The museum's loss and Mo's gain. Nice to hear that the history of them will be retained.

STEAM ENGINES AND WATERWHEELS

Re: STEAM ENGINES AND WATERWHEELS

Re: STEAM ENGINES AND WATERWHEELS

A nice rebuild for Agnes

http://www.markhamgrangesteammuseum.co.uk/agnes.html

http://www.markhamgrangesteammuseum.co.uk/agnes.html

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: STEAM ENGINES AND WATERWHEELS

That's why I have written about them and put it on the web China!

Nice clip of Agnes Bodge. It was one of Newton's engines. I went there to have a look at a boiler they had for sale when I worked for John Ingoe and the owner took me in the engine house to see the engine and the retired engine tenter who looked after it and ran it occasionally. He showed me round and explained everything to me and after a while dried up, looked at me and said "You're Stanley Graham aren't you....." I confessed and he was a bit miffed, he felt a bit of a fool. I reassured him that the only reason I had kept quiet and let him go on was because I was in his kingdom and thought I might learn something. The last thing I wanted to do was belittle him. He realised I was trying to be nice to him and was OK. They looked after the engine well.

Nice clip of Agnes Bodge. It was one of Newton's engines. I went there to have a look at a boiler they had for sale when I worked for John Ingoe and the owner took me in the engine house to see the engine and the retired engine tenter who looked after it and ran it occasionally. He showed me round and explained everything to me and after a while dried up, looked at me and said "You're Stanley Graham aren't you....." I confessed and he was a bit miffed, he felt a bit of a fool. I reassured him that the only reason I had kept quiet and let him go on was because I was in his kingdom and thought I might learn something. The last thing I wanted to do was belittle him. He realised I was trying to be nice to him and was OK. They looked after the engine well.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: STEAM ENGINES AND WATERWHEELS

There are over a hundred of you logging in every day so I can't leave you hanging in mid air! So I have decided to tell you something about Rochdale Welding as it's all related. Mind you, it would make things a lot easier for me if you all registered on the site (dead easy and safe) and asked questions. Simples!!

ROCHDALE ELECTRIC WELDING

I have an idea you might get a flavour of how things improved after 1993 by the subjects we cover in this chapter. We can have a rest from weighty philosophical matters and get down to some straight engineering.

John Ingoe and Rochdale Electric Welding (REW) are going to figure largely from here on. I first got to know John and his father Matt at Bancroft Shed in Barlick. They were my boiler-repairers during the time when I was the mill engineer running the steam engine. In 1993 John gave me a job when nobody else would look at me because I was too old (57), were they ever wrong! At that time John’s shop was on Bridgefield Street in Rochdale. It was a large building with plenty of head room and the advantage of a five ton overhead crane. I have always liked sky hooks and this was a Rolls Royce. You could reach any part of the floor and it made shifting heavy weights easy. The workshop had a large roller shutter at one end, a good concrete floor and access to a yard outside. We could handle anything up to a sixty ton boiler with relative ease and were never stumped when it came to moving things around in the shop. The crane was de-rated from ten tons capacity for insurance purposes but would still lift far beyond its design capacity. Handy!

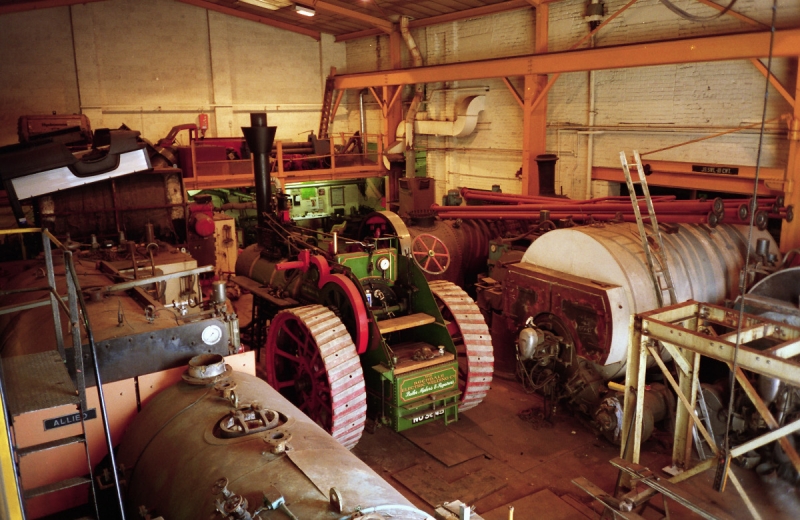

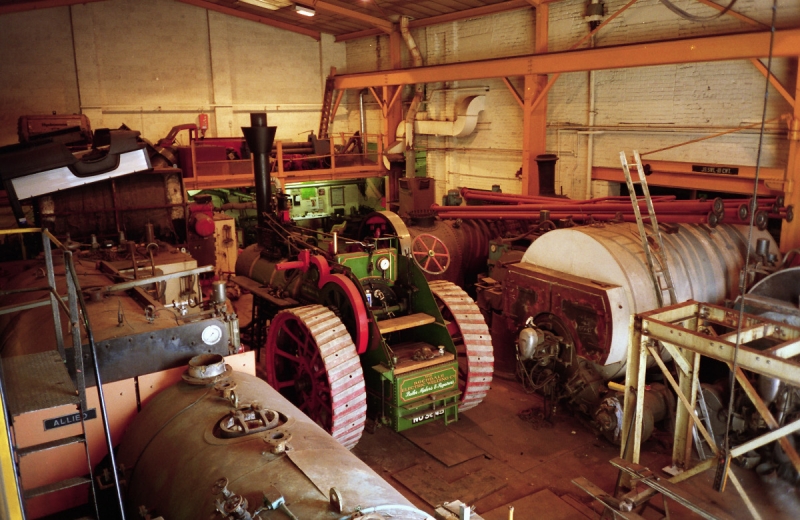

Inside the REW shop in 1996. There are eight industrial boilers, one loco boiler and a traction engine. Note the boiler plate laid on the floor, the bending rolls on the mezzanine and the track for the overhead crane. Every inch of space used.

Being at heart an historian I knew that there was a connection between Bridgefield Street and boiler insurance long before REW was founded. In 1854 a man called Williamson owned Bridgefield Mill and in September of that year the boiler exploded killing 10 workers, one of whom was the engineer, William Taylor. At the subsequent inquest, William Fairbairn, the Manchester engineer who perfected the Lancashire boiler, was called as an expert witness and in the course of his investigations found that the cause of the disaster was that Taylor, knowing the engine was always short of steam, had placed weights on the safety valve to raise the pressure. Normally the boiler never reached this pressure as demand kept the pressure down but on the morning in question the engine had stopped unexpectedly, while the plant was idle pressure rose and the boiler burst.

The Bridgefield Mill explosion finally convinced Fairbairn that boilers had to be better supervised in the interests of profit and safety. On the 19th of September 1854 the Mayor of Manchester called a meeting in his Parlour at Manchester Town Hall with some of the of the most eminent engineers and manufacturers in Manchester and they formed the Manchester Steam Users Association which heralded the birth of the great engineering insurance companies that are still supervising boilers to this day. All industrial boilers in the UK have to be inspected annually and given a full survey every ten years in this country to this day (2010) and are much safer.

ROCHDALE ELECTRIC WELDING

I have an idea you might get a flavour of how things improved after 1993 by the subjects we cover in this chapter. We can have a rest from weighty philosophical matters and get down to some straight engineering.

John Ingoe and Rochdale Electric Welding (REW) are going to figure largely from here on. I first got to know John and his father Matt at Bancroft Shed in Barlick. They were my boiler-repairers during the time when I was the mill engineer running the steam engine. In 1993 John gave me a job when nobody else would look at me because I was too old (57), were they ever wrong! At that time John’s shop was on Bridgefield Street in Rochdale. It was a large building with plenty of head room and the advantage of a five ton overhead crane. I have always liked sky hooks and this was a Rolls Royce. You could reach any part of the floor and it made shifting heavy weights easy. The workshop had a large roller shutter at one end, a good concrete floor and access to a yard outside. We could handle anything up to a sixty ton boiler with relative ease and were never stumped when it came to moving things around in the shop. The crane was de-rated from ten tons capacity for insurance purposes but would still lift far beyond its design capacity. Handy!

