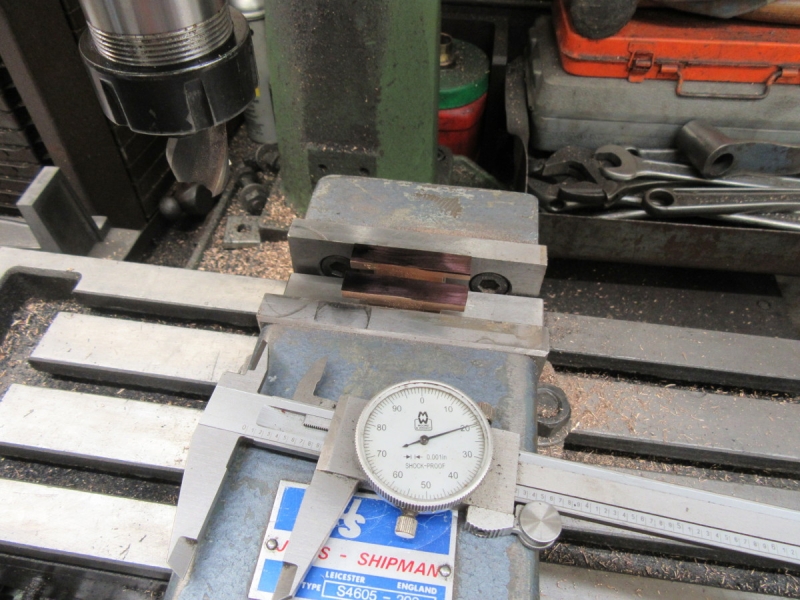

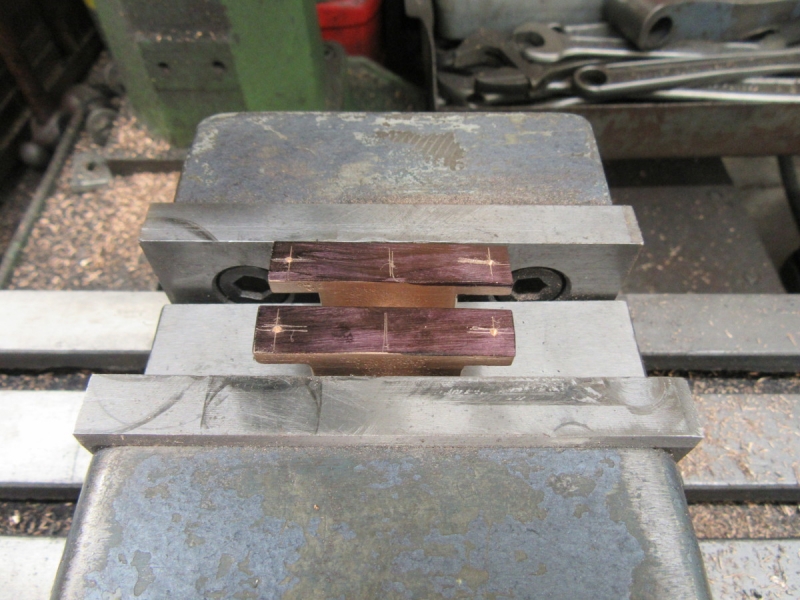

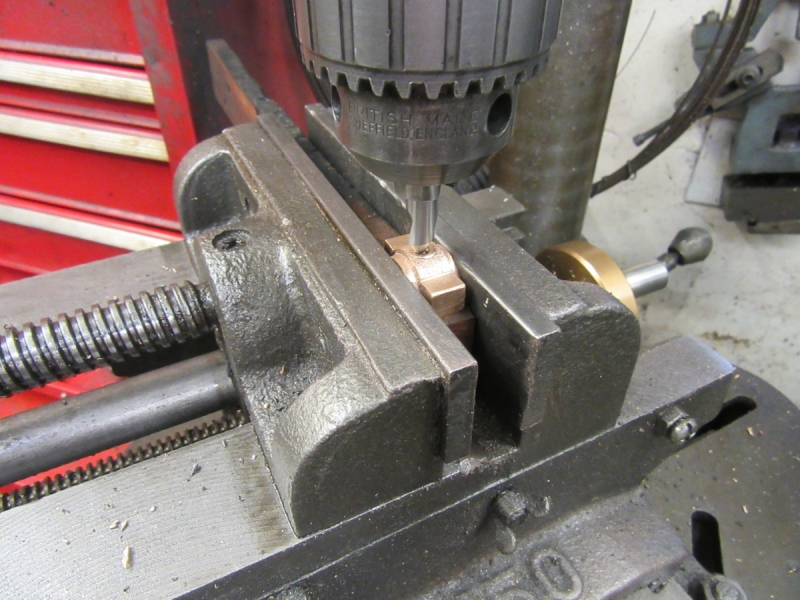

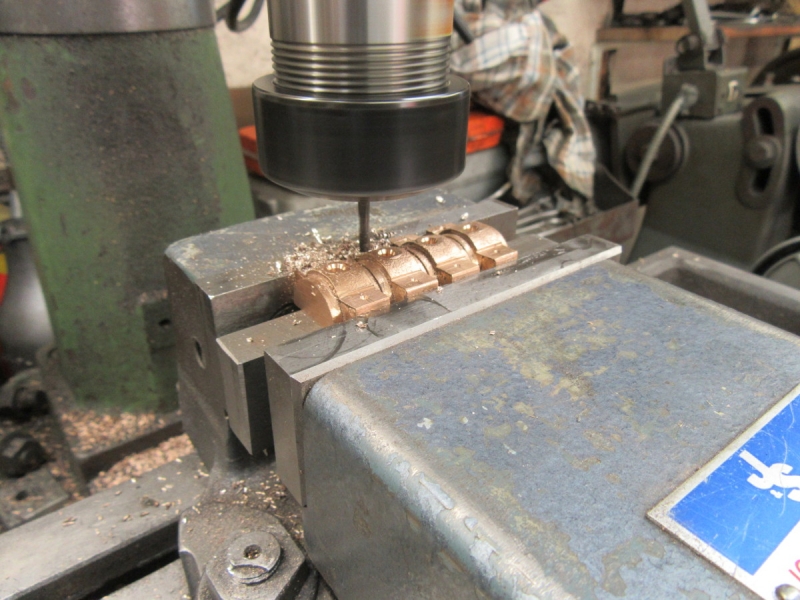

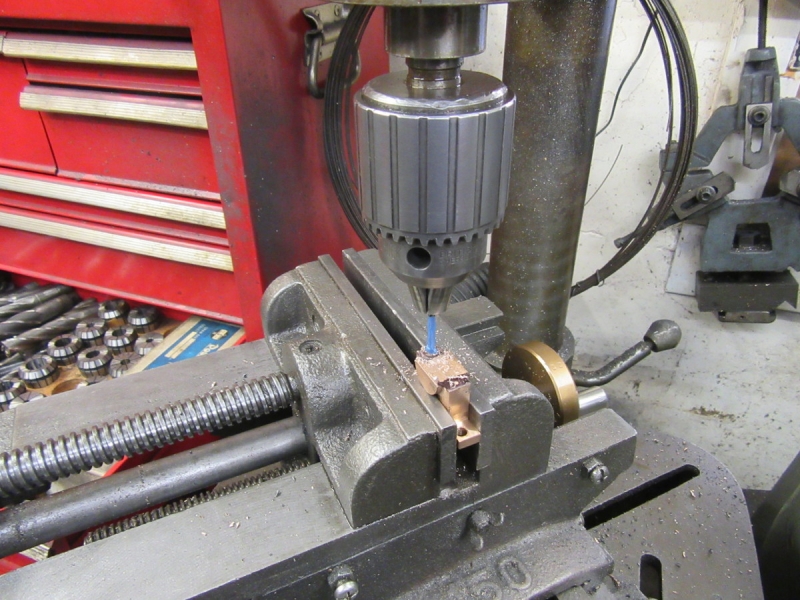

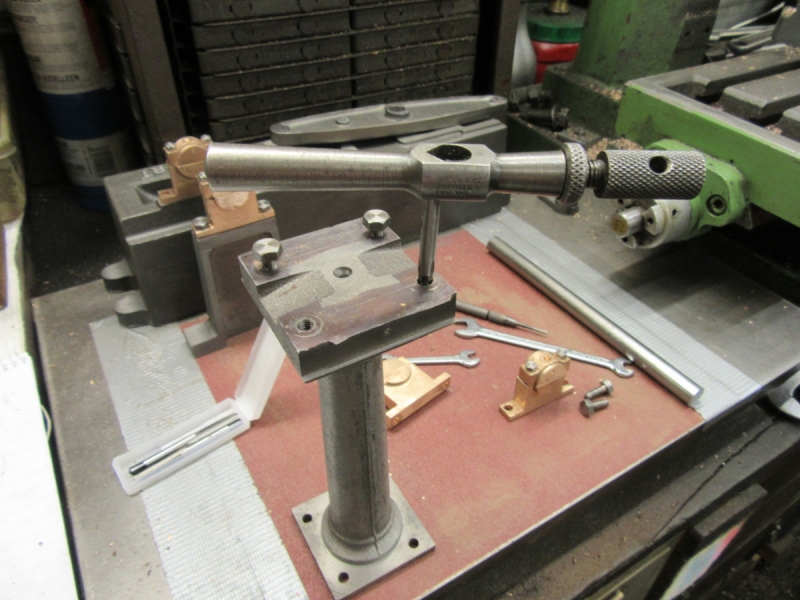

