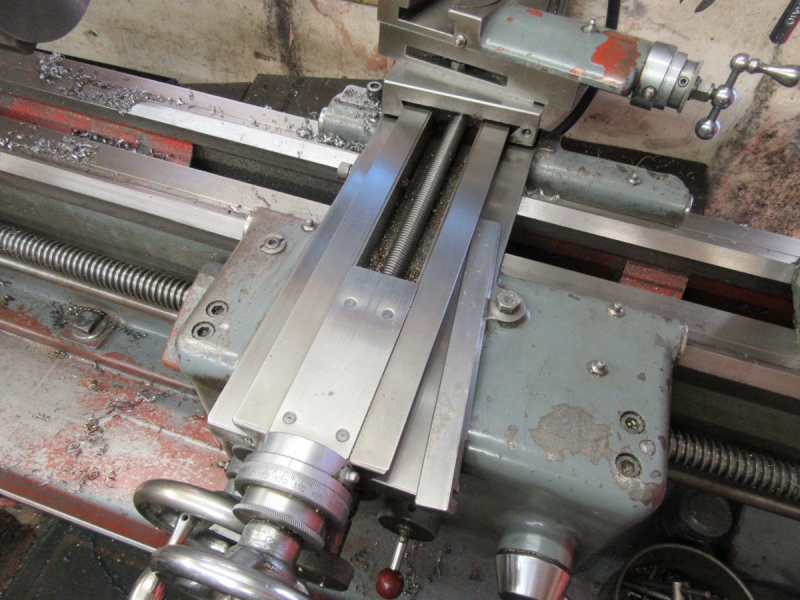

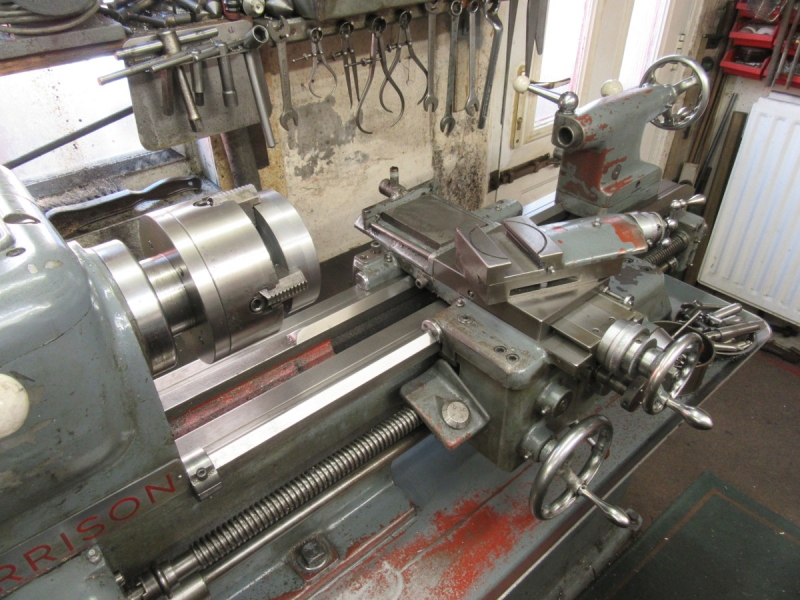

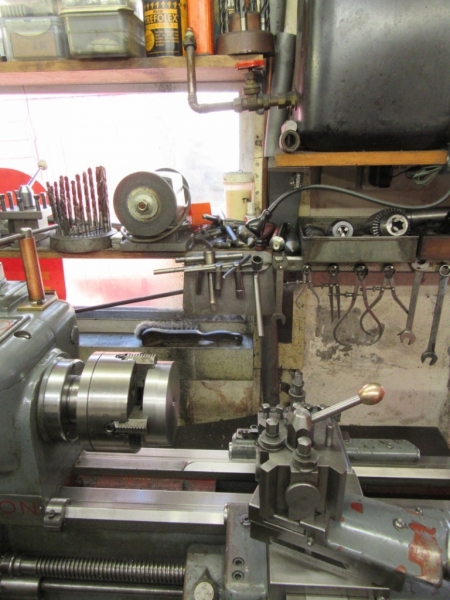

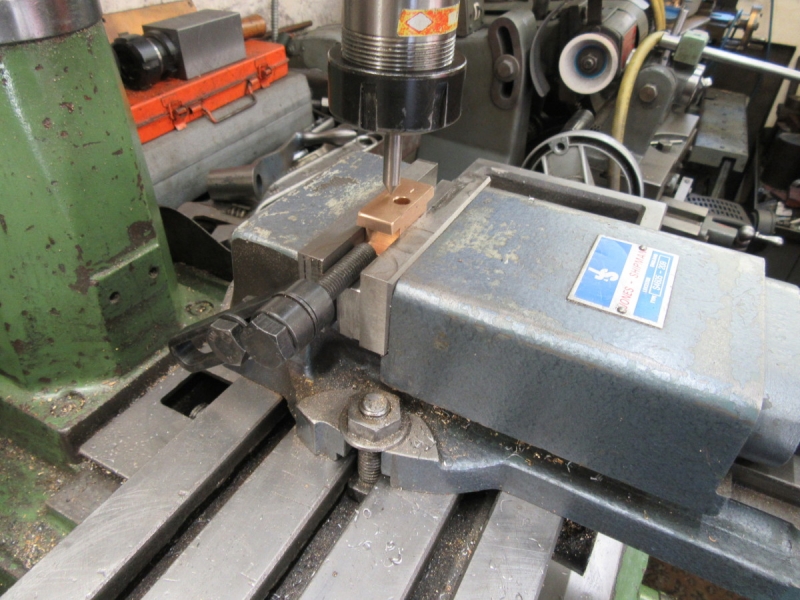

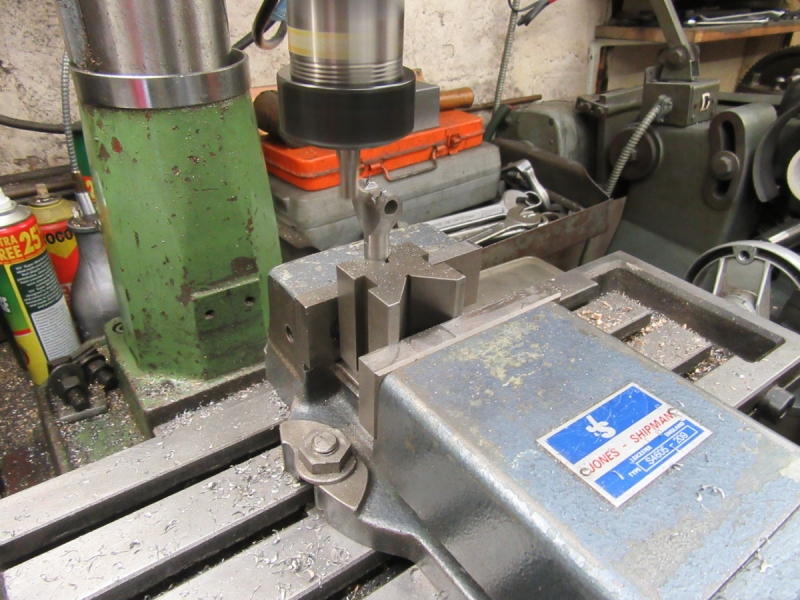

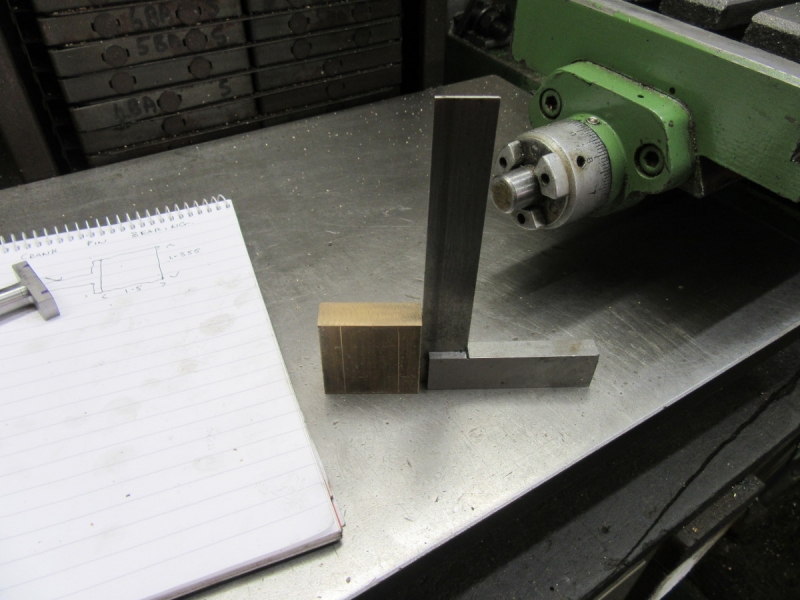

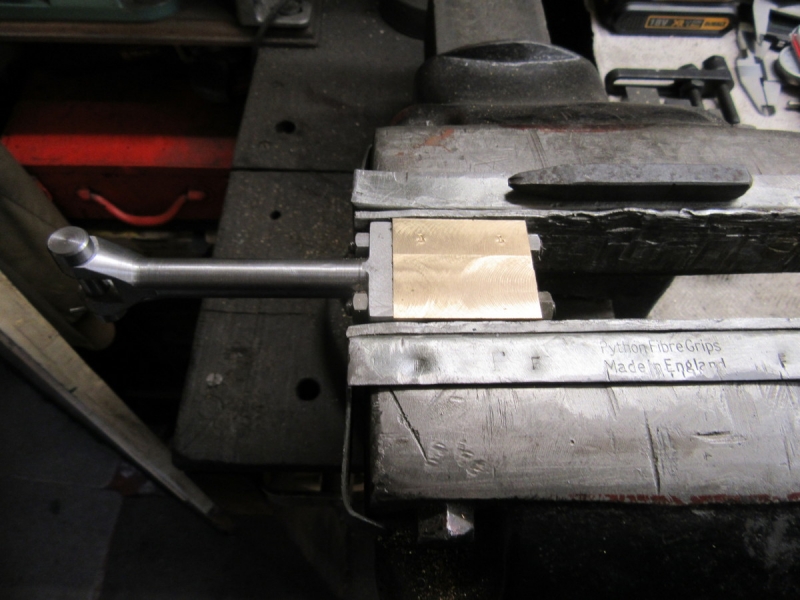

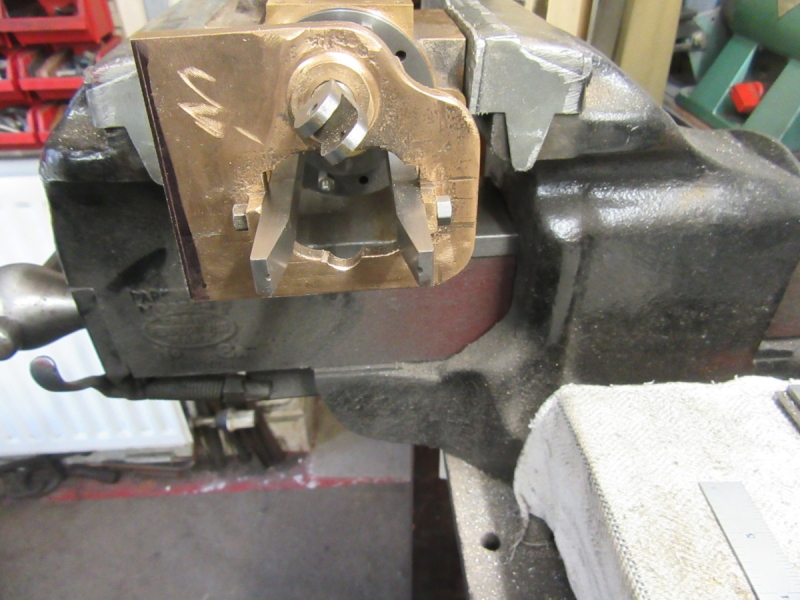

It was after 08:00 when I got in the shed, Friday is a busy day! Today's job is to end up with an accurate base plate and a clean piece of brass angle for the valve guide casting. It's handy if you can trust the top of the vise jaw to be parallel with the bed. Always a good plan to get a high end vise, the cheap Chinese ones will always let you down in the end! Some careful cuts and I soon had two parallel sides.

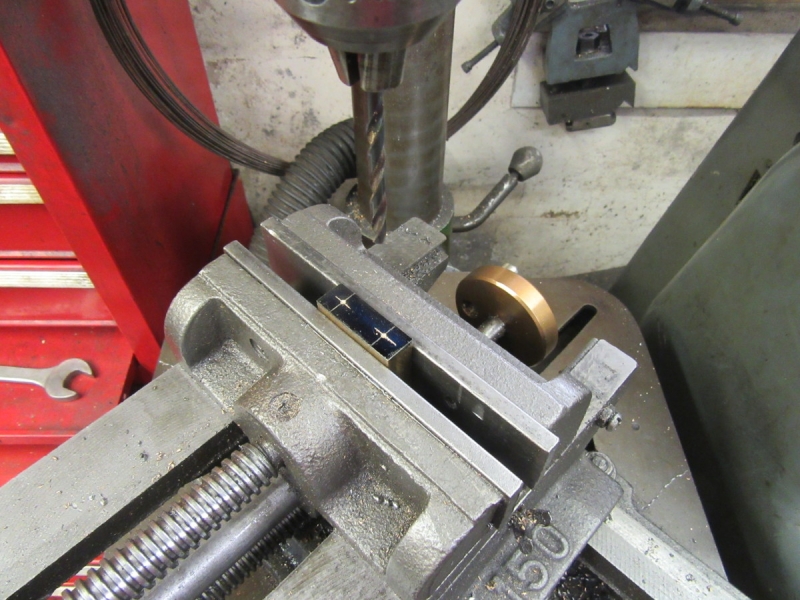

I was lucky with the ends, the vise just opened far enough to get the plate in on two parallels so cutting them square was easy.

