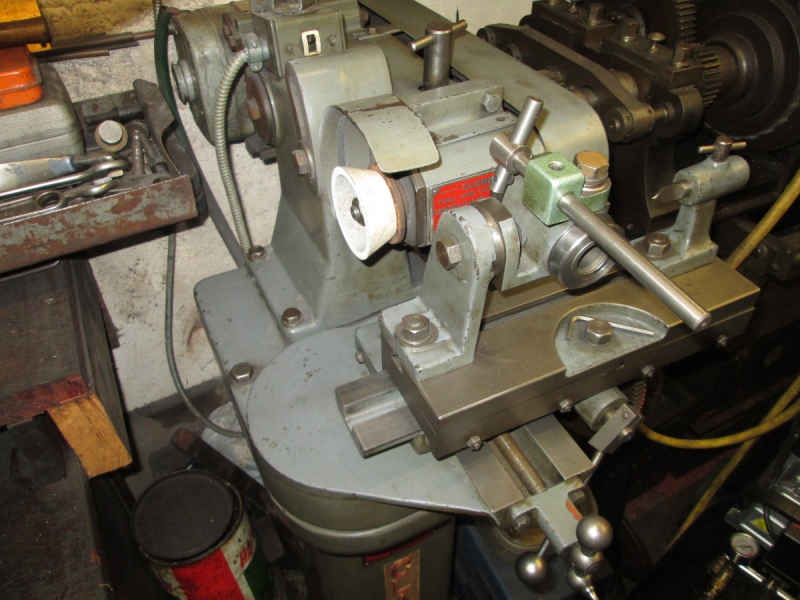

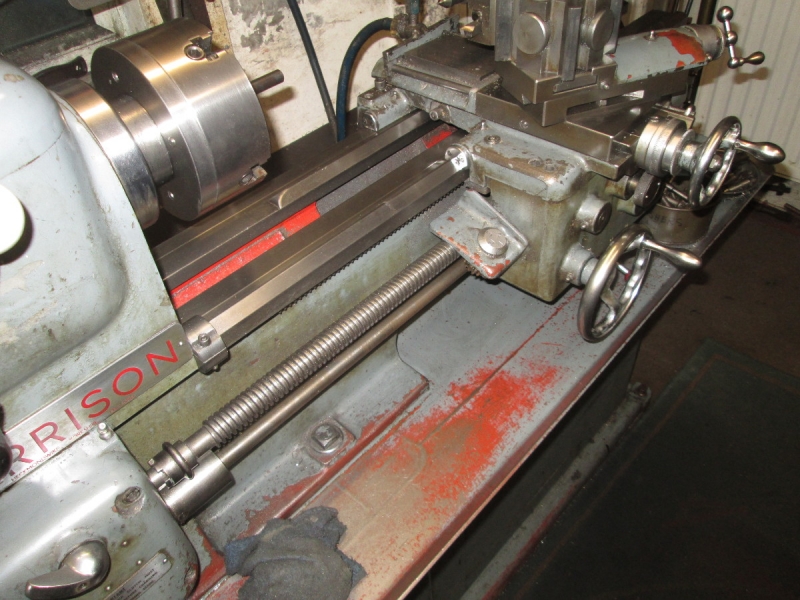

Despite promising myself I'd take it easy today after all the exercise yesterday and also the fact that I didn't do my finger any favours, it has been aching.... I was in the shed by 07:00. The pile of cutters is shrinking and my first instinct was to get straight into grinding, but then I remembered something....

