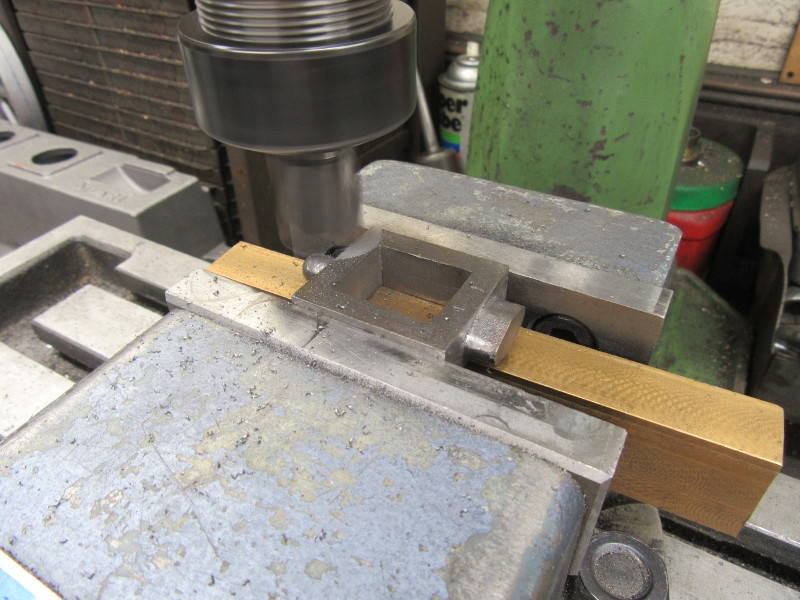

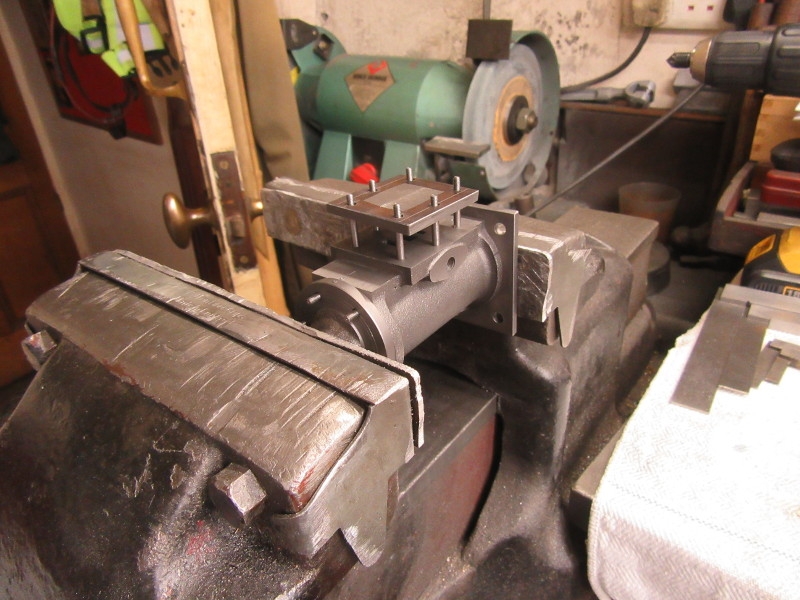

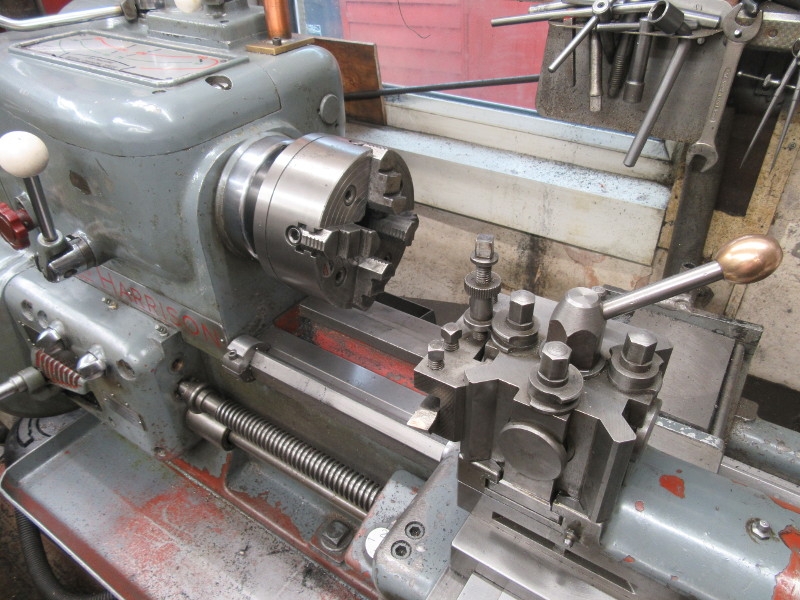

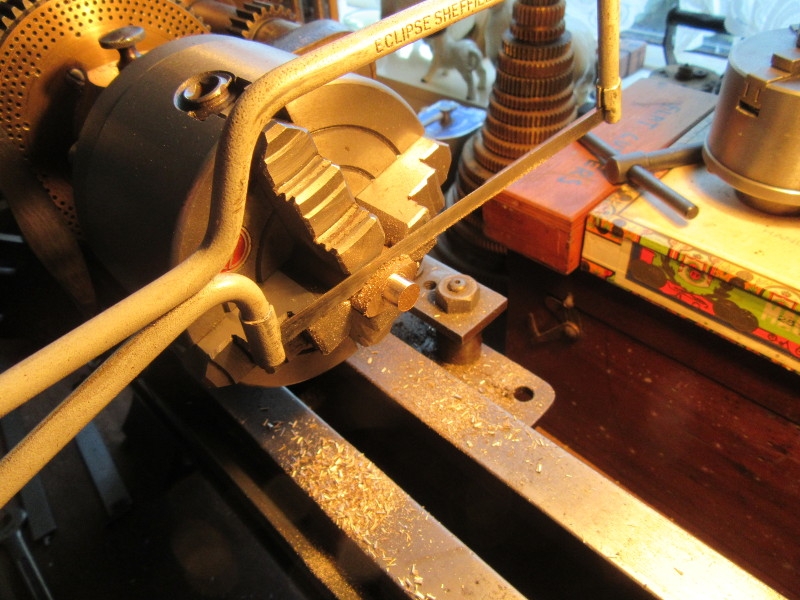

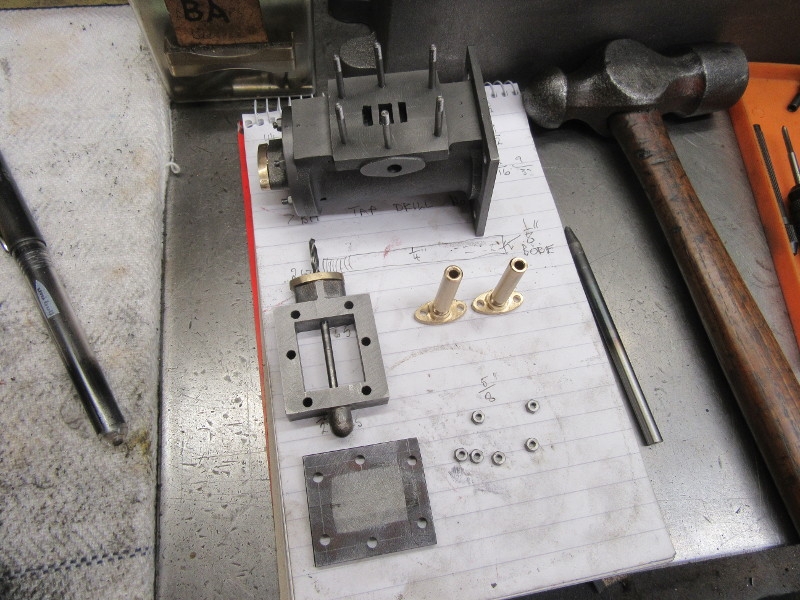

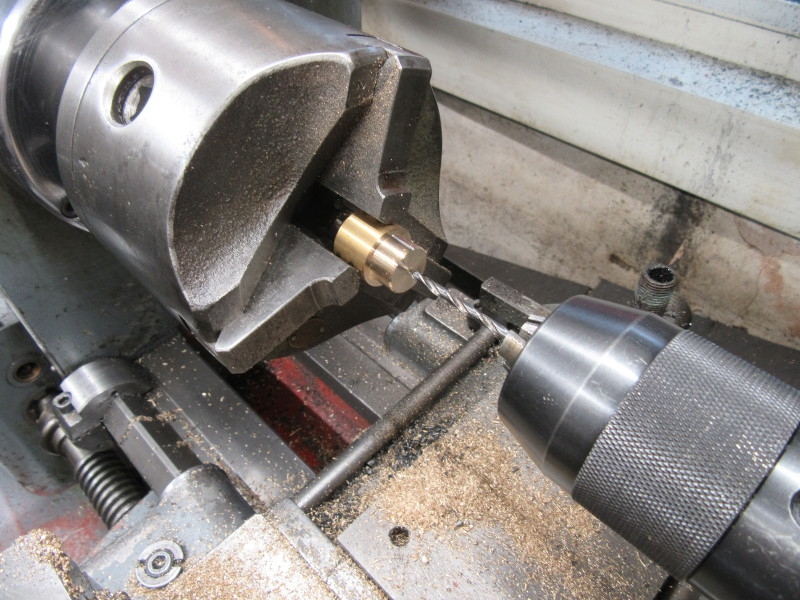

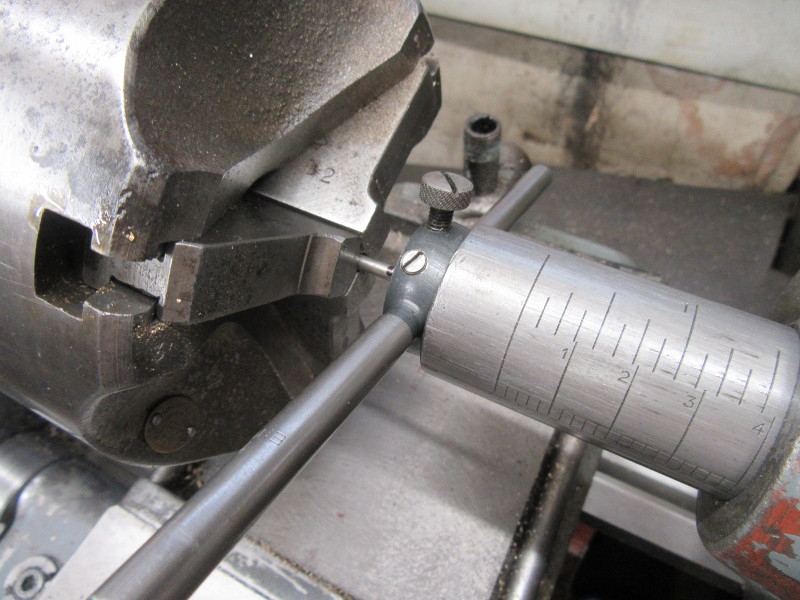

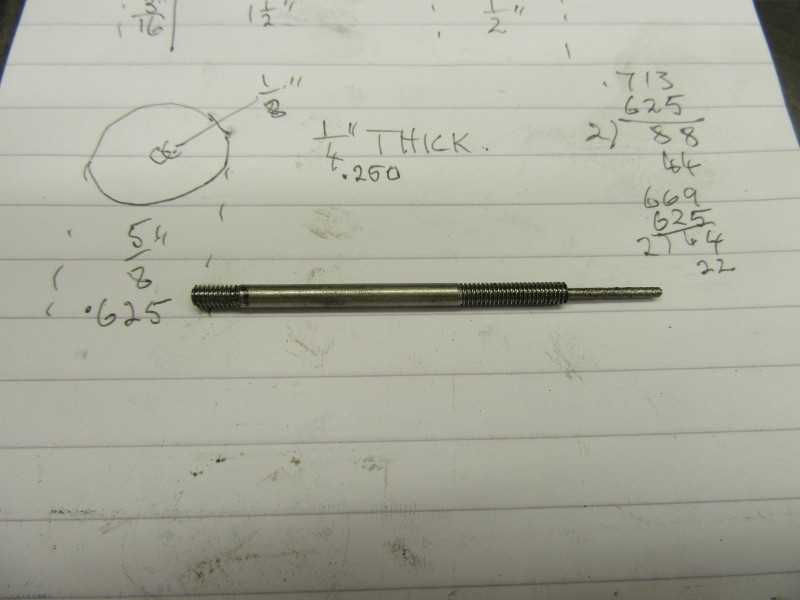

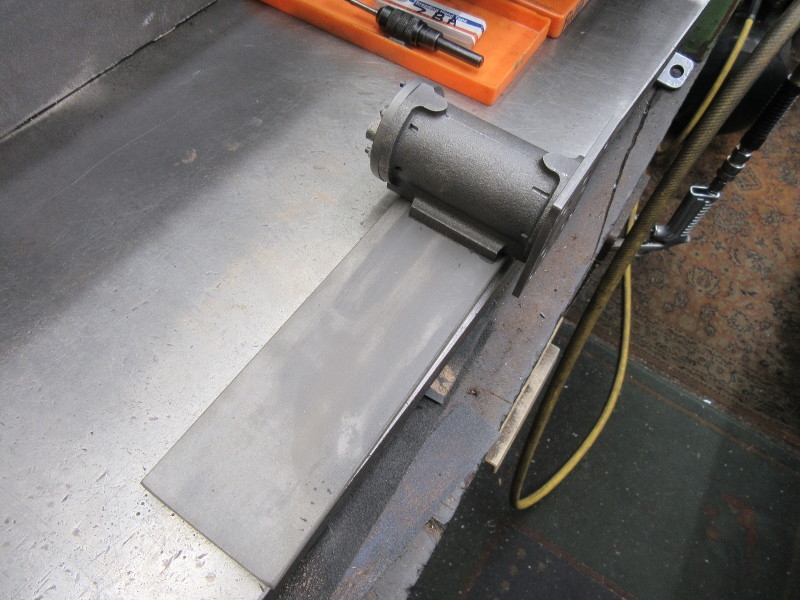

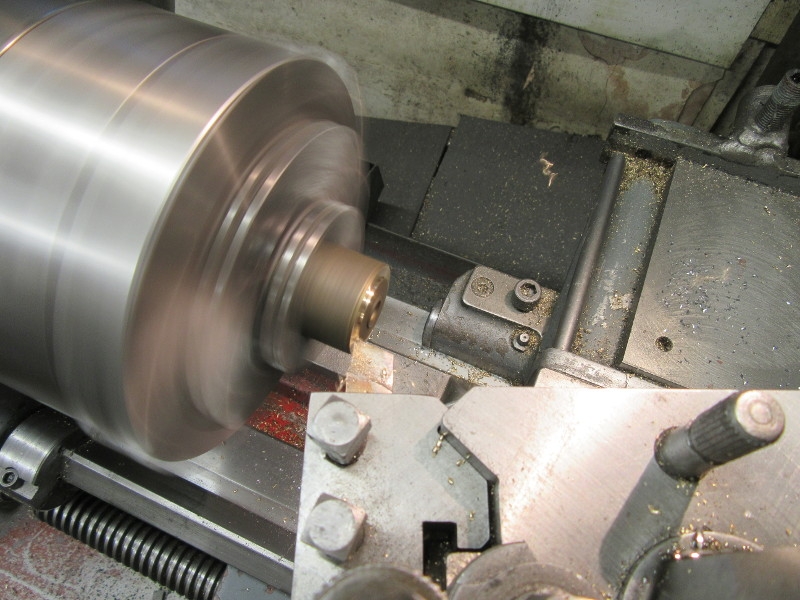

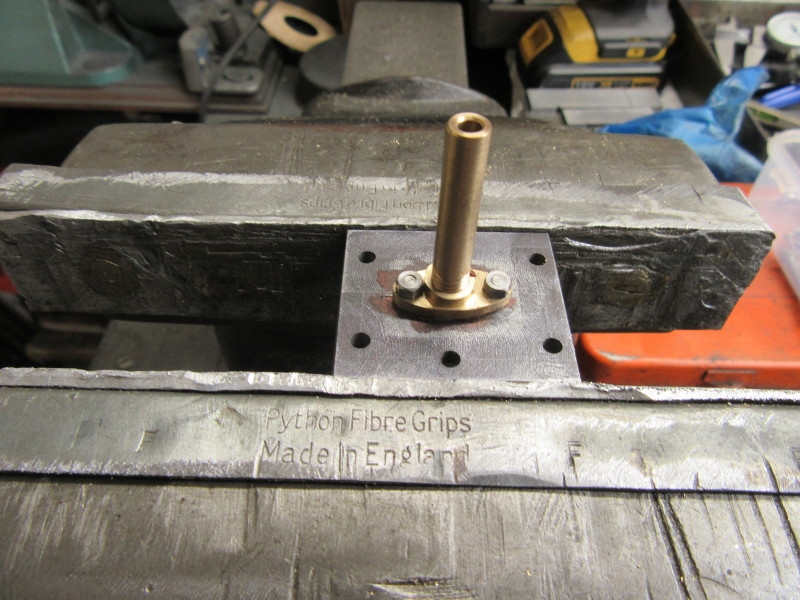

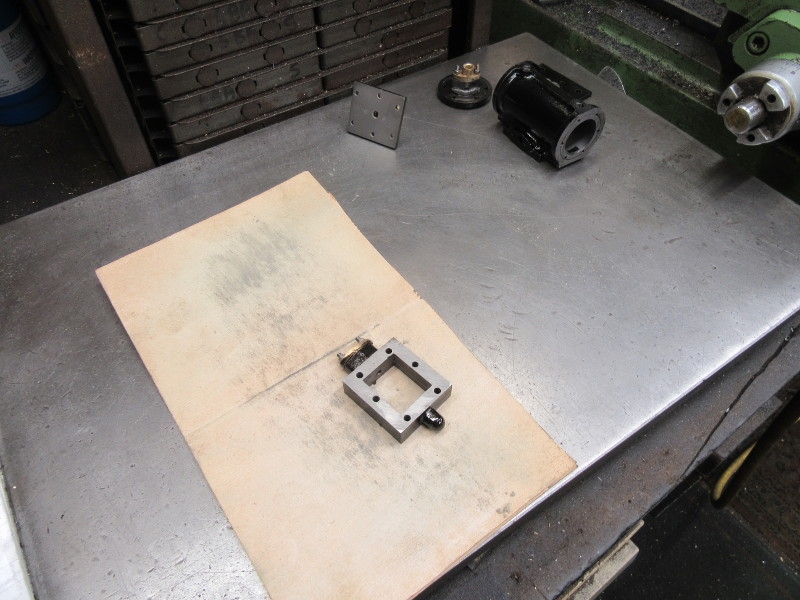