Inside the REW shop in 1996. There are eight industrial boilers, one loco boiler and a traction engine. Note the boiler plate laid on the floor, the bending rolls on the mezzanine and the track for the overhead crane. Every inch of space used.

Being at heart an historian I knew that there was a connection between Bridgefield Street and boiler insurance long before REW was founded. In 1854 a man called Williamson owned Bridgefield Mill and in September of that year the boiler exploded killing 10 workers, one of whom was the engineer, William Taylor. At the subsequent inquest, William Fairbairn, the Manchester engineer who perfected the Lancashire boiler, was called as an expert witness and in the course of his investigations found that the cause of the disaster was that Taylor, knowing the engine was always short of steam, had placed weights on the safety valve to raise the pressure. Normally the boiler never reached this pressure as demand kept the pressure down but on the morning in question the engine had stopped unexpectedly, while the plant was idle pressure rose and the boiler burst.

The Bridgefield Mill explosion finally convinced Fairbairn that boilers had to be better supervised in the interests of profit and safety. On the 19th of September 1854 the Mayor of Manchester called a meeting in his Parlour at Manchester Town Hall with some of the of the most eminent engineers and manufacturers in Manchester and they formed the Manchester Steam Users Association which heralded the birth of the great engineering insurance companies that are still supervising boilers to this day. All industrial boilers in the UK have to be inspected annually and given a full survey every ten years in this country to this day (2010) and are much safer.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: STEAM ENGINES AND WATERWHEELS

In 1930 William Ranson Ingoe would come into Rochdale via Whitworth and this view in 1979 is what he would have seen. Plenty of work! Every chimney was an opportunity.

John Ingoe’s grandfather, William Ranson Ingoe came to Rochdale from South Shields where he had been working in the ship repair industry, he chose the area because of the number of factory chimneys! As Newton Pickles was to say later, there was a boiler at the bottom of every one of them. He was an advocate of the relatively new process of electric arc welding, hence the name of the company, and set up business in 1930 to carry out heavy boiler repairs and fabrication. John thinks they were the first firm in the Manchester area to rely solely on electric arc welding. In 1993 when I went to REW, John’s father Matthew was still head of the firm but John was running the business which was just the same as in 1930, heavy boiler repair and all types of steam fitting. Matt died in 1995 aged 76 and the thing I remember about the funeral was that all his men turned up in their dark suits to show respect. Very Victorian and just as Matt would have wanted it.

Apart from the usual hand tools and welding equipment, the shop in Bridgefield Street had a good radial drill, bending rolls and, shortly after I started there, the advantage of our own live-in tinsmith, Les Burrell, on the mezzanine with a guillotine and a bending machine, he rented the space from John and was a godsend. I decided shortly after I started that John needed a lathe as well and sold him my Wilson which I got from Newton Pickles when Henry Brown Sons and Pickles went out of business but had no room for at East Hill Street. We installed it in a corner of the shop, John complained that they had never had any use for a lathe and over the next few years I made him thousands of pounds with it refurbishing valves.

I had moved my workshop from Bacup to East Hill Street and installed it in what used to be the back kitchen. This was centrally heated like the rest of the house so I had the best equipped workshop in Barlick and no rust problems, Newton was very envious! (This is my old mate Newton Pickles who taught me all I know about steam engines and turning.) Come to think, it wouldn’t be a bad idea to tell you what was in there. I had a Harrison nine inch lathe, a Harrison horizontal milling machine, a vertical miller, a drill press, a Clarkson tool and cutter grinder, Johnny Pickles’s big ornamental lathe and all the usual vices, surface plates and hand tools. In short, I could make anything I needed, size was the only restriction.

When I first started at REW there was no permanence, I went there to tidy the place up, get some order into the spares and generally look after the shop. John didn’t really know what I was capable of and his priority was getting the place somewhere near straight. There was one item that placed some demands on me from the start. John had bought a semi-derelict steam traction engine from a bloke called Johnson at Banks near Southport and was rebuilding it. The first thing he did was name it ‘Annie’ after his mother. He asked my advice on several matters while he was doing it and I had made him some lubricators and small parts for it in the workshop at home. We’ll deal with this engine first and I’ll get on to the boiler work later.

Annie outside Bridgefield works after we had got her sorted.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: STEAM ENGINES AND WATERWHEELS

TRACTION ENGINES

Until I started bothering with John’s engine I had never really taken any interest in traction and portable engines. I got quite attached to Annie in the end and learned a lot. What John bought was a semi-derelict Davey and Paxman colonial straw-burning engine. Strictly speaking it wasn’t a traction engine but a portable engine that was fitted with gearing so that it could move itself. It was designated a ‘colonial’ because it wasn’t built for this country but for export to the Argentine. The story was that Paxmans got an order for three of these engines, they built one and sent it to Argentina but never got paid for it so they stopped work on ours and it languished in a corner of the shop for years. It was eventually sold as it stood to an estate which used it as a stationary engine for driving barn machinery. It used to be quite common for large farms and estates to have a steam engine for this purpose.

The engine was intended for belt work, driving machinery with a long belt driven by the flywheel on the main shaft. Its primary job was meant to be threshing and it was made with large boiler tubes and a very big firebox so that it could be fired with straw from the threshed sheaves. The boiler was much larger than those for an ordinary engine and it was a very free steamer. All told it was a powerful and useful tool, I once had it on a saw at Harewood House and the sawyer said it was the best engine he’d ever had on the belt.

When John first got the engine it had it’s original front axle and two steel treaded back wheels from a Fowler but no gearing or back axle. There were various other bits missing as well but he started to refurbish it even though he had no drawings. The first time I came into contact with it was while I was doing Ellenroad and John asked me what I thought about the gearing. I liked what he had designed and also his idea that instead of getting the gears cast and gear-cut he would get them burned out of blank plate with a profile cutter. Flame cutting was perfectly acceptable for this sort of gearing. He did this and they were never any trouble. I told him that he had made the shafts for the gears far too close a fit in the bearings but he ignored me and did it his way. I had remembered a story my father once told me about refurbishing Baldwin locomotives when he worked at Armstrong Whitworth’s in Trafford Park Manchester after WW1. He said that they made all the motion bearings a perfect fit and the first time it got to a bend it seized up. The frame of a loco or a traction engine is never perfectly true because of variations in the surface it’s running on and so it’s a good thing to give the bearings some latitude. I later got the chance to do something about this and cured the troubles that it caused.

Over the next couple of years I made him a lubricator for the crank bearing, a new bobbin for the governor valve and various bits and pieces that were needed. I found him a good whistle for it, traction engine rallies demand lots of whistle-blowing! Les Burrell the tinsmith made new lagging for the boiler and John had it all painted up. The end result was a very creditable rebuild. Of course, all the ‘experts’ looked at it when it first went to a rally and said John had got it all wrong! Seeing as how the only other example had sunk without trace and there were no drawings I think John did very well. It still had some faults but he went into his first showing season with a unique and serviceable engine.

The crank brasses had always been a bit suspect and after one trip out in early 1993 John rang me and asked me to come and have a look at the bearing. They had tried to adjust it and got it a bit too tight. Not being used to bronze bearings they thought they could get away with it but of course it expanded, this made it tighter and it melted the brass. John was worried because someone had told him that this meant that the crankshaft would be buggered. I had a look and re-assured him, all it wanted was a new set of brasses properly made and fitted and it would be as good as new. Rather than make patterns and get some castings made I went to see Dick Bonser at the Lily Injector Works in Rochdale who had made all my bronze castings while I was working on Ellenroad and the Whitelees. I got a solid lump of bearing bronze cast and made the new set out of solid.

When I got the old brasses out to measure the journal and get the other particulars I found that they were the wrong ones, they weren’t even a match. Someone had found two odd brasses that were about the right size and they had been made to fit. This time they would be right and there was a big improvement when they were fitted so I went on a rally with John to have a play with the engine.

I think the first rally I went on was the one at Harewood in 1993, I know we won the ‘Golden Bolt’, a prize for the best refurbishment. We were having a problem with the regulator and Annie the engine ran very lumpy but we managed all right and I made a note to have a look at it and improve things. On the second day they asked us if we would drive the circular saw in the afternoon so I trotted off there after dinner, got set up with a good fire going and settled into some serious sawing. This was when the sawyer said we were the best engine he had ever had on the saw, they were cutting wet larch and he said it took a good engine to chuck sawdust up behind the blade. I was very pleased and threw a bit more coal on!