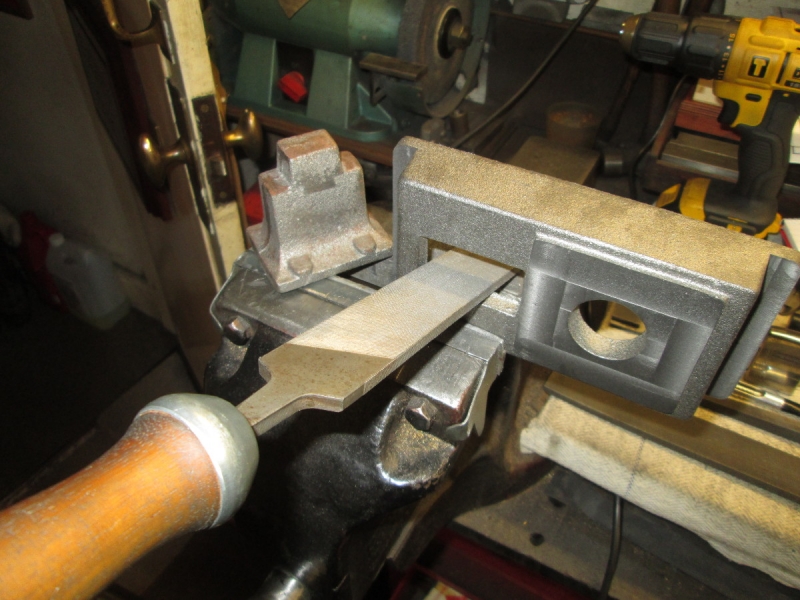

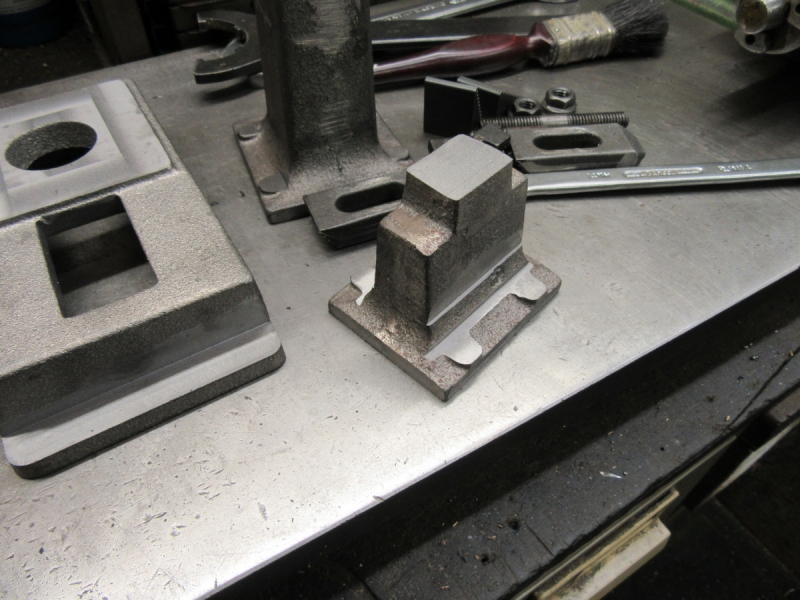

Down at the side of the grinder is where one of my non ferocious treasure boxes lives together with the brass ends and underneath it was a box with odd pieces of stock in it but when I took everything out to move the grinder I realised that there was another box underneath with useful pieces of larger stock in it that I had forgotten. So first thing this morning I sorted out the two boxes and made them more accessible. Well worth doing!