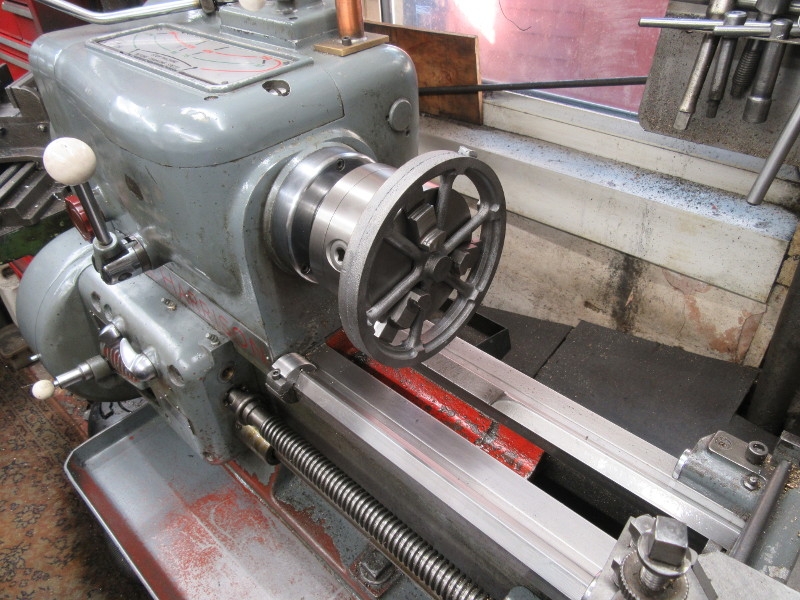

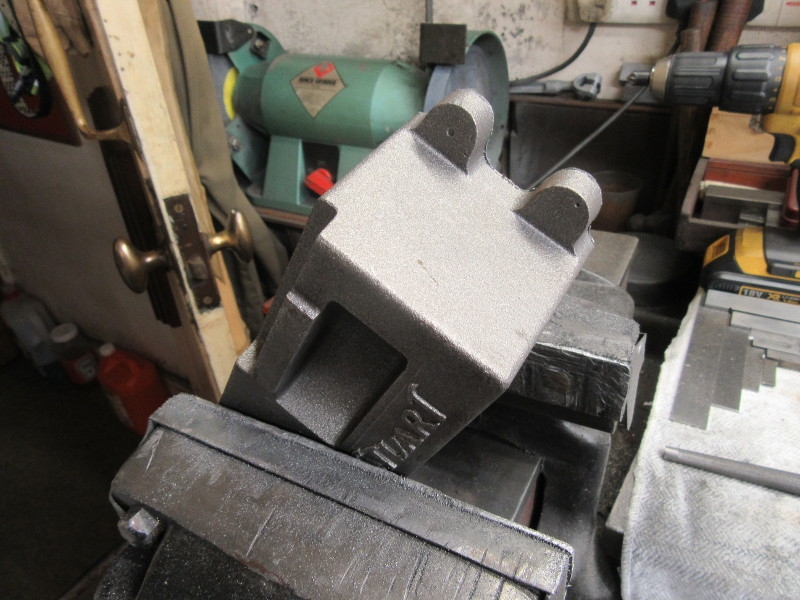

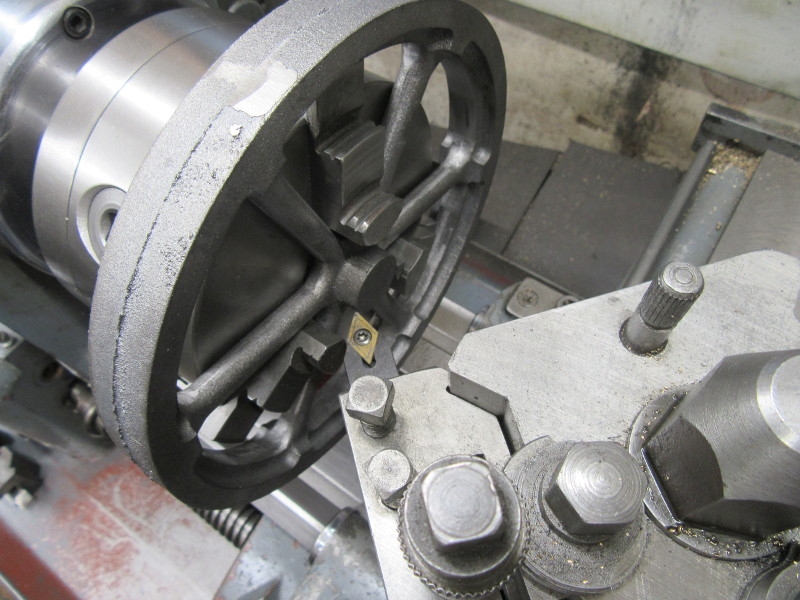

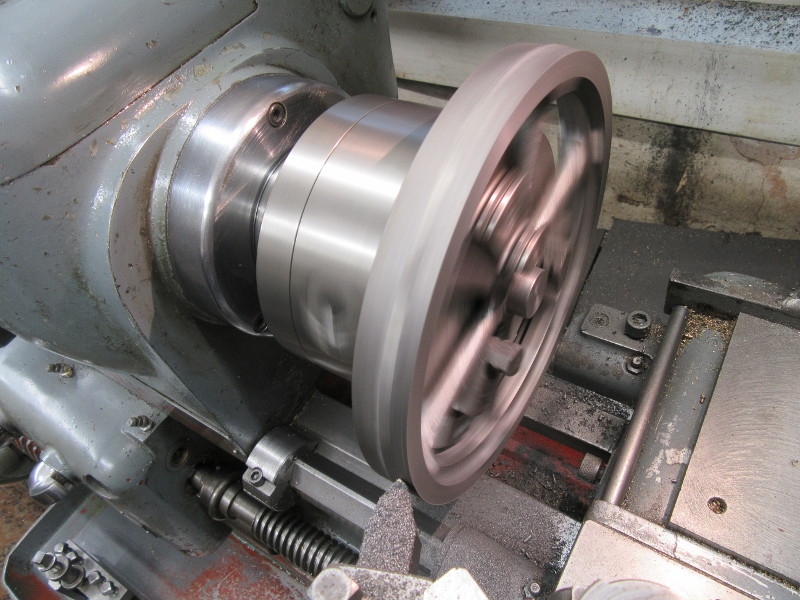

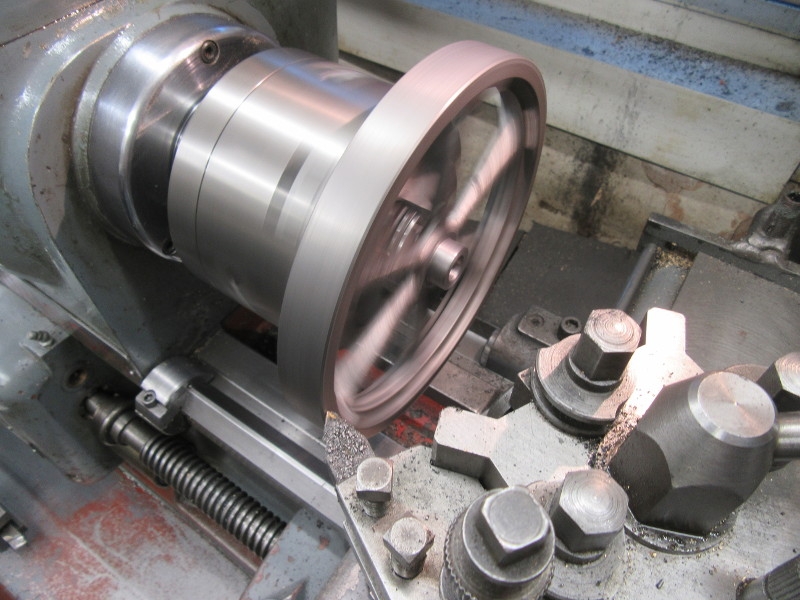

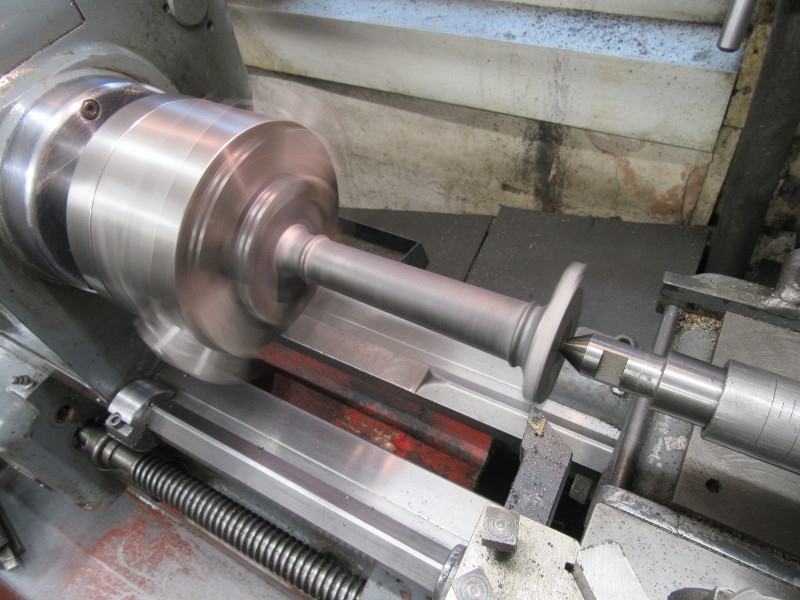

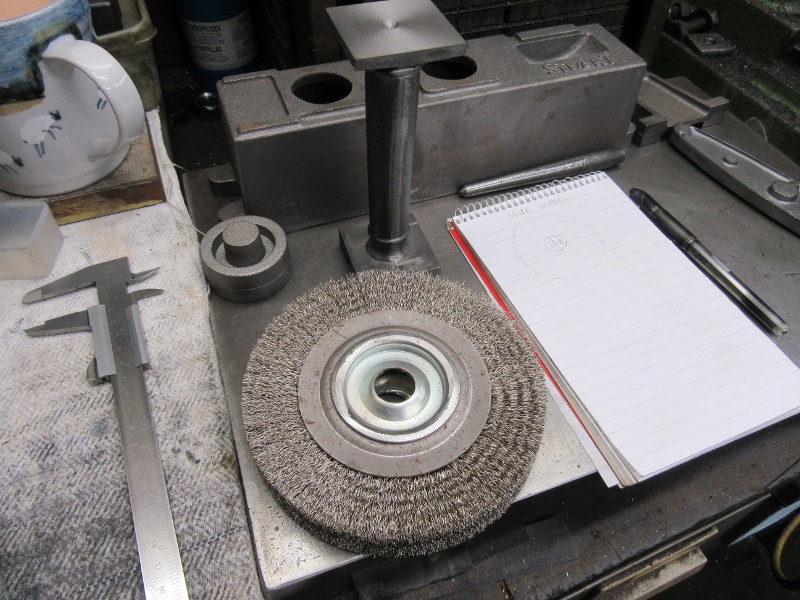

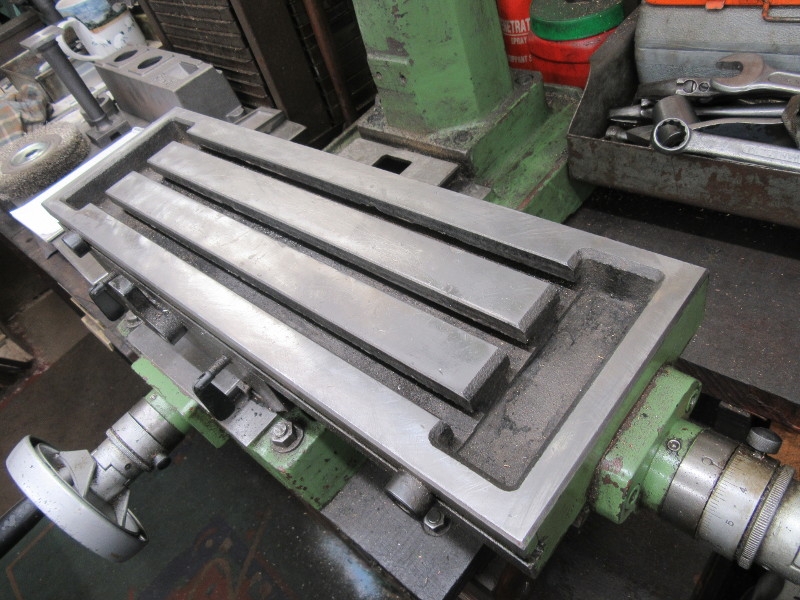

First job this morning was to reduce the thickness of the base to 1/8". I only have 1/16" of hold, that's how deep the register is, so light, careful cuts.