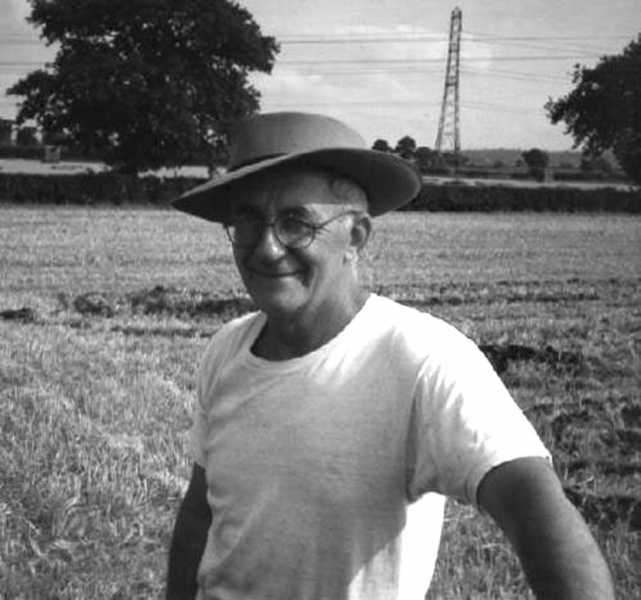

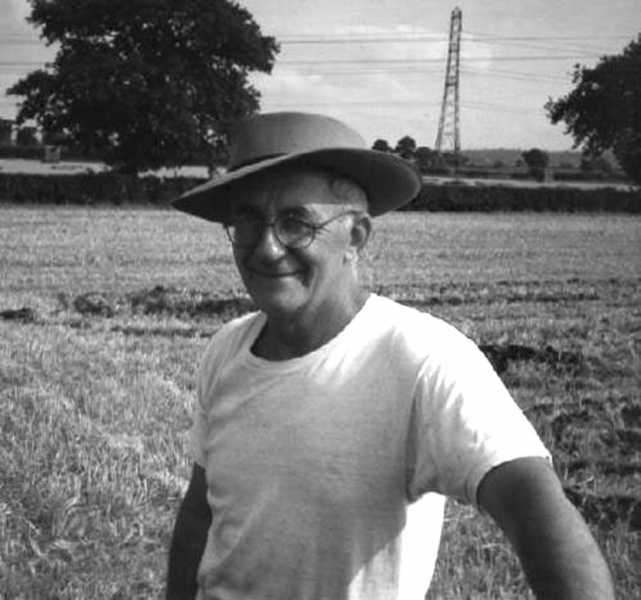

Stanley and Annie doing a good job sawing wet larch in 1993 at Harewood. My luck wasn't going to hold out!

Until I started bothering with John’s engine I had never really taken any interest in traction and portable engines. I got quite attached to Annie in the end and learned a lot. What John bought was a semi-derelict Davey and Paxman colonial straw-burning engine. Strictly speaking it wasn’t a traction engine but a portable engine that was fitted with gearing so that it could move itself. It was designated a ‘colonial’ because it wasn’t built for this country but for export to the Argentine. The story was that Paxmans got an order for three of these engines, they built one and sent it to Argentina but never got paid for it so they stopped work on ours and it languished in a corner of the shop for years. It was eventually sold as it stood to an estate which used it as a stationary engine for driving barn machinery. It used to be quite common for large farms and estates to have a steam engine for this purpose.

The engine was intended for belt work, driving machinery with a long belt driven by the flywheel on the main shaft. Its primary job was meant to be threshing and it was made with large boiler tubes and a very big firebox so that it could be fired with straw from the threshed sheaves. The boiler was much larger than those for an ordinary engine and it was a very free steamer. All told it was a powerful and useful tool, I once had it on a saw at Harewood House and the sawyer said it was the best engine he’d ever had on the belt.

When John first got the engine it had it’s original front axle and two steel treaded back wheels from a Fowler but no gearing or back axle. There were various other bits missing as well but he started to refurbish it even though he had no drawings. The first time I came into contact with it was while I was doing Ellenroad and John asked me what I thought about the gearing. I liked what he had designed and also his idea that instead of getting the gears cast and gear-cut he would get them burned out of blank plate with a profile cutter. Flame cutting was perfectly acceptable for this sort of gearing. He did this and they were never any trouble. I told him that he had made the shafts for the gears far too close a fit in the bearings but he ignored me and did it his way. I had remembered a story my father once told me about refurbishing Baldwin locomotives when he worked at Armstrong Whitworth’s in Trafford Park Manchester after WW1. He said that they made all the motion bearings a perfect fit and the first time it got to a bend it seized up. The frame of a loco or a traction engine is never perfectly true because of variations in the surface it’s running on and so it’s a good thing to give the bearings some latitude. I later got the chance to do something about this and cured the troubles that it caused.

Over the next couple of years I made him a lubricator for the crank bearing, a new bobbin for the governor valve and various bits and pieces that were needed. I found him a good whistle for it, traction engine rallies demand lots of whistle-blowing! Les Burrell the tinsmith made new lagging for the boiler and John had it all painted up. The end result was a very creditable rebuild. Of course, all the ‘experts’ looked at it when it first went to a rally and said John had got it all wrong! Seeing as how the only other example had sunk without trace and there were no drawings I think John did very well. It still had some faults but he went into his first showing season with a unique and serviceable engine.

The crank brasses had always been a bit suspect and after one trip out in early 1993 John rang me and asked me to come and have a look at the bearing. They had tried to adjust it and got it a bit too tight. Not being used to bronze bearings they thought they could get away with it but of course it expanded, this made it tighter and it melted the brass. John was worried because someone had told him that this meant that the crankshaft would be buggered. I had a look and re-assured him, all it wanted was a new set of brasses properly made and fitted and it would be as good as new. Rather than make patterns and get some castings made I went to see Dick Bonser at the Lily Injector Works in Rochdale who had made all my bronze castings while I was working on Ellenroad and the Whitelees. I got a solid lump of bearing bronze cast and made the new set out of solid.

When I got the old brasses out to measure the journal and get the other particulars I found that they were the wrong ones, they weren’t even a match. Someone had found two odd brasses that were about the right size and they had been made to fit. This time they would be right and there was a big improvement when they were fitted so I went on a rally with John to have a play with the engine.

I think the first rally I went on was the one at Harewood in 1993, I know we won the ‘Golden Bolt’, a prize for the best refurbishment. We were having a problem with the regulator and Annie the engine ran very lumpy but we managed all right and I made a note to have a look at it and improve things. On the second day they asked us if we would drive the circular saw in the afternoon so I trotted off there after dinner, got set up with a good fire going and settled into some serious sawing. This was when the sawyer said we were the best engine he had ever had on the saw, they were cutting wet larch and he said it took a good engine to chuck sawdust up behind the blade. I was very pleased and threw a bit more coal on!

Stanley and Annie doing a good job sawing wet larch in 1993 at Harewood. My luck wasn't going to hold out!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: STEAM ENGINES AND WATERWHEELS

All went well for about an hour and then as I bent down to look at the fire my glasses steamed up. I knew straight away something was wrong and had a look at the water level. It had been well up the glass but was dropping, we had blown a tube and water was escaping from the boiler into the firebox. This is every boiler-tenters nightmare and can be very dangerous, I had a big fire, high steam pressure, a leaking tube, falling water and about 150 people round the engine watching it working. Not good news. I called one of the marshalls over and asked him how fast he could run, I sent him off for the water bowser and told him to tell them it was an emergency. I had the feed pump on but couldn’t keep up with the water and couldn’t drop the fire as the ash pan was bolted on. I didn’t want to cry wolf and start a panic so I got the marshalls to move the people round the engine as far away as they could without causing alarm. The bowser arrived and I did what you should never do, I put the fire out with the hose from the pump on the bowser. You have to be very careful doing this because if you get water on any part of the boiler itself you cool the boiler plates down too quickly and this in itself could cause an explosion. I was laid on the footplate directing the water onto the fire bars and there were tremendous clouds of steam which pleased the crowd no end, they evidently thought this was something traction engine folk did regularly! Eventually I got the fire out and we all breathed a sigh of relief as the pressure began to fall. I was still driving the saw as this was the best way to get rid of the pressure and I kept on doing so until we ran out of steam.