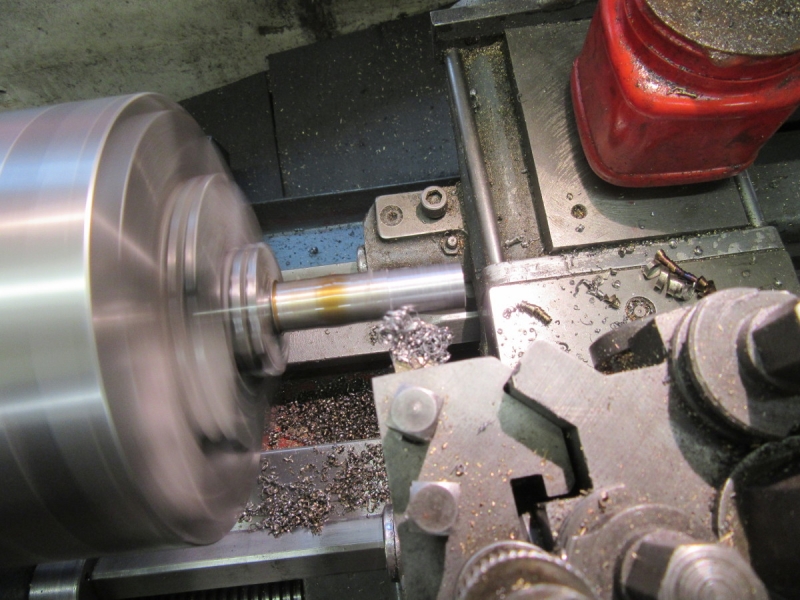

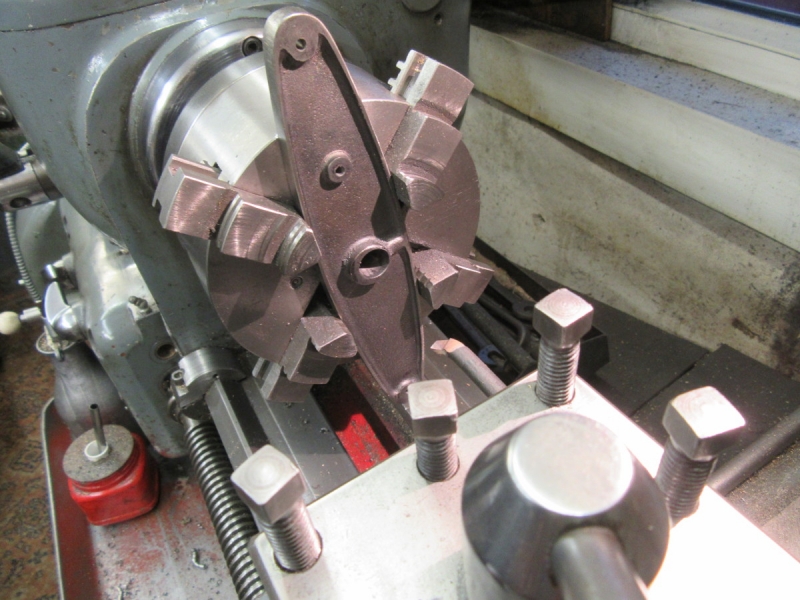

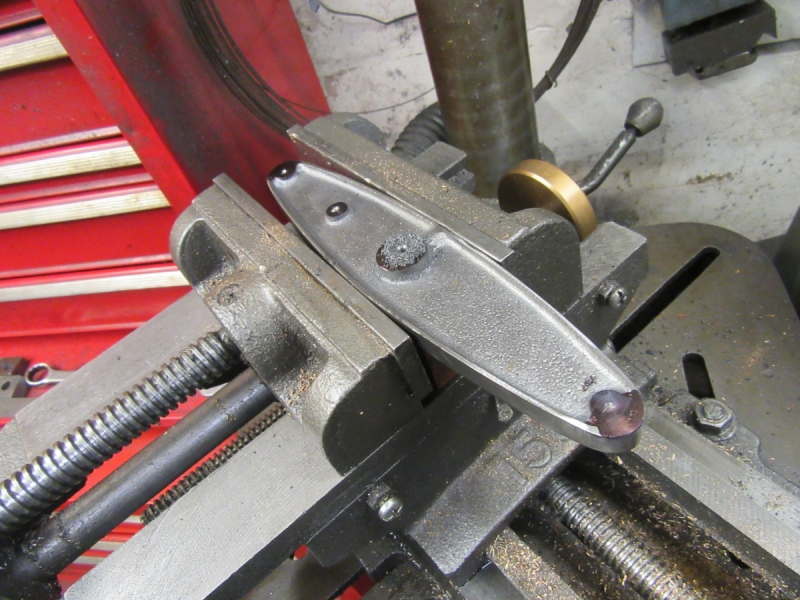

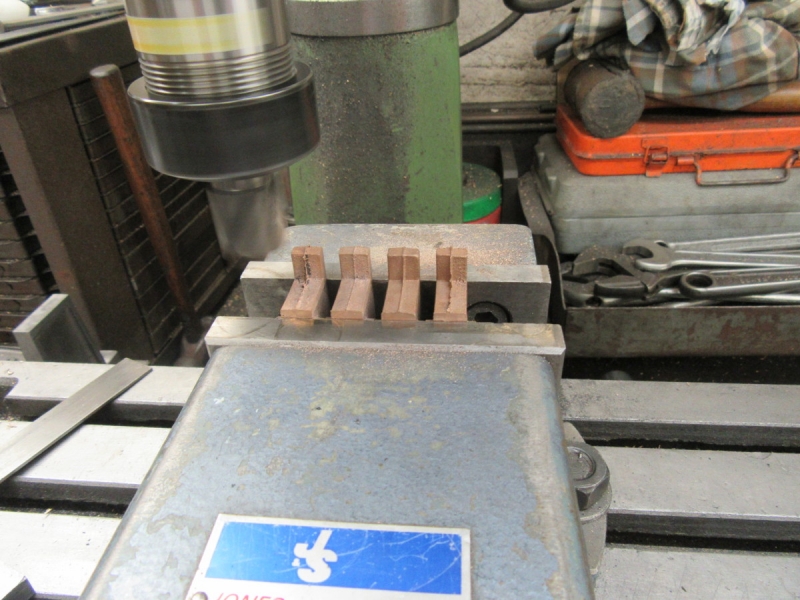

I decided that the castings are best squared up under the mill.