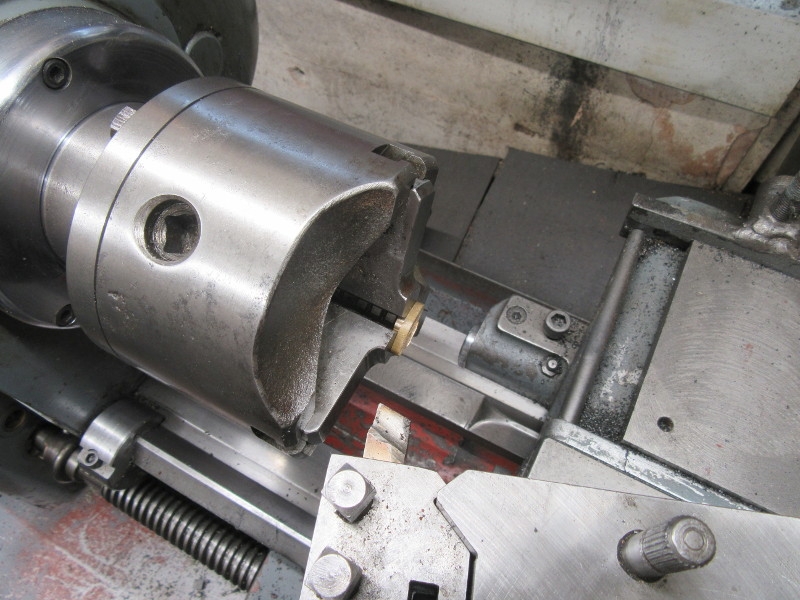

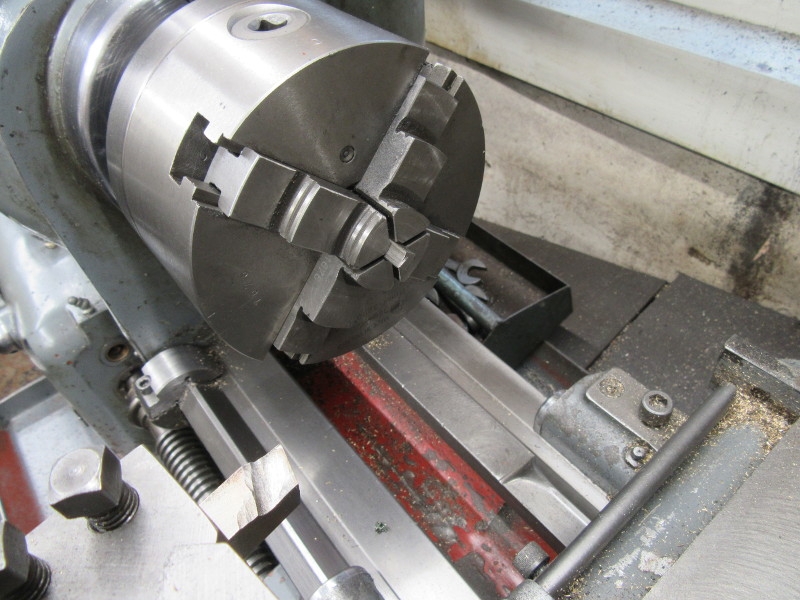

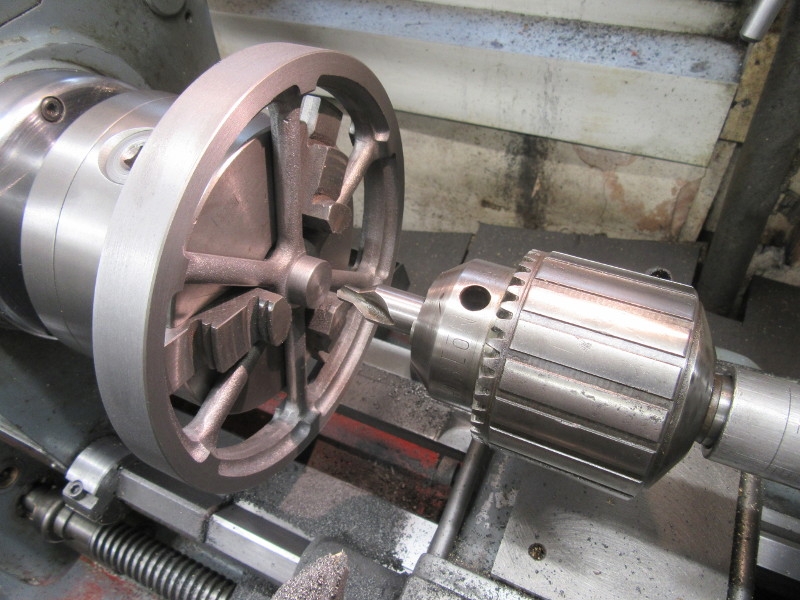

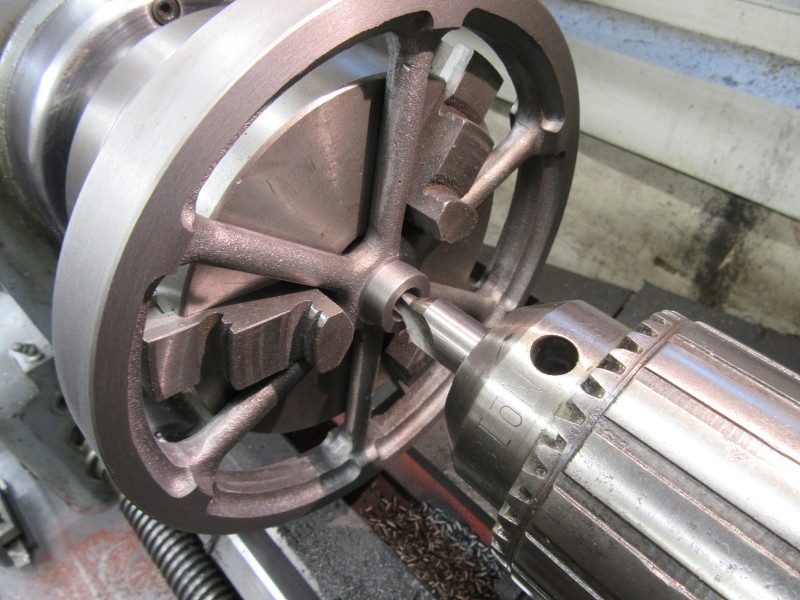

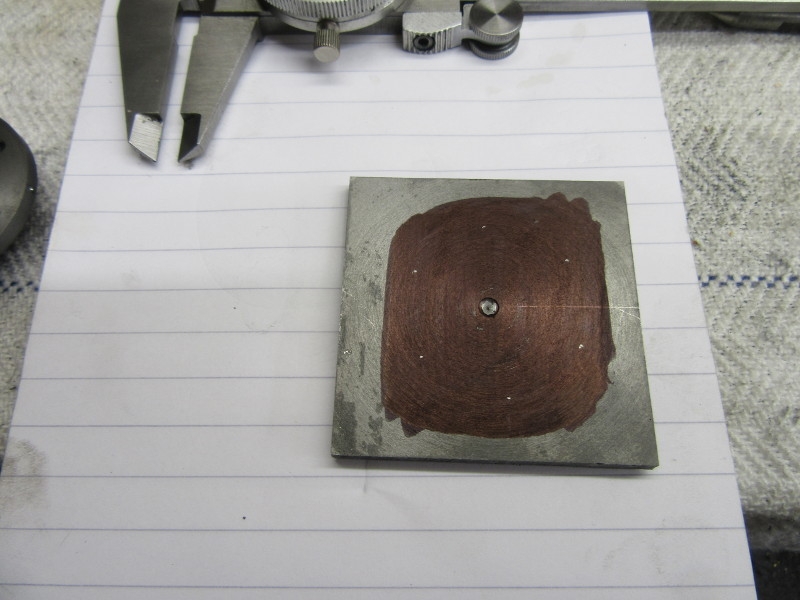

When I had it right I spotted the centre, I need to know where it is for the next difficult phase.

