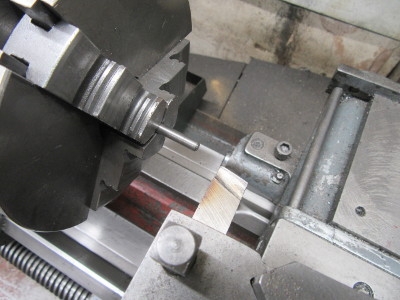

Unusually I did a bit of shed at midday today. I am at the point where I will need the base in order to start the final build. I need daylight for that as it has to be done outside and as it was dry I decided to do it today. The first job was to set the chop saw up and cut myself a piece of oak.

Then, and I hate this tool, it frightens me!, I cut the shape of the moulding round the outside of the base. Sanding and varnishing can be done during the hours of darkness!

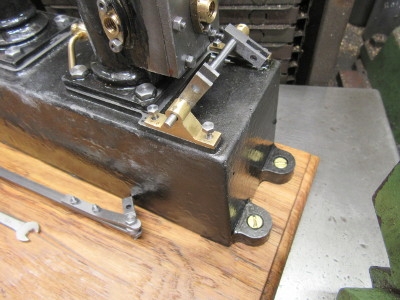

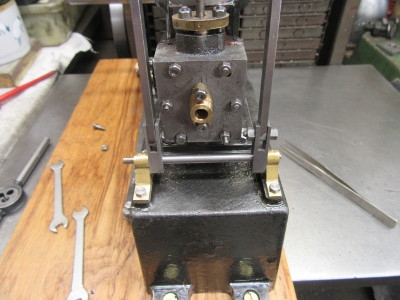

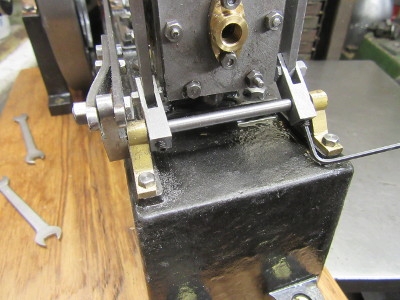

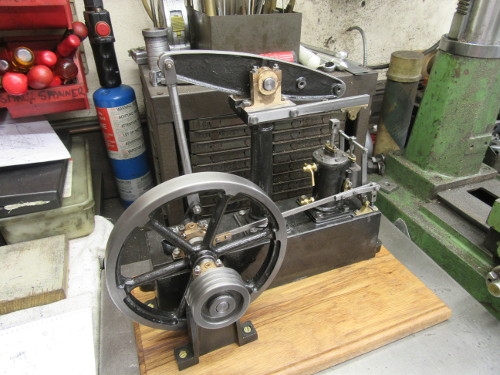

Here's where I finished up before I had a sweep up and tried to get rid of the sawdust!