We got one of the ploughing engines to winch us back up the hill and left Annie to quietly cool down. I went back with our low loader and driver the day afterwards and we winched her on board and took her back to Rochdale. The tractor was an old Scammel Crusader with a 500hp Detroit Diesel in it and a big winch behind the cab. I say it was ours but I was never sure because it started as John’s, then became the property of Nick Crewe the driver who ran his own haulage business but later still it came back to John who owns it now. It was rough but it was powerful and didn’t know when it was beaten. We were coming back through Pool and standing stationary in a queue of traffic. I noticed out of the passenger window that we were blocking an extremely attractive young lady in an expensive open sports car and so I struck up a conversation with her and apologised. Nick of course had to lean over and see what the attraction was. When he saw her he was knocked out and after we got going again he asked me what it was about her that made her so special. I said dead simple Nick, she’s innocent, never been polluted by the likes of you and me! I’ve never forgotten her and I know that Nick hasn’t either!

When we got Annie back in the shop, Dennis Sterricker one of John’s oldest and most experienced employees and a wonderful craftsman had a look in the firebox and said that it had blown a tube but that could be expanded up tight again. The more serious problem was that a seam in the firebox had opened and a pinhole blown through the throat plate. The bottom line was that it was the first time for years it had worked that hard and I had found the weak points in the boiler. Dennis welded the seams up and repaired the pin-hole, we did a hydraulic test on the boiler and all seemed OK.

Later that winter I was working for John full time and he asked me to go through the engine ready for the annual test and to see whether I could cure the regulator and the lumpy running. I stripped the engine down, ground the regulator seat and made a new tail rod for it. Then I took a lot of the play out of the slide valve so that it stayed on its seat when running on low steam. I took the cylinder cover off and drew the piston out and soon found out why it was running lumpy. I might as well warn you, we’re getting into another episode where Stanley knew more than the makers!

The cylinder had been bored wrong when Paxman’s made the engine. When you bore a steam engine cylinder you should always bore it out bell-mouthed at each end of the stroke. The idea is to have the piston ring just over the end of the bore when it reaches the end of its stroke. The reason for this is that cast iron rings in a cast iron bore will eventually wear the bore. If the leading edge of the piston ring is still within the confines of the bore at the end of the stroke it will eventually wear the bore where it travels but the place where it stops will have a ledge at that point. Normally this doesn’t cause any problems because as the crank brasses wear and are adjusted the piston gradually shortens its stroke and avoids the ledge. I had restored the full stroke when I made the new crank bearing and it was the piston ring hitting the ledge that was causing the lumpy running at low speed. It was the very pronounced ledge in the front end of the cylinder that was causing the trouble so I decided to take it out. Remember that the piston never actually reaches this part of the bore, only the leading edge of the ring so there was no need for a great deal of accuracy. I got a five inch grinder and started to grind the ledge out. Just at this moment John walked through the shop and had a fit when he saw what I was doing! He was convinced for a moment that his mad fitter was destroying his engine! I explained what I was doing and why and he had the sense to leave me alone. I built it all up again and turned it by hand, it was perfect, no obstruction at all. We fired it up later and found that this repair, combined with the adjustment to the valve and the regulator seat had done the trick. It ticked over on low steam like a rice pudding which pleased everyone because the ability to do this is a sign of a well-maintained engine.

Over the next couple of years I chased most of the faults out of the engine and eventually I was almost satisfied with it. We did have one major job though in 1995 when John stripped one of the keys in the gear shaft of the engine while he was pushing it onto the low loader with the ERF tractor. He gave me the job of sorting it out and fitting a dog clutch at the same time which would allow us to drive off one wheel only which would help with the steering. The key had chewed the shaft up and all I could do was pull the gear with a 30 ton hydraulic puller which I happened to have about me until I had enough room to let Mark Roberts in with the oxy-acetylene cutter. We cut the shaft and got it out in pieces. I got the gears rebored on a big lathe and a new shaft made at the same time. I made all the parts for the clutch and cut the keyways myself. While nobody was watching I took the bearing brasses out, got them in the Wilson lathe in the shop and bored them out 30 thousandths of an inch oversize. When we came to rebuild it John was amazed how easily it all went together and I had to own up what I had done. I don’t think he was best pleased at the time but later, when he realised how big an improvement it had made to the drive he relented but never admitted I had been right in the first place.

Annie being winched onto her trailer at Ellenroad in 1993. Nick Crewe is on the Scammel Crusader operating its powerful winch. The same driver and outfit rescued us from Harewood.

We got one of the ploughing engines to winch us back up the hill and left Annie to quietly cool down. I went back with our low loader and driver the day afterwards and we winched her on board and took her back to Rochdale. The tractor was an old Scammel Crusader with a 500hp Detroit Diesel in it and a big winch behind the cab. I say it was ours but I was never sure because it started as John’s, then became the property of Nick Crewe the driver who ran his own haulage business but later still it came back to John who owns it now. It was rough but it was powerful and didn’t know when it was beaten. We were coming back through Pool and standing stationary in a queue of traffic. I noticed out of the passenger window that we were blocking an extremely attractive young lady in an expensive open sports car and so I struck up a conversation with her and apologised. Nick of course had to lean over and see what the attraction was. When he saw her he was knocked out and after we got going again he asked me what it was about her that made her so special. I said dead simple Nick, she’s innocent, never been polluted by the likes of you and me! I’ve never forgotten her and I know that Nick hasn’t either!

When we got Annie back in the shop, Dennis Sterricker one of John’s oldest and most experienced employees and a wonderful craftsman had a look in the firebox and said that it had blown a tube but that could be expanded up tight again. The more serious problem was that a seam in the firebox had opened and a pinhole blown through the throat plate. The bottom line was that it was the first time for years it had worked that hard and I had found the weak points in the boiler. Dennis welded the seams up and repaired the pin-hole, we did a hydraulic test on the boiler and all seemed OK.

Later that winter I was working for John full time and he asked me to go through the engine ready for the annual test and to see whether I could cure the regulator and the lumpy running. I stripped the engine down, ground the regulator seat and made a new tail rod for it. Then I took a lot of the play out of the slide valve so that it stayed on its seat when running on low steam. I took the cylinder cover off and drew the piston out and soon found out why it was running lumpy. I might as well warn you, we’re getting into another episode where Stanley knew more than the makers!

The cylinder had been bored wrong when Paxman’s made the engine. When you bore a steam engine cylinder you should always bore it out bell-mouthed at each end of the stroke. The idea is to have the piston ring just over the end of the bore when it reaches the end of its stroke. The reason for this is that cast iron rings in a cast iron bore will eventually wear the bore. If the leading edge of the piston ring is still within the confines of the bore at the end of the stroke it will eventually wear the bore where it travels but the place where it stops will have a ledge at that point. Normally this doesn’t cause any problems because as the crank brasses wear and are adjusted the piston gradually shortens its stroke and avoids the ledge. I had restored the full stroke when I made the new crank bearing and it was the piston ring hitting the ledge that was causing the lumpy running at low speed. It was the very pronounced ledge in the front end of the cylinder that was causing the trouble so I decided to take it out. Remember that the piston never actually reaches this part of the bore, only the leading edge of the ring so there was no need for a great deal of accuracy. I got a five inch grinder and started to grind the ledge out. Just at this moment John walked through the shop and had a fit when he saw what I was doing! He was convinced for a moment that his mad fitter was destroying his engine! I explained what I was doing and why and he had the sense to leave me alone. I built it all up again and turned it by hand, it was perfect, no obstruction at all. We fired it up later and found that this repair, combined with the adjustment to the valve and the regulator seat had done the trick. It ticked over on low steam like a rice pudding which pleased everyone because the ability to do this is a sign of a well-maintained engine.