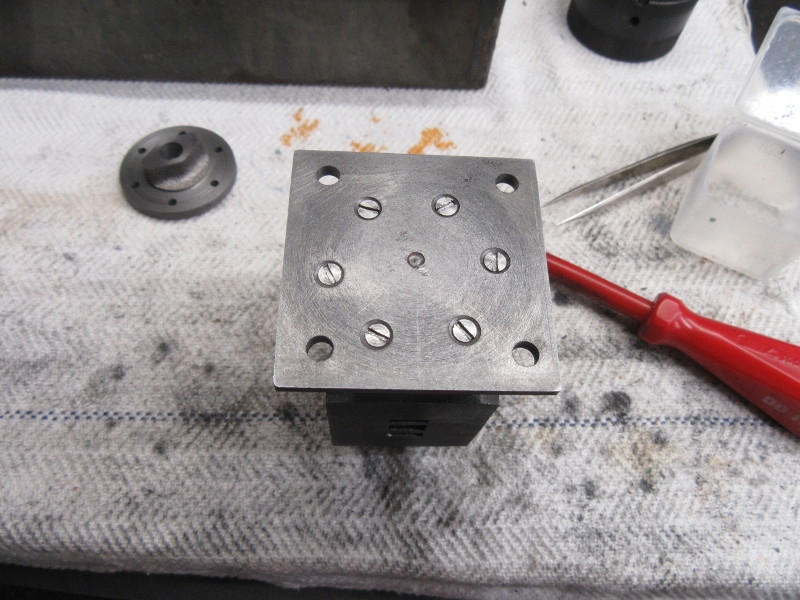

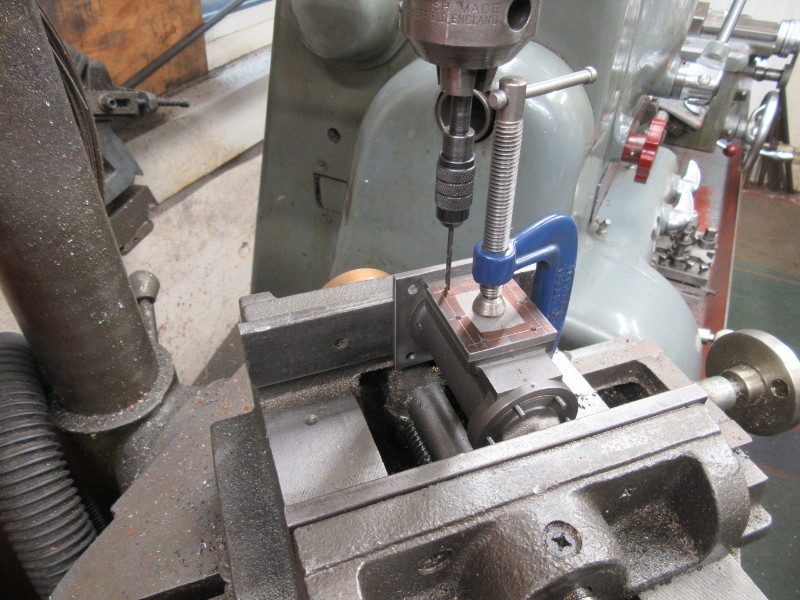

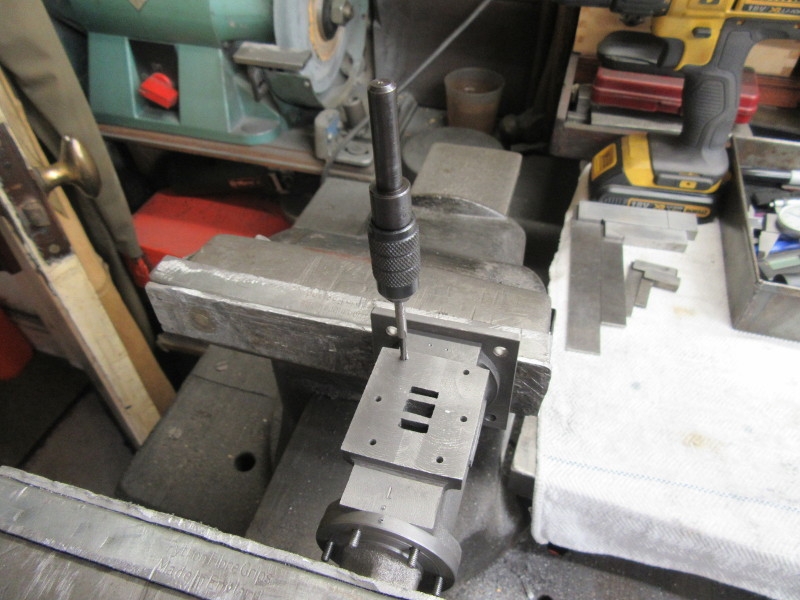

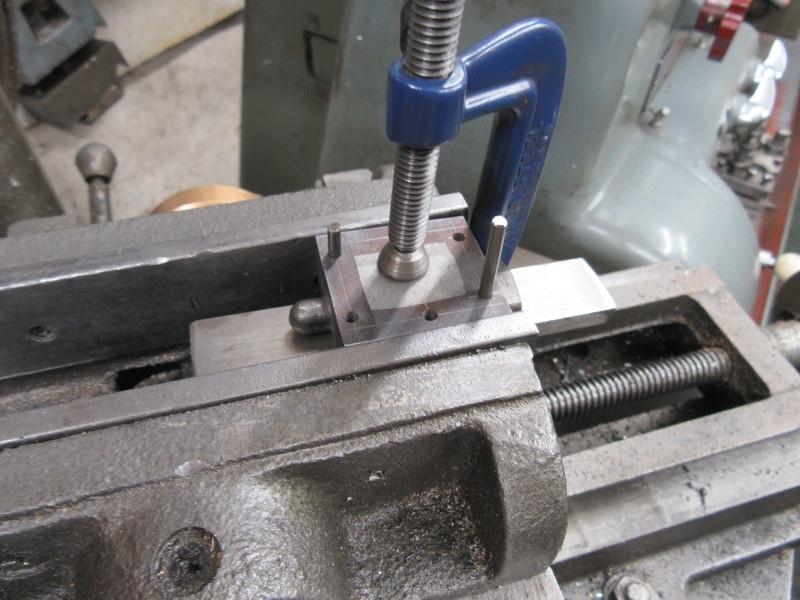

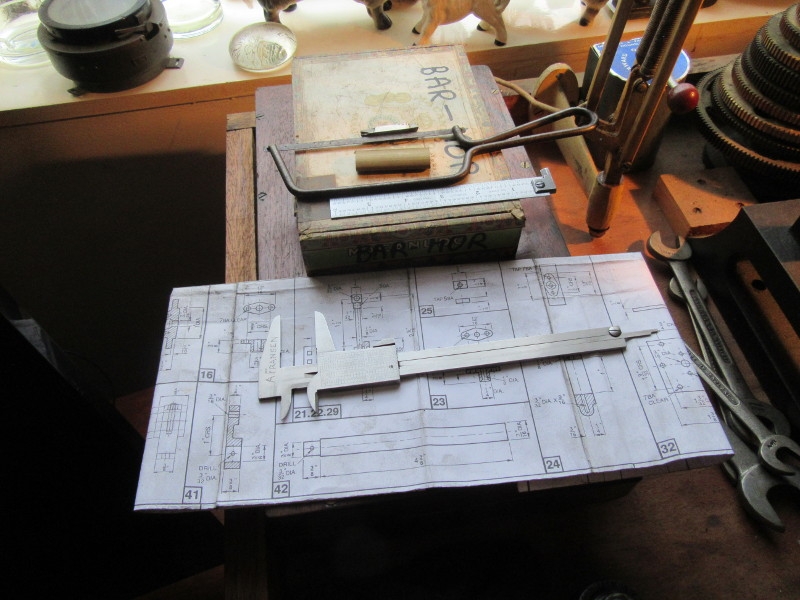

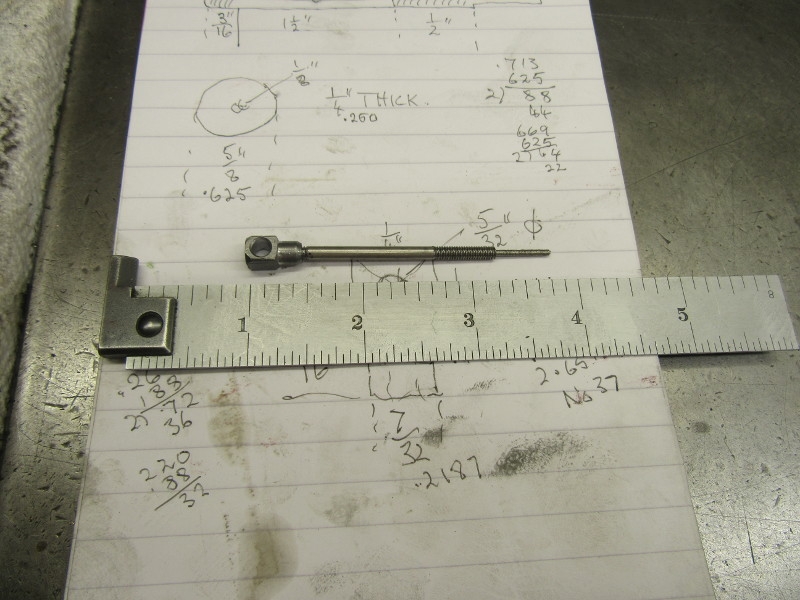

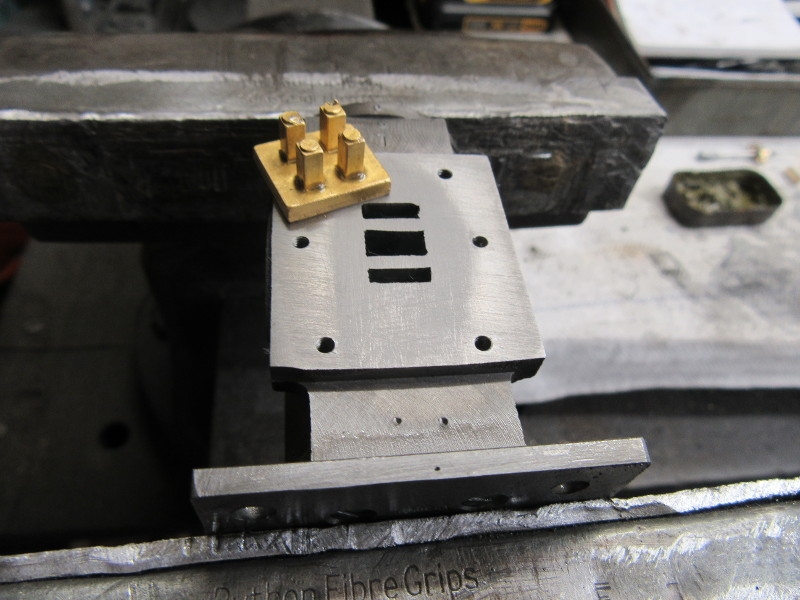

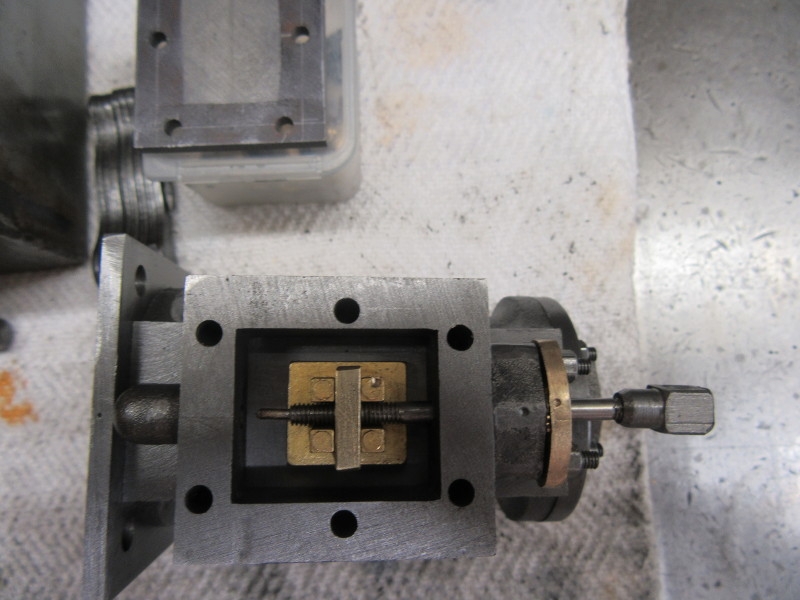

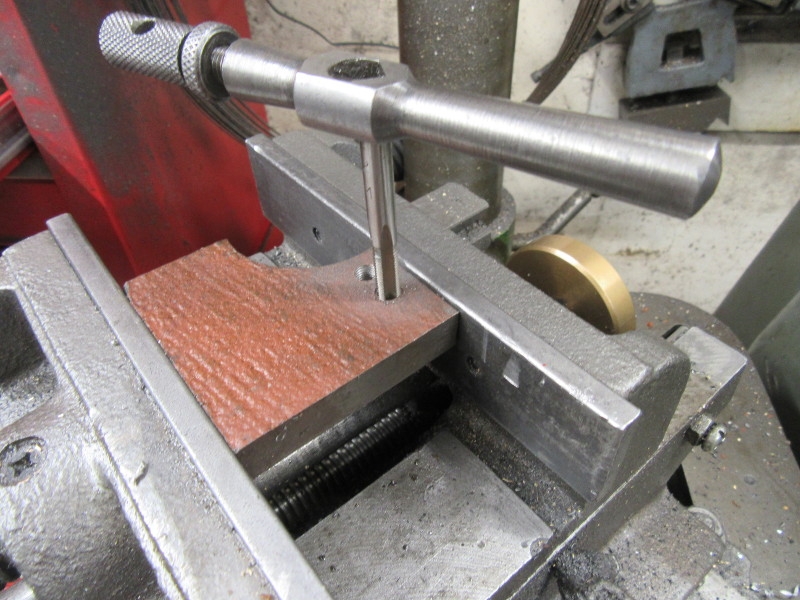

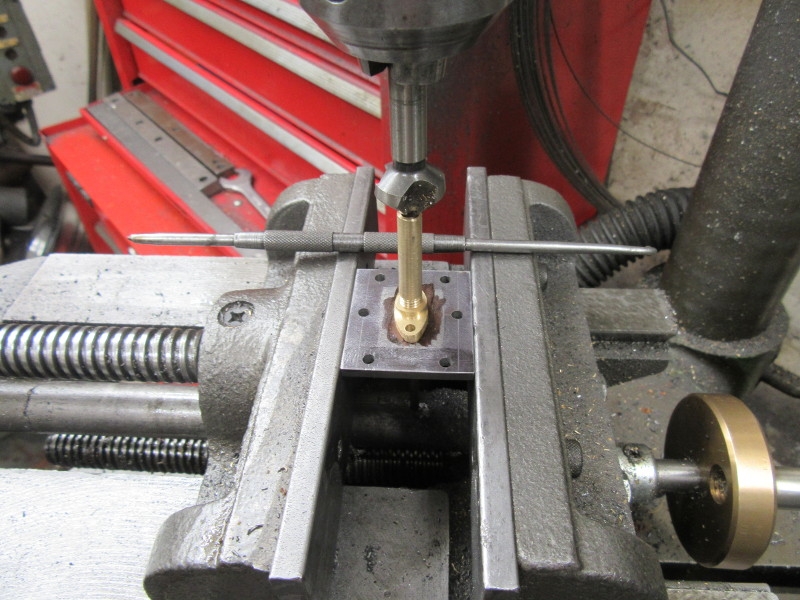

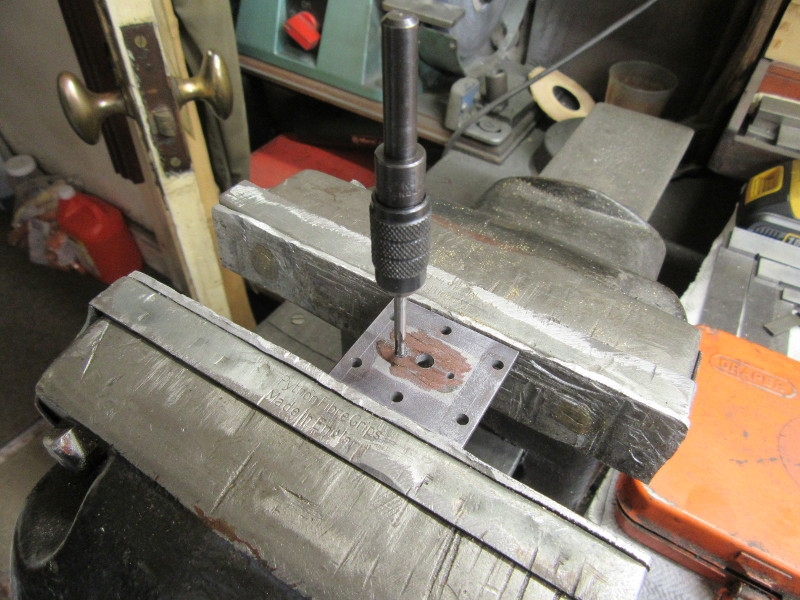

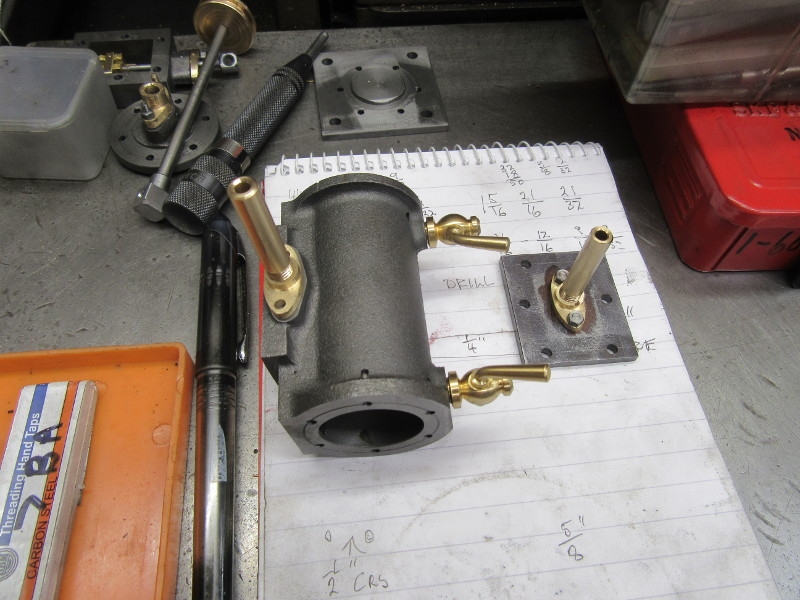

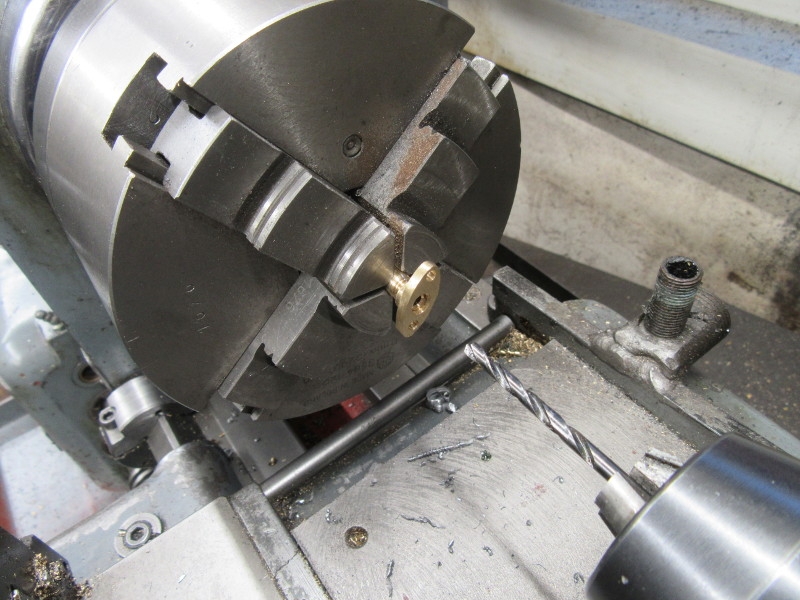

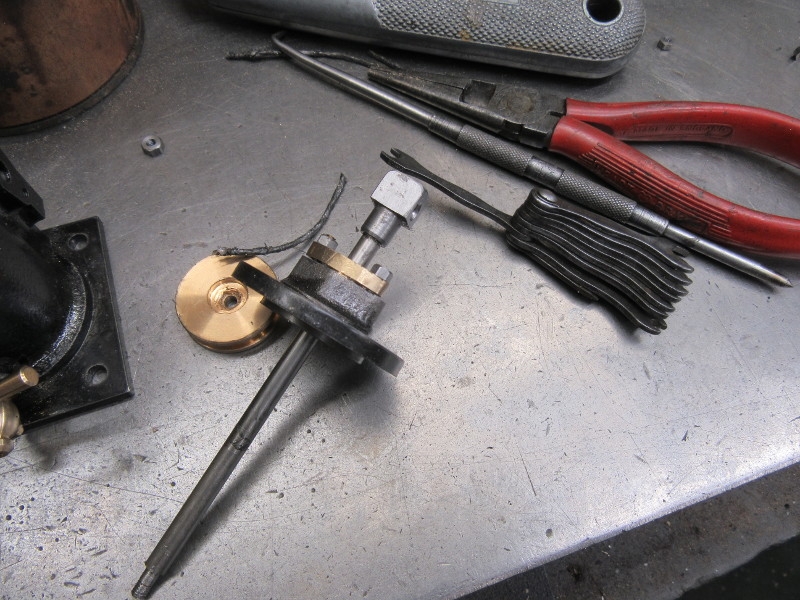

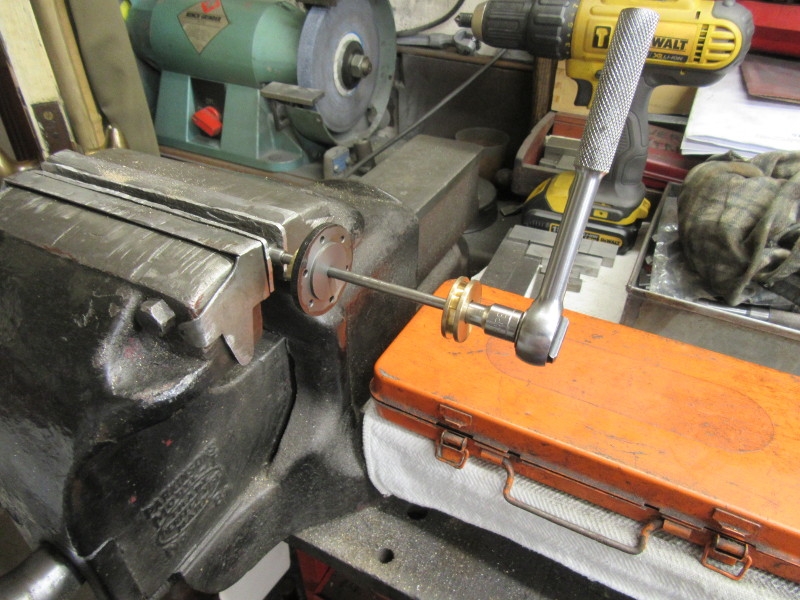