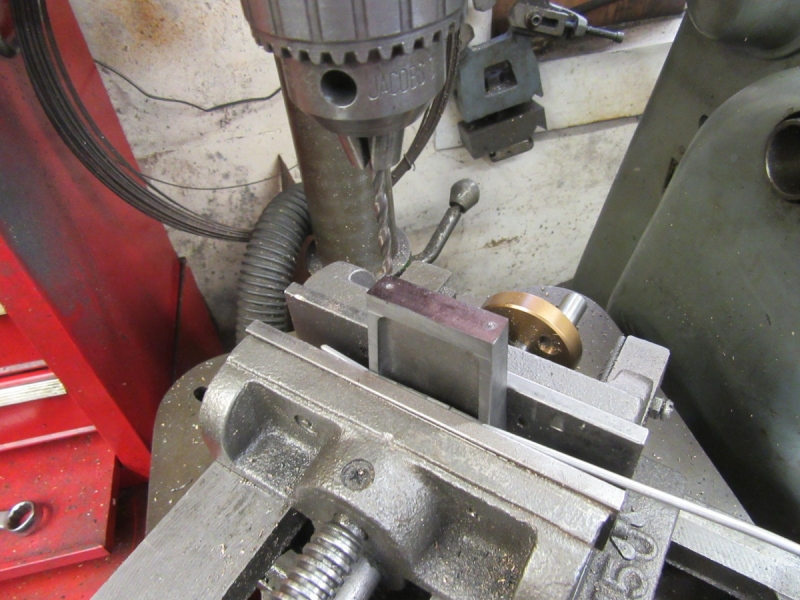

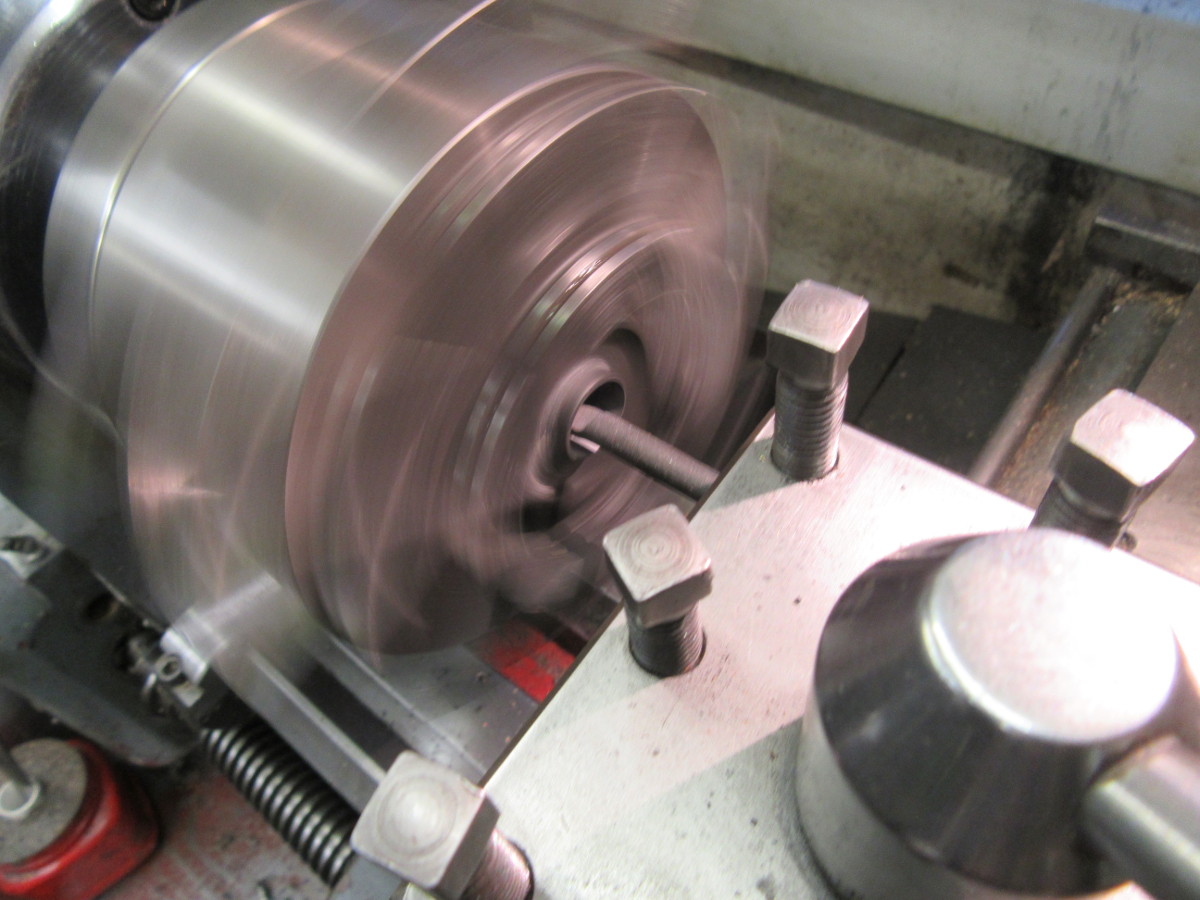

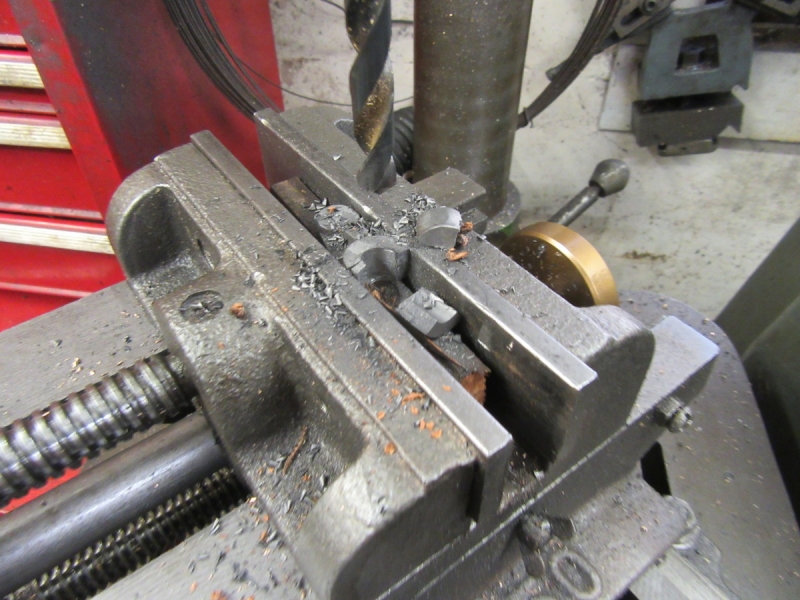

A bit of very careful milling, taking off as little metal as possible.