Over the next couple of years I chased most of the faults out of the engine and eventually I was almost satisfied with it. We did have one major job though in 1995 when John stripped one of the keys in the gear shaft of the engine while he was pushing it onto the low loader with the ERF tractor. He gave me the job of sorting it out and fitting a dog clutch at the same time which would allow us to drive off one wheel only which would help with the steering. The key had chewed the shaft up and all I could do was pull the gear with a 30 ton hydraulic puller which I happened to have about me until I had enough room to let Mark Roberts in with the oxy-acetylene cutter. We cut the shaft and got it out in pieces. I got the gears rebored on a big lathe and a new shaft made at the same time. I made all the parts for the clutch and cut the keyways myself. While nobody was watching I took the bearing brasses out, got them in the Wilson lathe in the shop and bored them out 30 thousandths of an inch oversize. When we came to rebuild it John was amazed how easily it all went together and I had to own up what I had done. I don’t think he was best pleased at the time but later, when he realised how big an improvement it had made to the drive he relented but never admitted I had been right in the first place.

Annie being winched onto her trailer at Ellenroad in 1993. Nick Crewe is on the Scammel Crusader operating its powerful winch. The same driver and outfit rescued us from Harewood.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: STEAM ENGINES AND WATERWHEELS

There was one rally in the year that I never went to before 2003, Masham in the Yorkshire Dales. I was always teaching Carleton College when that one was on. I remember coming back into the shop after teaching in 1995 and noticed the engine as I came in. I asked John how the rally had gone and he said OK. I asked if they had had any trouble with the flywheel and he looked at me sharply and said “How did you know that? One of the keys came loose but we knocked it back in.” I told him that it wasn’t any better and needed seeing to. He was baffled and asked me how I knew. I took him to the engine and showed him the streaks of red oxide radiating from the keyways on the surface of the flywheel. This was classic ‘bleeding’ and is oxide caused by fretting corrosion when there is play in what should be a tight fit, I told him that it was a sure sign the keys were loose and needed refitting and probably replacing so he told me to get on with it.

I drew the keys and found that one was cosmetic, it was the wrong size and wasn’t doing anything at all, the other was so badly fitted it was only touching the keyway in one place and was no good. I got some key steel and made two new keys. I cut a channel down the top and bottom face of both keys. This is a trick that Newton taught me, you never get a key to fit perfectly especially when you are fitting to a worn bore and keyway. If you cut a channel down the middle of the bearing surface it is relatively easy to make sure that the key is bearing evenly down each side. As the original key was almost certainly fitted to the middle of the key ways, this means you are getting a grip on those parts of the shaft and the gear where there will be no wear. You can get a far better fit and make sure you are gripping each face equally. I also machined a notch under the gib so that they could be easily pulled using a round-backed drift. I drove them up tight and they will never shift again while I am alive!

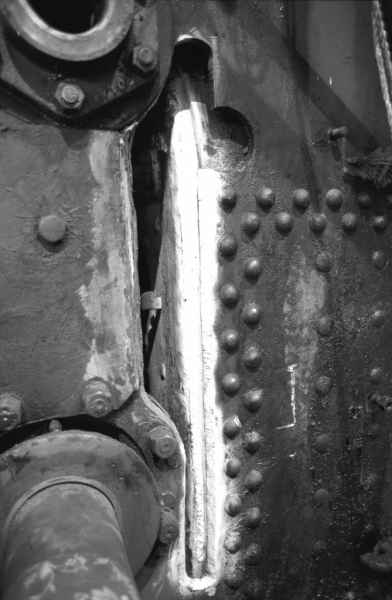

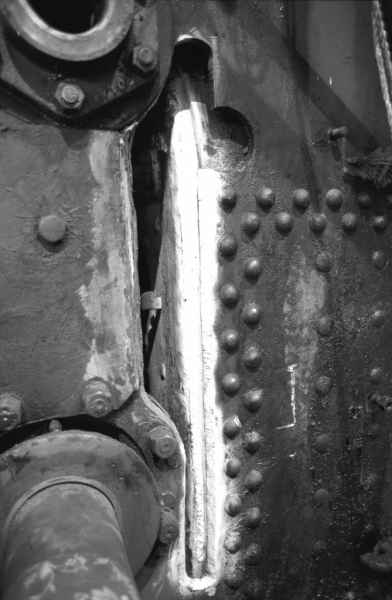

Another interesting job was refitting the water gauges. We couldn’t stop them leaking round the flanges and in the end I got John to let me take them off and make oversize studs. I refitted these studs, put the gauges back on and it cured the leaks. This wasn’t just a matter of fitting the next size of stud, I made new ones that were the same as the old ones in all respects but made the threaded end that screwed into the plate a bastard size. I threaded them myself in the lathe and put the same thread on the end but about 25 thousandths of an inch bigger in diameter. After cleaning the thread in the hole up with the original size tap, the new studs were screwed in bedded on Manganesite and were an interference fit, they made their own thread. This is an old trick and the replacements would actually be a better fit than the originals because they had 100% contact. I learned something else while I was doing this job. I had often seen older cocks that had ‘asbestos packed’ stamped on them but didn’t really know what this meant. As the cocks were leaking a bit I took them to bits to repack them and all was revealed. There were channels in the mating faces of the bore and plug of the cock and as I had never come across this before I took one down to my packing genius Roger Kierby. Luckily his dad was there and as soon as he saw the cocks he told me what I needed to do. He said I had to drive ‘indurated asbestos’ into the channels with a punch that just fitted in the channel. The idea was that you rammed it in tight and the next time the cock got hot the asbestos cured hard into a perfect fit. I asked him where I could get some of this magic compound and he told me that I couldn’t because it was illegal. However, he had a look in the stores and found a tin that had been there for years and gave it to me. I made a punch the right size and shape, packed the cocks and they were perfect. I’m not absolutely certain but I reckon that the reason why it sets so well is because it has rubber mixed with it and in effect the heat vulcanises it and converts it to a solid but flexible sealing compound. I still have some left in the workshop so if you get into trouble, give me a shout!

John was taking the traction engine very seriously and he asked me and Paul Greenwood if we’d like to go with him to Holland in May 1994 for a fortnight all expenses paid, he had been invited to take Annie to the big rally at Utrecht and ‘Dordt in Stoom’ at Dordrecht. Of course we agreed immediately!

On the way to Utrecht. Staying the night in a Travelodge in Norfolk.

I drew the keys and found that one was cosmetic, it was the wrong size and wasn’t doing anything at all, the other was so badly fitted it was only touching the keyway in one place and was no good. I got some key steel and made two new keys. I cut a channel down the top and bottom face of both keys. This is a trick that Newton taught me, you never get a key to fit perfectly especially when you are fitting to a worn bore and keyway. If you cut a channel down the middle of the bearing surface it is relatively easy to make sure that the key is bearing evenly down each side. As the original key was almost certainly fitted to the middle of the key ways, this means you are getting a grip on those parts of the shaft and the gear where there will be no wear. You can get a far better fit and make sure you are gripping each face equally. I also machined a notch under the gib so that they could be easily pulled using a round-backed drift. I drove them up tight and they will never shift again while I am alive!

Another interesting job was refitting the water gauges. We couldn’t stop them leaking round the flanges and in the end I got John to let me take them off and make oversize studs. I refitted these studs, put the gauges back on and it cured the leaks. This wasn’t just a matter of fitting the next size of stud, I made new ones that were the same as the old ones in all respects but made the threaded end that screwed into the plate a bastard size. I threaded them myself in the lathe and put the same thread on the end but about 25 thousandths of an inch bigger in diameter. After cleaning the thread in the hole up with the original size tap, the new studs were screwed in bedded on Manganesite and were an interference fit, they made their own thread. This is an old trick and the replacements would actually be a better fit than the originals because they had 100% contact. I learned something else while I was doing this job. I had often seen older cocks that had ‘asbestos packed’ stamped on them but didn’t really know what this meant. As the cocks were leaking a bit I took them to bits to repack them and all was revealed. There were channels in the mating faces of the bore and plug of the cock and as I had never come across this before I took one down to my packing genius Roger Kierby. Luckily his dad was there and as soon as he saw the cocks he told me what I needed to do. He said I had to drive ‘indurated asbestos’ into the channels with a punch that just fitted in the channel. The idea was that you rammed it in tight and the next time the cock got hot the asbestos cured hard into a perfect fit. I asked him where I could get some of this magic compound and he told me that I couldn’t because it was illegal. However, he had a look in the stores and found a tin that had been there for years and gave it to me. I made a punch the right size and shape, packed the cocks and they were perfect. I’m not absolutely certain but I reckon that the reason why it sets so well is because it has rubber mixed with it and in effect the heat vulcanises it and converts it to a solid but flexible sealing compound. I still have some left in the workshop so if you get into trouble, give me a shout!