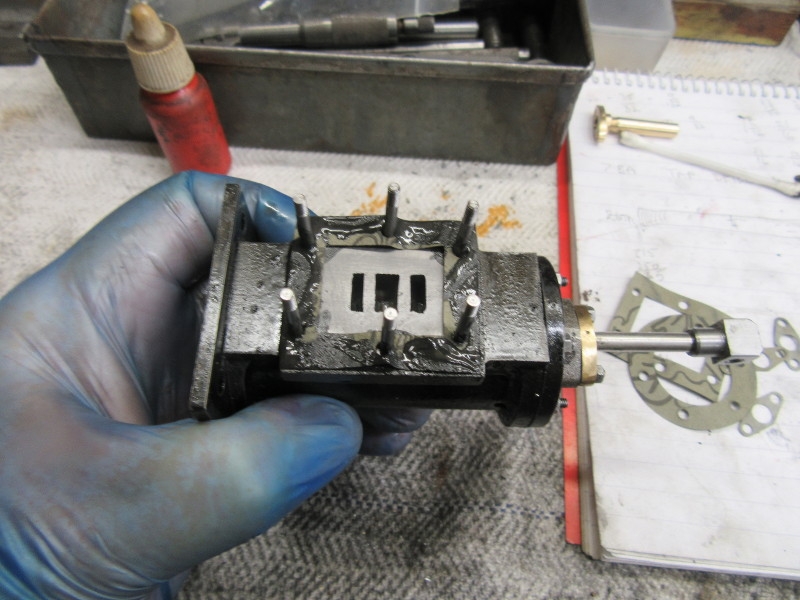

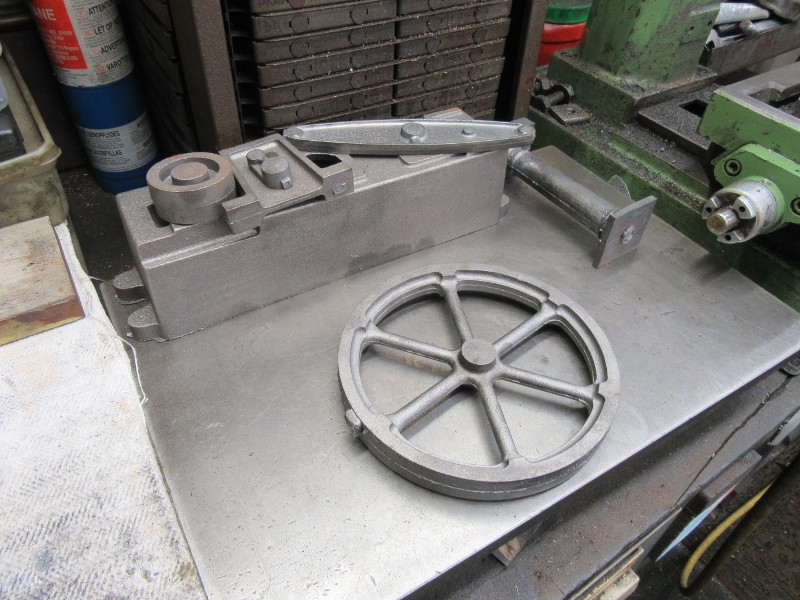

The task was to mark the bottom of the base for six holes in the bottom of the cylinder. If you think about it this is not easy. What I did was use a transfer punch to locate the lid in the centre of the base using the centre pop and then mark the location of the holes with another transfer punch. The tricky part of this job is getting the orientation right. Think about it! However, here we are with six spot marks. Then I Tried my new optical punch but it was no good on this application so I reverted to trusting my eyes!