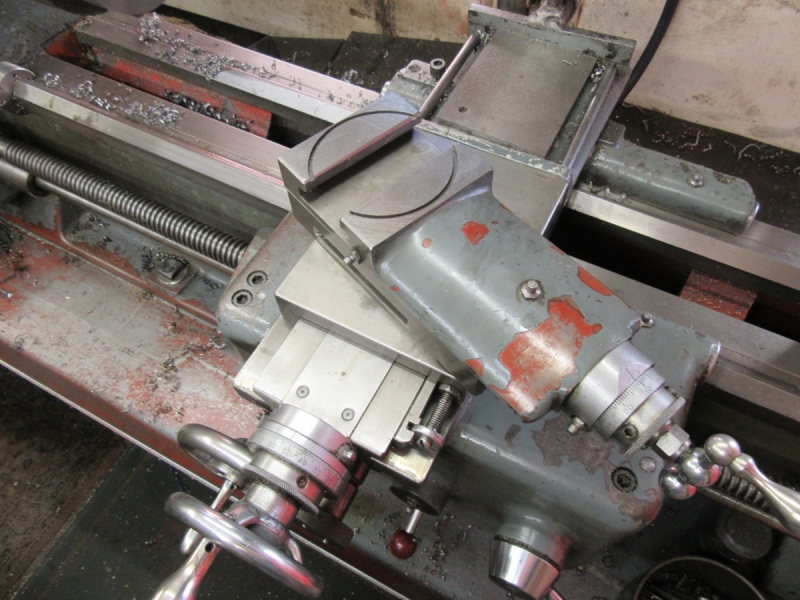

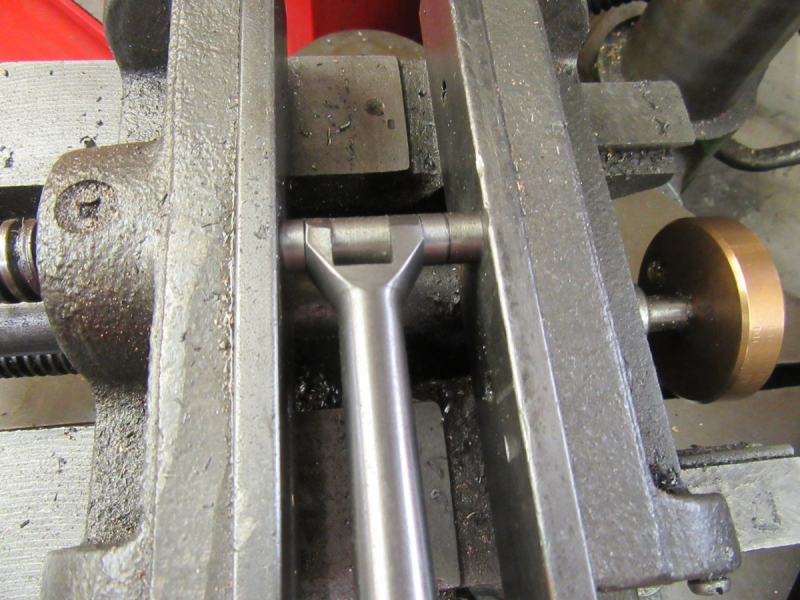

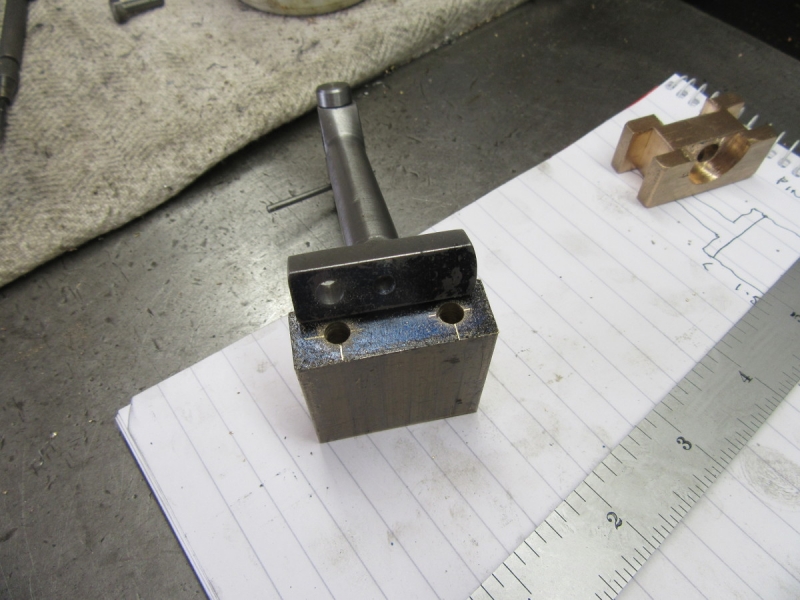

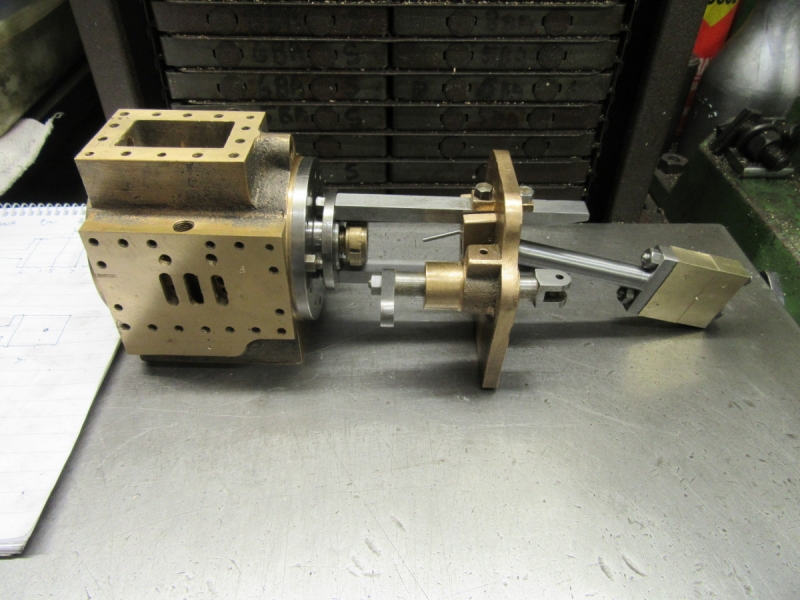

Cutting the web off the angle was easy. Just set it up and cut the corner out with one pass.

