Instead there are two of these.....

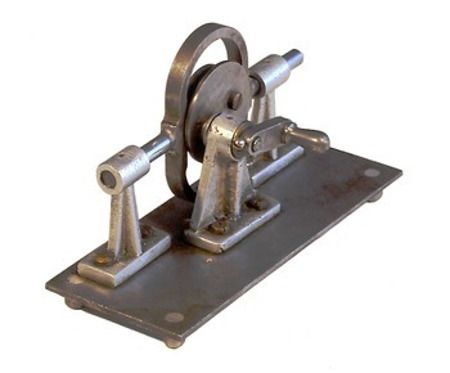

This is a working model of a Scotch Yoke Eccentric. A mechanism for converting rotational to linear motion. I had accepted that this was the case for the drive from the steam cylinders to the pump but had assumed that in the case of the steam valves and the drive to the feed pump that these were conventional eccentrics. I was wrong, the drive is another version of the Scotch Yoke mechanism. The drive isn't from an eccentrically mounted crank pin as in the crank shaft but from an eccentric lobe on the inside of each flywheel.

I can see the way forwards now!