John was taking the traction engine very seriously and he asked me and Paul Greenwood if we’d like to go with him to Holland in May 1994 for a fortnight all expenses paid, he had been invited to take Annie to the big rally at Utrecht and ‘Dordt in Stoom’ at Dordrecht. Of course we agreed immediately!

On the way to Utrecht. Staying the night in a Travelodge in Norfolk.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: STEAM ENGINES AND WATERWHEELS

STEAM IN HOLLAND. 1994

We set off for the Norfolk Line ferry from Felixstowe to Scheveningen in Holland on May 20 1994 in high spirits but with a very strange cargo. John had an acquaintance called Peter Clare who he had done some work for on his Sentinel steam wagon. Peter had a hand-operated children’s carousel which would hold about 15 passengers and was invited to go to Holland. His problem was getting the ride over there, it was mounted on wheels and theoretically could be towed behind a car but it wasn’t fit to be on the road, certainly not for a long journey.

Our low loader was a big trailer and loaded from the front. It had a hydraulic neck powered by batteries which could be lowered down to the ground when the trailer was detached from the tractor. As it came down the swan neck unfolded and by the time it was right down it formed a long ramp up on to the trailer. The hydraulics were very powerful as when it was hooked to the tractor the rams had to be capable of lifting the front of the trailer with the load on. Peter Clare had worked it out that there was room on the neck for his roundabout when it was lifted and he asked John if we would take it over for him. John, being a soft touch, agreed, but I have to tell you that when we got the whole outfit loaded up it looked most peculiar with this Toytown, garishly painted roundabout perched on the trailer just behind the cab!

We set off for Felixstowe with the four of us in the cab and had decided we would stay for the night in a motel near Felixstowe and have a short journey to the ferry the following morning. Apart from the brakes dragging on the trailer and Stanley having to make some adjustments by the roadside all went well, good job I had my toolbox with me! There were only two other small things. John had decided to give the tractor cab a good clean out and had disinfected it with Jeyes Fluid, a very strong phenol based disinfectant. As the cab warmed up the smell of Jeyes became intense and we had to drive with the windows open. Peter Clare was travelling with us and to put it mildly, he was a pain in the bum! He watched his precious roundabout every bit of the way and even John got fed up with him enquiring whether it was safe. Eventually we arrived at the motel and booked in for the night. John was paying for Paul and me and finished up paying for Peter Clare as well, I wonder if he ever got the money back? There was no restaurant at the motel so, as I had no Dutch currency, I took everyone out for a meal because they would have to look after me until we found a bank. The funny thing was that even though he was invited, Peter Clare vanished. I don’t think he wanted to be put in a position where it was his turn to pay for anything. This didn’t worry us, we had a good night out, a few drinks and got to bed in good time.

There was one funny thing as we were driving down to the motel. We passed a big Foden tractor unit and low loader on a lay-by with an engine sheeted up on the trailer. We all waved to each other as we passed and speculated what they were doing on the lay-by. We eventually decided that they must be hard up and sleeping in the cab overnight. What we didn’t realise was that it was a bloke called Richard Metcalfe and his wife Delia from Macclesfield who were on their way to catch the same ferry as us and they were broken down. They weren’t waving, they were drowning! They got going after throwing a lot of money at the fault and caught the ferry at the same time as us the following morning. We met up with them on the ferry and found out about it. There was much wry comment about the fraternity being supposed to help each other but we made up for it later.

The following morning we loaded the wagon on the ferry and set sail for Scheveningen. This was all new to me, I hadn’t crossed the North Sea on a ferry since I went to Berlin in 1954. It was a good crossing and the food was great. We had day cabins and I managed to get a sleep before we disembarked in the early evening just as it was getting dark.

It was then that we hit the first of the roundabout problems. What neither we or Peter Clare had realised was that the loading gauge in Holland is about three feet lower than in the UK. Annie was all right, with her chimney down she was just inside the limit but the roundabout was way too high and there was no way we could lower it. A bloke called Robert Deventer was in charge of the transfer from Scheveningen to Utrecht and he had a Land Rover Discovery so he said he would tow the roundabout to Utrecht if we got it off the trailer. We held everyone up while we dropped the neck and got the roundabout off and hitched it, very insecurely, to the back of the Discovery.

We set off down the road in the gathering gloom and were alarmed to see the way the roundabout snaked about as it was being towed, we were laying a shade of odds that it wouldn’t arrive in one piece! Eventually, we got to Utrecht, parked up in a street near the Railway Museum with a police guard and were all ferried out to a caravan park called the Bear Pit where we would be staying while we were there. Things started to go pear-shaped for me and Paul, he was sharing with John and I was in with Peter Clare! The problem about John was that his feet smelt terrible and Paul had this to put up with, John was the only bloke I have ever seen since my army days whose boots marked time all night under the bed! Peter Clare was strange, I shall draw a discreet veil over the first night but he wasn’t too particular about personal hygiene and talked in his sleep! To cap it all, we soon realised the caravans were infested with small black bugs! And so to bed.

The trailer park at Dordrecht. Metcalfe's big Foden next to our ERF.

We set off for the Norfolk Line ferry from Felixstowe to Scheveningen in Holland on May 20 1994 in high spirits but with a very strange cargo. John had an acquaintance called Peter Clare who he had done some work for on his Sentinel steam wagon. Peter had a hand-operated children’s carousel which would hold about 15 passengers and was invited to go to Holland. His problem was getting the ride over there, it was mounted on wheels and theoretically could be towed behind a car but it wasn’t fit to be on the road, certainly not for a long journey.

Our low loader was a big trailer and loaded from the front. It had a hydraulic neck powered by batteries which could be lowered down to the ground when the trailer was detached from the tractor. As it came down the swan neck unfolded and by the time it was right down it formed a long ramp up on to the trailer. The hydraulics were very powerful as when it was hooked to the tractor the rams had to be capable of lifting the front of the trailer with the load on. Peter Clare had worked it out that there was room on the neck for his roundabout when it was lifted and he asked John if we would take it over for him. John, being a soft touch, agreed, but I have to tell you that when we got the whole outfit loaded up it looked most peculiar with this Toytown, garishly painted roundabout perched on the trailer just behind the cab!

We set off for Felixstowe with the four of us in the cab and had decided we would stay for the night in a motel near Felixstowe and have a short journey to the ferry the following morning. Apart from the brakes dragging on the trailer and Stanley having to make some adjustments by the roadside all went well, good job I had my toolbox with me! There were only two other small things. John had decided to give the tractor cab a good clean out and had disinfected it with Jeyes Fluid, a very strong phenol based disinfectant. As the cab warmed up the smell of Jeyes became intense and we had to drive with the windows open. Peter Clare was travelling with us and to put it mildly, he was a pain in the bum! He watched his precious roundabout every bit of the way and even John got fed up with him enquiring whether it was safe. Eventually we arrived at the motel and booked in for the night. John was paying for Paul and me and finished up paying for Peter Clare as well, I wonder if he ever got the money back? There was no restaurant at the motel so, as I had no Dutch currency, I took everyone out for a meal because they would have to look after me until we found a bank. The funny thing was that even though he was invited, Peter Clare vanished. I don’t think he wanted to be put in a position where it was his turn to pay for anything. This didn’t worry us, we had a good night out, a few drinks and got to bed in good time.

There was one funny thing as we were driving down to the motel. We passed a big Foden tractor unit and low loader on a lay-by with an engine sheeted up on the trailer. We all waved to each other as we passed and speculated what they were doing on the lay-by. We eventually decided that they must be hard up and sleeping in the cab overnight. What we didn’t realise was that it was a bloke called Richard Metcalfe and his wife Delia from Macclesfield who were on their way to catch the same ferry as us and they were broken down. They weren’t waving, they were drowning! They got going after throwing a lot of money at the fault and caught the ferry at the same time as us the following morning. We met up with them on the ferry and found out about it. There was much wry comment about the fraternity being supposed to help each other but we made up for it later.

