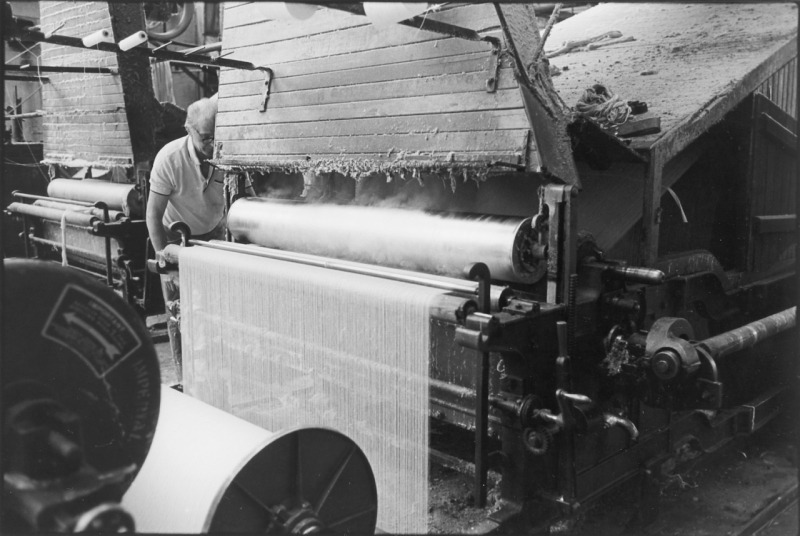

One weekend he invited me to go down to Upton near Altrincham where he was going to plough with the man who had the matching engine to his, they worked in pairs. I was so impressed with the way they handled the load, a six furrow plough and a big cultivator. There was no fuss, they just pulled immediately the throttle was opened. Even when the cultivator was stopped in mid travel and had to be started again against the dead load of all those big tines buried in the ground it just started as though there was nothing to pull. The man who owned the farm had just spent an enormous amount on a big new tractor. He admitted that when the lads had approached him to ask if they could plough his stubble he thought they would just be playing out but when he saw the Fowlers at work he was amazed how fast and efficient they were. He said that there was no way his tractor could restart with the cultivator bedded into the ground.

I only saw a pair of engines at work in the flesh once before in the 1950s when I was farming in Warwickshire. They were dredging the lake at Compton Wynyates, a big country house. They dragged an enormous bucket through the lake with no fuss at all. If you ever get the chance to see them at work, go for it!