Oil was delivered into the warehouse in 40 gallon steel barrels and we could roll them from there into the engine house. I had the gantry crane parked at that end of the house and that was about all we used it for, lifting the drums onto the heavy wooden stillage that stood inside the door. I had treacle valves on all of them, you never see them today.....

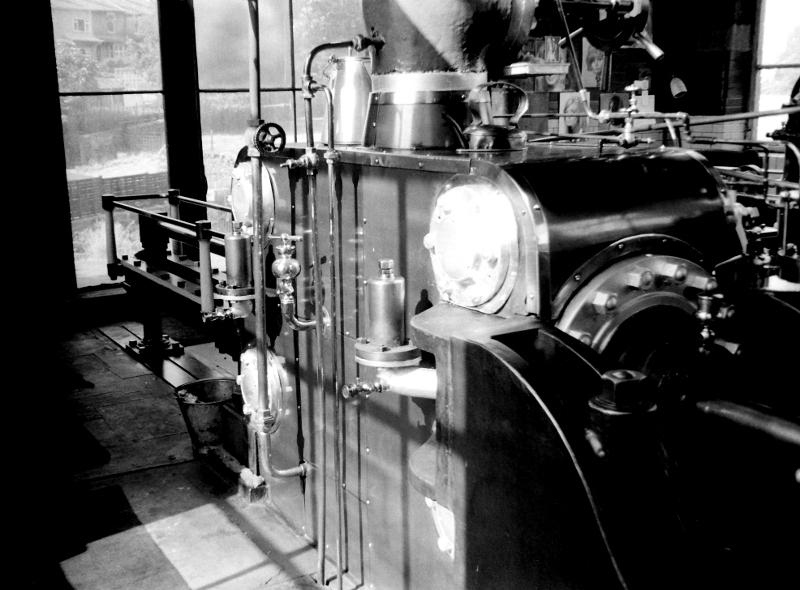

The old-fashioned cylinder oil that was in use in the 1920s when the engine was installed was like very thick treacle and had to be warmed before you could easily pour it into the lubricators. There was a nicely shaped oval oil kettle sunk into a custom made recess in the insulation on the top of the high pressure cylinder.

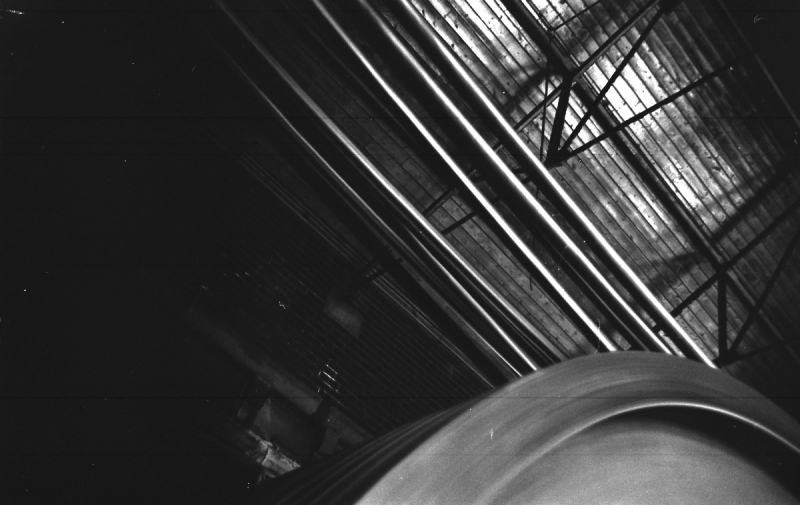

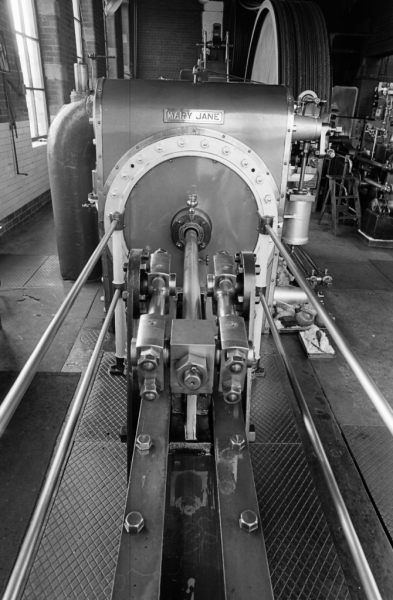

If you look carefully you can see the upper half of it just in front of the steam pipe. The large stainless steel jug behind the pipe holds the reserve supply which was also kept warm. The Walker's cylinder oil was nothing like treacle but it paid to keep it warm, it went in through the built in sieve on the HP lubricator much easier.

