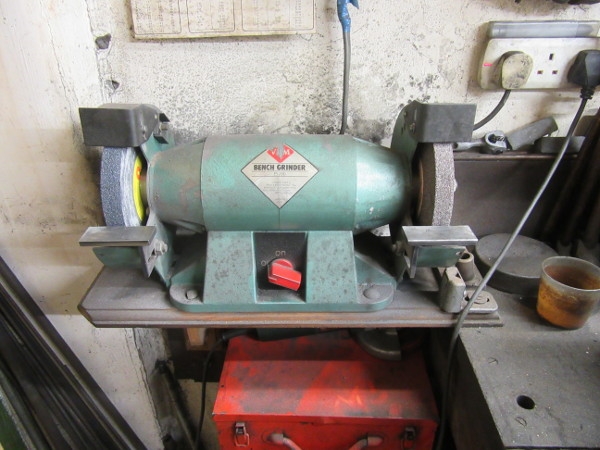

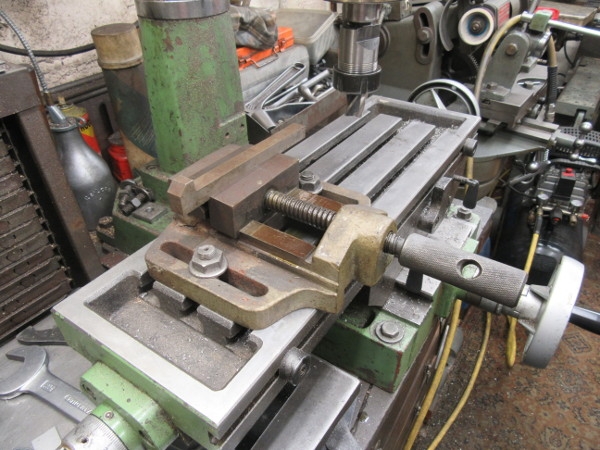

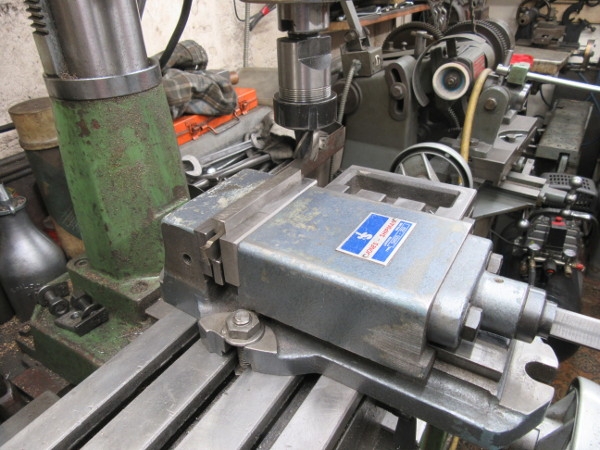

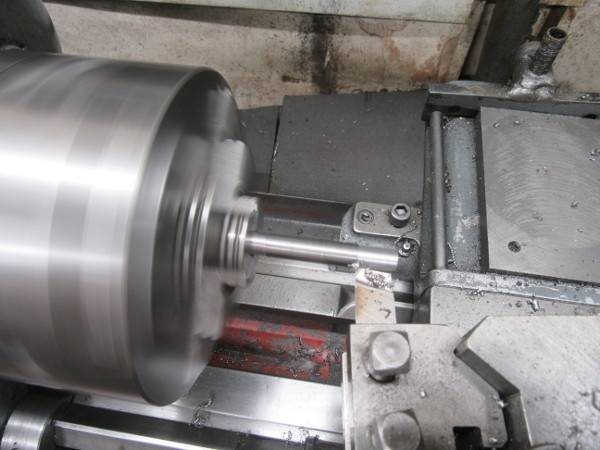

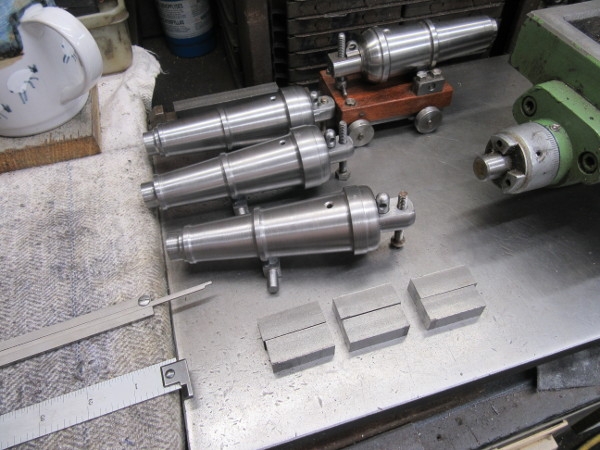

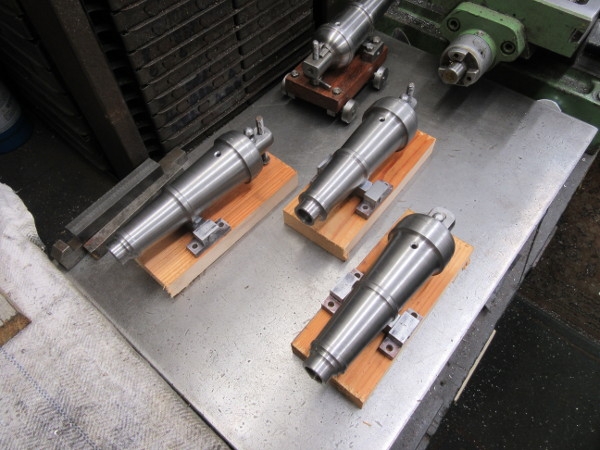

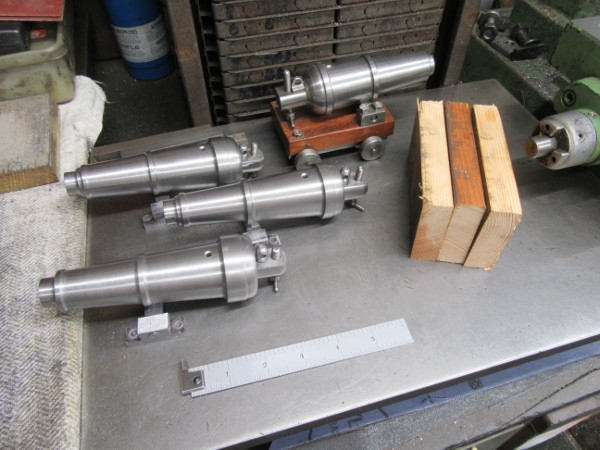

These three pics tell you what I've been doing this morning. I had decided to b ring this 5" Burgess grinder back into use after reaching the conclusion that the problems with the big 8" grinder are beyond me. I have tried everything I know and it is still out of balance.

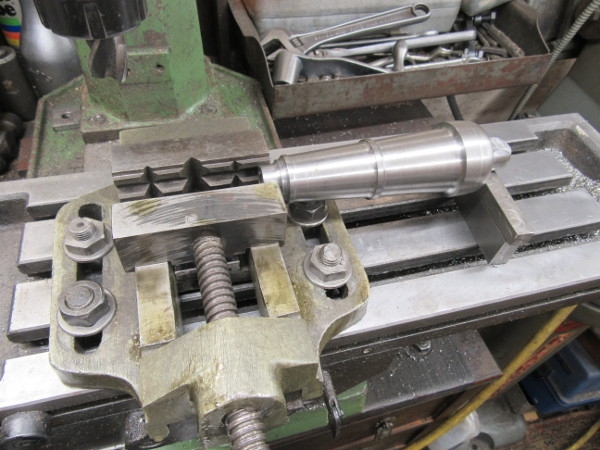

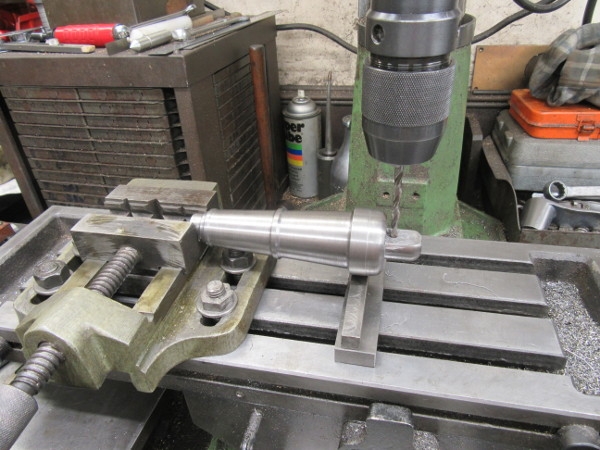

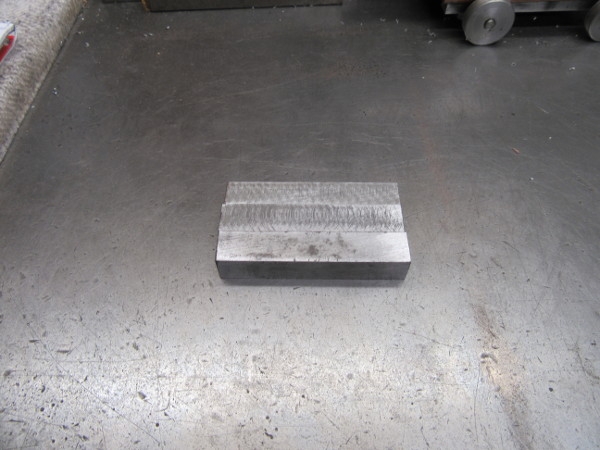

You might wonder why I had stripped all the shrouding off it. This was because I was using as a grinding head I could mount on the horizontal mill table and use it to sharpen the wheel in my circular saw which has carbide inserts. I did that successfully and never brought the grinder back to general use. however, I put all the shrouding and fitting screws in a corner of the shed and never forgot where they were. This morning I got them out and reinstated them on the Burgess grinder. I only used the green grit wheel from the new wheels I got because the ordinary grey grit wheel for steel is in good condition. The fact that Abtec only sent bushes to convert one wheel to 1/2" was also a factor! So I used the bushes in the green grit wheel as the original was badly out of shape because I dressed it to a shape that fitted the carbide tipped wheel I was sharpening. (I've mailed Abtec and asked them for the conversion bushes for the other wheel.)

Tomorrow I shall take the big grinder out of the shed and reinstate the 5" grinder. If I find the need for a bigger grinder I shall consider getting another but I shall have to be sure it doesn't vibrate.... (I remember that the one I have was remarkably cheap, probably something to do with the vibration.)