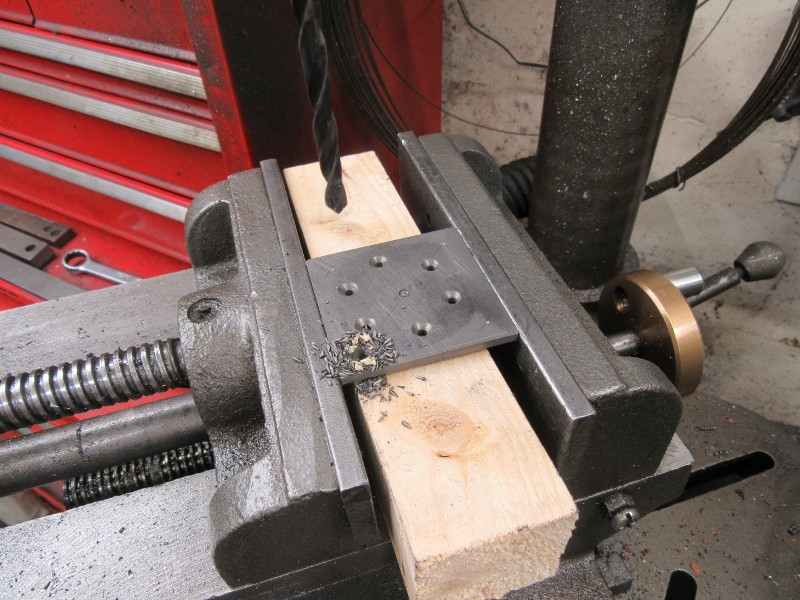

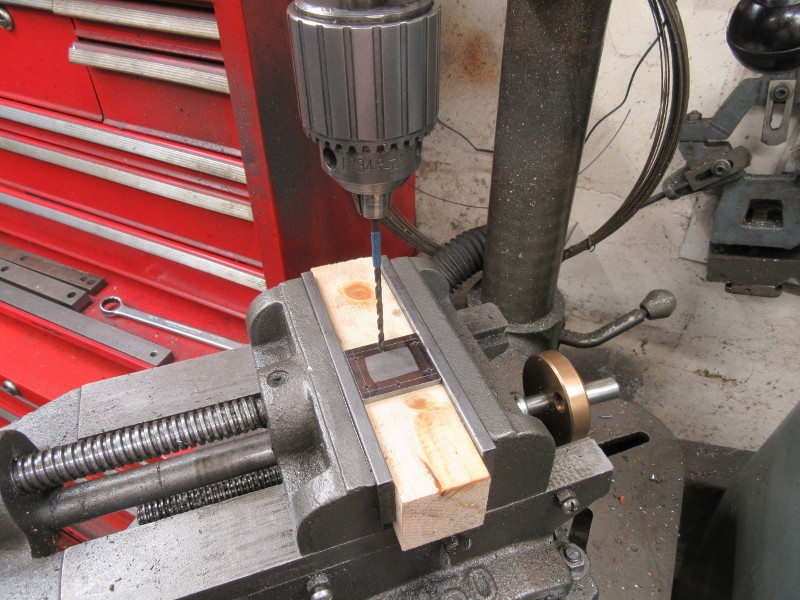

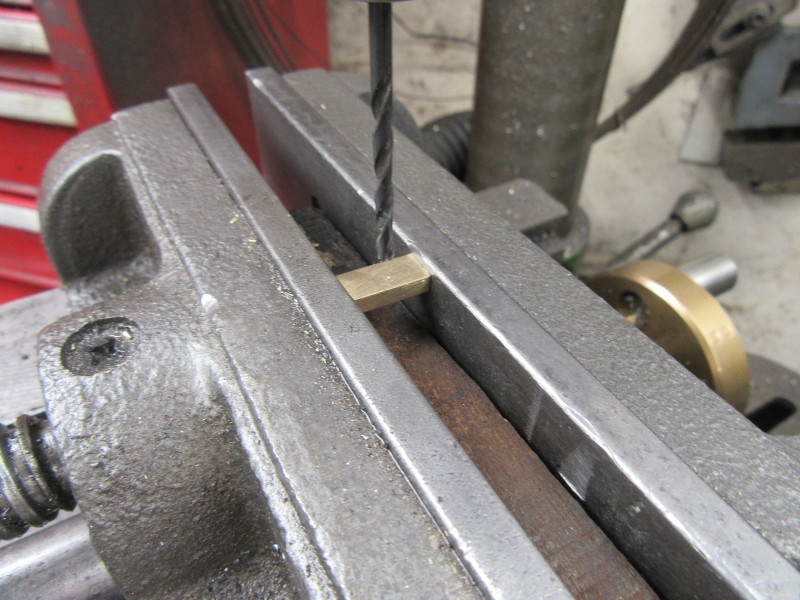

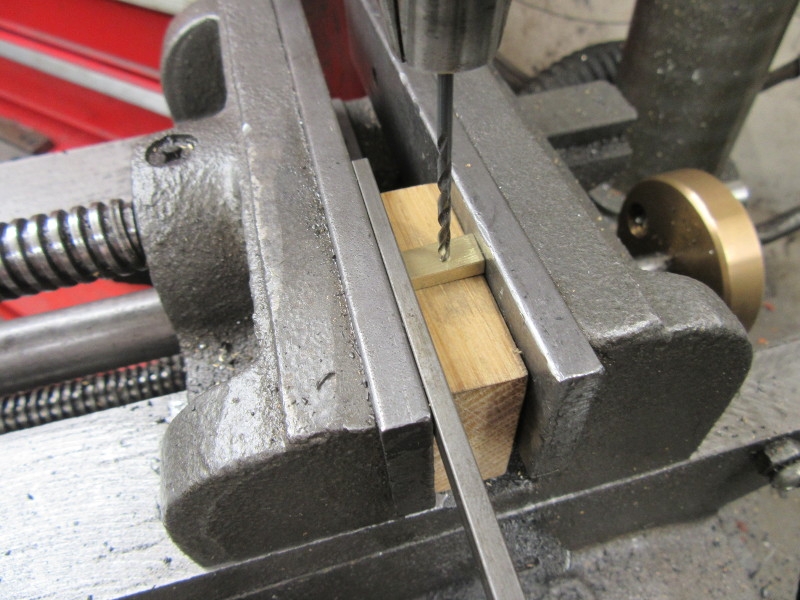

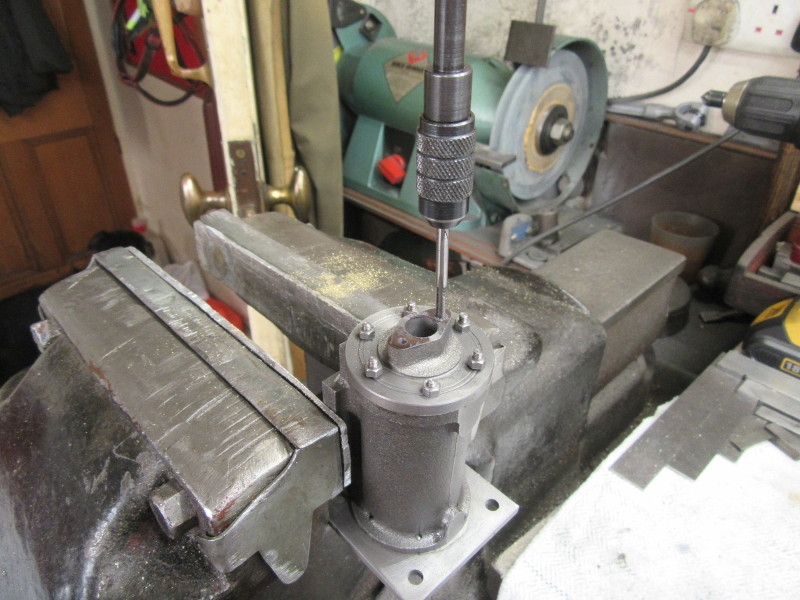

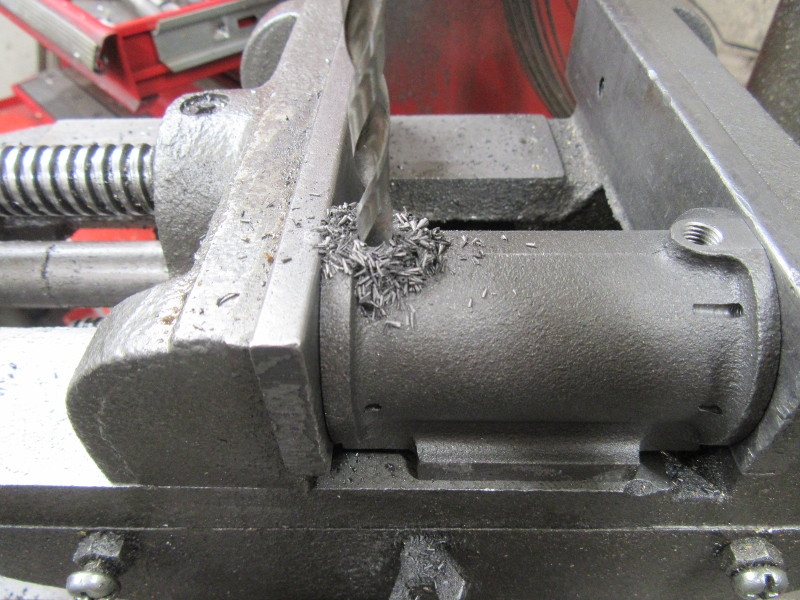

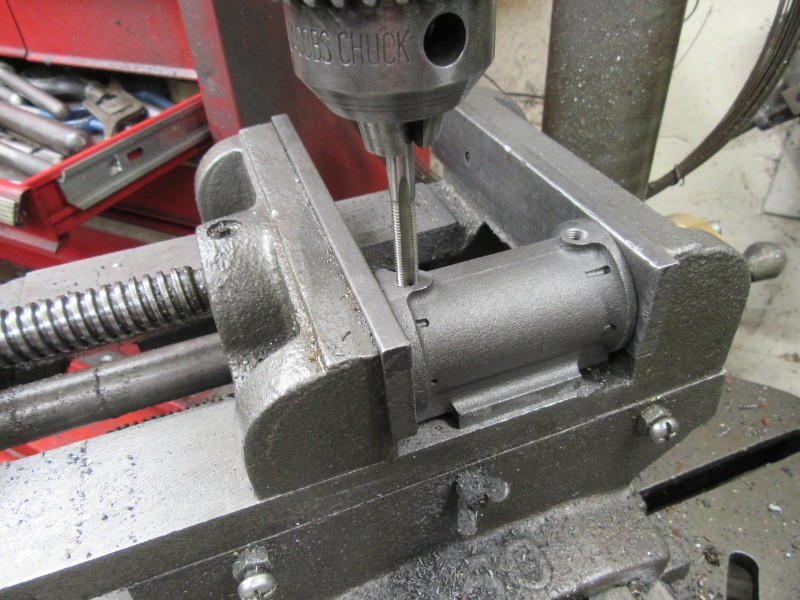

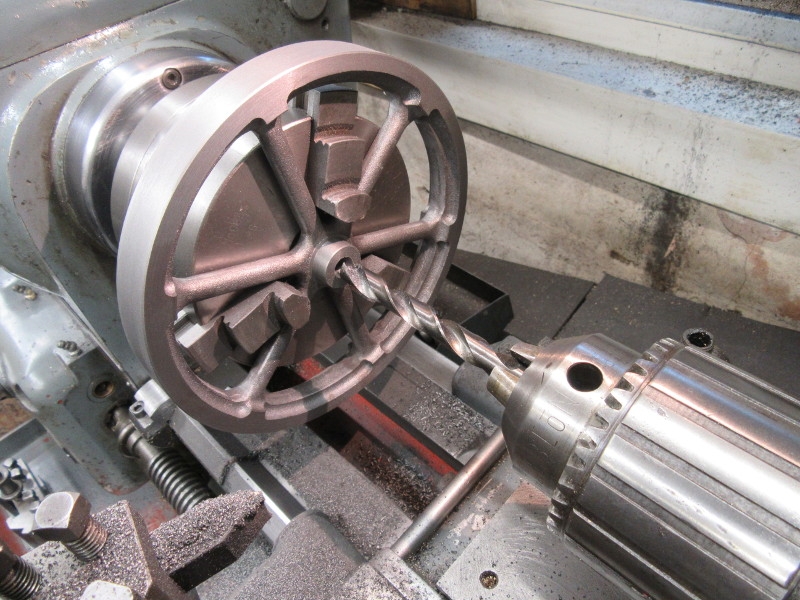

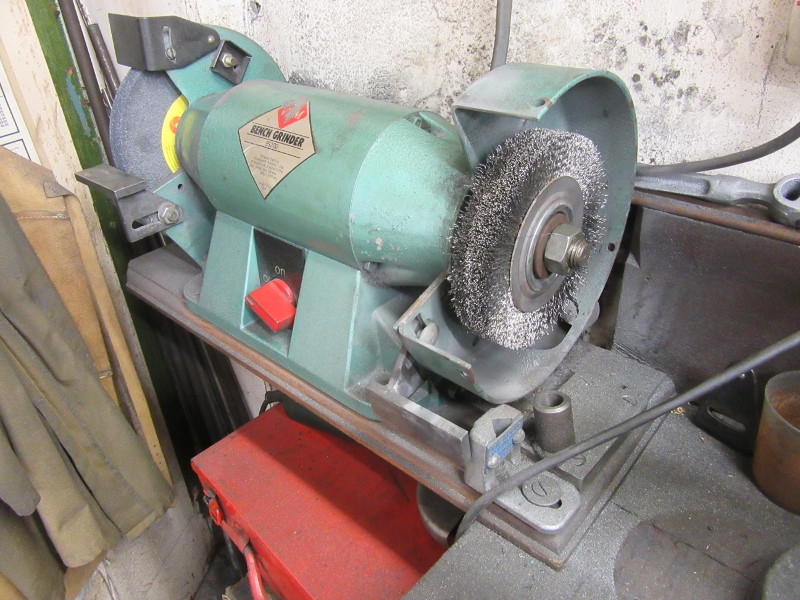

Then under the pillar drill and trust my marks.....