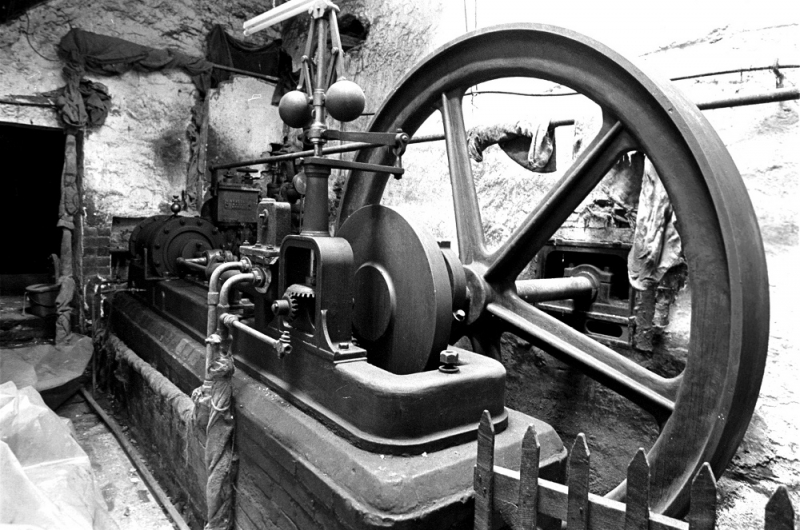

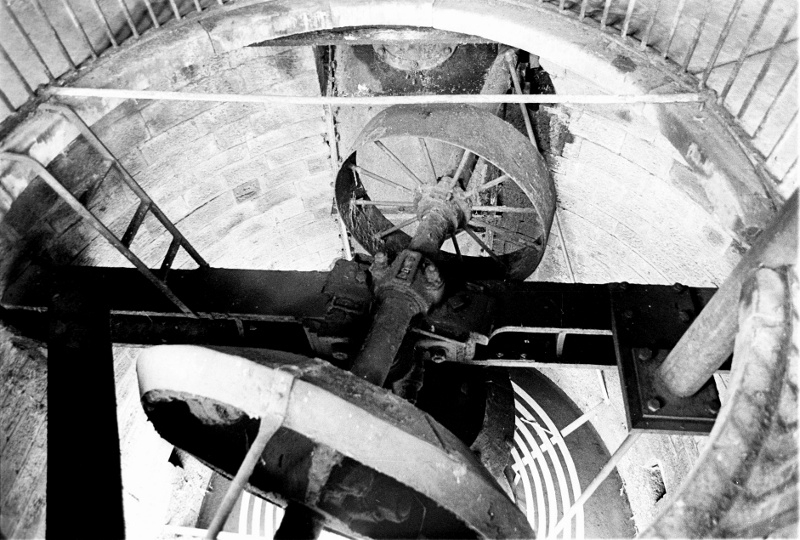

The bearing oil was a straight 40SAE mineral oil and there was a top-up jug next to every lubricator on the engine that had a reservoir. Even though I was aware of the fact, we always used excess oil in the bearings on the grounds it was better to be safe than sorry. Some engineers went far further and literally flooded the bearings! very noticeable when volunteers are running them..... My motto was little and often. In fact I took the four lubricators off the head of the bell crank that drove the air pump and just gave the pins a shot of cylinder oil on starting, that was all they needed, they weren't rotating just reciprocating a few degrees. They used to throw oil all over the place!

Look, no lubricators! It never came to any harm......