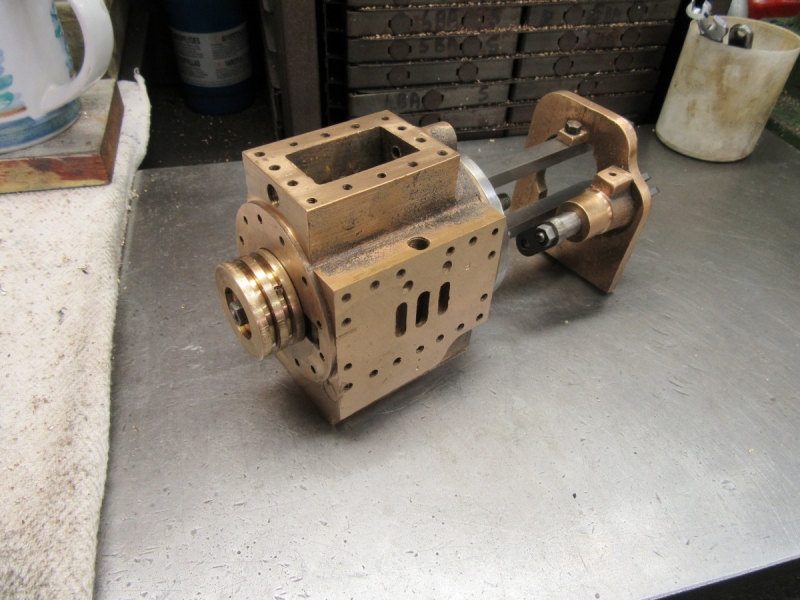

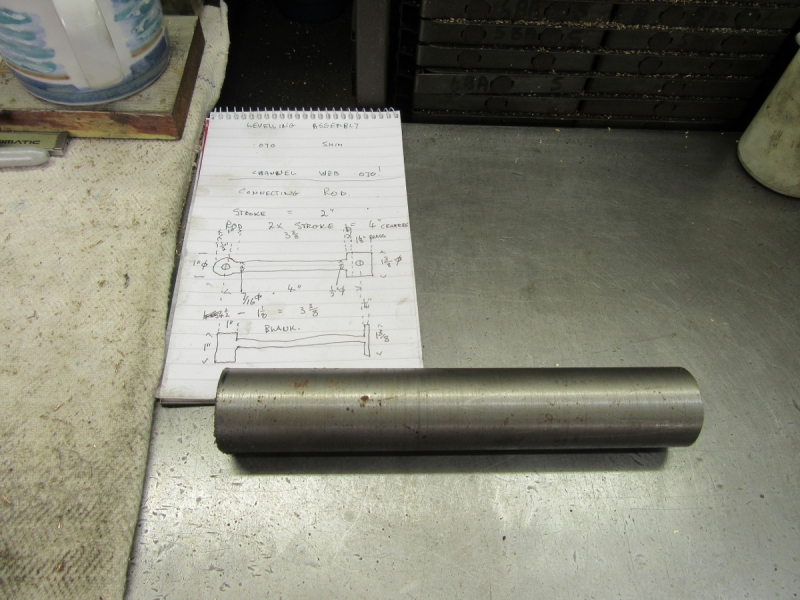

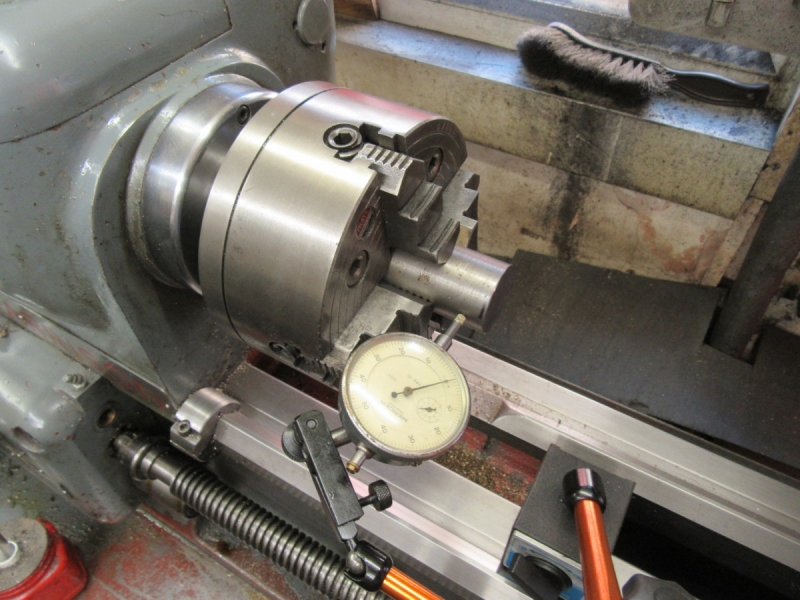

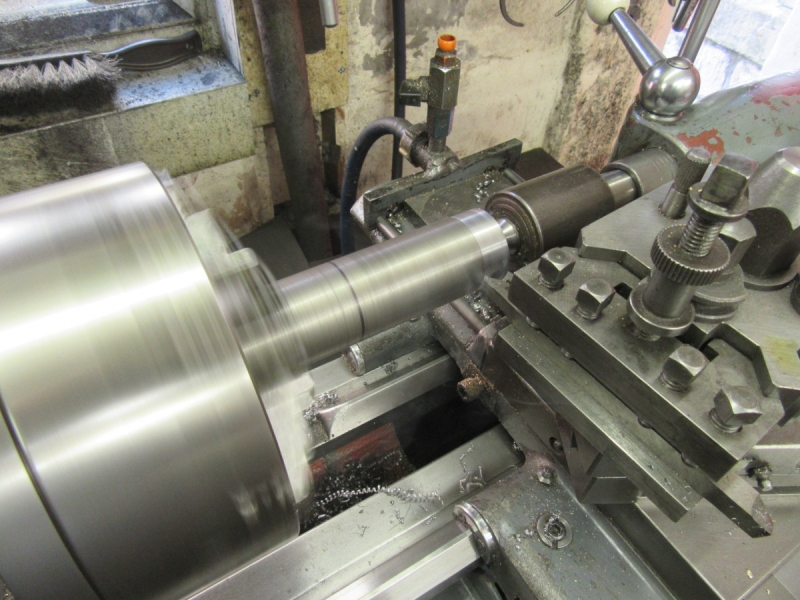

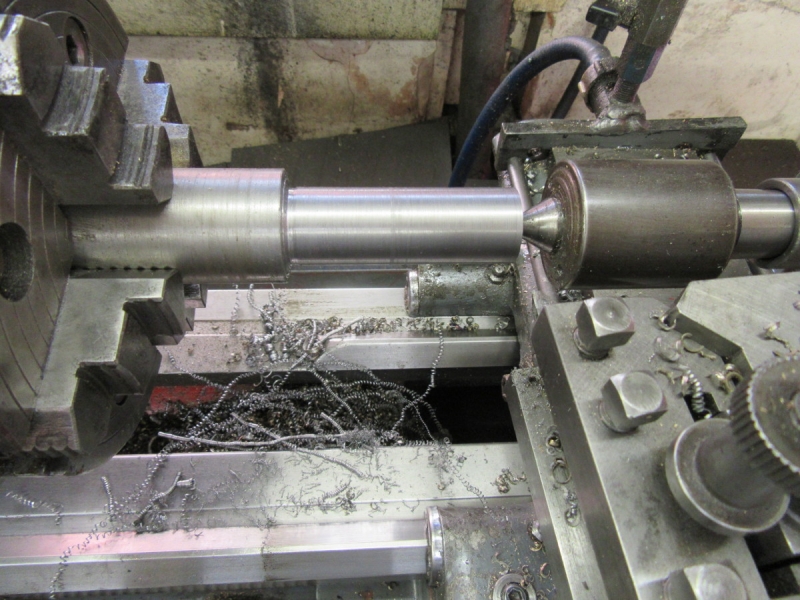

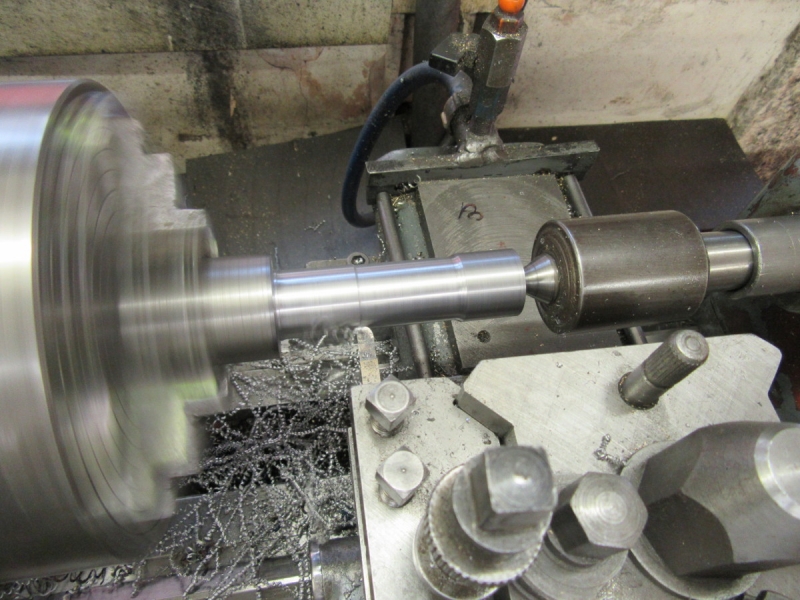

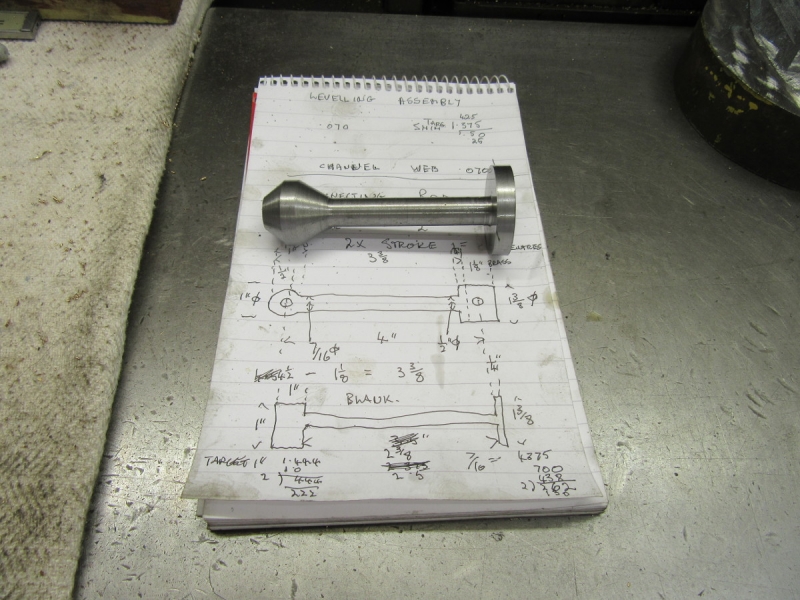