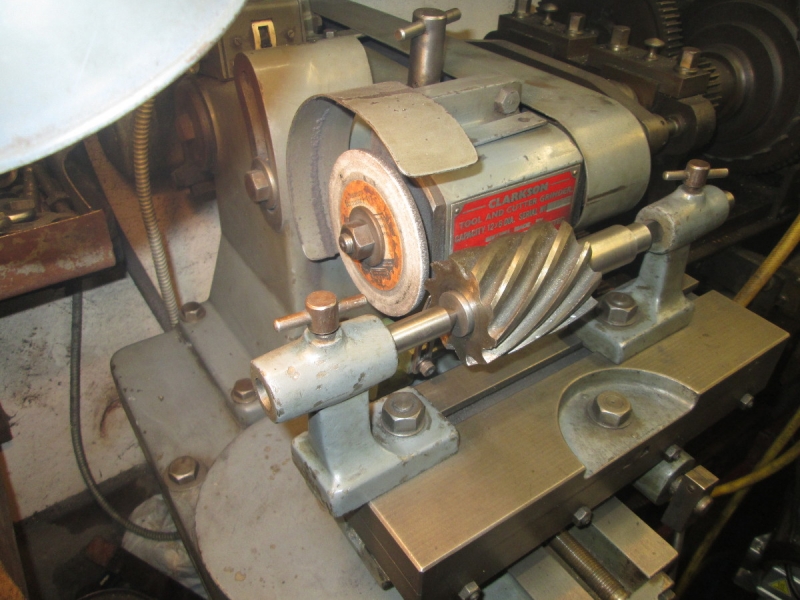

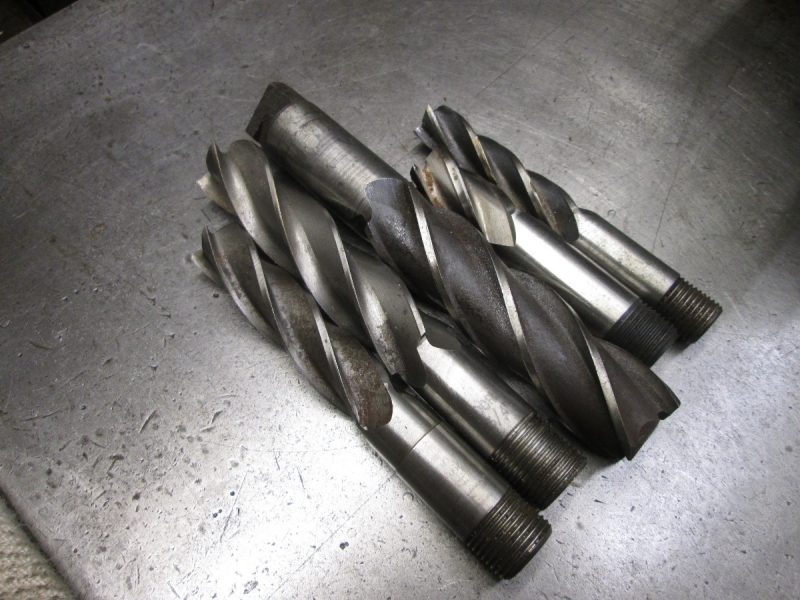

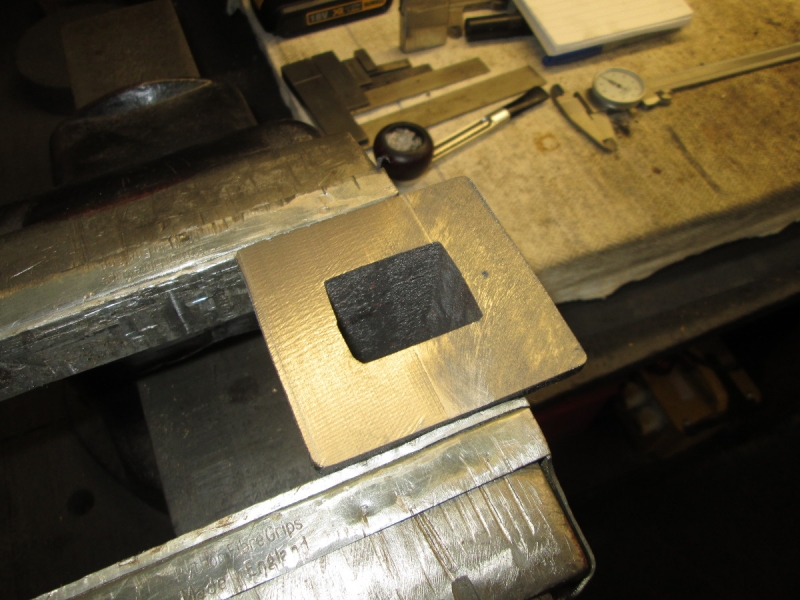

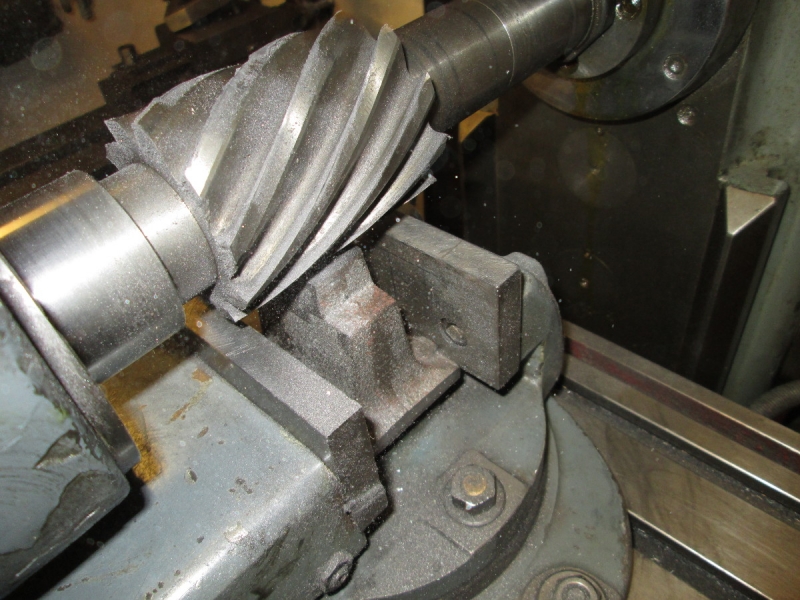

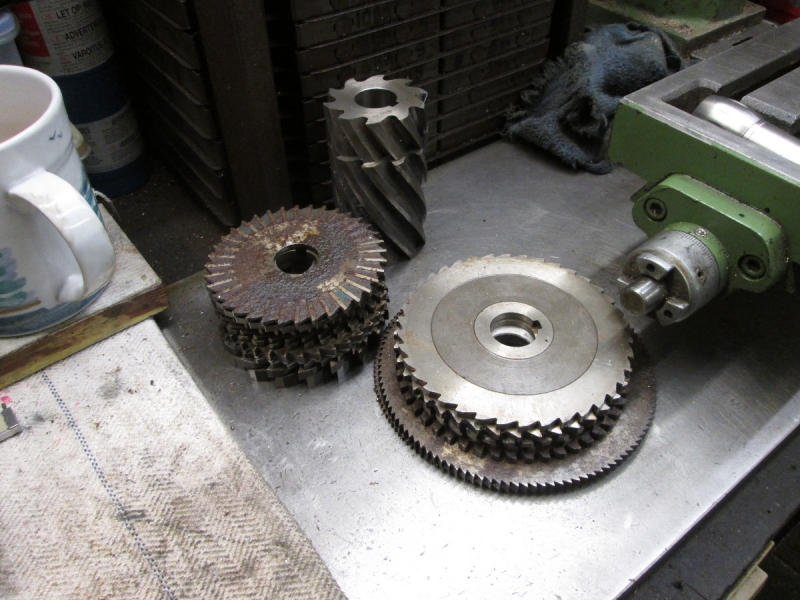

But then I cracked on with the cutters. I'll not bore you with lots of pics but here's one cutter that caught my attention. I think it's lived in a puddle for a long time! But it's still a good piece of HSS so I treated it the same as the others. When I tested it it cut beautifully, well worth the effort!

