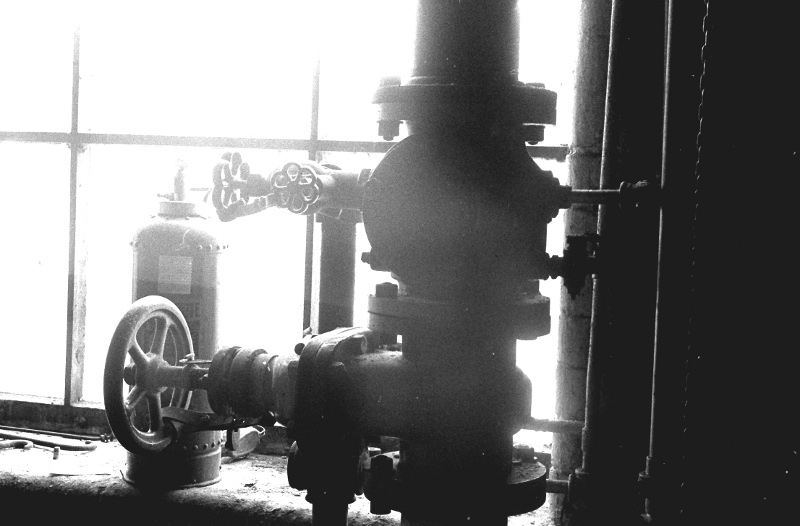

One of the improvements was the replacing of the small rope drives which drove the recirculation pumps on the four largest bearings, those on the flywheel shaft and the second motion shaft. I had watched Kenyon's rope splicers making three new driving ropes for the governor which were original and were slipping slightly affecting the accuracy of the governor and decided I could splice my own for the lubricators. They had to be done in situ because you can't lift the shafts to slip a ready made rope on to them! It was far harder that I thought and it took me a few attempts to get a satisfactory result.

John and I improved the feed to the boiler beyond all recognition by installing an extra, very large capacity three ram feed pump running at slow speed. That was a big job. Newton's fitters actually installed the pump but John and I did everything else. The biggest physical task was carrying the concrete for the bed into the cellar in two gallon buckets. We were glad when that was done!

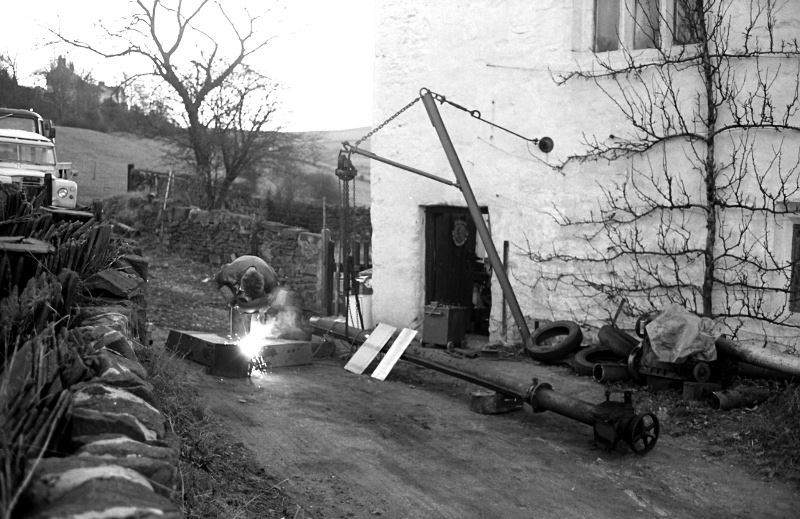

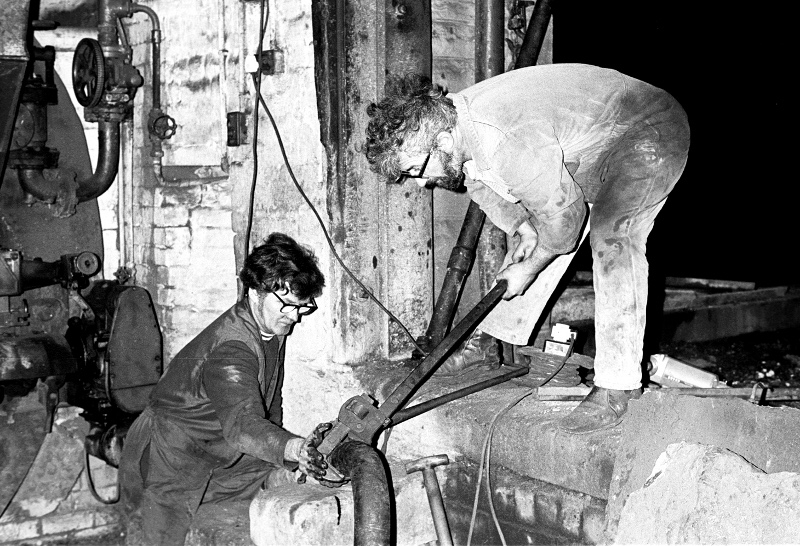

One of the elements essential to maintaining the boiler was to blow down a small quantity of water every morning before starting firing as during the night dissolved scale would settle at the front of the boiler under the still conditions and a small blast of the blow-down valve would get it out of the boiler. John did this early one morning and the external blow-down pipe fractured. He shut off and we carried on but during the day I robbed some redundant 4" pipe out of the system and when we stopped that night we replaced the corroded pipe with serviceable second hand pipe.

It took us about seven hours to complete the job and we earned our overtime!

There was an interesting sequel to this job. I was snoozing in my armchair the next day in the engine house when someone shook me to wake me up. I opened my eyes and there was our Mr Birtles the managing director. He wasn’t a happy bunny, he had found both me and John asleep in our chairs and told me in no uncertain terms that he didn’t pay us for sleeping. I asked him to have a look at the pressure gauge and tell me what we were running at. He reported 140psi on the button. I said that in that case he shouldn’t worry about the firebeater because as long as he was asleep he wasn’t burning coal. The engine was plonking away smoothly at 69rpm and I knew that the weavers were having a good day because it wasn’t long before I had been for a walk round. As for me being asleep, he knew fine that the least variation in the engine would get me on my feet. I pointed out that what he didn’t know, because we hadn’t made a song and dance about it, was that John and I had been working until 2am that day repairing a burst blow down main. I think he got the message, he went away and left us alone.