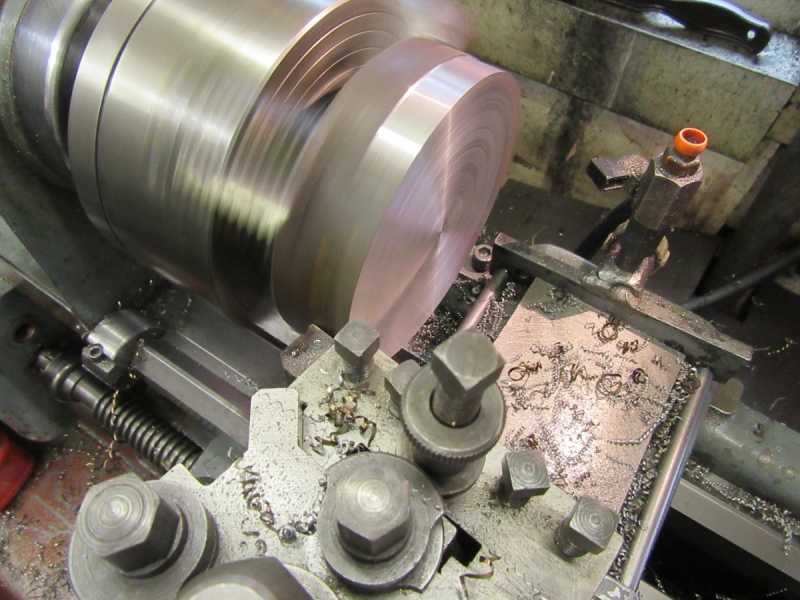

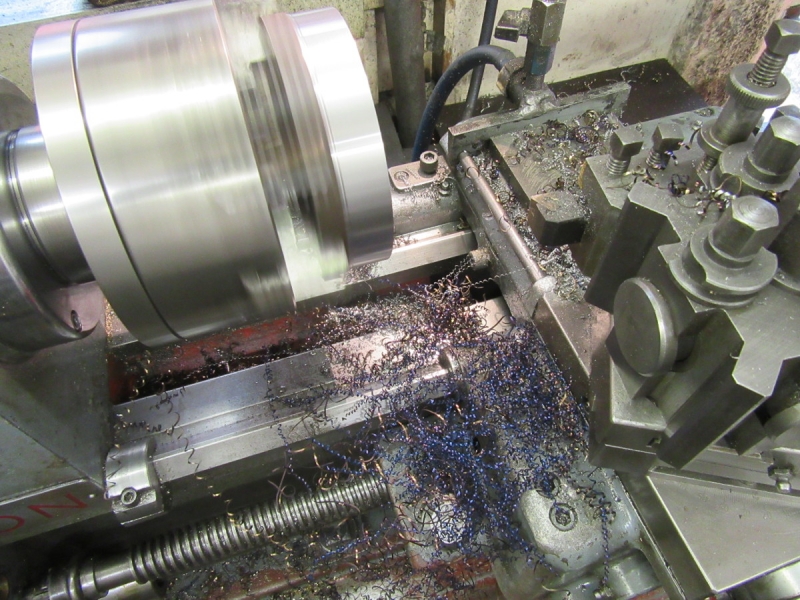

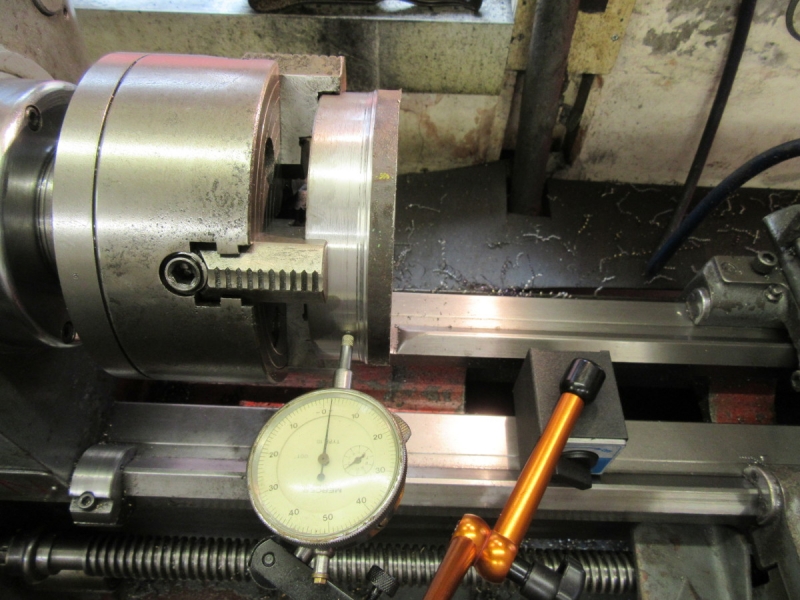

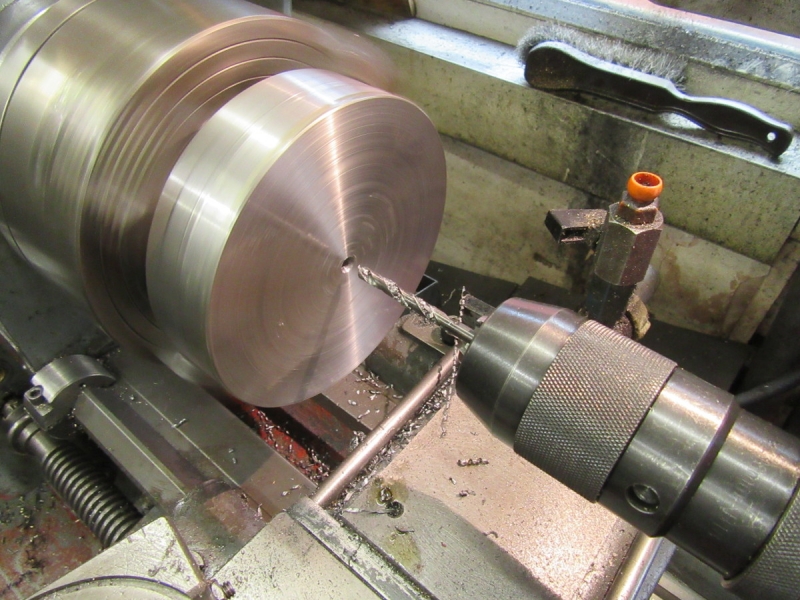

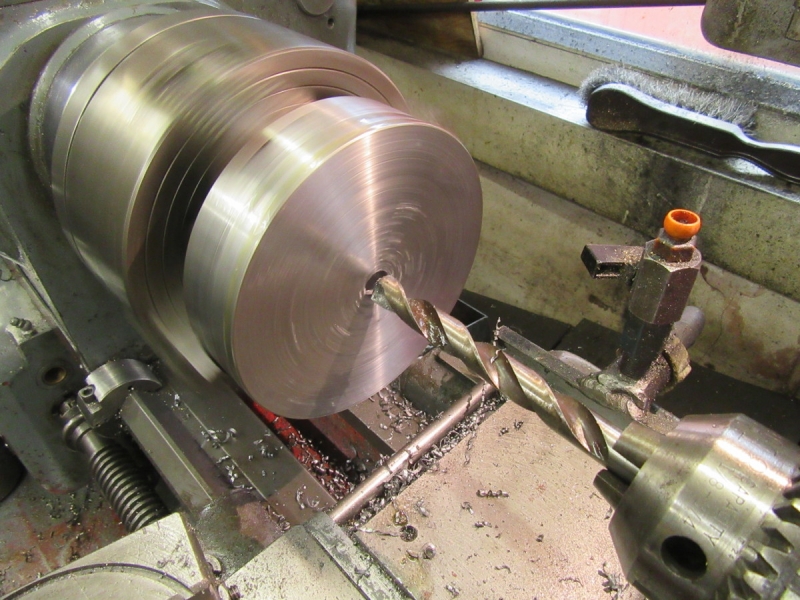

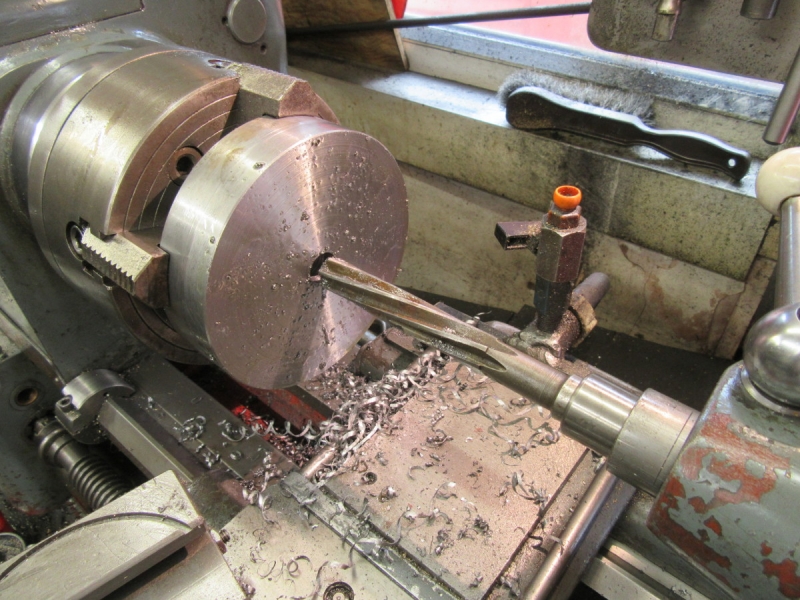

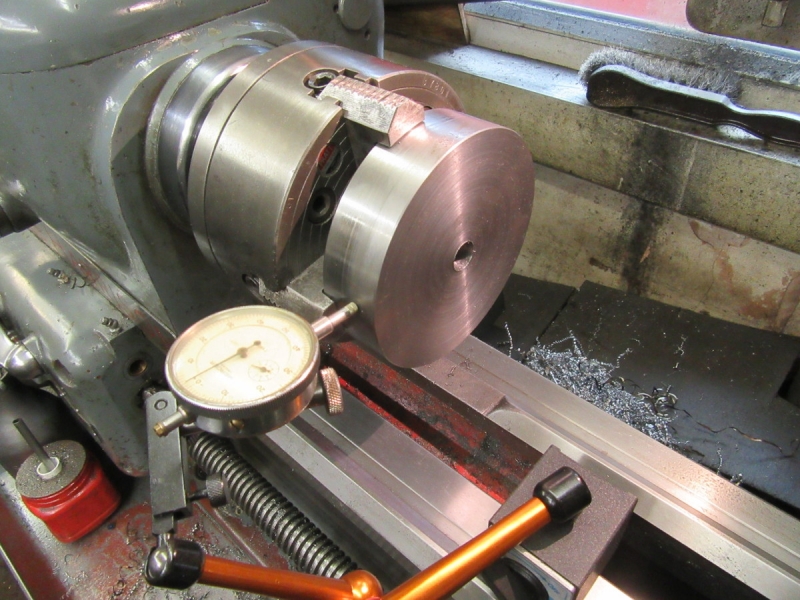

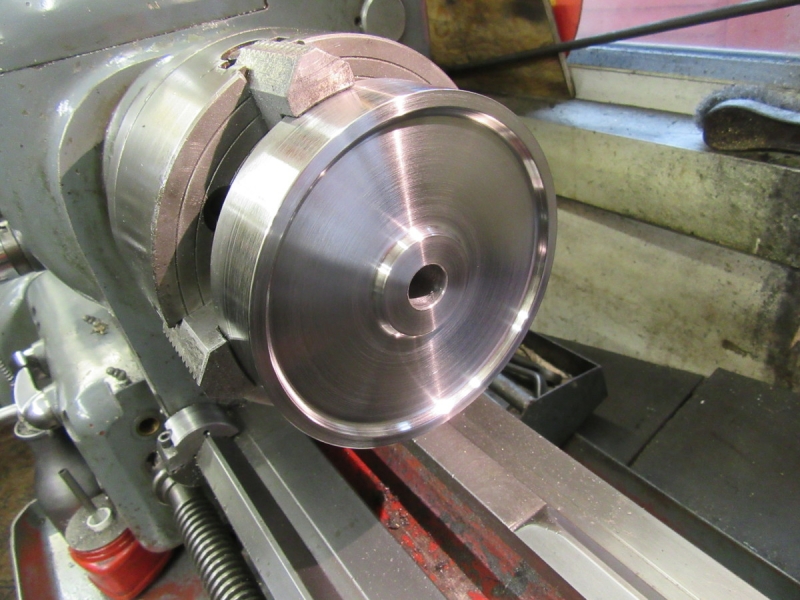