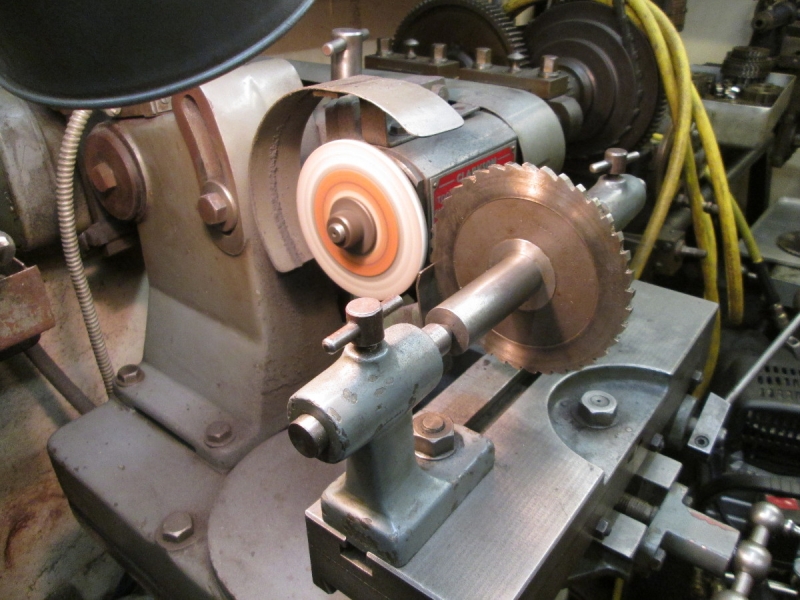

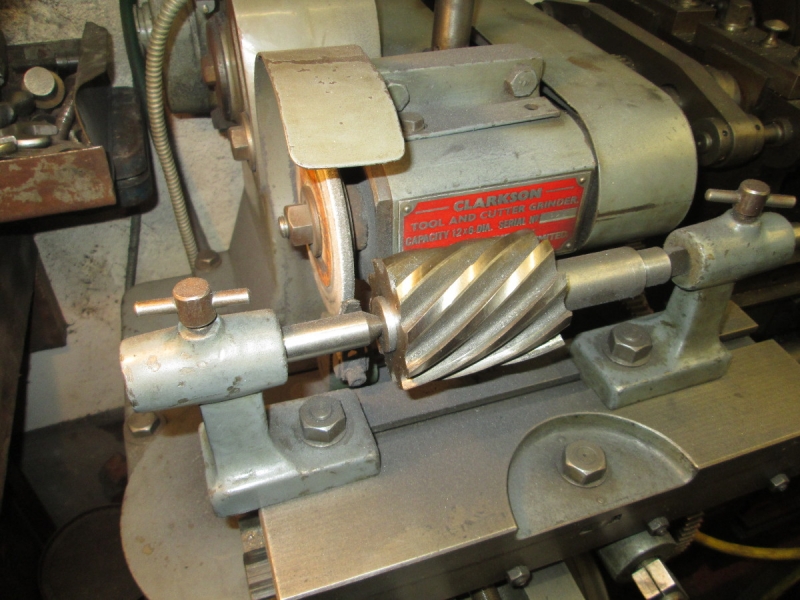

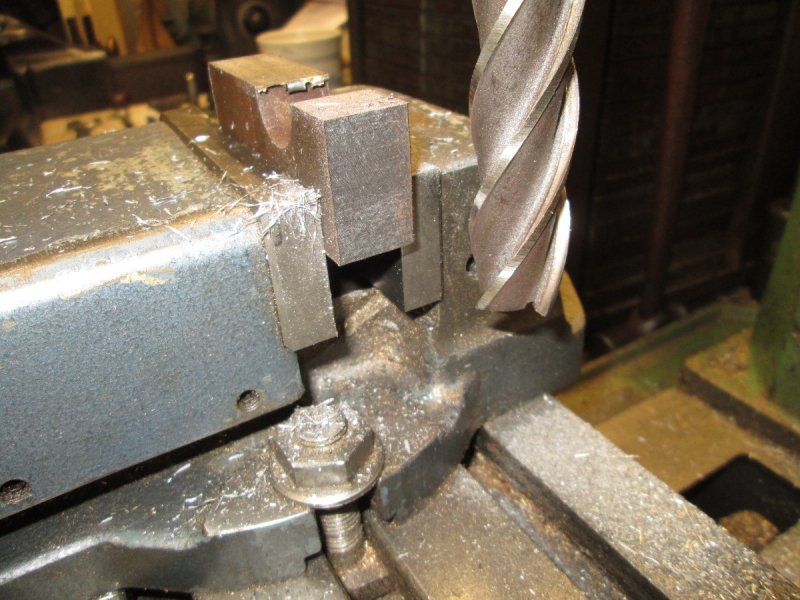

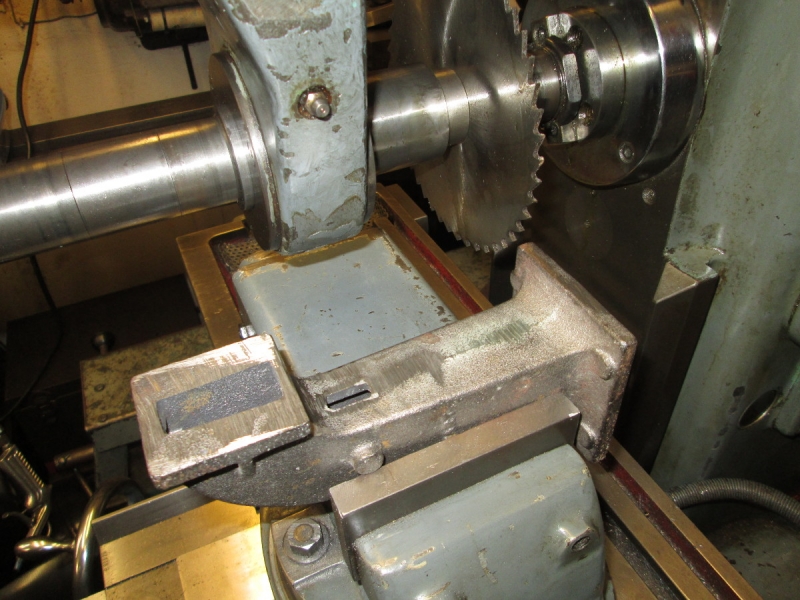

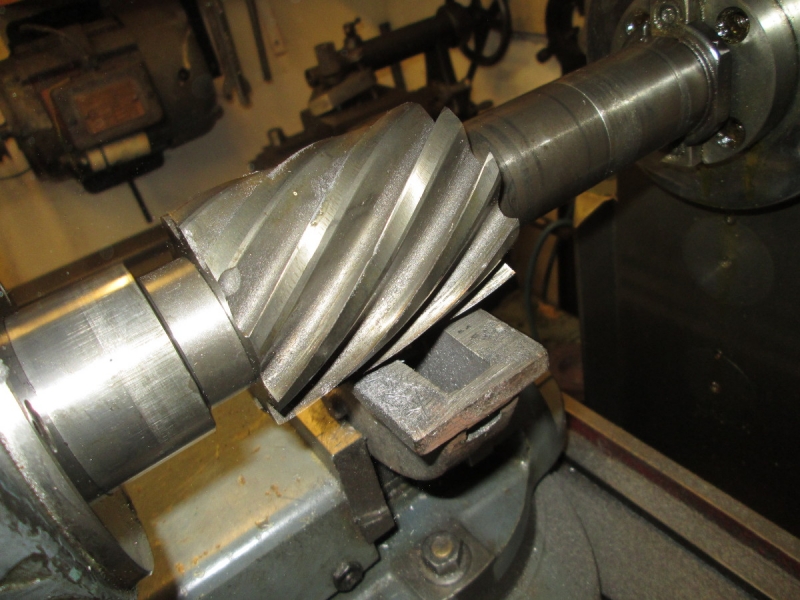

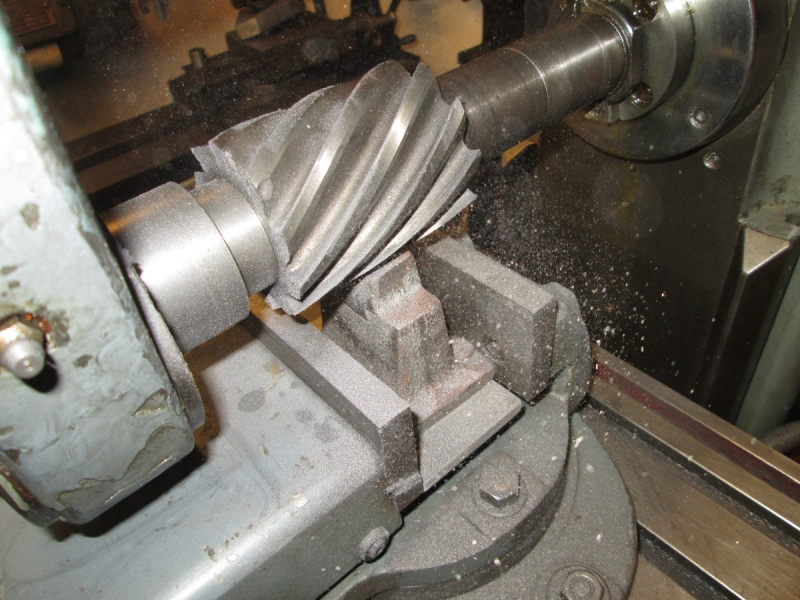