The following morning we loaded the wagon on the ferry and set sail for Scheveningen. This was all new to me, I hadn’t crossed the North Sea on a ferry since I went to Berlin in 1954. It was a good crossing and the food was great. We had day cabins and I managed to get a sleep before we disembarked in the early evening just as it was getting dark.

It was then that we hit the first of the roundabout problems. What neither we or Peter Clare had realised was that the loading gauge in Holland is about three feet lower than in the UK. Annie was all right, with her chimney down she was just inside the limit but the roundabout was way too high and there was no way we could lower it. A bloke called Robert Deventer was in charge of the transfer from Scheveningen to Utrecht and he had a Land Rover Discovery so he said he would tow the roundabout to Utrecht if we got it off the trailer. We held everyone up while we dropped the neck and got the roundabout off and hitched it, very insecurely, to the back of the Discovery.

We set off down the road in the gathering gloom and were alarmed to see the way the roundabout snaked about as it was being towed, we were laying a shade of odds that it wouldn’t arrive in one piece! Eventually, we got to Utrecht, parked up in a street near the Railway Museum with a police guard and were all ferried out to a caravan park called the Bear Pit where we would be staying while we were there. Things started to go pear-shaped for me and Paul, he was sharing with John and I was in with Peter Clare! The problem about John was that his feet smelt terrible and Paul had this to put up with, John was the only bloke I have ever seen since my army days whose boots marked time all night under the bed! Peter Clare was strange, I shall draw a discreet veil over the first night but he wasn’t too particular about personal hygiene and talked in his sleep! To cap it all, we soon realised the caravans were infested with small black bugs! And so to bed.

The trailer park at Dordrecht. Metcalfe's big Foden next to our ERF.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: STEAM ENGINES AND WATERWHEELS

The following morning we walked down to the engines and started to set up. The event was being held near the Railway Museum where they had the replica of Stephenson’s Rocket in steam on a short stretch of track and we were part of the overspill in a small public park outside the museum. I’m not sure what the significance of the park was but the turf was hallowed ground. Every area where we ran on to it was covered by large timber rafts made from six inch square mahogany baulks. I wish we could have brought some of them back with us, it was lovely timber.

None of the engines had steam up and we had to nose or tow them in with the tractors. Our ERF tractor was very bad for this as there was so little weight on the single back axle when it was solo. Annie weighed about fourteen tons and was not easy to shift. Luckily, Richard Metcalfe’s Foden tractor was very special, it was the only one of its type left running and had been built specially for heavy haulage. It had a 500 hp Cummins engine, double wheel drive and was rated at 150 tons. It was the perfect vehicle for shifting the engines and he shoved us into position on the field when he had got his own engine in. I got a chance to do a bit of shunting in this motor and it was perfect for the job. The bottom three gears drove through a fluid flywheel and all you had to do was put it in crawler gear and control it with the brake pedal. Ticking over it pushed Annie as though she was a feather. I should point out here that John was cab happy and wouldn’t let anybody else drive, at least, not until he had to do but more about that later. I still had my Class One heavy vehicle licence, a hangover from my trucking days.

Later on when I was working on Richard’s unit I found that the double-drive rear axles had built in reduction gears in the hubs. In high range the unit was rated at 75 tons, in low range it was 150 tons. What amused me was the warning cast into the end plate of the hub which reminded the operator that all the hub gears must be changed at the same time. I think that the results of one hub being differently geared than the others with 500hp coming down the drive train would be fairly spectacular!

We got settled in on the field, sorted ourselves out, raised steam and sat there with the engine ticking over. Because we had steel wheels that was all they wanted us to do, we would have done too much damage if we’d started trundling about. We just sat there, drank beer, talked to the locals and when we got bored, took turns to wander off and have a look at the other exhibits. It was while I was on one of these peregrinations that I came across Peter Clare outside the museum coining it in with his roundabout. I forget what he was charging but I watched him for a while, timed the length of the rides, did a bit of mental arithmetic and decided that he was making a bomb! I seem to remember that we got to a figure of something like £1000 in the three days we were in Utrecht and Dordrecht was still to come! I told my mates about this and Paul raised the question of what he would be doing with the money. We didn’t think he would go to the museum to get his coins changed into notes because he wouldn’t want to advertise how much he was taking in and being weekend the banks weren’t open. We decided to watch him to see what he did.

We noticed that he had a brown canvas bag which he carried wherever he went and decided that this was the stash! When he went for a meal he took it with him and sat on it. When he was at the roundabout he kept it stowed away underneath the ride and kept touching it with his foot. That night, when it came time to pack up we offered him a lift back to the caravan park in the tractor but he refused and staggered off into the gloom with his sack which we reckoned was getting quite heavy! That night he took it to bed with him and slept with it in his arms, he evidently didn’t trust me at all.

This went on for three days and was a running joke. We pulled his leg about it but in the end he avoided us. The arrangement we had with him, because we couldn’t carry his ride between venues, was that he found his own transport while he was in Holland and met us at the Hook of Holland on the way back where we would reload him before we boarded the ferry for Harwich.

John had to fly home on the Sunday night because there was business to attend to in Rochdale. While he was in the UK he had another mission, the day after we arrived in Utrecht Richard Metcalfe had found that the alternator on his tractor wasn’t charging so we were keeping him going by charging his batteries from our tractor and jump starting him when he needed it. We had identified which alternator he needed and arranged for it to be delivered to REW in Rochdale and John was going to bring it back with him. Guess who was going to fit it! It was no sweat though, we were getting on well with the Metcalfes especially Delia who was a good sort, we spent all our time together while we were on the field and looked after each other’s engines.

We weren't allowed to trundle round the sacred ground of the park so sat there all day in steam with the engines ticking over. The Fowler and the Paxman on the mahogany mats. Paul John, Peter and Delia his wife drinking beer. I stuck to tea during the day, someone had to keep a clear head!

[Lots more pics in the book, Staney's Story Volume four and you can get it on LULU.COM.]

None of the engines had steam up and we had to nose or tow them in with the tractors. Our ERF tractor was very bad for this as there was so little weight on the single back axle when it was solo. Annie weighed about fourteen tons and was not easy to shift. Luckily, Richard Metcalfe’s Foden tractor was very special, it was the only one of its type left running and had been built specially for heavy haulage. It had a 500 hp Cummins engine, double wheel drive and was rated at 150 tons. It was the perfect vehicle for shifting the engines and he shoved us into position on the field when he had got his own engine in. I got a chance to do a bit of shunting in this motor and it was perfect for the job. The bottom three gears drove through a fluid flywheel and all you had to do was put it in crawler gear and control it with the brake pedal. Ticking over it pushed Annie as though she was a feather. I should point out here that John was cab happy and wouldn’t let anybody else drive, at least, not until he had to do but more about that later. I still had my Class One heavy vehicle licence, a hangover from my trucking days.

Later on when I was working on Richard’s unit I found that the double-drive rear axles had built in reduction gears in the hubs. In high range the unit was rated at 75 tons, in low range it was 150 tons. What amused me was the warning cast into the end plate of the hub which reminded the operator that all the hub gears must be changed at the same time. I think that the results of one hub being differently geared than the others with 500hp coming down the drive train would be fairly spectacular!

We got settled in on the field, sorted ourselves out, raised steam and sat there with the engine ticking over. Because we had steel wheels that was all they wanted us to do, we would have done too much damage if we’d started trundling about. We just sat there, drank beer, talked to the locals and when we got bored, took turns to wander off and have a look at the other exhibits. It was while I was on one of these peregrinations that I came across Peter Clare outside the museum coining it in with his roundabout. I forget what he was charging but I watched him for a while, timed the length of the rides, did a bit of mental arithmetic and decided that he was making a bomb! I seem to remember that we got to a figure of something like £1000 in the three days we were in Utrecht and Dordrecht was still to come! I told my mates about this and Paul raised the question of what he would be doing with the money. We didn’t think he would go to the museum to get his coins changed into notes because he wouldn’t want to advertise how much he was taking in and being weekend the banks weren’t open. We decided to watch him to see what he did.

