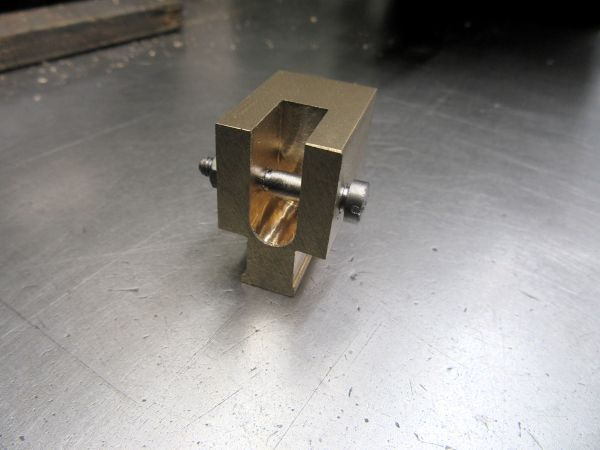

First job I finished drilling, tapping and installing the bolts that hold the crosshead guides down onto the bed. Then I could do some accurate measurements and mark the block of bronze that will become the crosshead for the cuts that enable it to fit in the guides. I finished the first cut down one side and set up for doing the other side. That will be where I start tomorrow. Again, a nice quiet hour and as far as I can see an error-free outcome. More of the same tomorrow.....