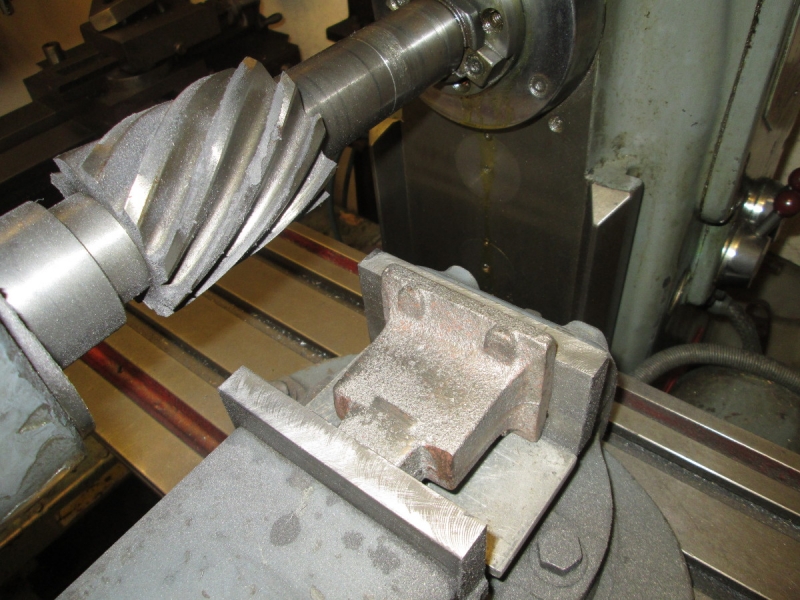

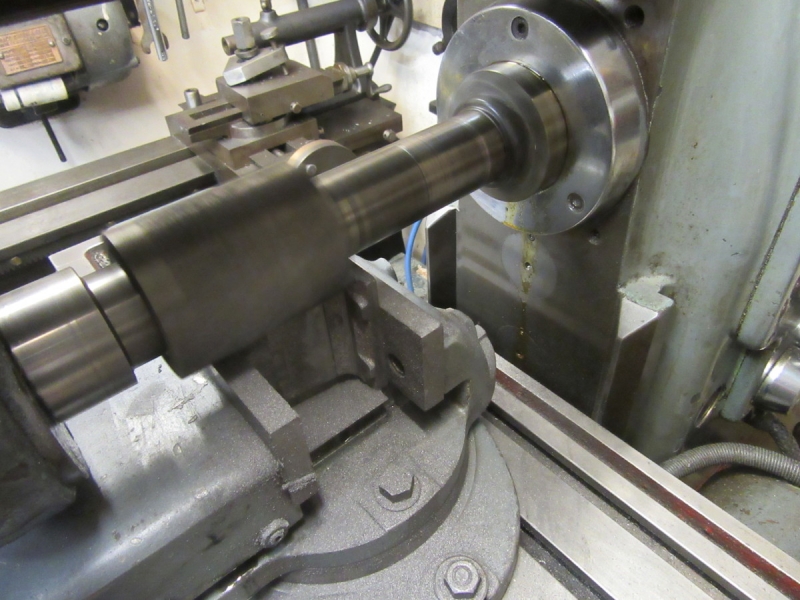

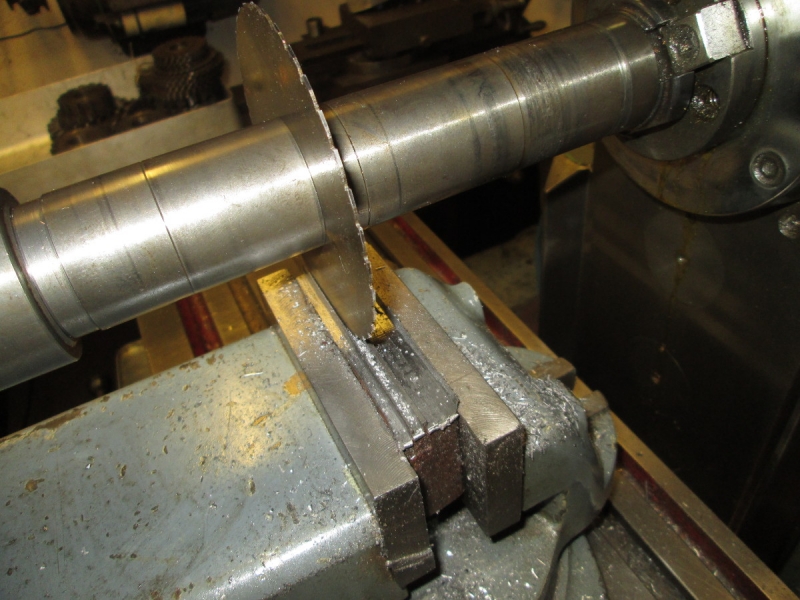

The reason why this pic is here is that this 4" X 1/32" slitting saw was, on first viewing, a lost cause. It hardly had any teeth left. But a saw this thin would be very useful for slitting bearings so I decided that it was worth the challenge. It wasn't easy but the results were fine, this may be it's last incarnation but it's a useful cutter. Here it is doing a good job....