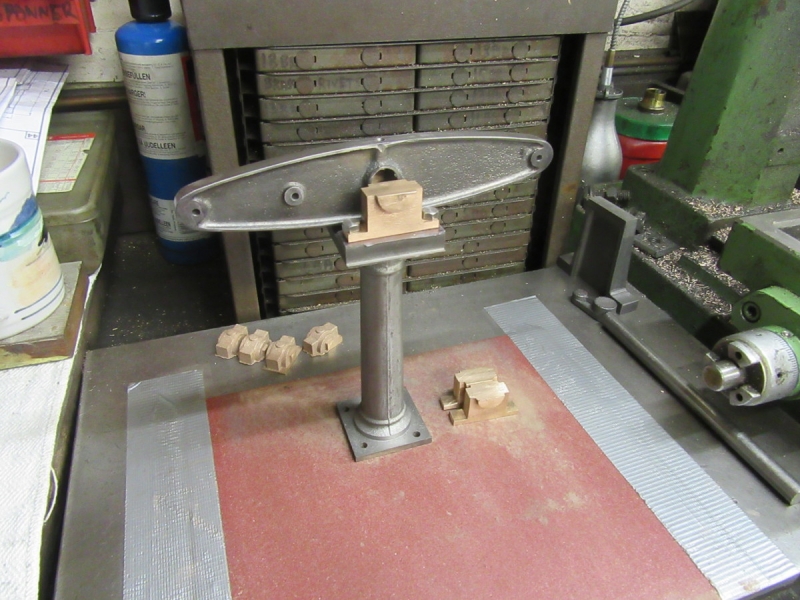

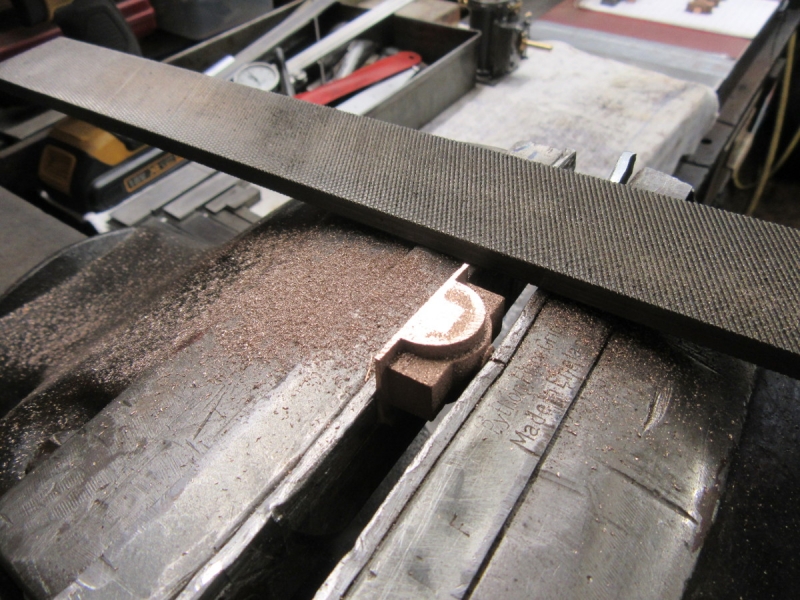

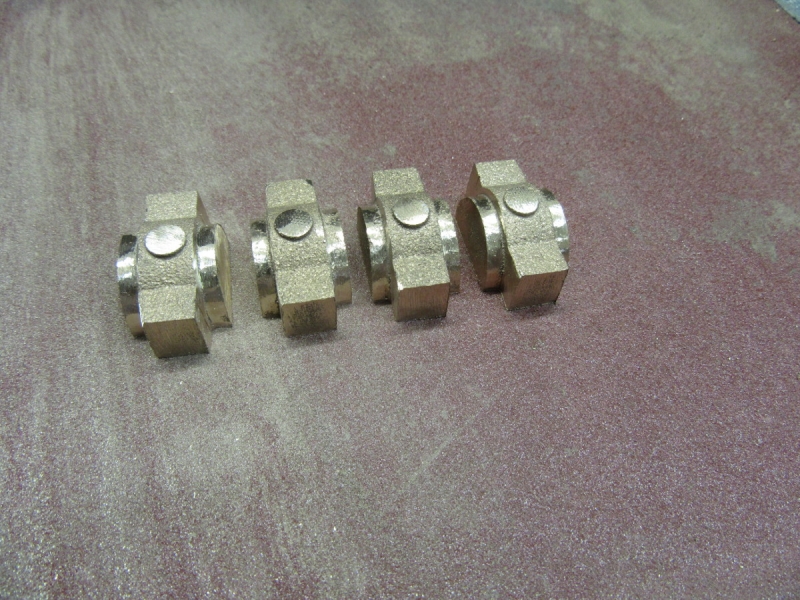

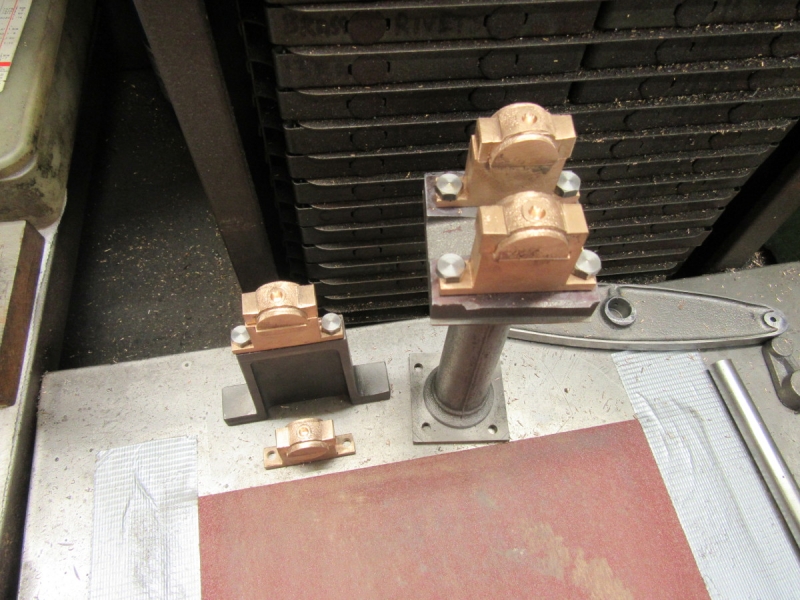

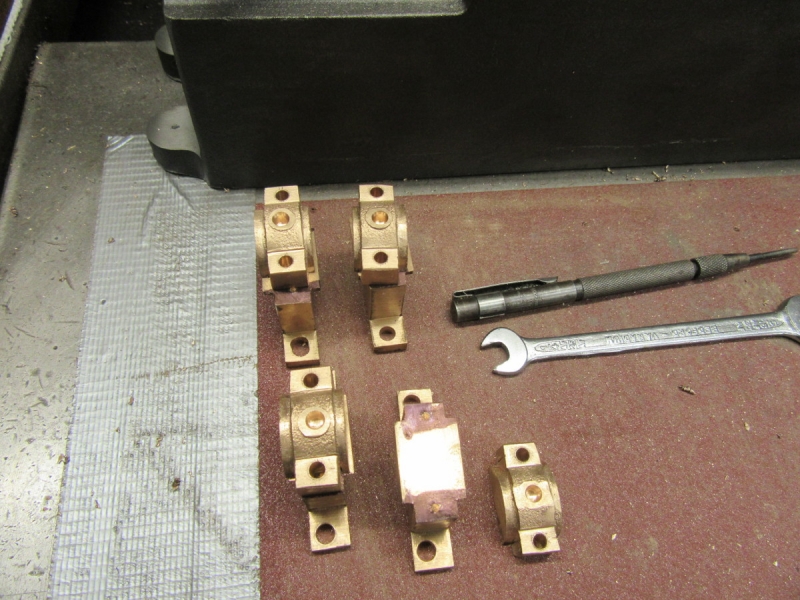

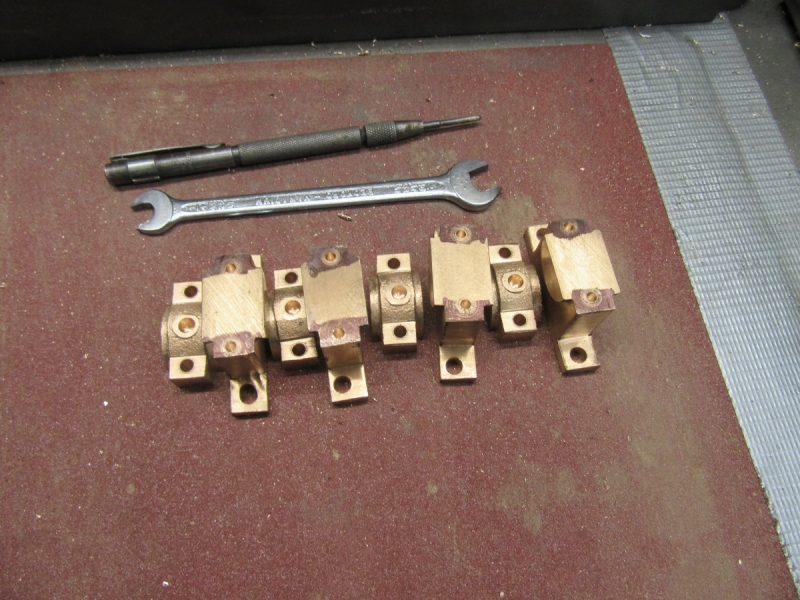

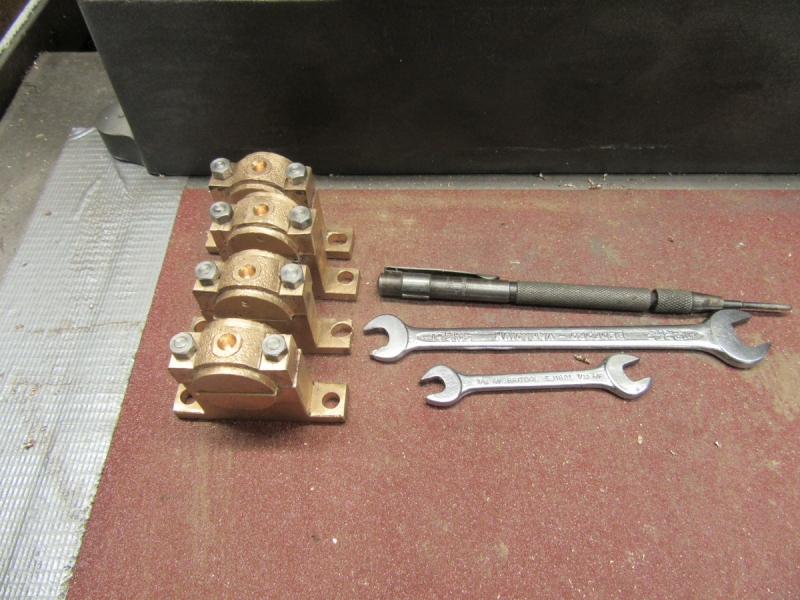