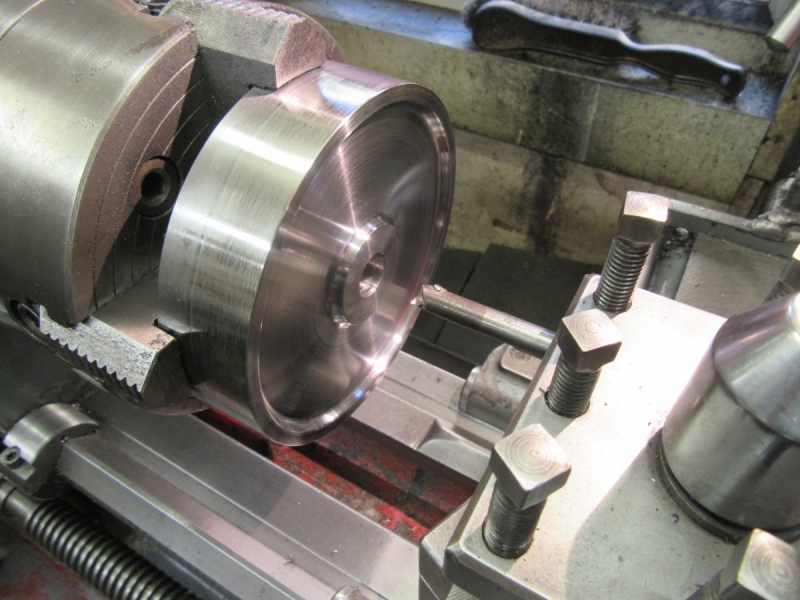

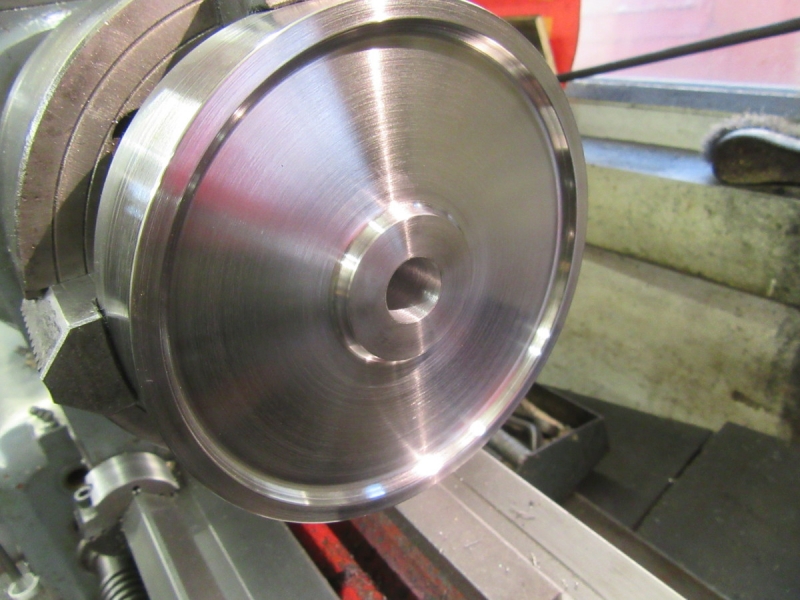

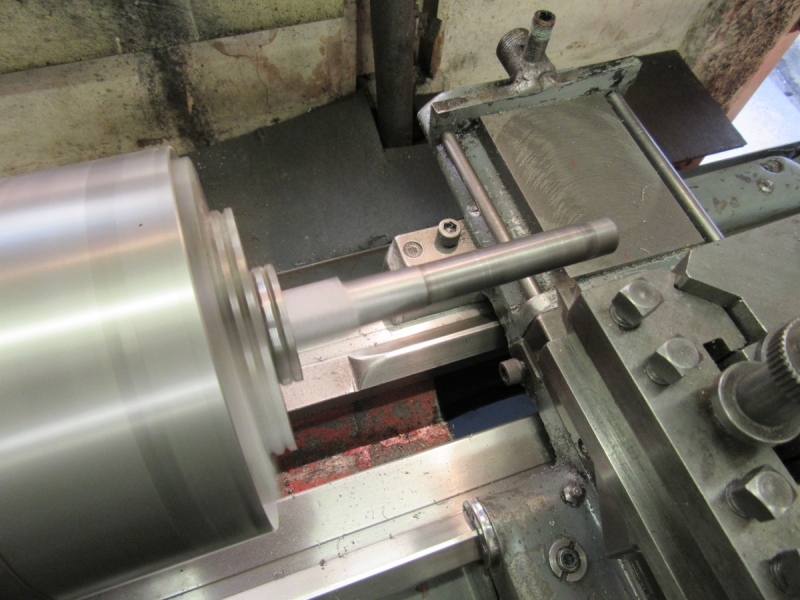

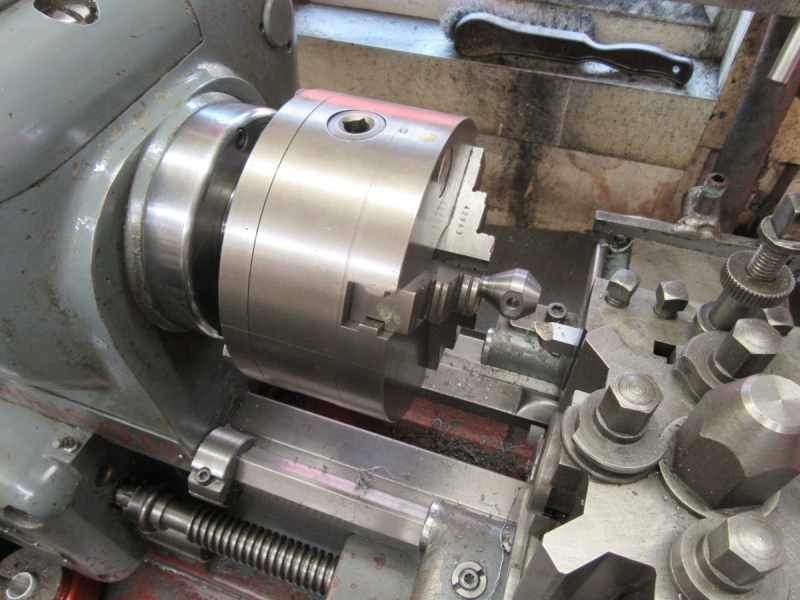

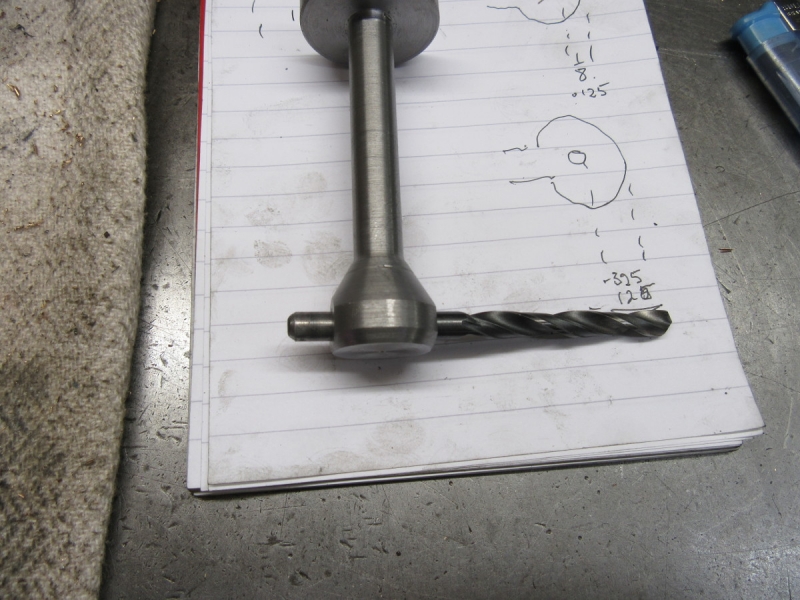

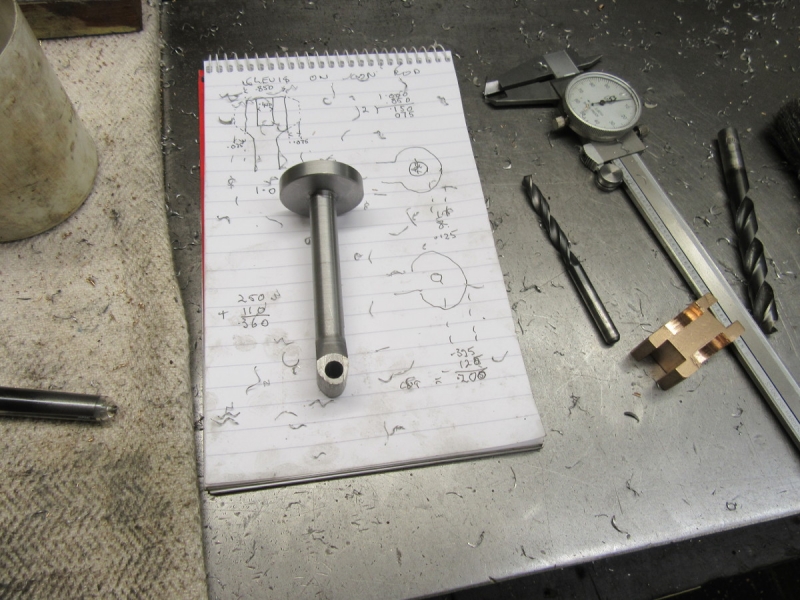

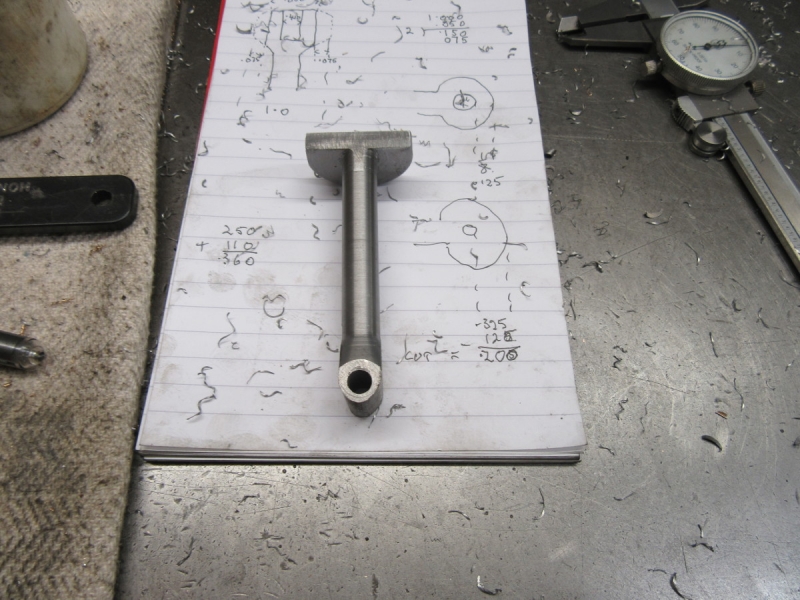

