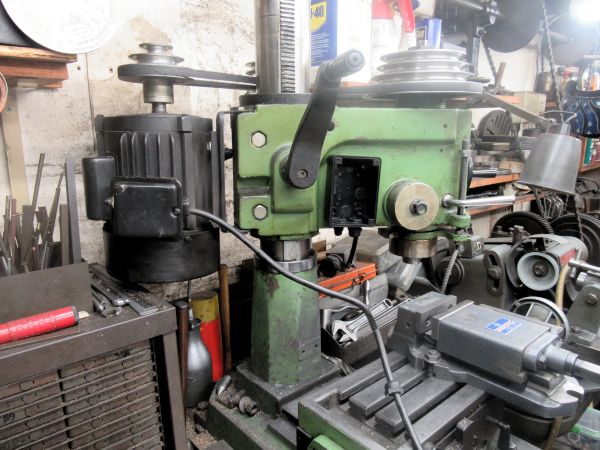

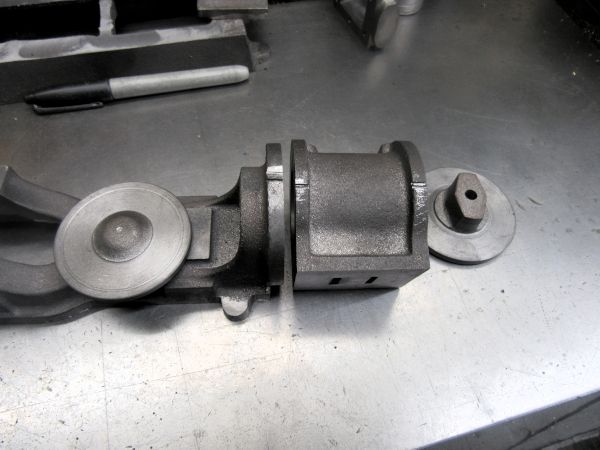

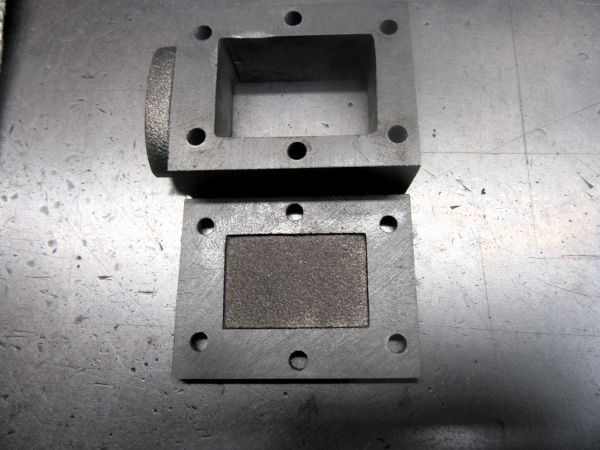

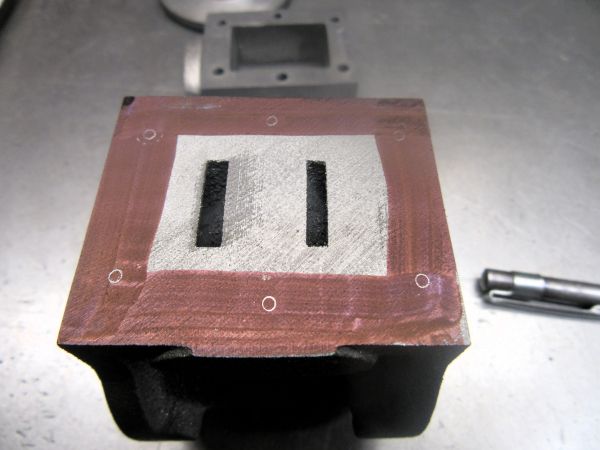

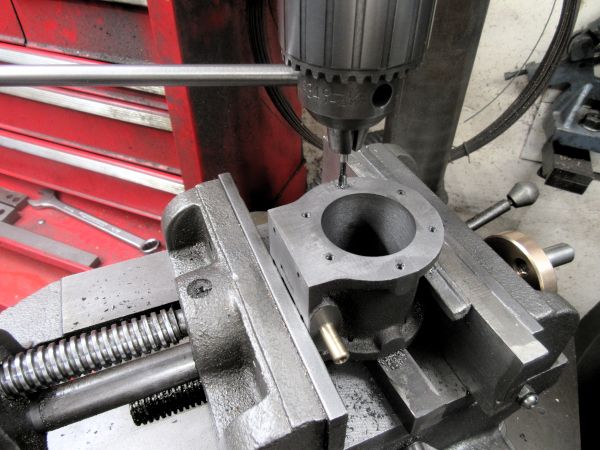

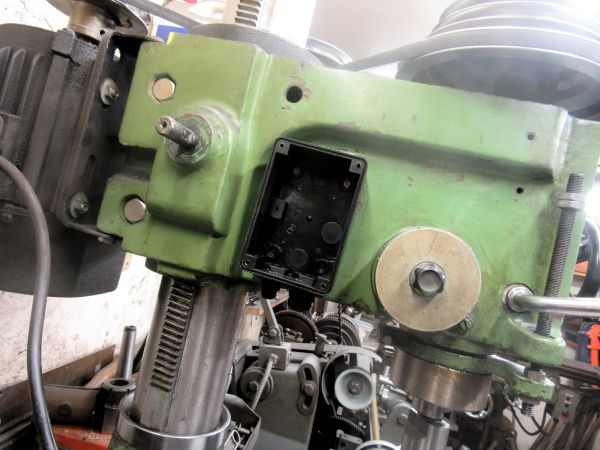

The replacement switch for the mill arrived yesterday. I had a look at it and decided I could understand the wiring instructions and so this morning I started on that job. The first job was to decide where to mount the switch as it couldn't go where the old one was as it would foul the handle for lowering and raising the quill. Then I had to decide how to mount it and decided on self-tappers. It took me the rest of the hour and a quarter I was in the shed to drill through the cast iron and adjust the drill size to suit the screws I had. I have done that and the body is mounted securely if not dead straight! (You can't have everything) I have the terminal kit and now I need to connect the switch. I think I need some help, I am not good at fiddly work like this in an awkward position, it nearly put my lights out this morning. So I am appealing for some help....... I shall ask elsewhere on the site as well.