I used the 120 grit paper taped to the surface plate to clean up the unimportant faces and break all the sharp corners.

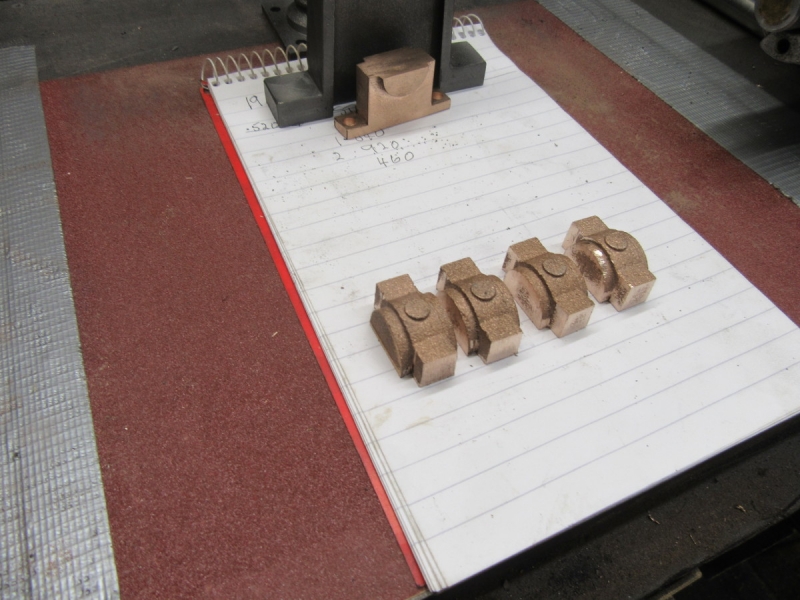

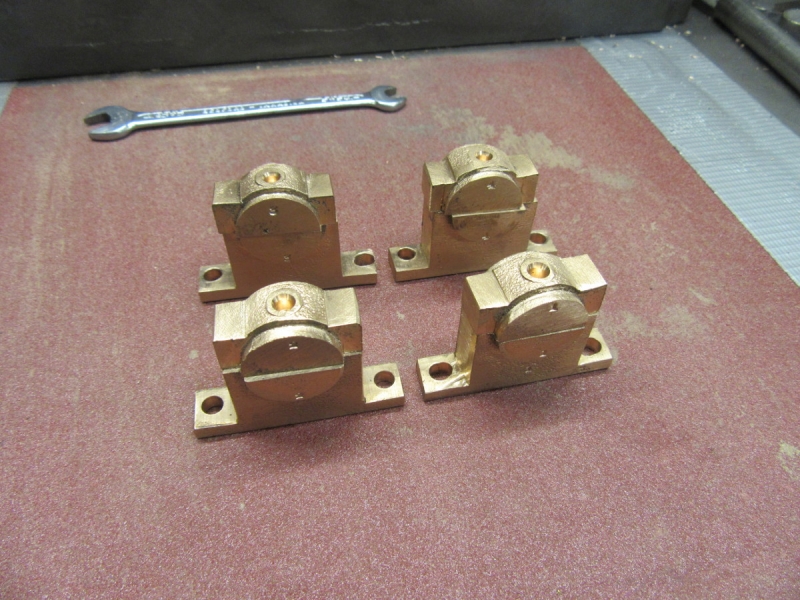

My last blow was to sharpen a wire brush and give them all a good brushing. This cleaned up what the mill and the 120 grit paper had missed.