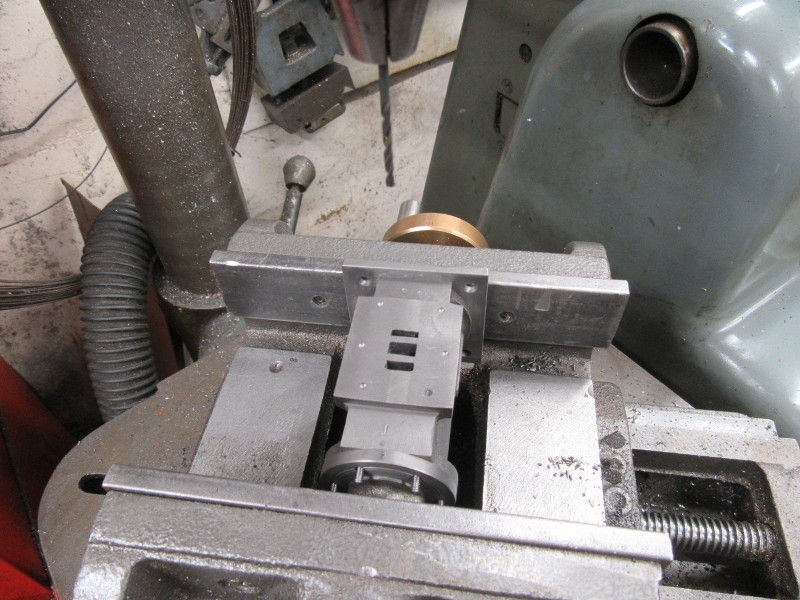

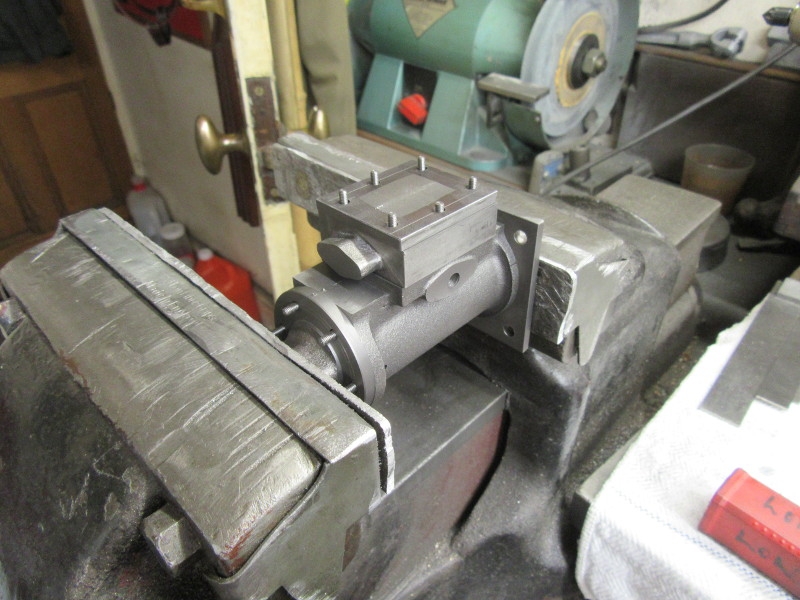

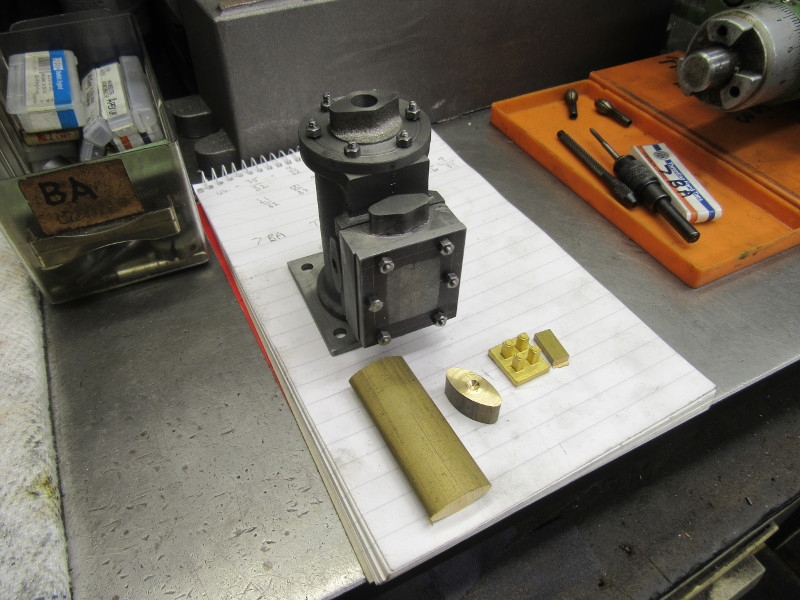

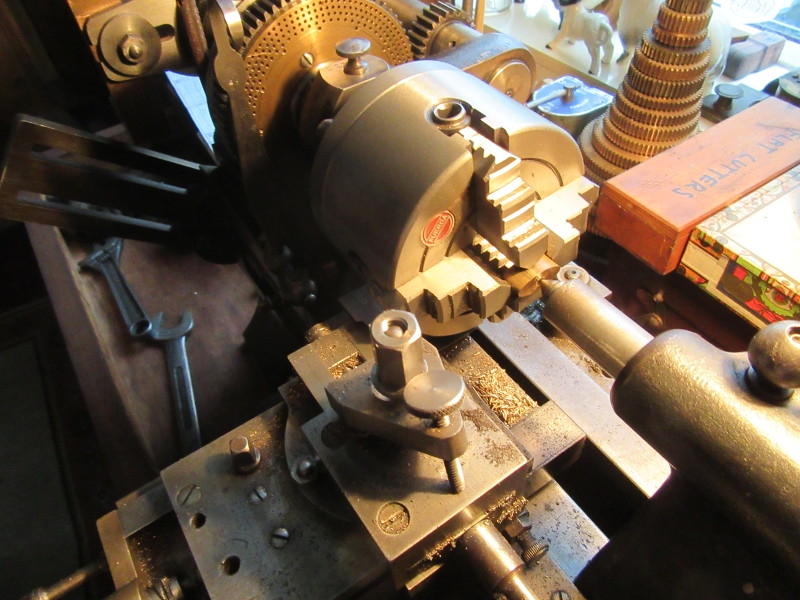

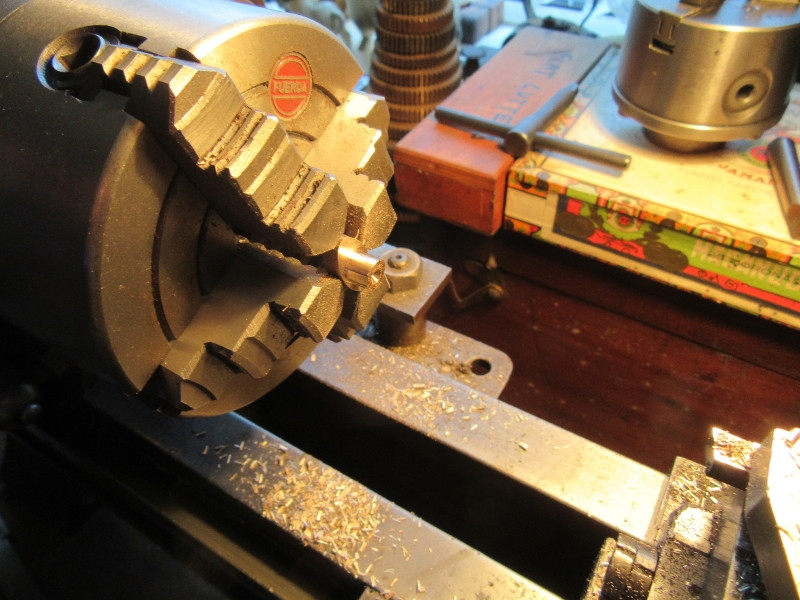

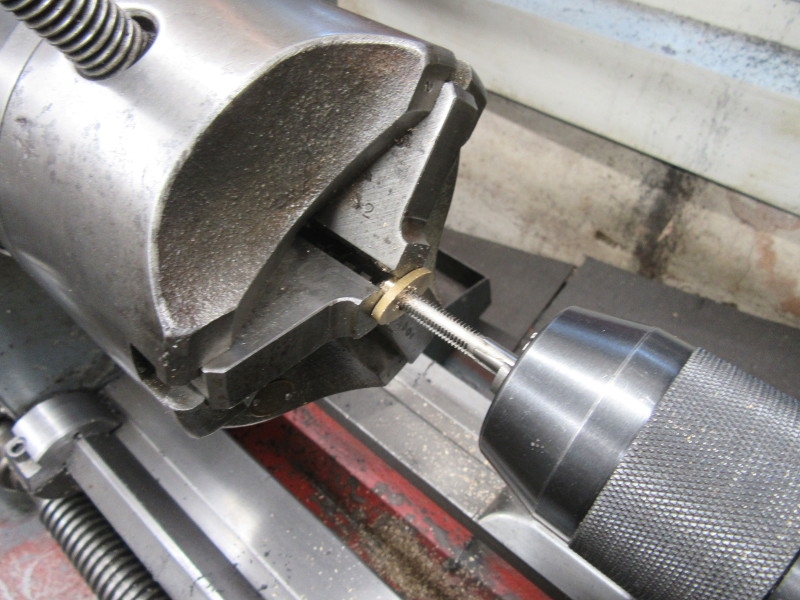

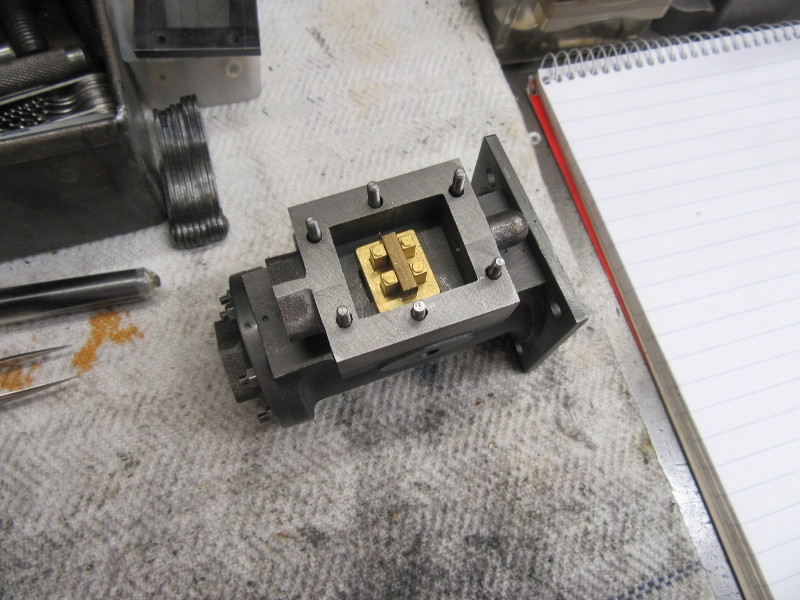

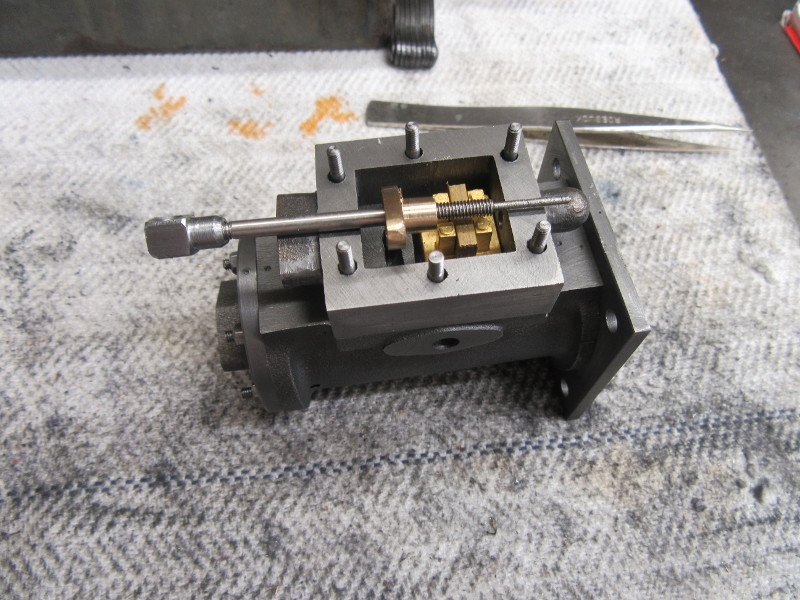

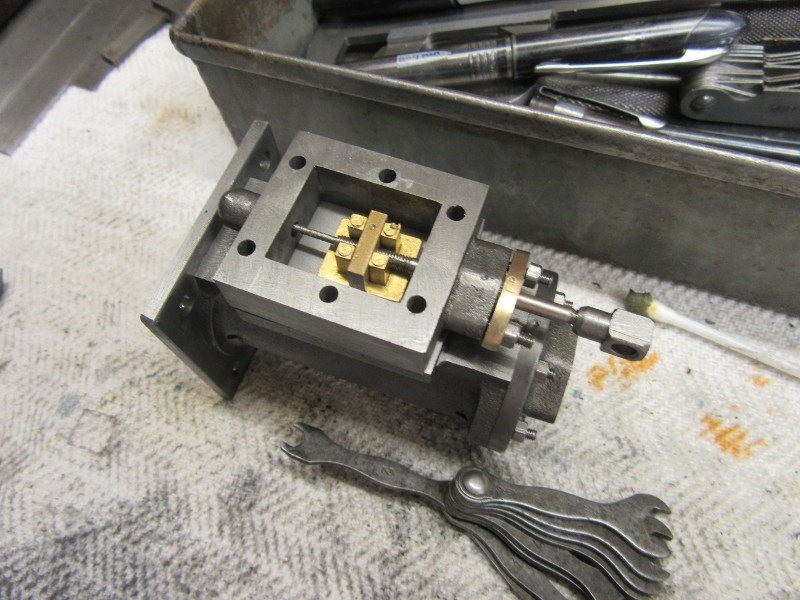

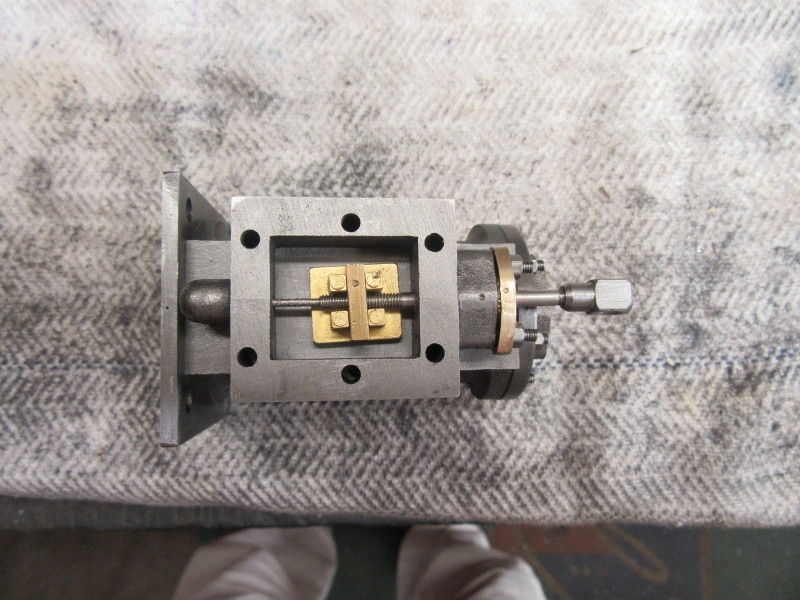

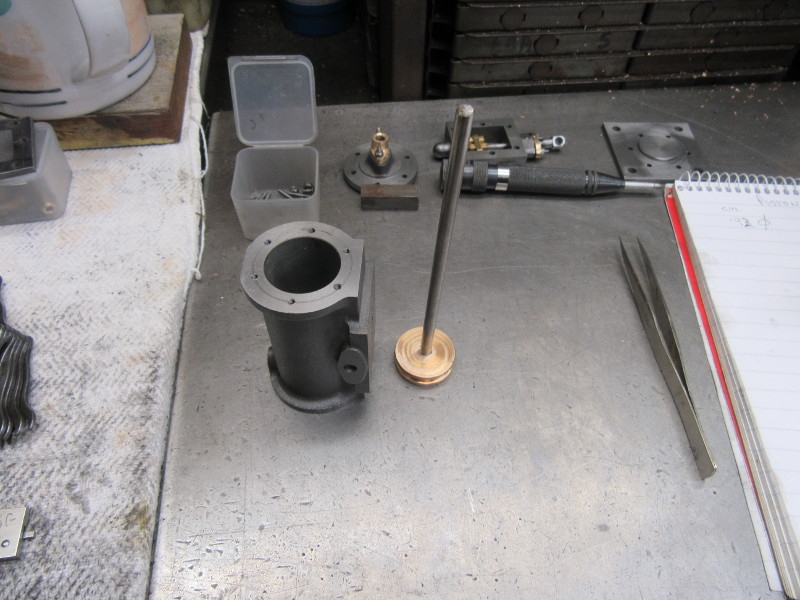

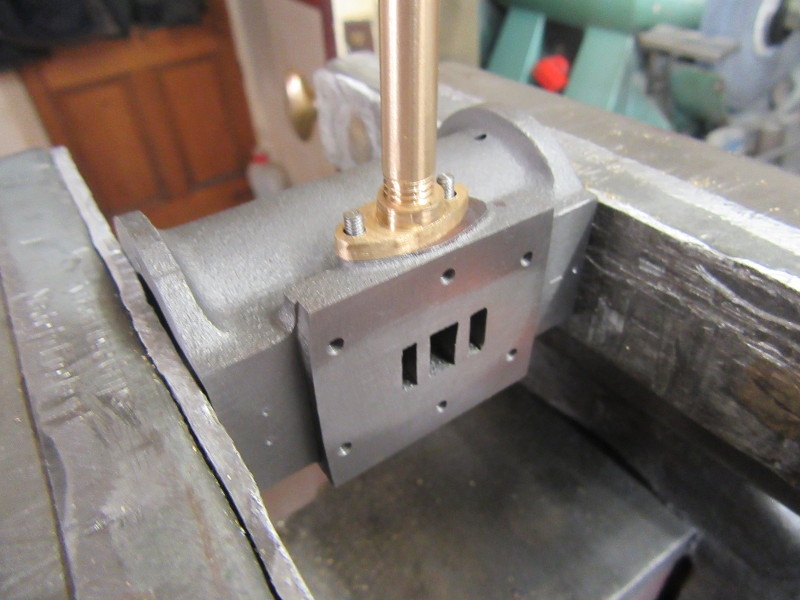

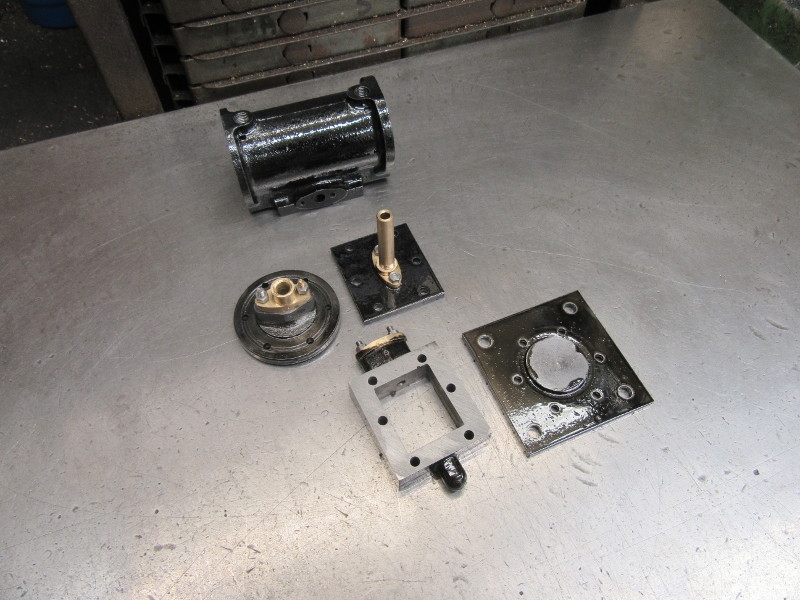

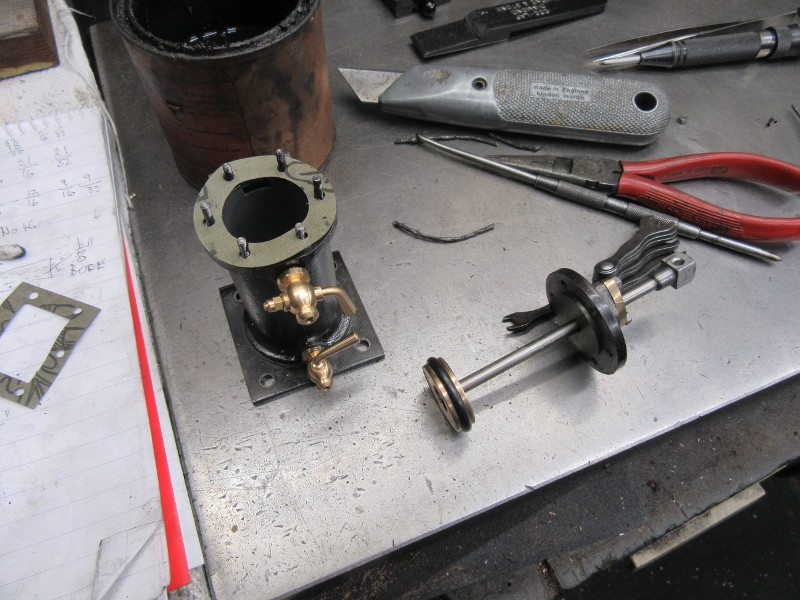

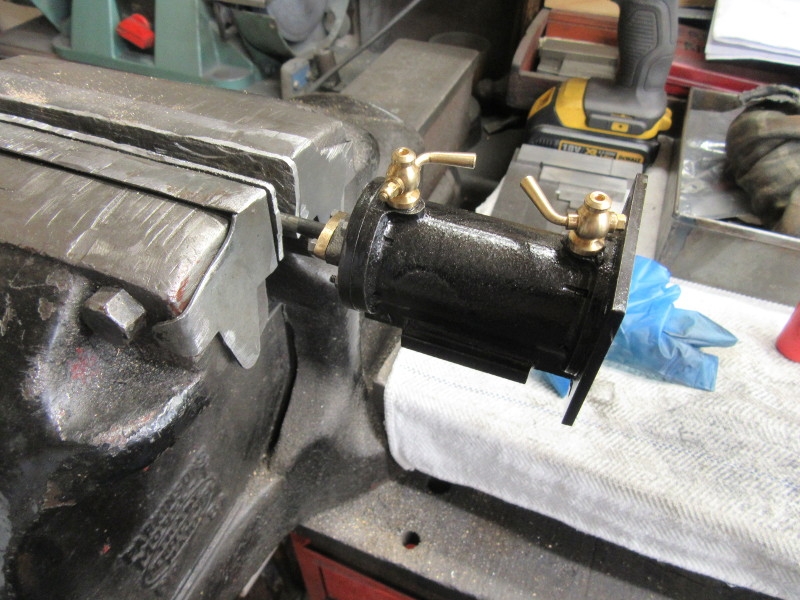

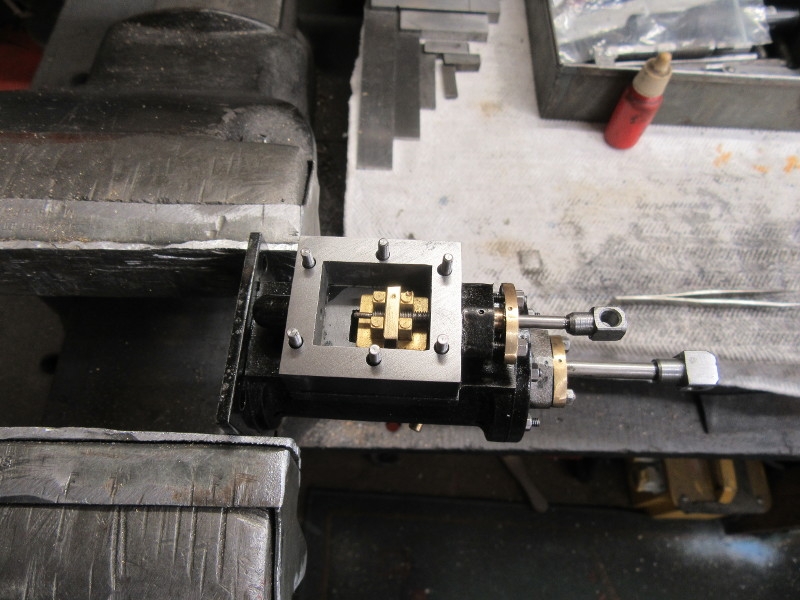

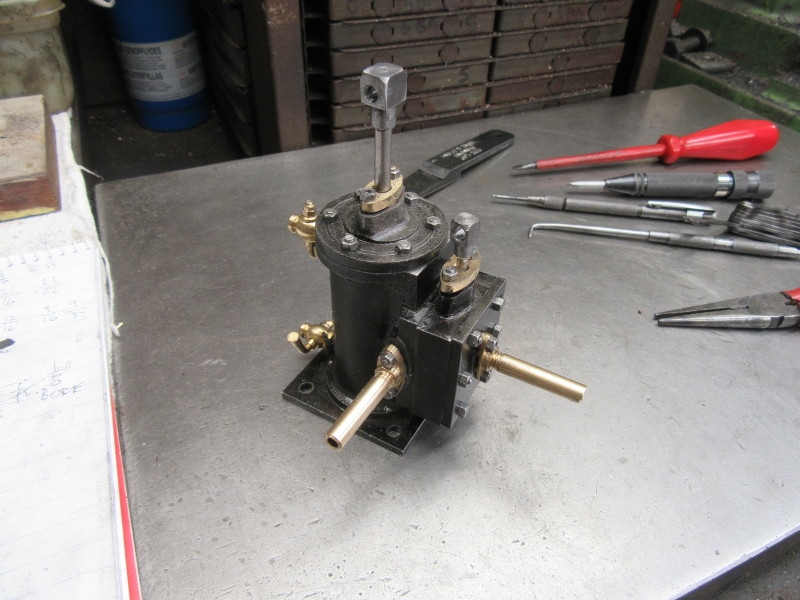

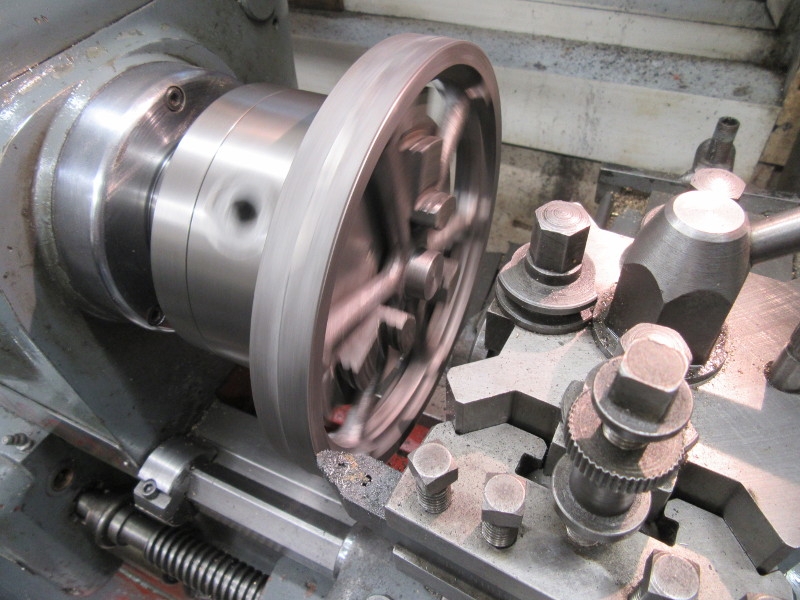

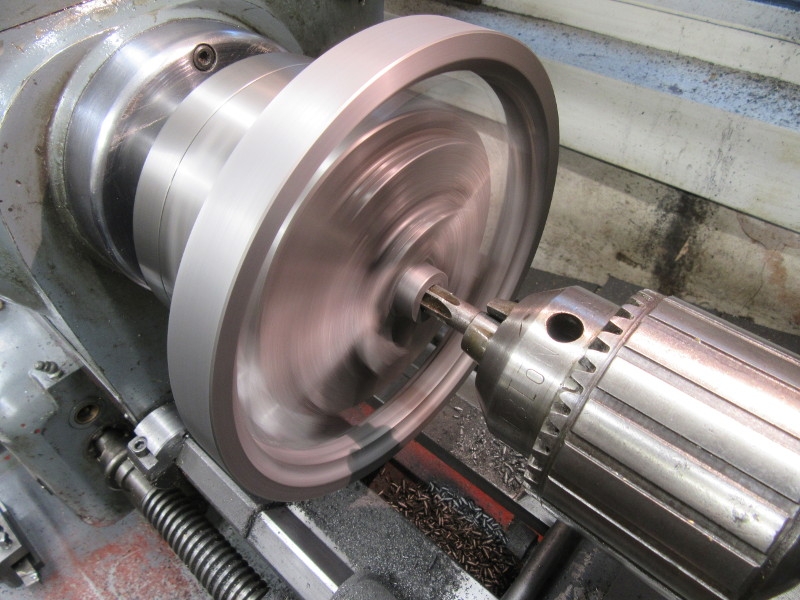