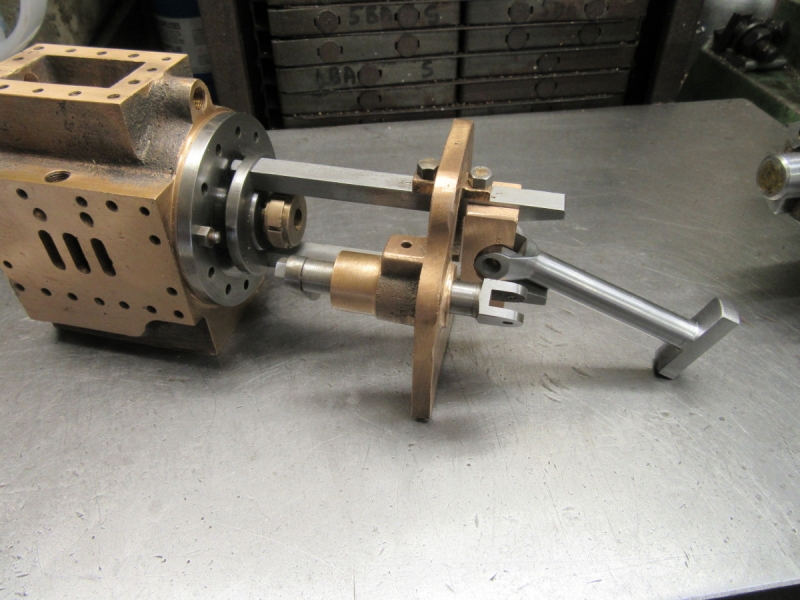

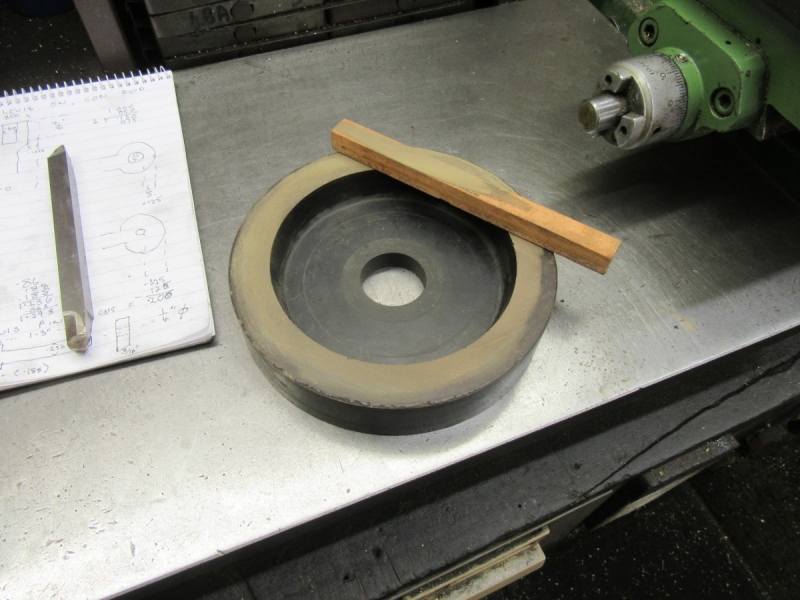

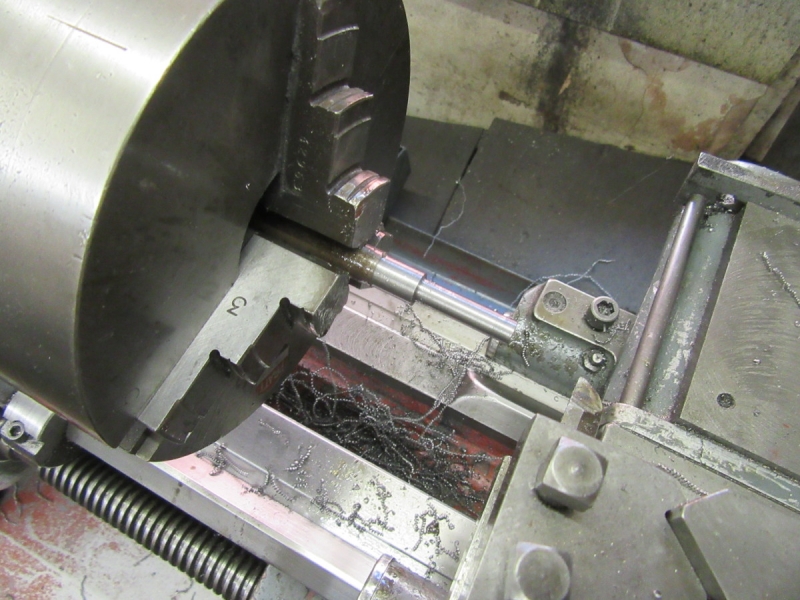

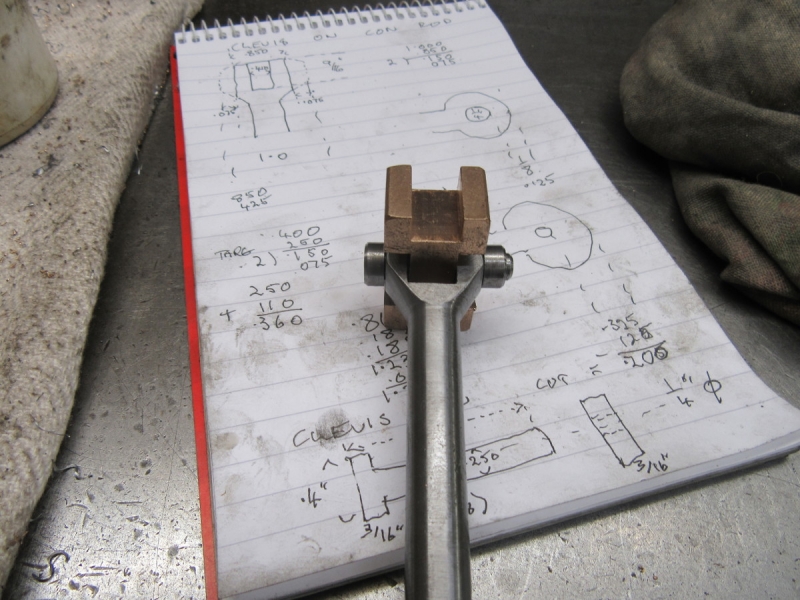

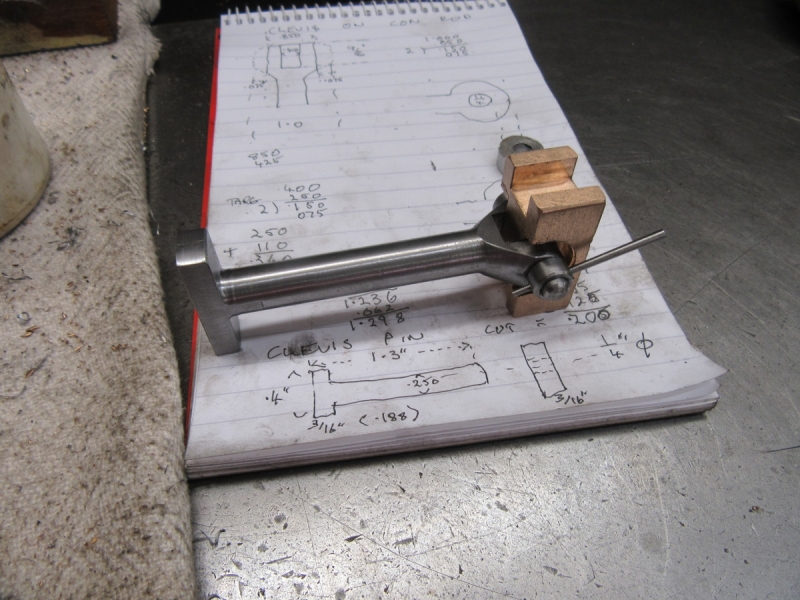

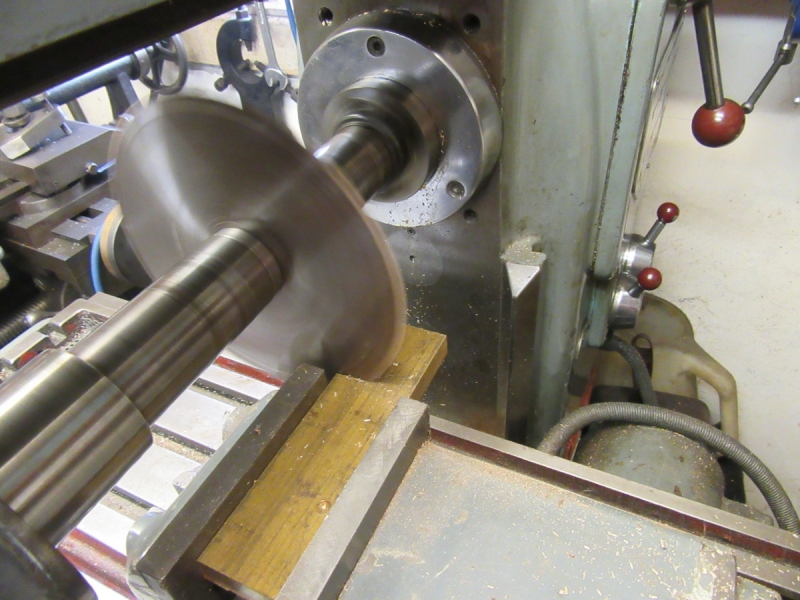

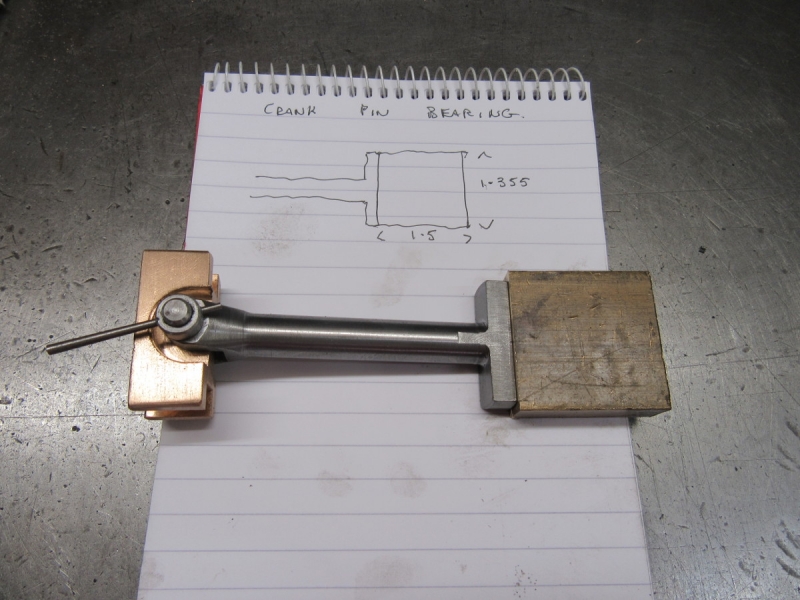