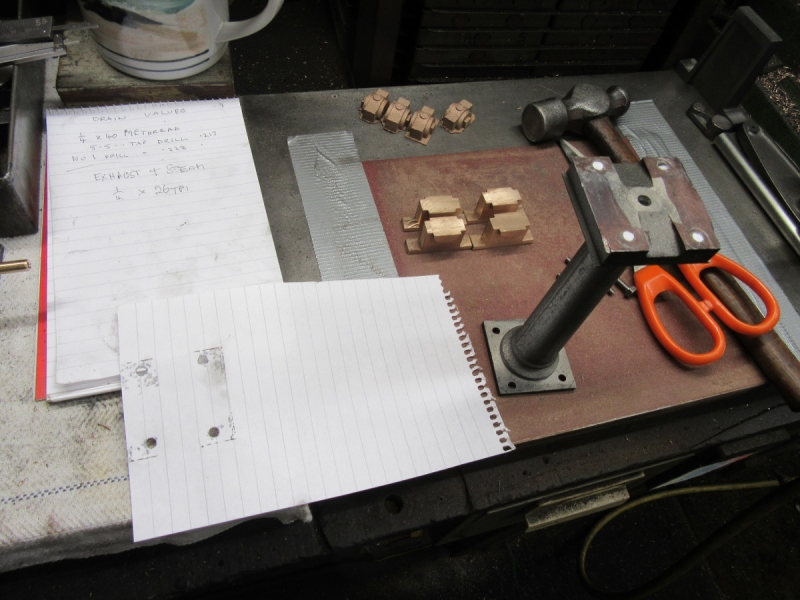

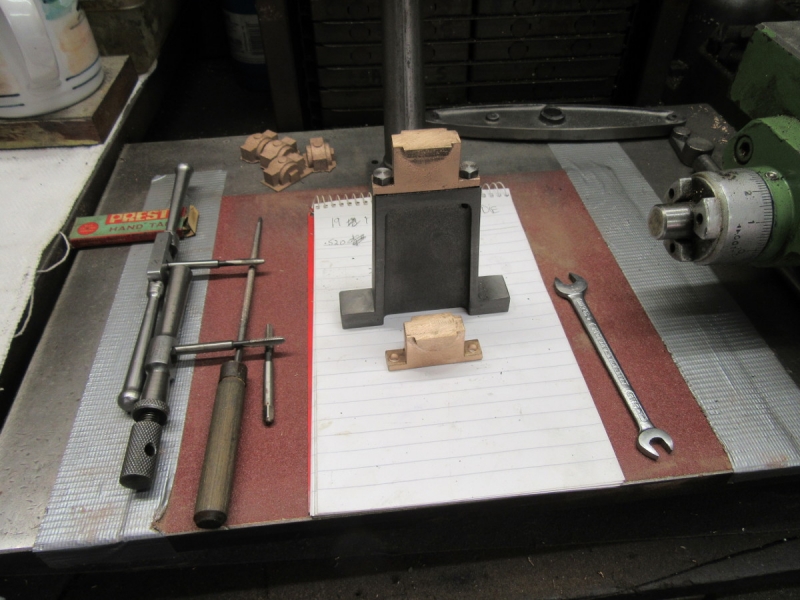

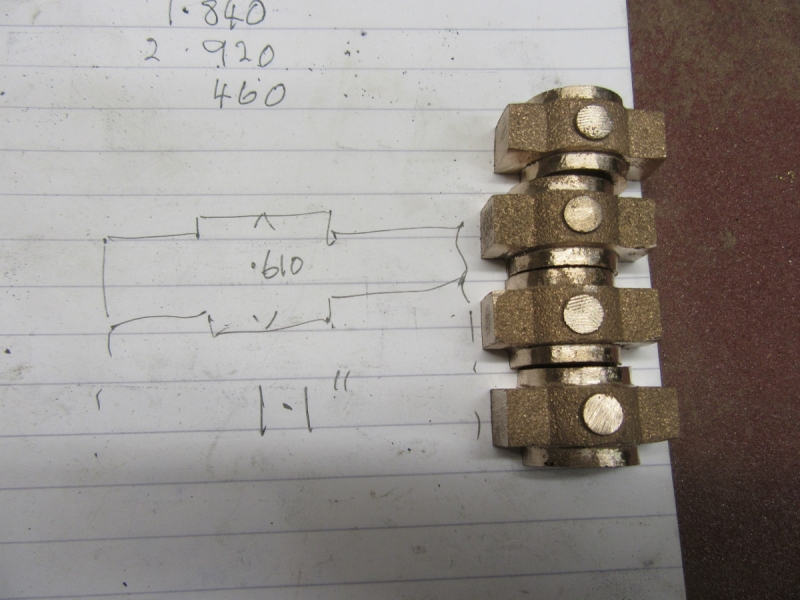

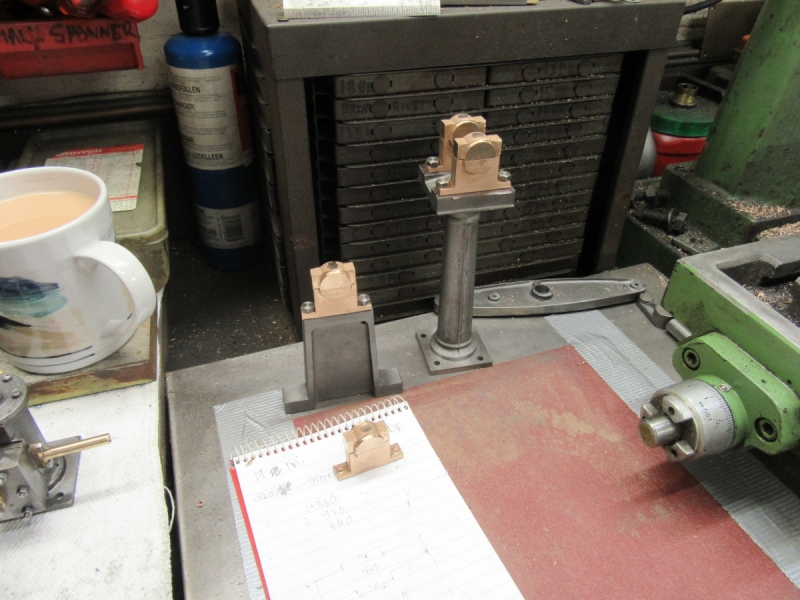

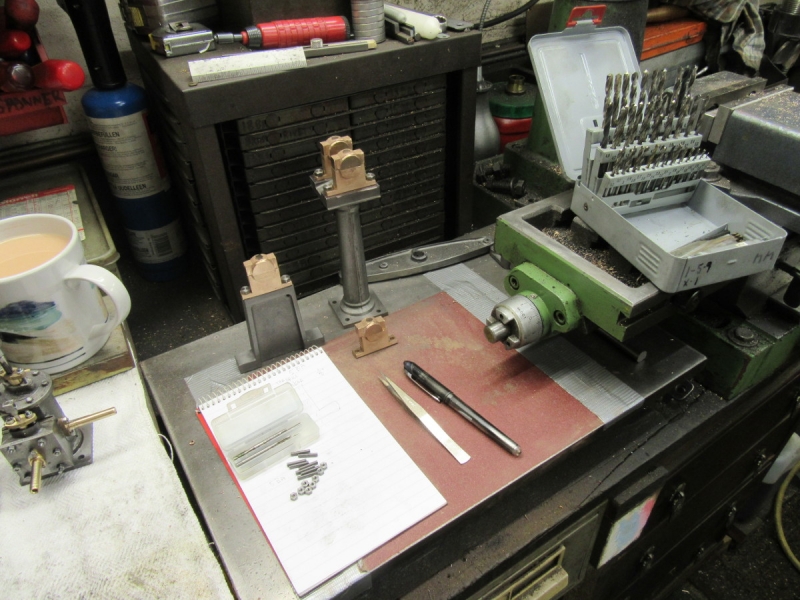

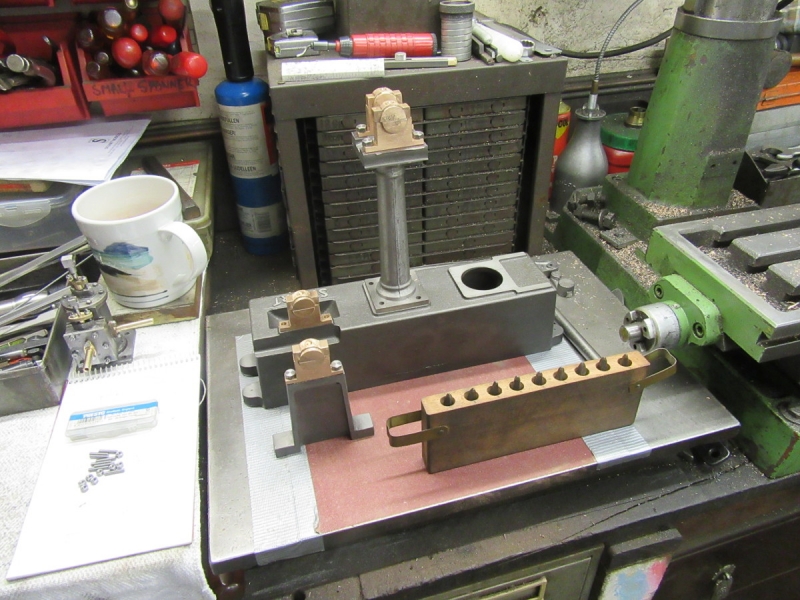

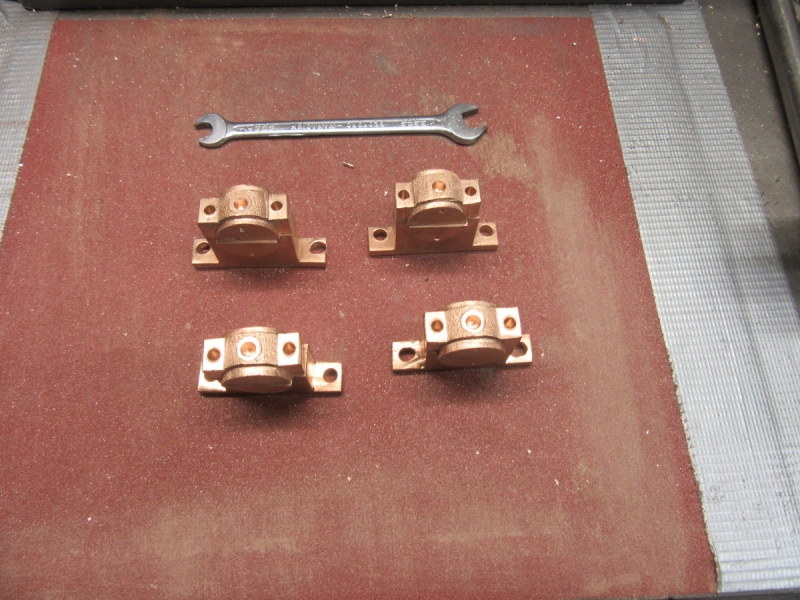

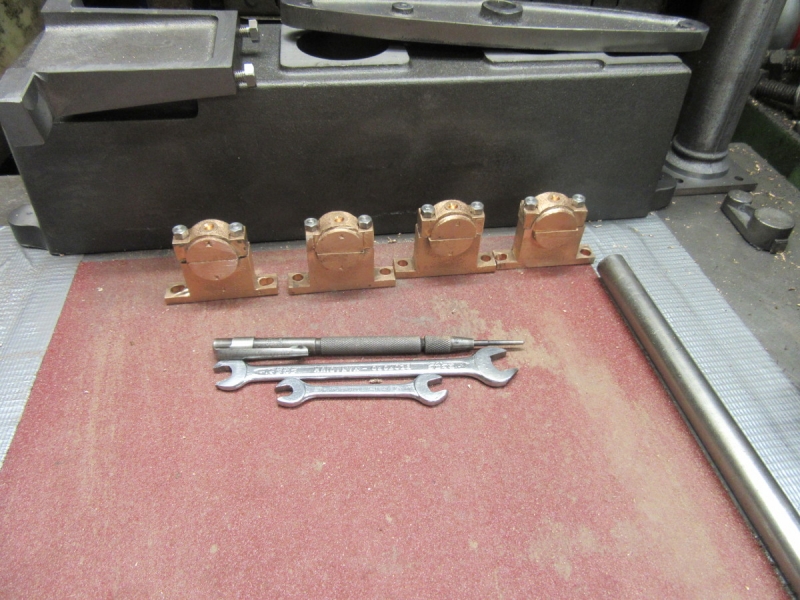

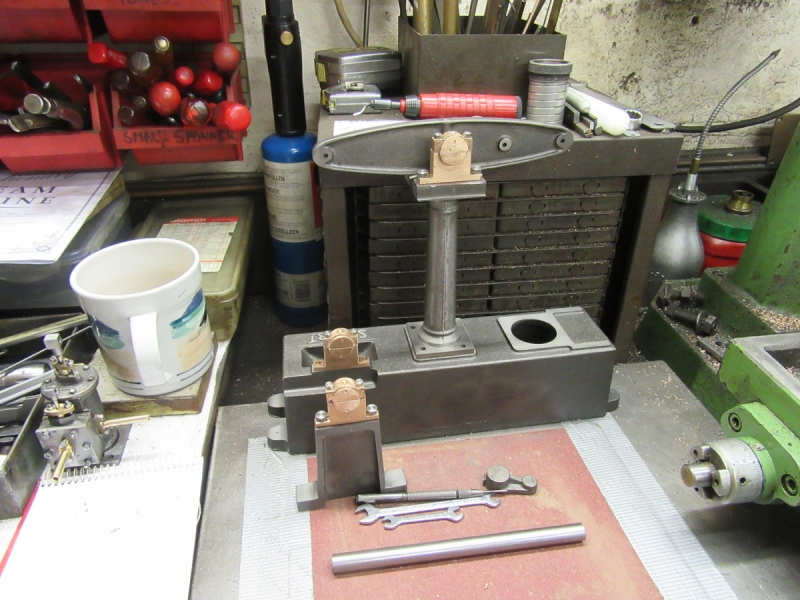

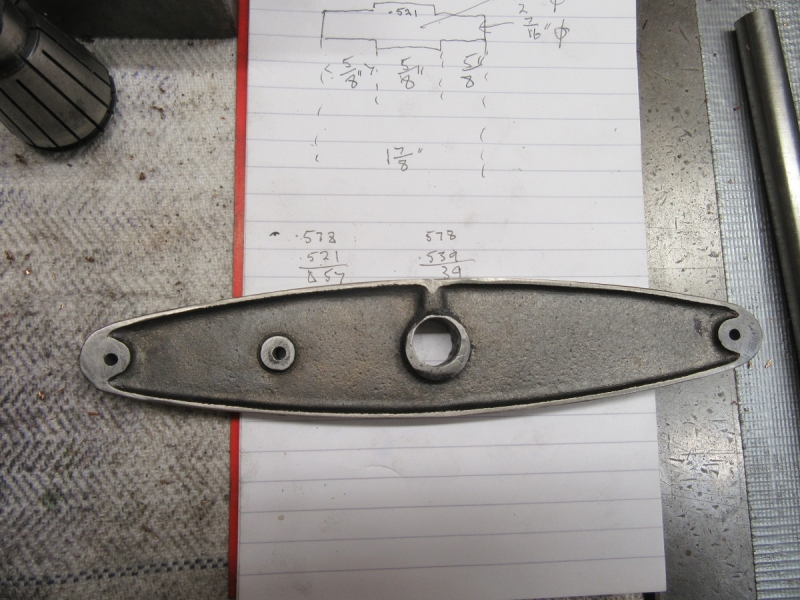