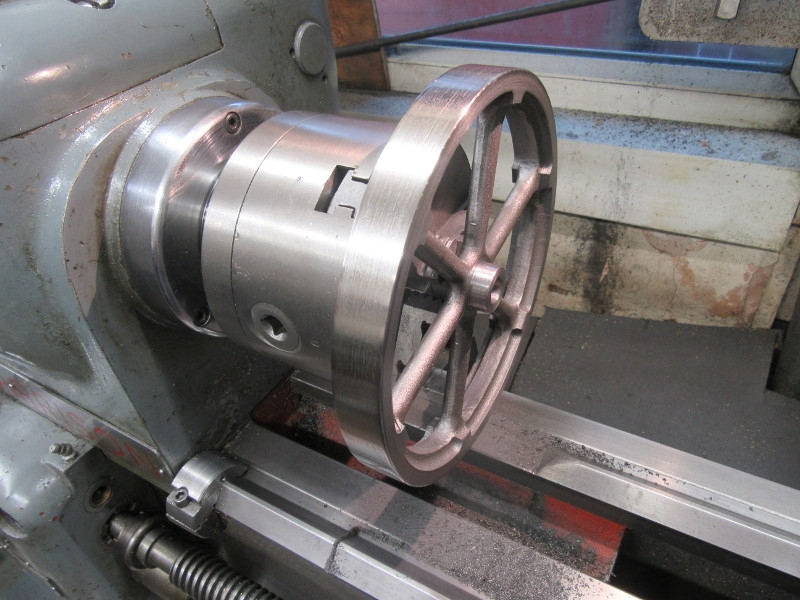

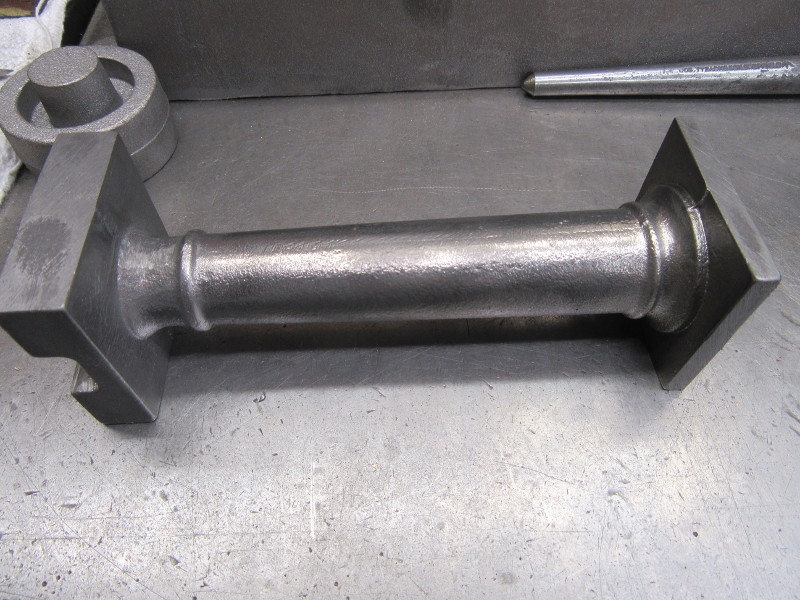

I put the studs in the cylinder and god bless us the hole pattern is almost perfect. Only problem is the register is fouling, I haven't got it quite central so I popped the lid back in the chuck and reduced its size. It's no detriment to how the cylinder will work.

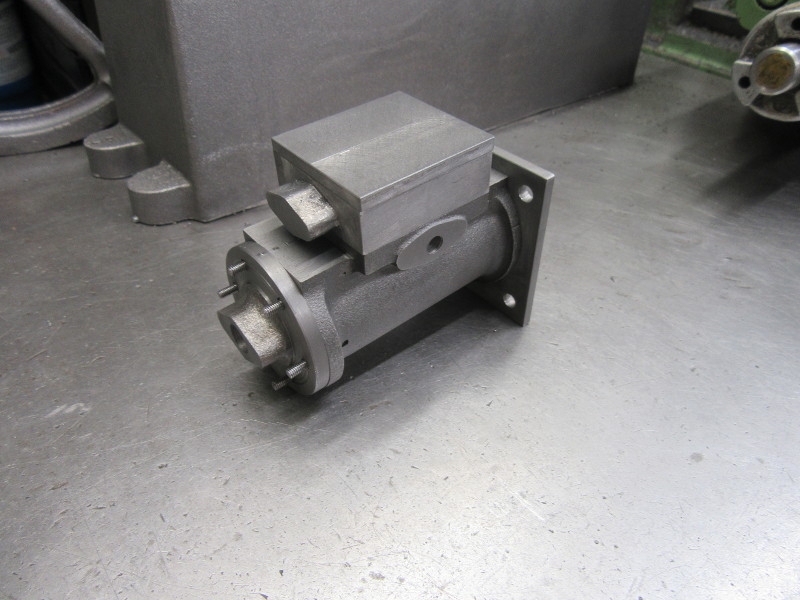

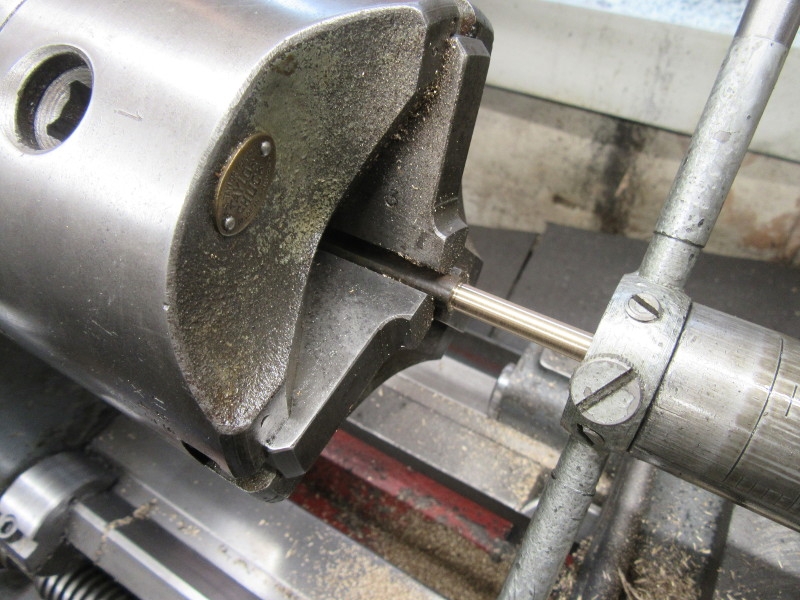

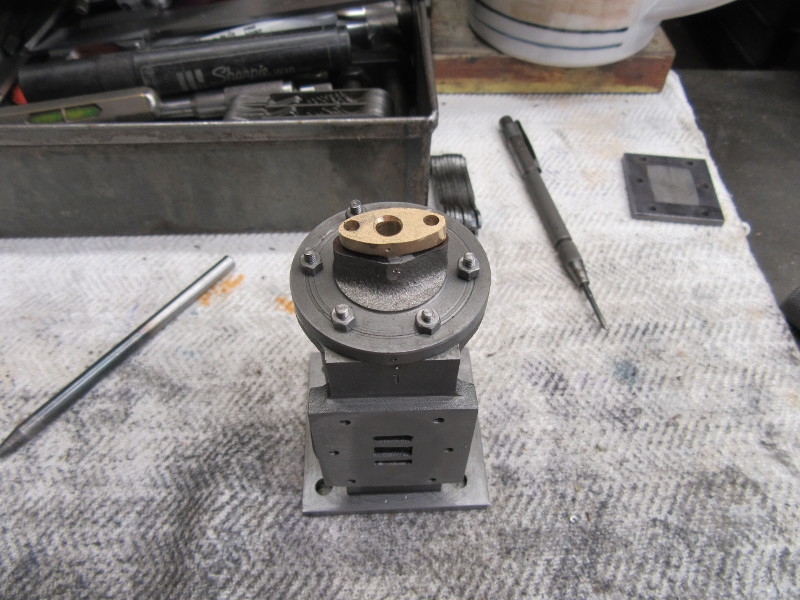

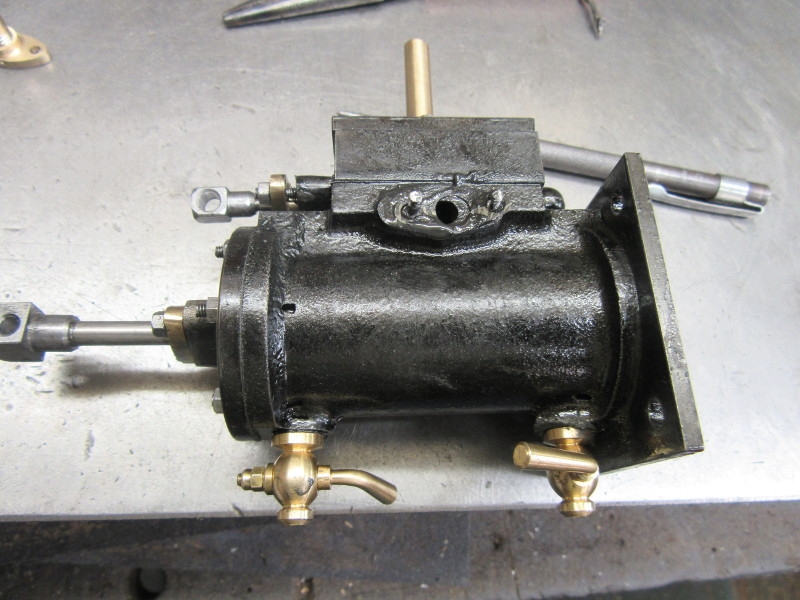

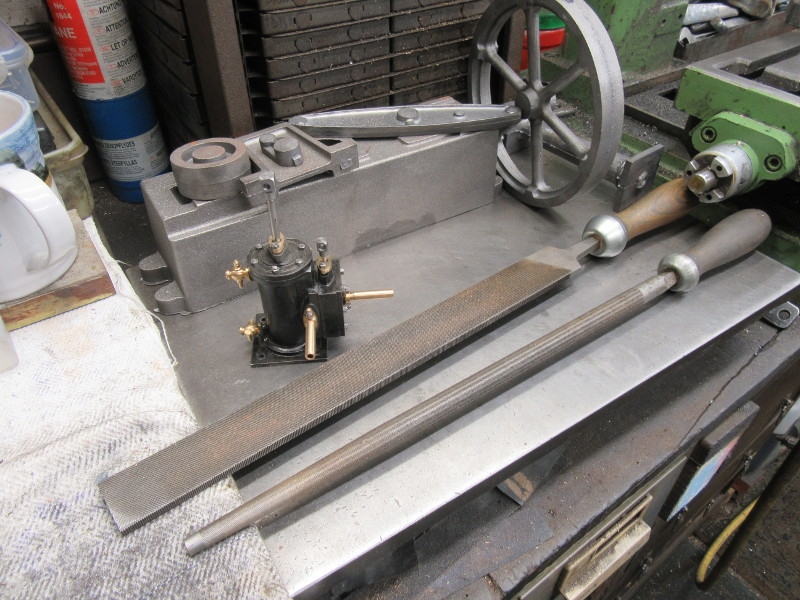

Here it is at knocking off time, the studs are registered and the base is snug against the cylinder. I'm ready to get on with the next step, countersinking the holes and fitting the countersunk head screws. That was a difficult hour, thank god it all worked out well!