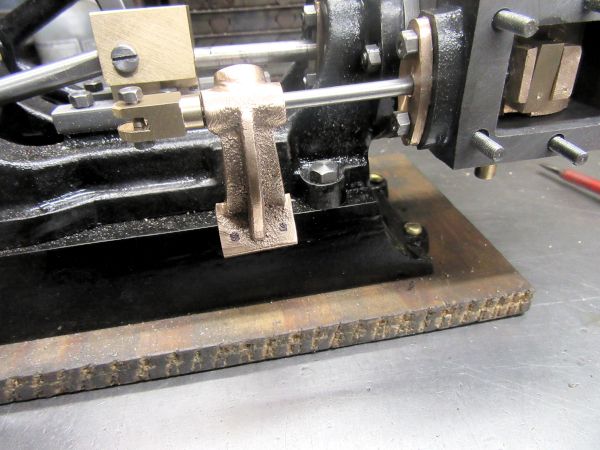

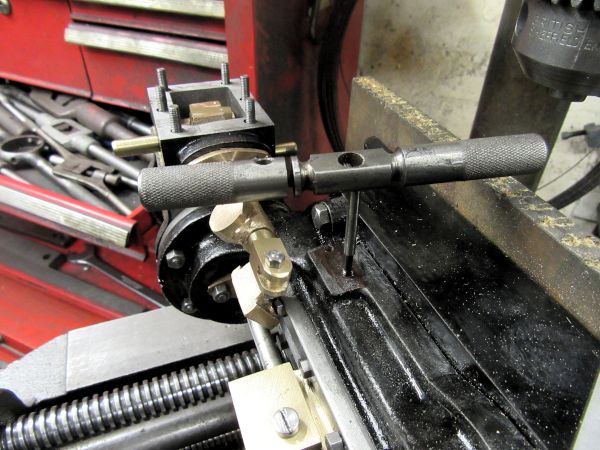

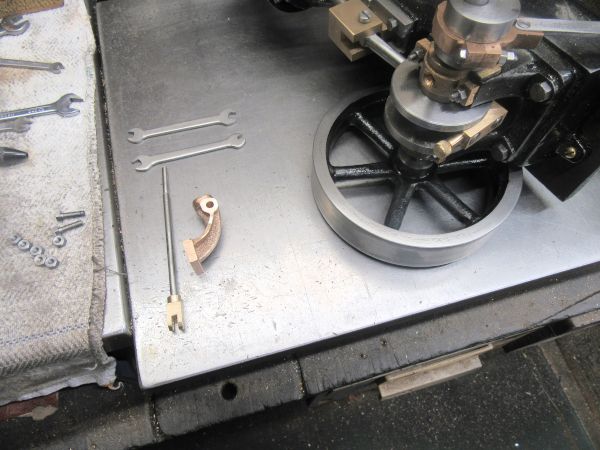

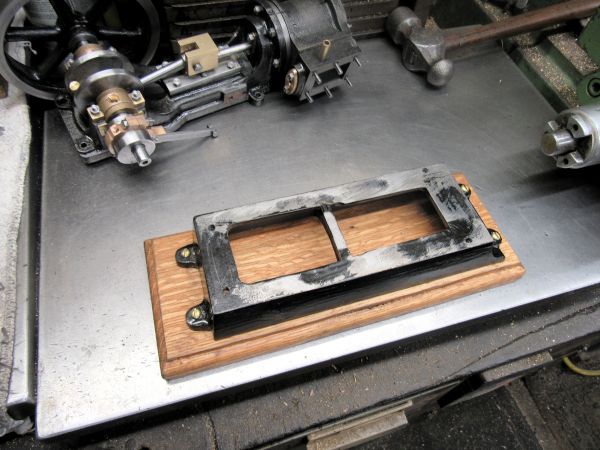

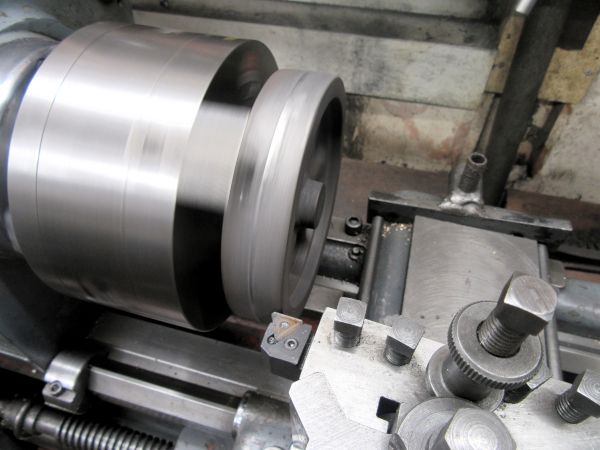

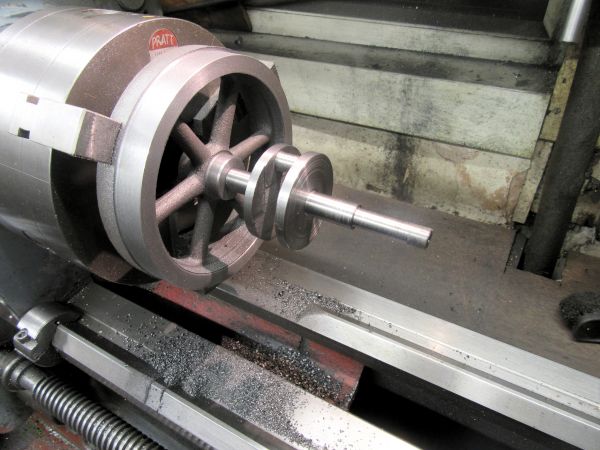

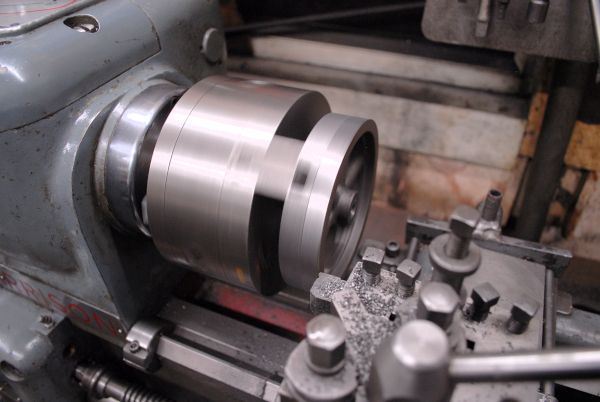

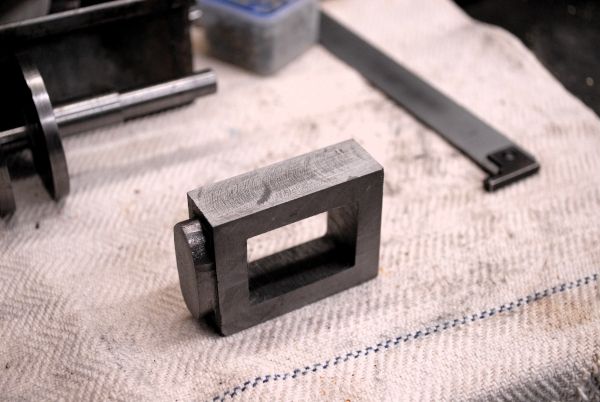

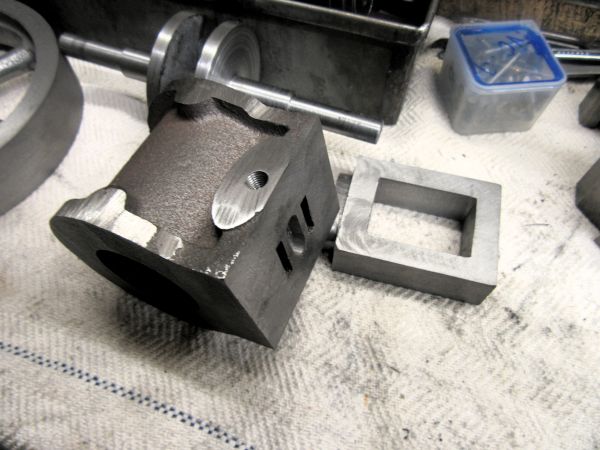

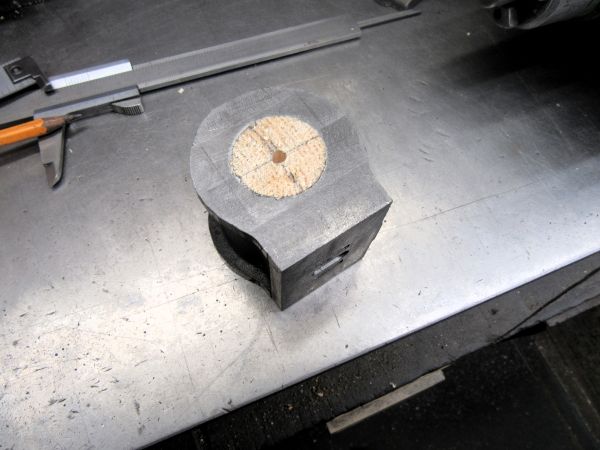

One engine went out of the shed yesterday as a gift to a young friend of Mine, Vicky Barritt. As I am sure you remember I am convinced I cannot die while I am building an engine so immediate steps needed to be taken. I have already spent £633 on a fresh set of castings and so I unpacked them this morning after putting the detritus that is always left after a build into the various boxes I have waiting for them. As you can see I have everything out of its shrink wrapping and ready to be worked on, the smaller items being in their own plastic box. All the packing materials in the bin outside. I also spent a few minutes cleaning up and sharpening an old and very well worn US army knife which I have decided will be OK as a bench knife.

That was a good and productive hour. I am ready now on the starting blocks of another steam engine. And yes it's the same as the last but I know my limitations and there is less chance of cock-ups due to senior moments because I know the build so well.