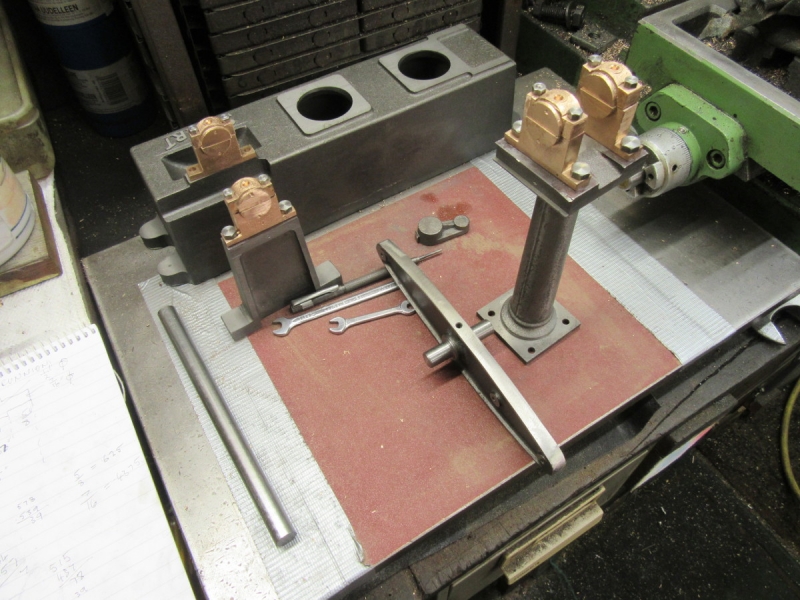

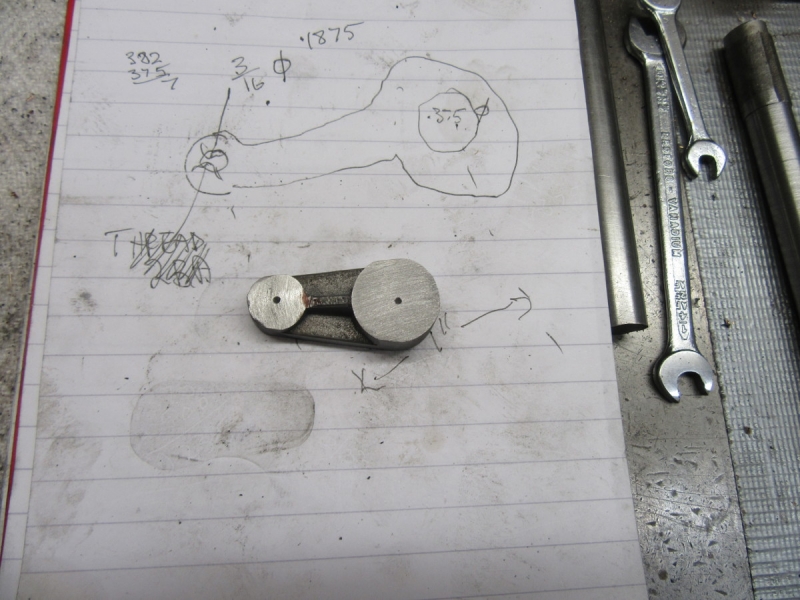

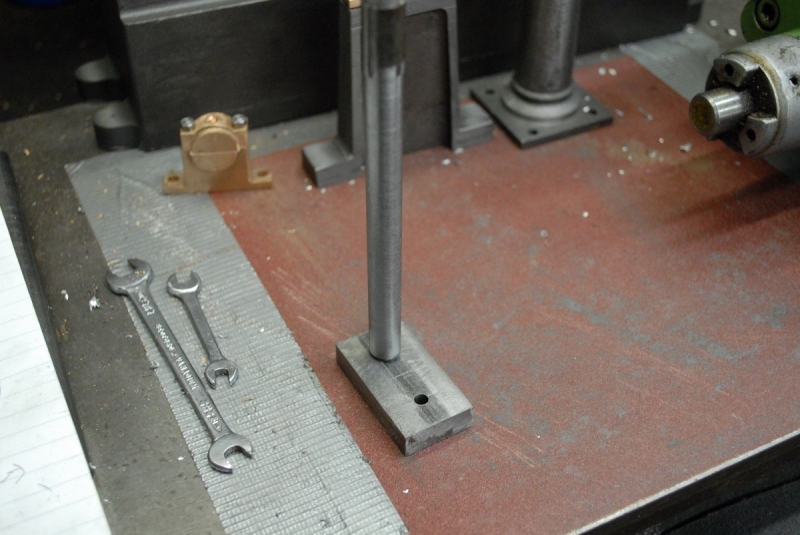

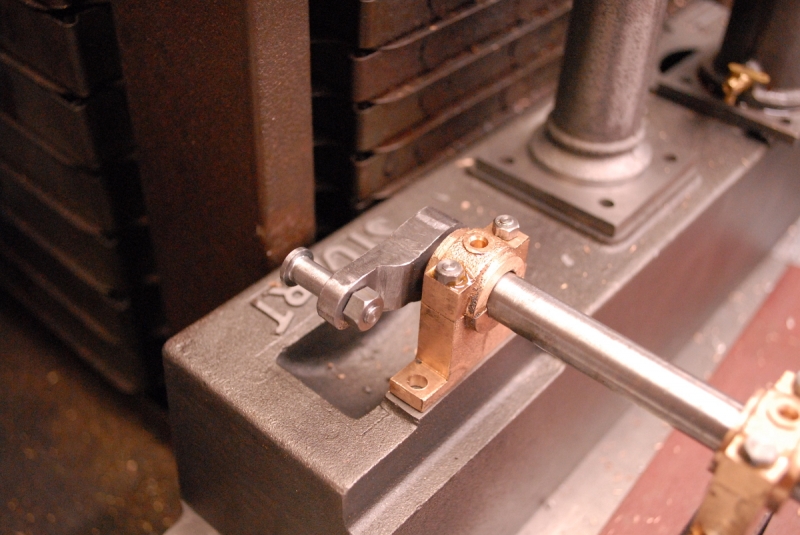

Knocking off time. Two of these bearings are for the beam trunnions and I have already drilled and tapped for the bolts. The drillings for the other two haven't been done yet so I'll drill all the bearing bodies to fit these studs on the column and make the other fastenings to suit.

