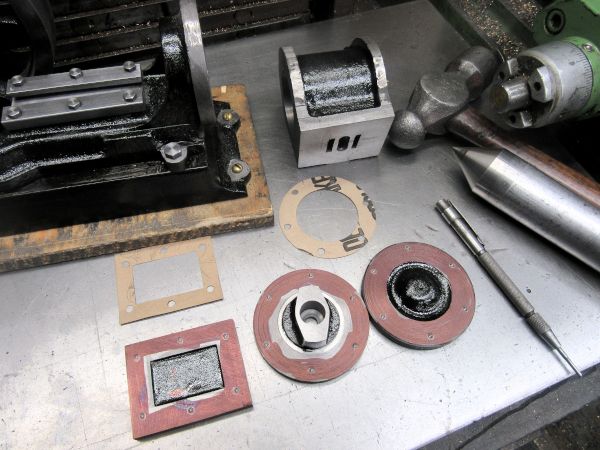

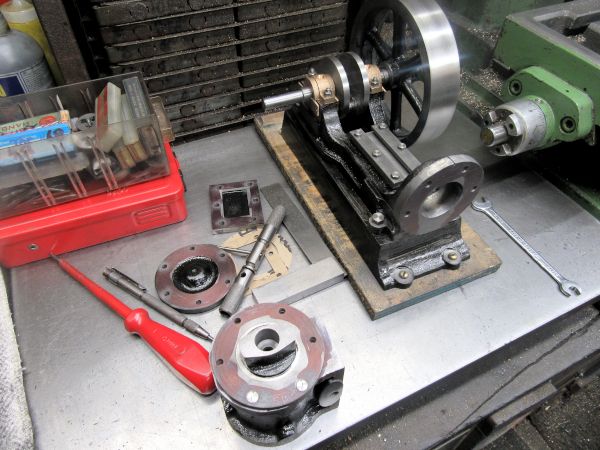

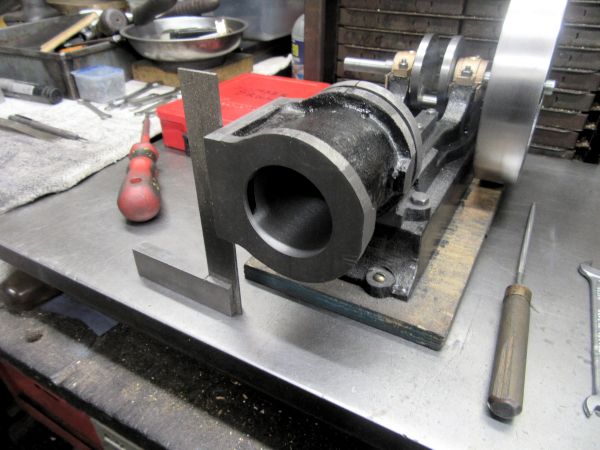

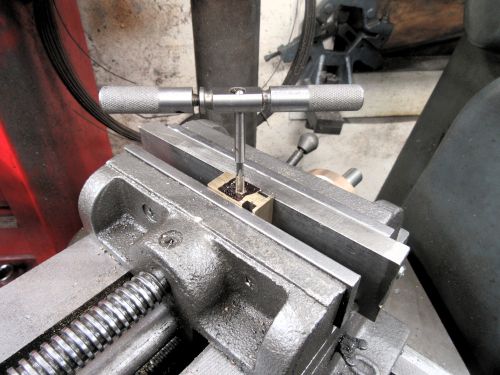

Today started with careful work, using the paper gaskets to mark the locations of the holes that need to be drilled in the castings. I made a mistake at this point in the last engine in the orientation of the two countersunk holes in the front lid and made quite sure I didn't repeat that this morning. I finished up with the back lid in the vise under the drill ready for drilling but that's the first job for tomorrow. There was a sidetrack when I dropped the chuck key and had to search for it and while I was at it I emptied the shop vacuum, it had a good load of cast iron dust in it. I'm satisfied with the morni9ng, now for breakfast!

1

1