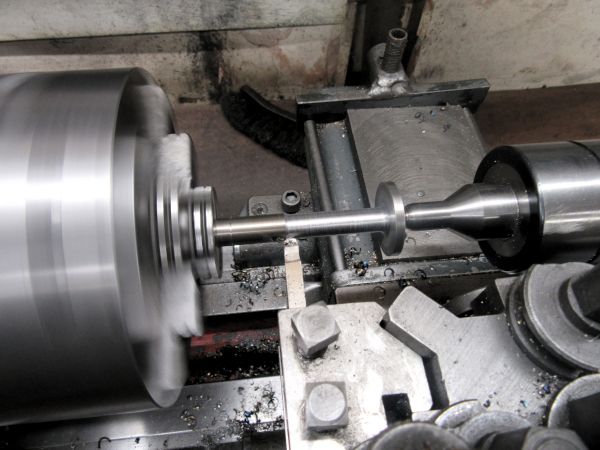

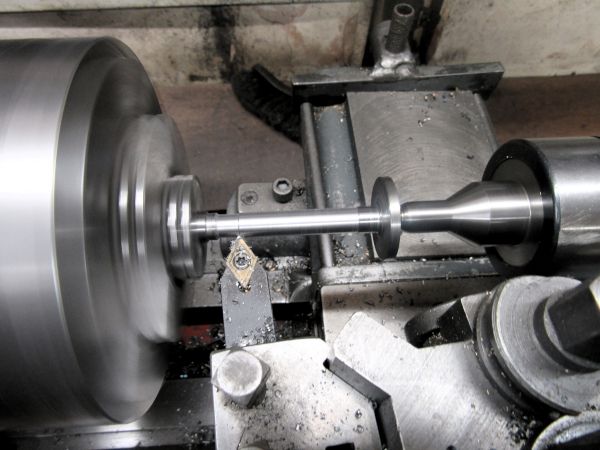

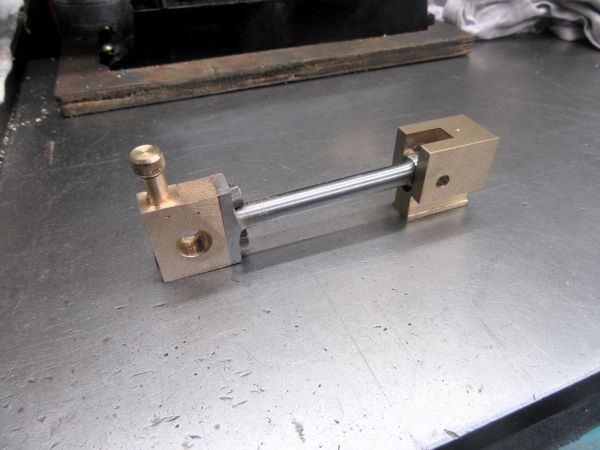

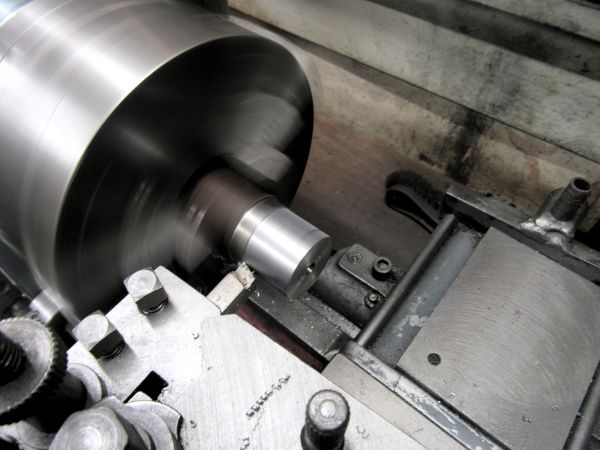

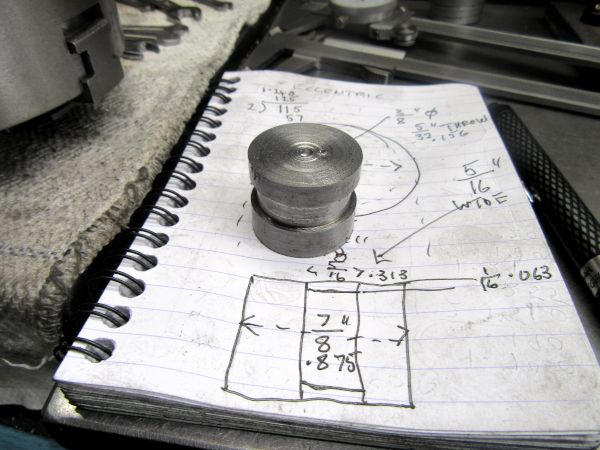

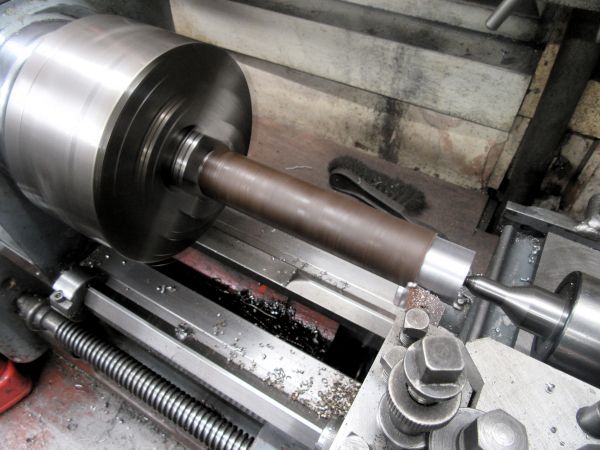

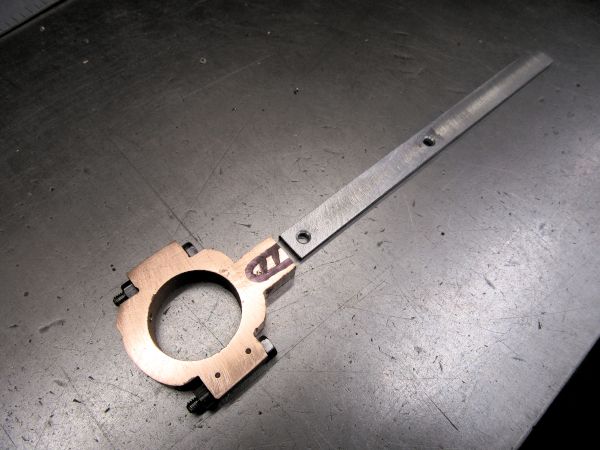

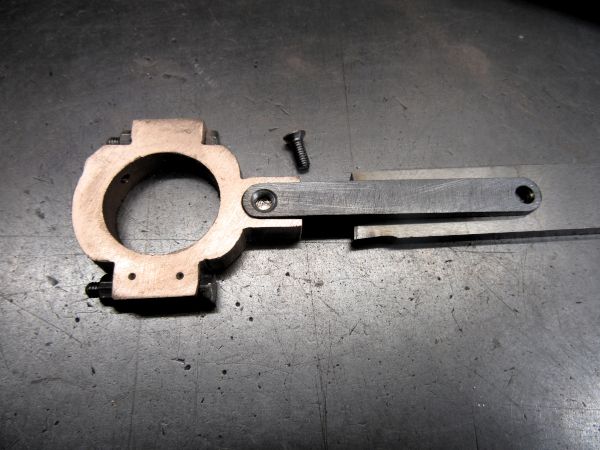

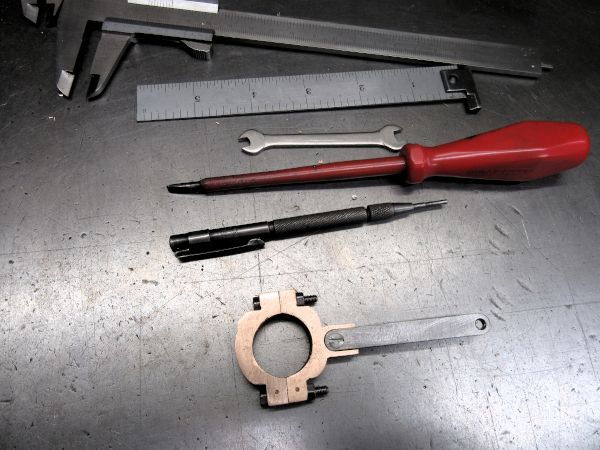

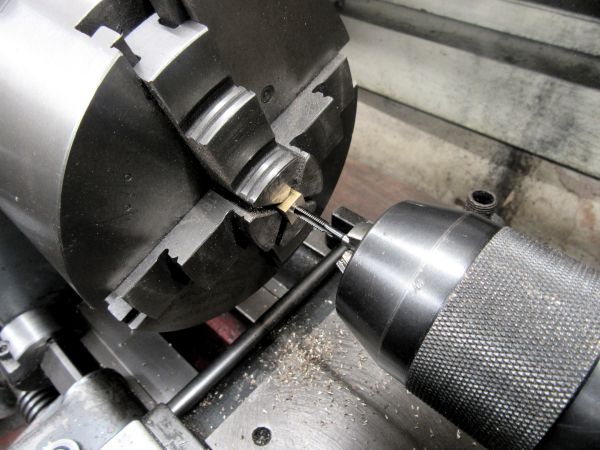

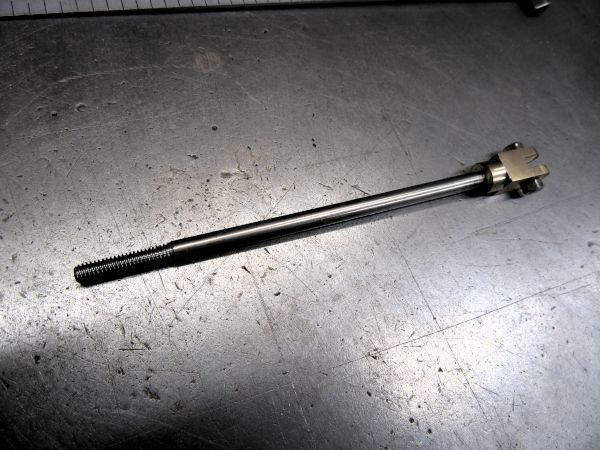

Still reducing my piece of hard scrap to a connecting rod. I started the day by reducing the body of the stock to the minor diameter of 7/16" and when I got there, cutting the rod off from the body of the stock using a hacksaw. You may wonder why I went down the route of manual sawing when I could have parted it off. This is such hard material that there was every chance of the parting operation failing and I wanted to avoid that so I put a new all hard 18tpi blade in my hacksaw frame and settled into twenty minutes of hard work. It was the right decision and you'll see that I finished up with a clean cut. I cleaned the chips off Mrs Harrison and swept the floor. I ended with a nice little piece of stock that I can refine until it is a con-rod and a straight edge in a clean shed. That makes it a good morning!