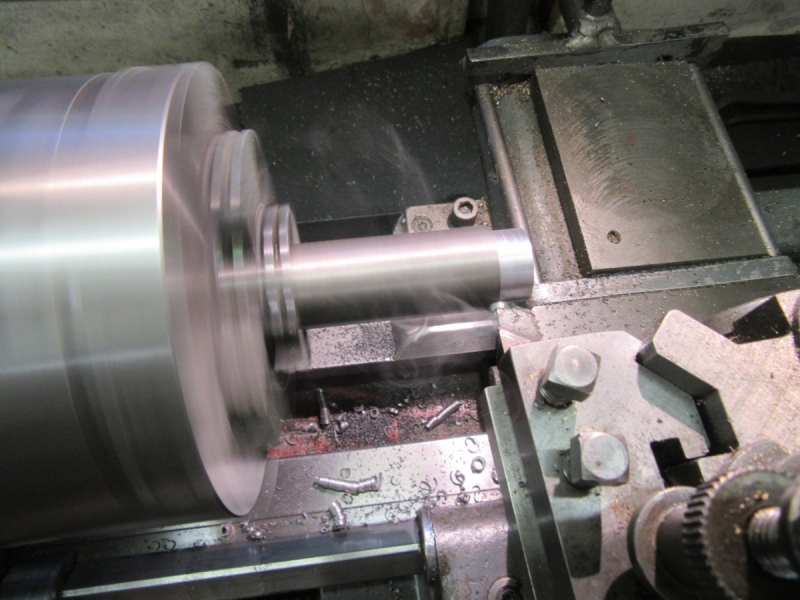

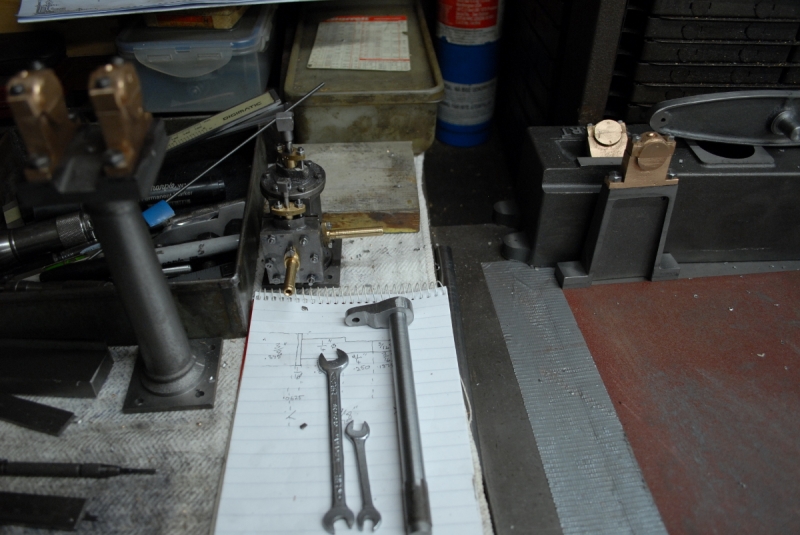

That's enough for this morning. I shall decide tomorrow where I go next. At the moment I am favouring cleaning the bearing caps up ready for fitting. Then they need boring to suit their respective shafts and all this has to be done before they are bolted down.....