We noticed that he had a brown canvas bag which he carried wherever he went and decided that this was the stash! When he went for a meal he took it with him and sat on it. When he was at the roundabout he kept it stowed away underneath the ride and kept touching it with his foot. That night, when it came time to pack up we offered him a lift back to the caravan park in the tractor but he refused and staggered off into the gloom with his sack which we reckoned was getting quite heavy! That night he took it to bed with him and slept with it in his arms, he evidently didn’t trust me at all.

This went on for three days and was a running joke. We pulled his leg about it but in the end he avoided us. The arrangement we had with him, because we couldn’t carry his ride between venues, was that he found his own transport while he was in Holland and met us at the Hook of Holland on the way back where we would reload him before we boarded the ferry for Harwich.

John had to fly home on the Sunday night because there was business to attend to in Rochdale. While he was in the UK he had another mission, the day after we arrived in Utrecht Richard Metcalfe had found that the alternator on his tractor wasn’t charging so we were keeping him going by charging his batteries from our tractor and jump starting him when he needed it. We had identified which alternator he needed and arranged for it to be delivered to REW in Rochdale and John was going to bring it back with him. Guess who was going to fit it! It was no sweat though, we were getting on well with the Metcalfes especially Delia who was a good sort, we spent all our time together while we were on the field and looked after each other’s engines.

We weren't allowed to trundle round the sacred ground of the park so sat there all day in steam with the engines ticking over. The Fowler and the Paxman on the mahogany mats. Paul John, Peter and Delia his wife drinking beer. I stuck to tea during the day, someone had to keep a clear head!

[Lots more pics in the book, Staney's Story Volume four and you can get it on LULU.COM.]

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: STEAM ENGINES AND WATERWHEELS

On the Sunday night we reloaded the engines and got everything ready for leaving for Dordrecht on the Monday morning. I was the driver so I put Paul in charge of the route, he got all the paperwork off Robert Deventer and we were all set to go. John’s departure for UK had one good outcome, I moved in with Paul for the last night at Utrecht! I have to report he is an excellent room mate and we had no problems whatsoever, that is apart from him objecting to me wearing the shower cap and walking about with my teeth out! We had one last job to do on the Sunday night, we were low on diesel and went to a filling station on the major road near the Bear Pit. John had wanted to leave me some money but I told him the best way was for me to pay on my credit card and he could square up with me afterwards. I pulled into the filling station and put about 500 litres of fuel in. I went to the kiosk to pay and after the attendant had put my card through the machine he asked for my identification. It transpired that it was illegal to use a credit card in Holland without photographic identification, in our case, a passport. Mine was back at the caravan so this was a problem. However, we decided we had enough currency to pay cash but that was a problem too! The bloke had swiped my card and in effect this meant he couldn’t process any other transactions until that one was cleared. Unfortunately he didn’t know what the code number was to clear it. To get round this he had to call the credit card centre and get a cancellation code. The problem about this was that he had lost the number! Eventually he found it and called them only to find it was the wrong number, he had to ring someone else to find what it was.

While all this was going on, Paul and I were stood there doing a good impression of a couple of idiots. I kept apologising for all the trouble we were causing to all the incredibly patient people waiting and the attendant kept assuring everyone it was his fault because he should have checked the identification before swiping the card. At this moment a police car came on to the forecourt with blue lights flashing and siren blaring. The officers leapt out, came in the kiosk and started to have an animated conversation with the attendant. Paul and I thought we were going straight to gaol for attempted fraud until it dawned on us that we weren’t the cause of the trouble. Because of the incompetence of the attendant the queue waiting to get into the filling station had paralysed the surrounding roads, the traffic was backing up on the freeway and had tailed back to the slip road and onto the major road beyond! The police told us it wasn’t our fault and they helped the attendant sort out the problem. Eventually we managed to pay for the fuel, got a receipt and were very glad to get back to the Bear Pit and a quiet drink in the bar! Or at least we thought that was what we were going for but we got involved in something called ‘The Banana Dance’. I hadn’t the faintest idea what it was all about but suspected that sex might have been involved. (Don’t worry Jennie, to the pure all things are pure and your husband did nothing to be ashamed of.) There was one last mystery, I can’t explain how it was that I found myself in possession of a policeman’s peaked hat the following morning. It didn’t fit me so I gave it to Paul to put in his dressing up box.

Came Monday morning and we were all set. Richard and Delia went into conference with Paul the navigator and it was decided that since he had the directions, they would follow me, so we lit our pipes and set off for Dordrecht. We came to the first roundabout and Paul confidently directed me which way to go. One funny thing I noticed was that there was a sign that said ‘Anderes Richtingen’, I think that was the spelling. I heard later that it meant ‘all other routes’ and the joke was that a foreigner had thought it was a town and had followed these signs all the way round Holland and never actually arrived anywhere! To tell you the truth I wasn’t taking much notice, my work was cut out driving the outfit. Apart from the weight, it was a strange motor to me because John never let me drive it. It was a long and very awkward trailer and I had to have all my wits about me not to carve anyone up on the roundabouts. It was a good job Paul knew where we were going!

While all this was going on, Paul and I were stood there doing a good impression of a couple of idiots. I kept apologising for all the trouble we were causing to all the incredibly patient people waiting and the attendant kept assuring everyone it was his fault because he should have checked the identification before swiping the card. At this moment a police car came on to the forecourt with blue lights flashing and siren blaring. The officers leapt out, came in the kiosk and started to have an animated conversation with the attendant. Paul and I thought we were going straight to gaol for attempted fraud until it dawned on us that we weren’t the cause of the trouble. Because of the incompetence of the attendant the queue waiting to get into the filling station had paralysed the surrounding roads, the traffic was backing up on the freeway and had tailed back to the slip road and onto the major road beyond! The police told us it wasn’t our fault and they helped the attendant sort out the problem. Eventually we managed to pay for the fuel, got a receipt and were very glad to get back to the Bear Pit and a quiet drink in the bar! Or at least we thought that was what we were going for but we got involved in something called ‘The Banana Dance’. I hadn’t the faintest idea what it was all about but suspected that sex might have been involved. (Don’t worry Jennie, to the pure all things are pure and your husband did nothing to be ashamed of.) There was one last mystery, I can’t explain how it was that I found myself in possession of a policeman’s peaked hat the following morning. It didn’t fit me so I gave it to Paul to put in his dressing up box.

Came Monday morning and we were all set. Richard and Delia went into conference with Paul the navigator and it was decided that since he had the directions, they would follow me, so we lit our pipes and set off for Dordrecht. We came to the first roundabout and Paul confidently directed me which way to go. One funny thing I noticed was that there was a sign that said ‘Anderes Richtingen’, I think that was the spelling. I heard later that it meant ‘all other routes’ and the joke was that a foreigner had thought it was a town and had followed these signs all the way round Holland and never actually arrived anywhere! To tell you the truth I wasn’t taking much notice, my work was cut out driving the outfit. Apart from the weight, it was a strange motor to me because John never let me drive it. It was a long and very awkward trailer and I had to have all my wits about me not to carve anyone up on the roundabouts. It was a good job Paul knew where we were going!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: STEAM ENGINES AND WATERWHEELS

All was going well, I was getting pretty comfortable with the outfit and as long as we took it steady there was no sweat. Richard followed at a respectable distance and we were a pretty formidable sight as over 100 tons of traction engine and heavy transport made its way quietly and competently towards Dordrecht and the next rally. The other traffic on the road realised our problems and the unusual nature of the loads we were carrying attracted a lot of attention as we passed.

Paul was doing well, he gave directions in plenty of time and we were soon on a straight road driving through open countryside and there was an opportunity to relax, or so I was beginning to think! I became slightly perturbed when I noticed that the road was getting narrower. The trees on the side of the road all bore marks where they had been hit by the mirrors of large vehicles and it slowly dawned on me that we were on the wrong road, I know lost when I see it! There was nowhere to turn and we went on for miles deeper into the hinterland of Holland and I had made my mind up that the first opportunity we got we had to turn round and go back to the major road and get some directions from there, we stopped and I had a word with Richard who was in total agreement. Shortly afterwards I saw a wide opening off the road into the drive to a private house. I pulled up and had a look at it and realised that although it was big enough to reverse into and turn round, the surface was soft and we would carve it up if we screwed the trailer wheels round on it with all that weight.