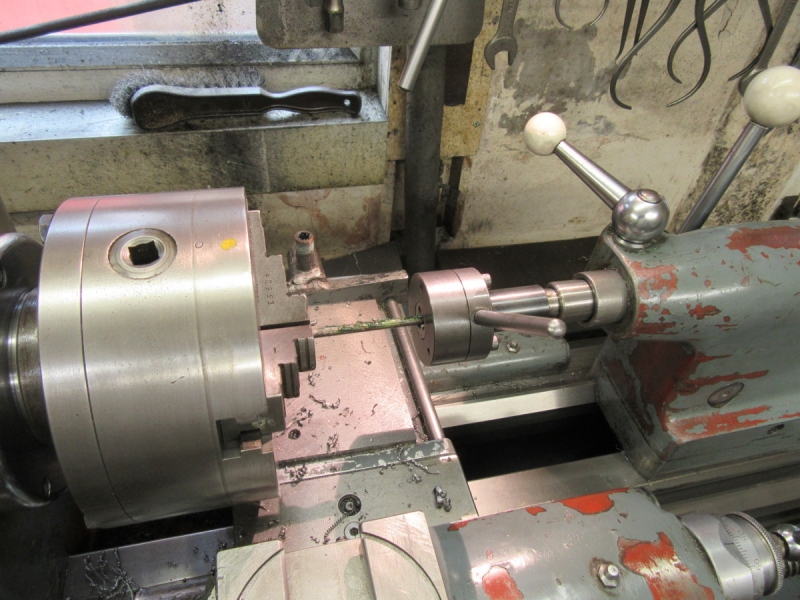

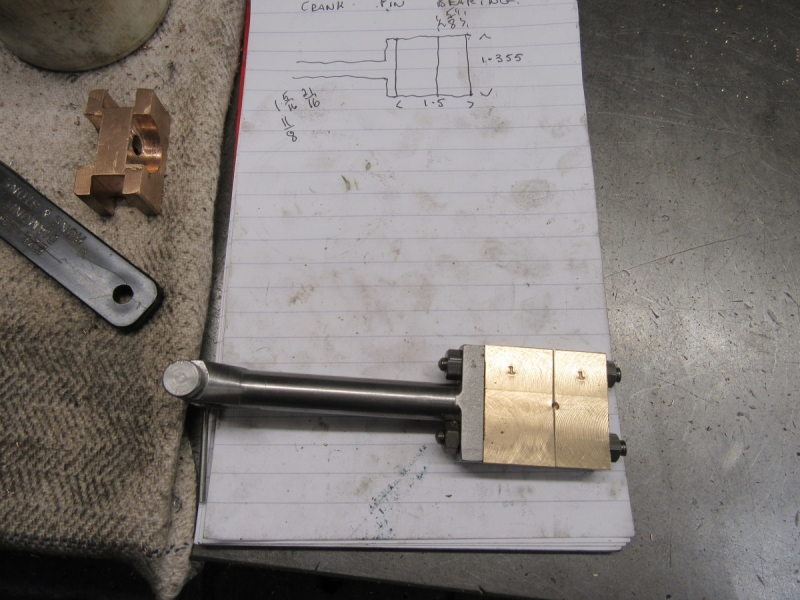

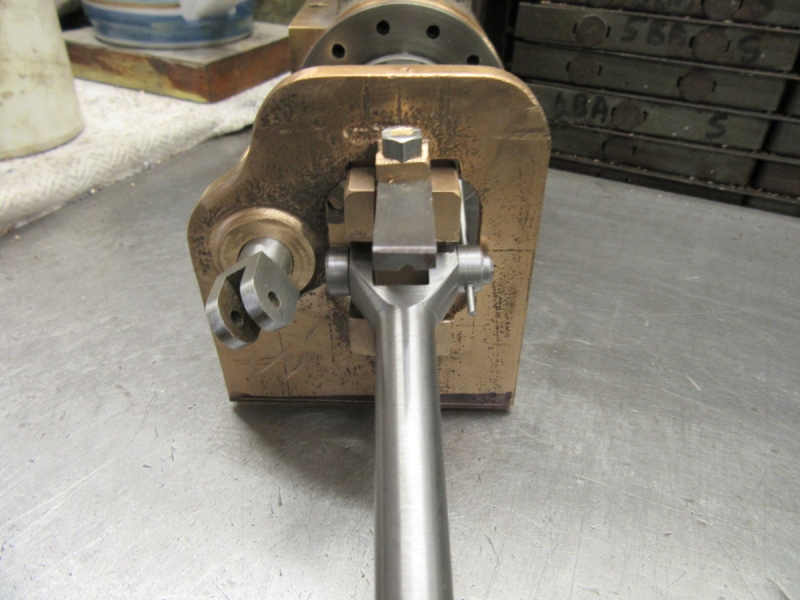

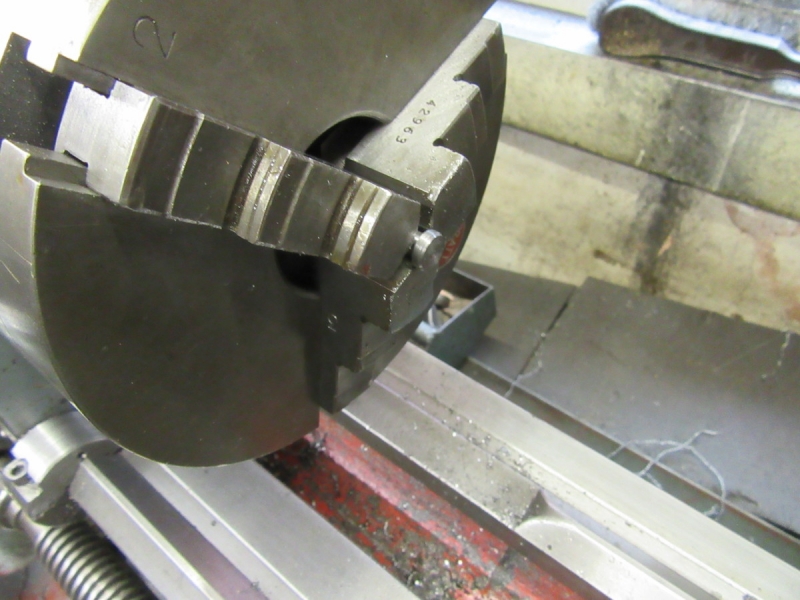

Break all the edges with a smooth file and then set the two pieces on one side. My next move is going to be some proper turning, I need a con rod, valve rod, eccentric, flywheel and shaft. Once I have them I can make decisions about the bed and this influences the fastening of the base we have made this morning.

One last job, have a chip chase and vacuum the floor so that I have a clear start. Not a big stint but good progress..... A good morning.