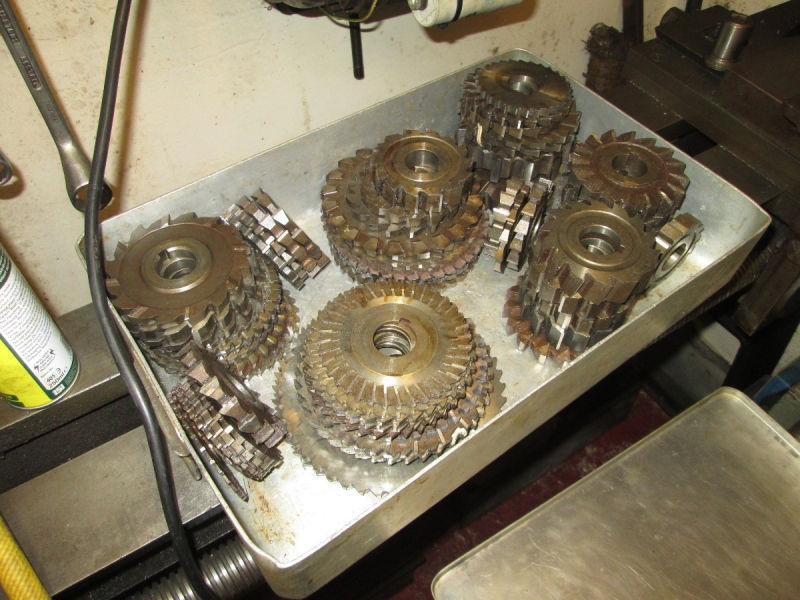

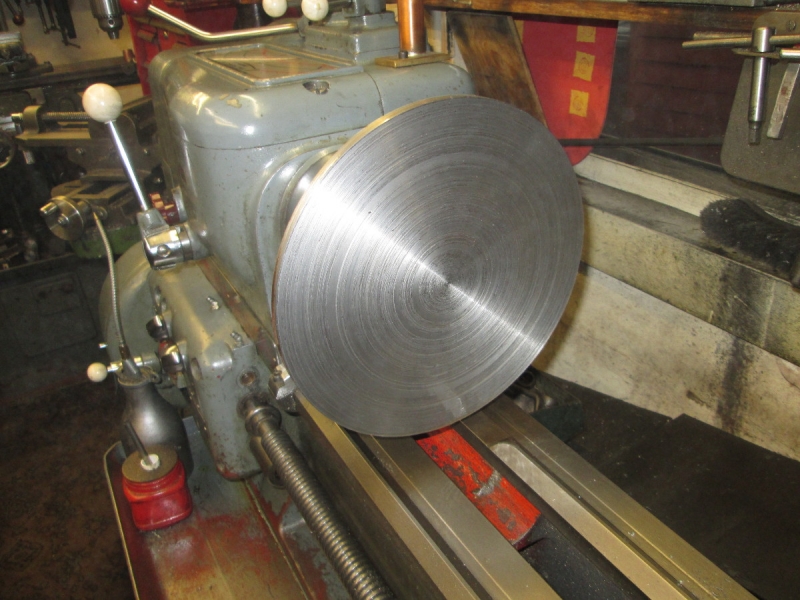

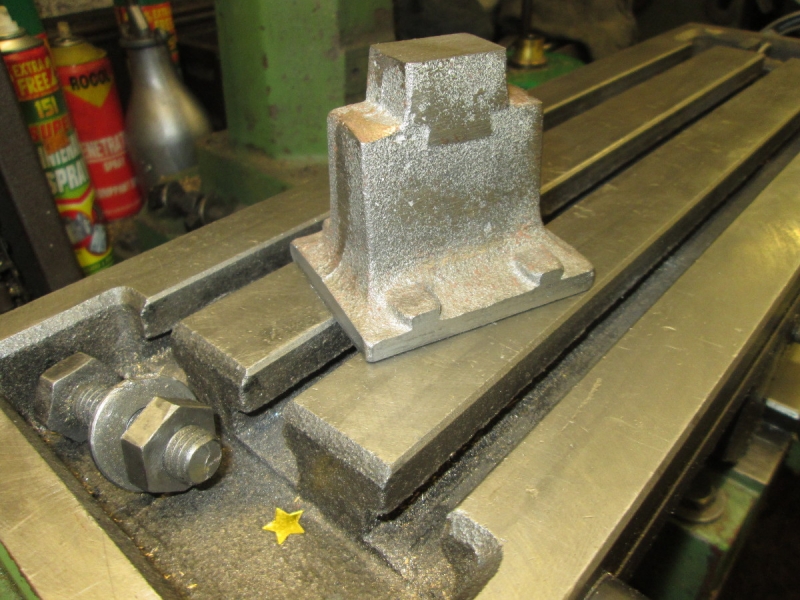

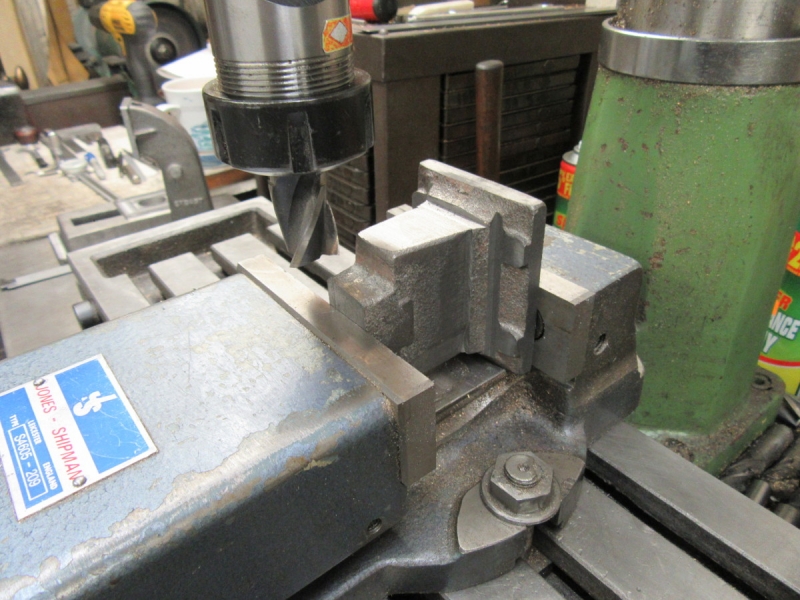

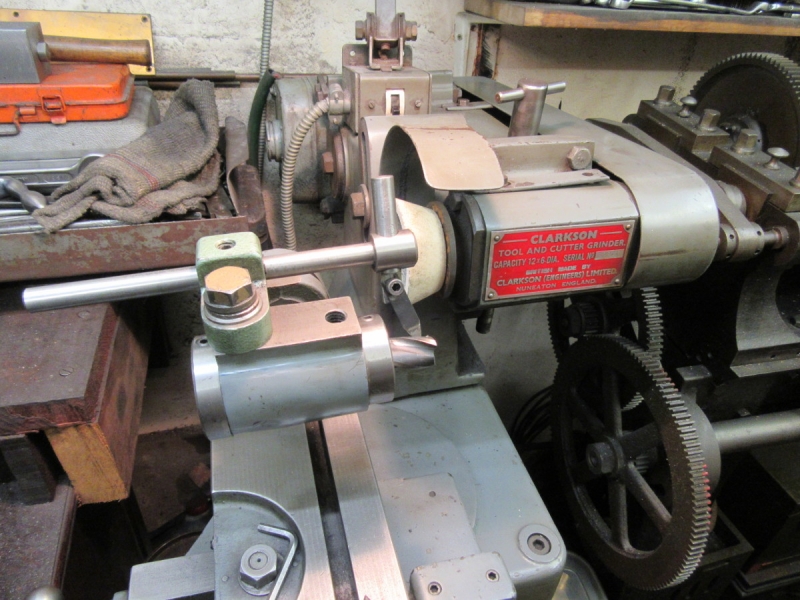

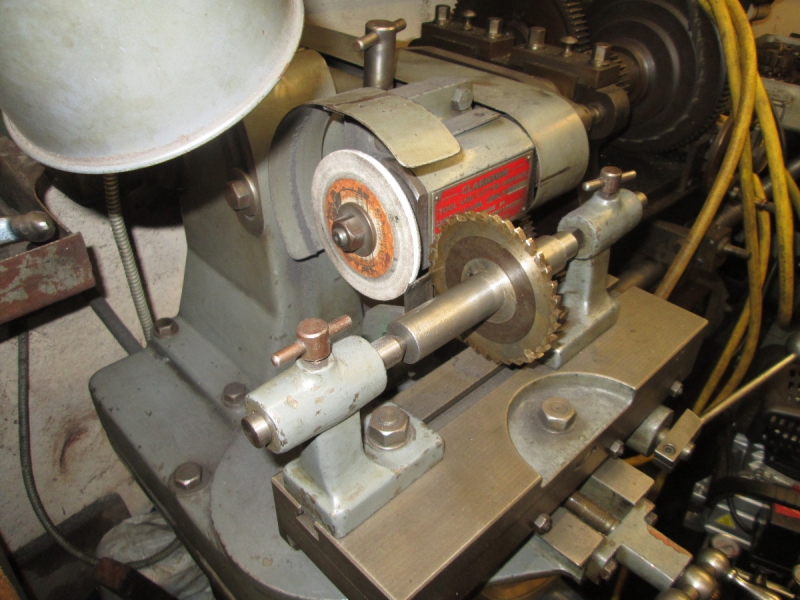

Here's where I ended up, about eight cutters rescued and the next one ready for shaving. In case you're wondering, the motor got hot this morning but that's usual, it's rated as continuous but these Hoover motors run quite warm and need watching. I think the oil has got into the bearings now, no squeal at all and running quieter that it did. I think I may have got away with it! A good morning....we're making progress!